Unlocking Longer Component Life: A Deep Dive into Al-Si-Cu-Mg Alloy Fatigue Behavior

This technical summary is based on the academic paper "Low-cycle fatigue behavior of permanent mold cast and die-cast Al-Si-Cu-Mg alloys" by Chen Lijia, Wang Di, Che Xin, and Li Feng, published in CHINA FOUNDRY (2012).

Keywords

- Primary Keyword: Al-Si-Cu-Mg Alloy Fatigue Behavior

- Secondary Keywords: die-casting, permanent mold casting, low-cycle fatigue, cyclic stress response, fatigue life, Coffin-Manson equation, Basquin equation

Executive Summary

- The Challenge: Fatigue failure is a primary mode of failure for critical Al-Si-Cu-Mg aluminum alloy components, yet the influence of the casting method on this behavior is not widely detailed.

- The Method: Researchers conducted low-cycle fatigue tests under total strain-control mode on Al-Si-Cu-Mg alloy specimens produced by both permanent mold casting and die-casting.

- The Key Breakthrough: The die-cast Al-Si-Cu-Mg alloy demonstrates significantly higher cyclic deformation resistance and a longer fatigue life compared to the permanent mold cast alloy at the same total strain amplitude.

- The Bottom Line: The die-casting process produces a finer grain microstructure, which directly enhances the fatigue performance and durability of Al-Si-Cu-Mg components under cyclic loading conditions.

The Challenge: Why This Research Matters for HPDC Professionals

Al-Si-Cu-Mg alloys are increasingly used in the automotive industry for their excellent castability, low shrink rate, and good flow properties. However, for structural components subjected to repeated loading, fatigue failure is a critical concern. While it is known that the casting method strongly affects microstructure and mechanical properties, there has been limited research focusing specifically on the low-cycle fatigue behavior of these alloys. This knowledge gap makes it difficult to optimize component design and manufacturing processes for maximum durability and reliability. This investigation provides a direct comparison between permanent mold cast and die-cast alloys to establish a theoretical foundation for fatigue-resistant design.

The Approach: Unpacking the Methodology

To ensure a direct and reliable comparison, the researchers established a controlled experimental procedure to evaluate the two casting methods.

Method 1: Material and Specimen Preparation

An Al-Si-Cu-Mg alloy with a composition of 8.5-9.5wt.% Si, 3.7-4.3wt.% Cu, and 0.38-0.42wt.% Mg was used. Permanent mold cast specimens were created by pouring the alloy melt at 740 °C into a permanent mold, with test bars later machined from the resulting ingots. Die-cast specimens were fabricated directly on an Evo.53D cold chamber die-casting machine with an injection pressure of 60 MPa, a mold temperature of 200 °C, and a pouring temperature of 720 °C.

Method 2: Low-Cycle Fatigue Testing

All fatigue tests were performed on a computer-controlled servo-hydraulic test machine (PLD-50) at room temperature. A total strain-control mode was used, applying a triangular waveform with total strain amplitudes ranging from 0.25% to 0.45% at a cyclic frequency of 0.5 Hz. The low-cycle fatigue life was defined as the number of cycles to the final separation of the specimen.

The Breakthrough: Key Findings & Data

The study revealed clear and significant differences in the fatigue performance of alloys produced by the two casting methods.

Finding 1: Die-Cast Alloys Exhibit Superior Cyclic Stress Resistance

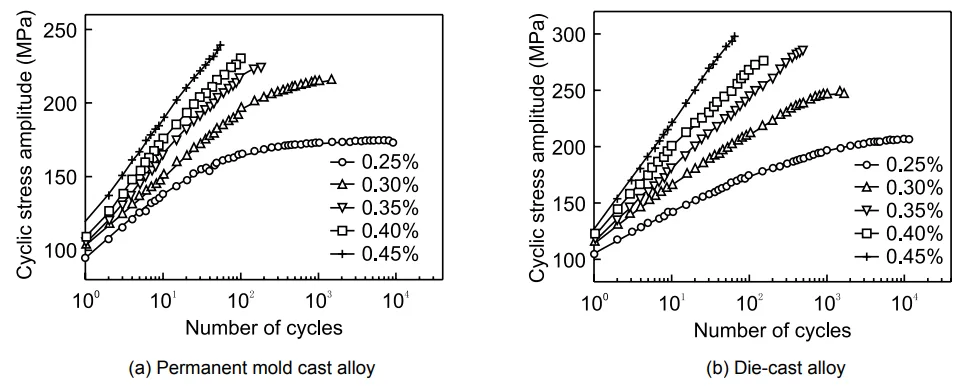

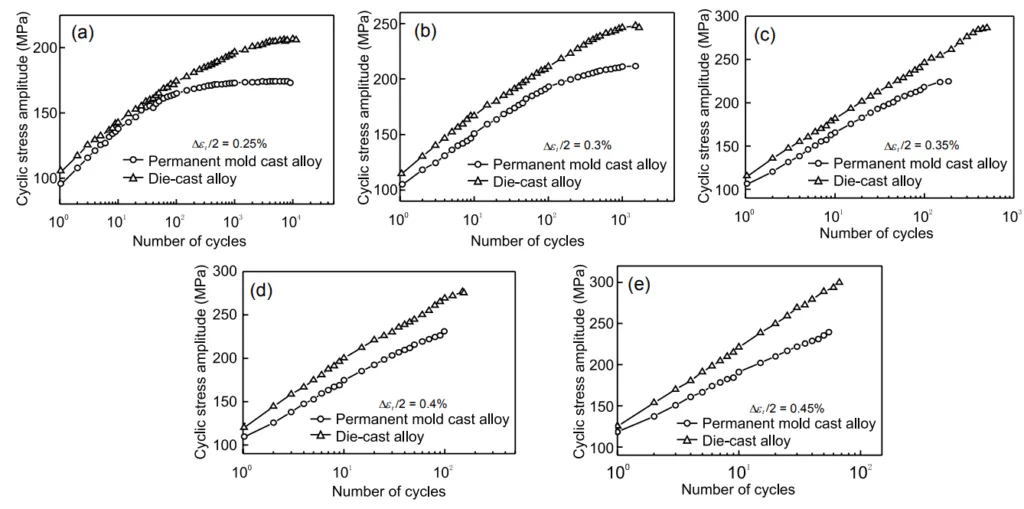

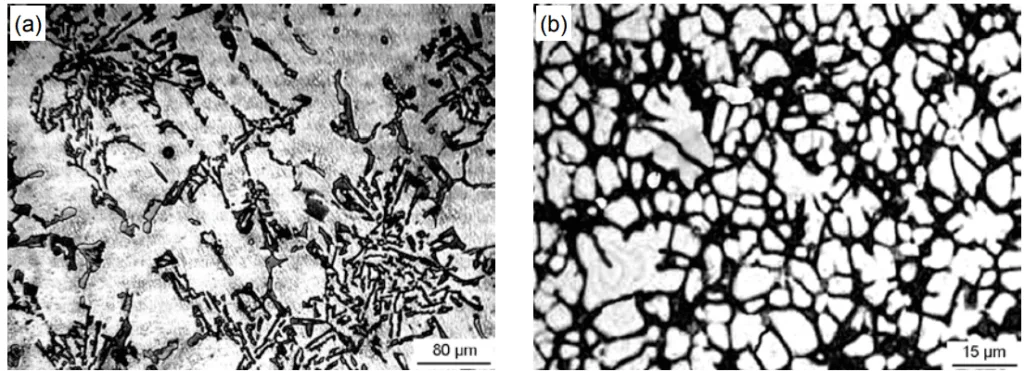

At every tested strain amplitude, the die-cast alloy showed a much higher cyclic stress amplitude than the permanent mold cast alloy. This indicates that the die-cast material has a significantly higher resistance to cyclic deformation. For example, as shown in Figure 3(c) at a total strain amplitude of 0.35%, the stabilized cyclic stress amplitude for the die-cast alloy is approximately 250 MPa, whereas for the permanent mold cast alloy, it is below 200 MPa. This superior performance is attributed to the grain refinement effect of the die-casting process, which creates a finer microstructure (as seen in Figure 4) that impedes dislocation mobility.

Finding 2: Die-Casting Leads to Significantly Longer Fatigue Life

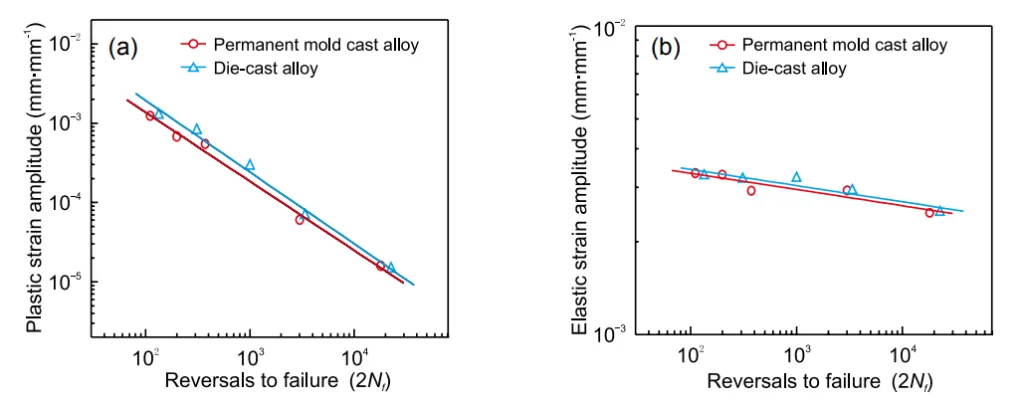

The research confirms a direct correlation between the casting method and the fatigue life of the component. As shown in Figure 5, the fatigue life of the die-cast alloy is consistently longer than that of the permanent mold cast alloy across all tested strain amplitudes. The fine microstructure of the die-cast alloy provides greater resistance to both the initiation and propagation of fatigue cracks, resulting in a more durable component under low-cycle fatigue conditions.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for components where fatigue life is a critical design requirement, specifying the die-casting process over permanent mold casting can yield substantial improvements in durability due to the resulting grain refinement.

- For Quality Control Teams: The data in Figure 4 illustrates the direct link between microstructure and performance. Microstructural analysis can serve as a powerful quality control tool to predict and ensure the fatigue resistance of manufactured components.

- For Design Engineers: The findings indicate that the choice of manufacturing process is a critical design consideration. The enhanced fatigue life of die-cast Al-Si-Cu-Mg alloys allows for the design of more robust and reliable components, potentially enabling weight reduction without compromising durability.

Paper Details

Low-cycle fatigue behavior of permanent mold cast and die-cast Al-Si-Cu-Mg alloys

1. Overview:

- Title: Low-cycle fatigue behavior of permanent mold cast and die-cast Al-Si-Cu-Mg alloys

- Author: *Chen Lijia, Wang Di, Che Xin, and Li Feng

- Year of publication: 2012

- Journal/academic society of publication: CHINA FOUNDRY

- Keywords: permanent mold cast; die-cast; aluminum alloy; low-cycle fatigue; fatigue life; cyclic stress response

2. Abstract:

Fatigue failure is one of the main failure forms of Al-Si-Cu-Mg aluminum alloys. To feature their mechanical aspect of fatigue behavior, the low-cycle fatigue behavior of permanent mold cast and die-cast Al-Si-Cu-Mg alloys at room temperature was investigated. The experimental results show that both permanent mold cast and die-cast Al-Si-Cu-Mg alloys mainly exhibit cyclic strain hardening. At the same total strain amplitude, the die-cast Al-Si-Cu-Mg alloy shows higher cyclic deformation resistance and longer fatigue life than does the permanent mold cast Al-Si-Cu-Mg alloy. The relationship between both elastic and plastic strain amplitudes with reversals to failure shows a monotonic linear behavior, and can be described by the Basquin and Coffin-Manson equations, respectively.

3. Introduction:

The application of Al-Si-Cu alloy castings in the automotive industry is increasing due to their favorable casting properties. The microstructures and properties of these alloys are strongly affected by the casting method. Permanent mold cast alloys allow for precise microstructural control, while die-cast alloys exhibit high dimensional accuracy, strength, and hardness. Fatigue failure is a primary concern for these structural materials. However, research concerning cast Al-Si-Cu aluminum alloys has mainly focused on microstructure and tensile properties, with little attention given to fatigue properties. This investigation was initiated to study the low-cycle fatigue behavior of both permanent mold cast and die-cast Al-Si-Cu-Mg alloys to address their mechanical fatigue behavior and provide a theoretical foundation for fatigue-resistant design.

4. Summary of the study:

Background of the research topic:

Al-Si-Cu-Mg alloys are widely used in the automotive industry. Fatigue failure is a major mode of failure for these alloys when used in structural applications.

Status of previous research:

Previous research on cast Al-Si-Cu aluminum alloys has primarily focused on their microstructure, impact, and tensile properties, with limited investigation into their fatigue properties.

Purpose of the study:

The study aimed to investigate and compare the low-cycle fatigue behavior of permanent mold cast and die-cast Al-Si-Cu-Mg alloys at room temperature. The goal was to characterize their mechanical fatigue behavior and provide a theoretical basis for the fatigue-resistant design of components made from these alloys.

Core study:

The core of the study involved conducting strain-controlled low-cycle fatigue tests on Al-Si-Cu-Mg alloy specimens prepared by two different casting methods: permanent mold casting and die-casting. The study analyzed and compared their cyclic stress response, fatigue life, and the relationship between strain amplitudes and reversals to failure.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. Two sets of Al-Si-Cu-Mg alloy specimens were prepared using identical chemical compositions but different casting processes (permanent mold vs. die-casting). These specimens were then subjected to identical low-cycle fatigue testing conditions to isolate the effect of the casting method on fatigue behavior.

Data Collection and Analysis Methods:

Data was collected using a computer-controlled servo-hydraulic test machine. Cyclic stress response curves, total strain amplitude versus fatigue life curves, and hysteresis loops at half-life were generated. The relationships between elastic/plastic strain amplitudes and reversals to failure were analyzed using linear regression to determine fatigue parameters according to the Basquin and Coffin-Manson equations. Microstructures were observed to explain the differences in mechanical behavior.

Research Topics and Scope:

The research focused on the low-cycle fatigue behavior of a specific Al-Si-Cu-Mg alloy at room temperature. The scope included:

- Characterization of cyclic stress response behavior.

- Determination of fatigue life at various total strain amplitudes (0.25% to 0.45%).

- Comparison of fatigue performance between permanent mold cast and die-cast alloys.

- Application of the Coffin-Manson and Basquin equations to model fatigue behavior.

6. Key Results:

Key Results:

- Both permanent mold cast and die-cast alloys exhibit cyclic strain hardening.

- At the same total strain amplitude, the die-cast alloy shows significantly higher cyclic deformation resistance and longer fatigue life than the permanent mold cast alloy.

- The superior performance of the die-cast alloy is attributed to its much finer grain microstructure resulting from the die-casting process.

- The relationship between elastic and plastic strain amplitudes and reversals to failure is linear for both alloys and can be described by the Basquin and Coffin-Manson equations.

- The die-cast alloy possesses higher fatigue ductility (εf') and fatigue strength (σf') coefficients compared to the permanent mold cast alloy.

Figure Name List:

- Fig. 1: Geometry of fatigue specimen (mm)

- Fig. 2: Cyclic stress response curves of Al-Si-Cu-Mg alloys

- Fig. 3: Comparison of cyclic stress response curves for permanent mold cast and die-cast Al-Si-Cu-Mg alloys at given total stain amplitudes

- Fig. 4: Microstructures of permanent mold cast (a) and die-cast (b) Al-Si-Cu-Mg alloys

- Fig. 5: Total strain amplitude versus fatigue life curves for permanent mold cast and die-cast Al-Si-Cu-Mg alloys

- Fig. 6: Plastic (a) and elastic (b) strain amplitude versus reversals to failure curves of permanent mold cast and die-cast Al-Si-Cu-Mg alloys

- Fig. 7: Cyclic stress-strain curves of permanent mold cast and die-cast Al-Si-Cu-Mg alloys

7. Conclusion:

(1) The permanent mold cast and die-cast Al-Si-Cu-Mg alloys mainly exhibit cyclic strain hardening, and the die-cast alloy shows much higher cyclic deformation resistance than the permanent mold cast alloy.

(2) Under low-cycle fatigue loading condition, the fatigue life of the die-cast Al-Si-Cu-Mg alloy is longer than that of the permanent mold cast alloy at the same total strain amplitude.

(3) For both the permanent mold cast and die-cast Al-Si-Cu-Mg alloys, the relationship between plastic and elastic strain amplitudes with reversals to failure follows the Coffin-Manson and Basquin equations, respectively.

8. References:

- [1] Chen C M, Yang C C, and Chao C G. Thixocasting of hypereutectic Al-25Si-2.5Cu-1Mg-0.5Mn alloys using densified powder compacts. Materials Science and Engineering A, 2004, 366: 183–194.

- [2] Ganesan M, Thuinet L, Dye D, et al. Quantification of micro-segregation in cast Al-Si-Cu alloys. Metallurgical and Materials Transactions B, 2007, 38(8): 557–566.

- [3] Birol Y. Semisolid processing of near-eutectic and hypereutectic Al-Si-Cu alloys. Journal of Materials Science, 2008, 43: 3577–3581.

- [4] Han Y F, Liu X F, Yang Z Q, et al. Influence of die casting on the structures of Al-Si-Cu alloys. Foundry, 2001, 50(4): 183–186. (in Chinese)

- [5] Li Rongde, He Cangguo, Li Runxia, et al. Effect of rare earth on microstructure and mechanical properties of Al-Si-Cu-Mg alloy. Foundry, 2008, 57(8): 818–822. (in Chinese)

- [6] Samuel A M, and Samuel F H. Effect of alloying elements and dendrite arm spacing on the microstructure and hardness of an Al-Si-Cu-Mg-Fe-Mn (380) aluminium die-casting alloy. Journal of Materials Science, 1995, 30: 1698–1708.

- [7] Mohamed A M A, Samuel F H, Samuel A M, et al. Influence of tin addition on the microstructure and mechanical properties of Al-Si-Cu-Mg and Al-Si-Mg casting alloys. Metallurgical and Materials Transactions A, 2008, 39(3): 490–501.

- [8] He Kezhun, Yu Fuxiao, Zhao Dazhi, et al. Microstructural evolution of direct chill cast Al-15.5Si-4Cu-1Mg-1Ni-0.5Cr alloy during solution treatment. China Foundry, 2011, 8(3): 264–268.

- [9] Che Xin, Xu Zhijun, Chen Lijia, et al. Low-cycle fatigue behavior of cast Al-Si-Cu-Mg(-Er) aluminum alloy. Foundry, 2011, 60(1): 20–23. (in Chinese)

- [10] Kobayashi T, Ito T, Yao Q, et al. Fatigue properties and microstructure of Al-Si-Cu system casting alloys. Materials Science and Technology, 1999, 15(9): 1037–1043.

- [11] Raske D T and Morrow J. Mechanics of materials in low cycle fatigue testing. ASTM STP 465. Philadelphia: American Society for Testing and Materials, 1969: 1–25.

Expert Q&A: Your Top Questions Answered

Q1: Why was a total strain-control mode chosen for the fatigue tests?

A1: The study focused on low-cycle fatigue (LCF), a regime characterized by significant plastic deformation in each cycle. A strain-control mode is standard for LCF testing because it directly controls the key variable (strain) that drives damage accumulation in this regime. This approach allows for a more accurate characterization of material behavior when plastic strains are comparable to or larger than elastic strains.

Q2: What is the specific microstructural reason for the die-cast alloy's superior fatigue performance?

A2: The paper explicitly attributes the superior performance to the grain refinement effect from the die-casting process. As shown in Figure 4, the die-cast alloy has significantly finer grains than the permanent mold cast alloy. This fine-grained structure enhances the cyclic deformation resistance by decreasing the mobility of dislocations, and it also offers greater resistance to the initiation and propagation of fatigue cracks.

Q3: What were the specific die-casting parameters used to produce the test specimens?

A3: The "Experimental procedure" section details the technological parameters for die-casting. They were: an injection pressure of 60 MPa, a mold temperature of 200 °C, a pouring temperature of 720 °C, and a pressure holding time of 12 seconds.

Q4: How did the hardening behavior differ between the two alloys?

A4: Both alloys exhibited cyclic strain hardening. However, the die-cast alloy consistently showed a higher cyclic stress amplitude (i.e., greater hardening and deformation resistance) at all strain levels. For the permanent mold cast alloy, the hardening rate varied with strain amplitude: at 0.25%, it stabilized in later stages, while from 0.35% to 0.45%, the hardening rate was almost constant throughout the test.

Q5: Can the Coffin-Manson and Basquin equations reliably predict the fatigue life of these alloys?

A5: Yes, the study found that for both casting methods, the relationship between plastic/elastic strain amplitudes and reversals to failure is a "monotonic linear behavior." This indicates that the Coffin-Manson equation (for plastic strain) and the Basquin equation (for elastic strain) can be effectively used to describe and predict the fatigue life of these Al-Si-Cu-Mg alloys under the tested conditions.

Q6: Did the die-cast alloy show better fatigue properties in all measured parameters?

A6: Yes. According to the data presented, the die-cast alloy demonstrated superior performance across the board. It had a higher cyclic stress response (Figure 3), longer fatigue life (Figure 5), and higher values for the key strain fatigue parameters, including the fatigue ductility coefficient (εf'), fatigue strength coefficient (σf'), cyclic strength coefficient (K'), and cyclic strain hardening exponent (n'), as listed in Table 1.

Conclusion: Paving the Way for Higher Quality and Productivity

The core challenge for engineers using Al-Si-Cu-Mg alloys in structural parts is mitigating the risk of fatigue failure. This research provides a clear and actionable insight: the manufacturing process is not just a matter of shaping metal, but a critical factor in determining component life. The key breakthrough is the definitive evidence that the die-casting process imparts superior Al-Si-Cu-Mg Alloy Fatigue Behavior compared to permanent mold casting, thanks to its grain-refining effect. This translates directly to enhanced cyclic deformation resistance and longer service life for components under load.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Low-cycle fatigue behavior of permanent mold cast and die-cast Al-Si-Cu-Mg alloys" by "Chen Lijia, Wang Di, Che Xin, and Li Feng".

Source: https://core.ac.uk/display/38520338

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.