Beyond Conventional HPDC: How Rheo-Casting Improves Mechanical Properties and Reduces Porosity

This technical summary is based on the academic paper "CASTING QUALITY ENHANCEMENT USING NEW BINDERS ON SAND CASTING AND HIGH-PRESSURE RHEO-DIE CASTING" by P. Puspitasari and J.W. Dika, published in Prog. Phys. Met., Vol. 20, No. 3 (2019). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Rheo-HPDC

- Secondary Keywords: High-Pressure Die Casting, Casting Quality, Semi-Solid Metal Casting, Slurry Preparation, Casting Defects, Porosity Reduction, Mechanical Properties

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Conventional High-Pressure Die Casting (HPDC) products often suffer from internal defects like gas porosity, which compromises mechanical properties and limits performance.

- The Method: The paper reviews High-Pressure Rheo-Die Casting (Rheo-HPDC), a technique that integrates semi-solid metal (slurry) processing with HPDC to overcome these limitations.

- The Key Breakthrough: Rheo-HPDC significantly improves mechanical properties—including ultimate tensile strength, yield strength, and elongation—while reducing porosity and creating a more refined, homogeneous microstructure compared to conventional HPDC.

- The Bottom Line: Adopting Rheo-HPDC, particularly with advanced slurry-making methods like the self-inoculation method (SIM), offers a reliable path to producing superior, high-precision cast components with enhanced performance.

The Challenge: Why This Research Matters for HPDC Professionals

In the demanding world of high-performance components, quality is paramount. For decades, High-Pressure Die Casting (HPDC) has been a go-to manufacturing process for its speed and precision. However, it is not without its drawbacks. As the paper highlights, conventional HPDC products "often suffer from internal defects, one of which is gas porosity due to air or gas entrapped during the mould filling done under high speeds which adversely affects the mechanical properties of the material."

This entrapped gas leads to porosity, a critical defect that can compromise the structural integrity, durability, and overall performance of a finished part. For engineers in the automotive, aerospace, and electronics industries, this is a persistent challenge that can lead to component failure, increased scrap rates, and design limitations. This research explores an advanced manufacturing technique designed to directly address these fundamental shortcomings.

The Approach: Unpacking the Methodology

To overcome the limitations of conventional HPDC, this paper reviews the development and advantages of High-Pressure Rheo-Die Casting (Rheo-HPDC). This technique is an advanced version of HPDC that integrates semi-solid metal (SSM) technology.

The core of the Rheo-HPDC process is the proper preparation of a metal slurry. Instead of injecting fully molten metal at high speed, Rheo-HPDC first cools a liquid metal alloy to a semi-solid state, creating a slurry with higher viscosity. This slurry is then processed in the HPDC machine. The paper reviews the continuous development of slurry-making processes, including:

- Twin-Screw Slurry Maker

- Ultrasonic Slurry Maker

- Mechanical Rotational Barrel (MRB)

- Air-Cooled Stirring Rod (ACSR)

- Self-Inoculation Method (SIM), noted as the latest innovation.

By focusing on the controlled preparation of this semi-solid slurry, Rheo-HPDC fundamentally changes the physics of mould filling, leading to significant improvements in product quality.

The Breakthrough: Key Findings & Data

The paper presents compelling evidence that Rheo-HPDC produces components with superior quality compared to conventional HPDC. The most significant findings are centered on mechanical properties, porosity, and microstructure.

Finding 1: Drastic Improvement in Mechanical Properties

The data clearly demonstrates that Rheo-HPDC components are mechanically superior. As shown in Table 6, which compares conventional HPDC with ACSR Rheo-HPDC, the improvements are substantial across the board:

- Ultimate Tensile Strength (UTS): Increased from 217 MPa with conventional HPDC to as high as 261 MPa with Rheo-HPDC.

- Yield Strength (YS): Rose from 108 MPa to 124 MPa.

- Elongation: Nearly doubled, increasing from 2.6% to 4.9%, indicating significantly better ductility.

- Hardness: Improved from 88 HV to 99 HV.

These quantitative improvements confirm that Rheo-HPDC is not just an incremental change but a transformative one for achieving high-performance material characteristics.

Finding 2: Significant Porosity Reduction and Refinement

Rheo-HPDC directly addresses the critical issue of gas porosity. As the paper notes, the higher viscosity of the slurry leads to "less entrapped gas contained in the materials and hence a final product with no porosity defects."

- Figure 24 provides a visual comparison of porosity levels. The data shows that while smaller pores (0-150 µm²) appear more frequently in Rheo-HPDC products, the larger, more detrimental pores (>150 µm²) are far more prevalent in casts from conventional HPDC. This shift towards smaller, less harmful porosity is a key advantage.

- The refined microstructure achieved through Rheo-HPDC is highlighted in Figure 25. The image of the Rheo-HPDC microstructure (Fig. 25a) is "much better and clearer" with "clearly visible grain boundaries and homogeneity of the spherical microstructure," which directly supports the superior mechanical properties observed.

Practical Implications for R&D and Operations

Based on the paper's Discussion and Conclusion sections, provide conditional insights for different professional roles.

- For Process Engineers: This study suggests that adjusting the slurry preparation method may contribute to reducing gas porosity and improving mechanical strength. The evolution from twin-screw systems to the self-inoculation method (SIM) indicates that optimizing the initial state of the metal before injection is a critical control point for enhancing final product quality.

- For Quality Control Teams: The data in Table 6 and Figure 24 of the paper illustrates the effect of Rheo-HPDC on key mechanical properties and porosity distribution. These metrics can serve as new benchmarks for defining higher quality inspection criteria and validating process improvements.

- For Design Engineers: The findings indicate that the superior mechanical properties and reduced porosity achieved with Rheo-HPDC could allow for the design of components with thinner walls and more complex geometries without compromising structural integrity. This opens up new possibilities for lightweighting and part consolidation.

Paper Details

CASTING QUALITY ENHANCEMENT USING NEW BINDERS ON SAND CASTING AND HIGH-PRESSURE RHEO-DIE CASTING

1. Overview:

- Title: CASTING QUALITY ENHANCEMENT USING NEW BINDERS ON SAND CASTING AND HIGH-PRESSURE RHEO-DIE CASTING

- Author: P. PUSPITASARI and J.W. DIKA

- Year of publication: 2019

- Journal/academic society of publication: Prog. Phys. Met., 2019, Vol. 20, No. 3

- Keywords: casting quality, moulding sand, binders, rheo-HPDC, smart mechanism, aluminium.

2. Abstract:

Casting quality is a perfection factor for measuring the success of the metal casting. One of efforts to obtain high-quality casting product is identifying the quality of sand moulding used. Identification of the sand-moulding quality is defined by the hardness, shear strength, tensile, and permeability. This article reviews the explanations of the strength of sand moulding with composition variation of binder type: (1) sand moulding, bentonite, fly ash, and water; (2) sand of mount Kelud eruption, bentonite, and water; (3) sand of mount Kelud eruption, Sidoarjo mud, and water; (4) sand of mount Kelud eruption, Portland cement, and water; (5) sand moulding, volcanic ash, and water; (6) green sand, bentonite, fly ash, and water; (7) sand of Malang, bentonite, tapioca flour, and sago flour; (8) sand moulding, bentonite, Portland cement, and water. High-pressure rheo-die casting commonly known in the literature as rheo-high-pressure die casting (rheo-HPDC) is a novel casting technique in producing good-quality cast products. Escalating market demand drives the development of new technology, with which casts with excellent mechanical properties, good microstructure, and minor casting defects can be produced. As an advanced version of HPDC, rheo-HPDC can be regarded as a smart manufacture technique, since it integrates the semi-solid metal technology that considers the proper preparation of slurry. The slurry-making process has been continuously developed, and the latest preparation method is the self-inoculation method. This review article discusses the procedure, mechanism, development, and product quality of sand casting with new binders as well as rheo-HPDC technique.

3. Introduction:

The paper begins by establishing casting as a critical engineering process where improving product quality, production systems, and costs is essential for international competitiveness. It reviews two primary casting methods: sand casting and metal mould casting (like HPDC). While sand casting is the oldest and most common method, it has limitations. The paper then introduces high-pressure rheo-die casting (Rheo-HPDC) as a novel and advanced technique for producing high-quality cast products. It highlights that market demand for casts with excellent mechanical properties, good microstructure, and fewer defects is driving the development of smart manufacturing technologies like Rheo-HPDC, which integrates semi-solid metal technology and features advanced slurry preparation methods.

4. Summary of the study:

Background of the research topic:

The fundamental challenge is to enhance the quality of metal castings. The paper reviews two distinct pathways to achieve this: improving the binders used in traditional sand casting and adopting advanced manufacturing technologies like Rheo-HPDC.

Status of previous research:

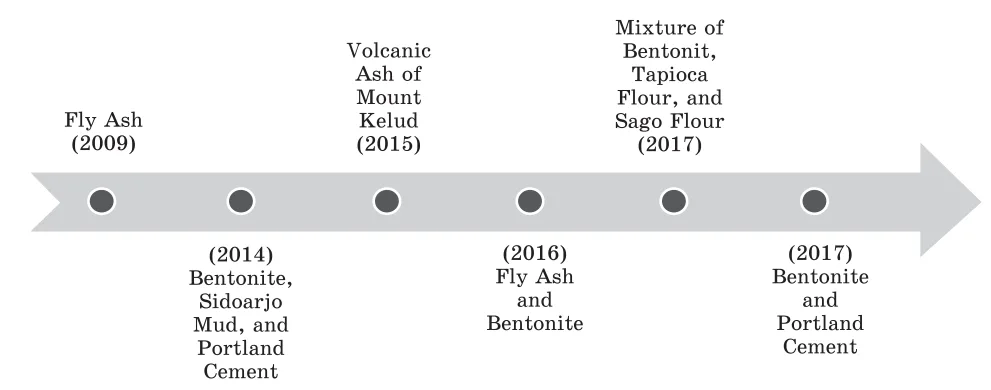

The paper provides a comprehensive review of prior research. For sand casting, it details a timeline of binder development from 2009 to 2017, examining materials like fly ash, volcanic ash, Sidoarjo mud, and various flours. For die casting, it establishes that conventional HPDC suffers from defects like gas porosity. It then traces the development of Rheo-HPDC as a solution, charting the evolution of slurry-making technologies from 2005 to 2017, including twin-screw, ultrasonic, MRB, ACSR, and the self-inoculation method (SIM).

Purpose of the study:

This review article aims to discuss the procedure, mechanism, development, and product quality associated with two approaches to enhancing casting quality: 1) using new binders in sand casting and 2) employing the Rheo-HPDC technique.

Core study:

The core of the study is a comparative analysis based on a literature review. It evaluates the effects of different binders on the mechanical properties (compressive, shear, tensile strength) of sand moulds. More critically for the HPDC industry, it synthesizes findings on Rheo-HPDC, comparing its outcomes—in terms of mechanical properties, porosity, and microstructure—against those of conventional HPDC.

5. Research Methodology

Research Design:

The study is a review article. It does not conduct new experiments but instead collects, synthesizes, and analyzes the findings from a wide range of existing research papers on sand casting binders and Rheo-HPDC technology.

Data Collection and Analysis Methods:

The authors collected data, figures, and conclusions from numerous published studies (cited as references [21], [22], [25-28] for sand casting and [51], [69], [70], [74], [75], [78], [84] for Rheo-HPDC). The analysis involves comparing the reported results to identify trends, best practices, and the quantitative advantages of different materials and techniques.

Research Topics and Scope:

The scope covers two main areas:

1. Sand Casting: Investigation of various binder compositions (bentonite, fly ash, volcanic ash, Portland cement, Sidoarjo mud, tapioca flour, sago flour) and their impact on the mechanical properties of sand moulds.

2. High-Pressure Rheo-Die Casting (Rheo-HPDC): A review of the mechanism, development, and product quality of the Rheo-HPDC process, with a focus on different slurry preparation methods (Twin-Screw, Ultrasonic, MRB, ACSR, and SIM) and a comparison of its products to those from conventional HPDC.

6. Key Results:

Key Results:

- Superior Mechanical Properties with Rheo-HPDC: Compared to conventional HPDC, ACSR Rheo-HPDC demonstrated significant improvements. UTS increased from 217 MPa to 261 MPa, yield strength from 108 MPa to 124 MPa, elongation from 2.6% to 4.9%, and hardness from 88 HV to 99 HV (Table 6).

- Reduced Porosity: Rheo-HPDC leads to reduced overall porosity. Specifically, it produces a higher quantity of smaller, less detrimental pores (0-150 µm²) and fewer large pores (>150 µm²) compared to conventional HPDC (Figure 24).

- Refined Microstructure: The microstructure of Rheo-HPDC products is more homogeneous and spherical, with clearer grain boundaries compared to conventional HPDC products (Figure 25). This refined structure is a direct contributor to the enhanced mechanical properties.

- Advanced Slurry Preparation: The paper identifies the self-inoculation method (SIM) as the "latest system" and "latest innovation" in slurry-making for Rheo-HPDC, suggesting it is the most advanced method for improving cast product quality.

- Optimal Sand Binder: For sand casting, the review found that moulding sand containing tapioca flour as a binder and used in dry condition had the highest overall strength.

Figure Name List:

- Fig. 1. The sequence of research development of binder compositions for sand moulding to optimise casting quality (2009-2017)

- Fig. 2. The study scheme of moulding sand compositions with fly ash [21]

- Fig. 3. The compressive strength graph for moulding sand added with fly ash [21]

- Fig. 4. The study scheme of moulding sand compositions with bentonite, Sidoarjo mud, and Portland cement [22]

- Fig. 5. Compressive strength (N/cm²) comparison of moulding sand specimens mixed with bentonite, Sidoarjo mud, and Portland cement [22]

- Fig. 6. Shear strength (N/cm²) comparison of moulding sand specimens mixed with bentonite, Sidoarjo mud, and Portland cement [22]

- Fig. 7. Tensile strength (N/cm²) comparison of moulding sand specimens mixed with bentonite, Sidoarjo mud, and Portland cement [22]

- Fig. 8. The study scheme of moulding sand compositions with volcanic ash [25]

- Fig. 9. Compressive strength (N/cm²) comparison of moulding sand specimens with 5%, 10% and 15% volcanic ash [25]

- Fig. 10. Compressive shear (N/cm²) comparison of moulding sand specimens with 5%, 10%, and 15% volcanic ash [25]

- Fig. 11. The study scheme of moulding sand compositions with fly ash [26]

- Fig. 12. Permeability (cm³/min) comparison of moulding sand specimens with 2%, 4%, and 6% fly ash [26]

- Fig. 13. Compressive strength (N/cm²) comparison of moulding sand specimens with 2%, 4%, and 6% fly ash [26]

- Fig. 14. The study scheme of moulding sand compositions with bentonite, tapioca flour, and sago flour [27]

- Fig. 15. The study scheme for moulding sand compositions with bentonite Portland cement binder [28]

- Fig. 16. Thin wall heat dissipation shells (a, b, and c — front, back, and perspective view, respectively), which are produced by air cooled stirring rod (ACSR) process combined with high-pressure die casting machine [51]. Here, A, B, C, and D — regions from which the samples were prepared [51] to study their microstructure and mechanical properties

- Fig. 17. Microstructure for the rheo-die cast AZ91D magnesium alloy component at various positions [74]

- Fig. 18. Development of casting process optimization through high-pressure rheo-die casting from 2005-2017

- Fig. 19. The rheo-die casting process with twin screw to make slurry [74]

- Fig. 20. Components of indirect ultrasonic vibration [69]: schematic illustration

- Fig. 21. Rheo-casting (RC) and rheo-die-casting (RDC) with mechanical rotational barrel (MRB) system to make semisolid slurry [78]

- Fig. 22. Components of the air cooled stirring rod (ACSR), where 1 — air compressor, 2 — airway, 3 — stirring rod, 4 — melt, 5 — crucible, 6 — thermocouple, 7 — primary α-Al particle) [51]

- Fig. 23. The RDC process combined with self-inoculation method (SIM) [84]

- Fig. 24. Comparison of porosity levels for Mg-Al (AM50) alloy produced by rheocasting (RC) and high pressure die casting (HPDC) [75]

- Fig. 25. Typical microstructure of the as-cast Al-Si-Mg (A357) alloy, which is prepared through the RDC (a) and HPDC (b) methods [70]. In the figure left (a), α₁-α₃ denote primary α-Al globules (α₁), dendritic fragments (α₂), and equiaxed particles (α₃) [70]

![Fig. 4. The study scheme of moulding sand compositions with bentonite, Sidoarjo mud, and Portland cement [22]](https://castman.co.kr/wp-content/uploads/image-3007.webp)

![Fig. 16. Thin wall heat dissipation shells (a, b, and c — front, back, and perspective view, respectively), which are produced by air cooled stirring rod (ACSR) process combined with high-pressure die casting machine [51]. Here, A, B, C, and D — regions from which the samples were prepared [51] to study their microstructure and mechanical properties](https://castman.co.kr/wp-content/uploads/image-3008.webp)

7. Conclusion:

The paper concludes that Rheo-HPDC is a smart manufacturing technique that significantly improves the quality of cast products compared to conventional HPDC. The proper preparation of slurry is identified as a crucial aspect of the process. The development of slurry-making equipment, culminating in the self-inoculation method (SIM), has enabled the production of casts with improved mechanical properties, including ultimate tensile strength, yield strength, elongation, hardness, density, and thermal conductivity. Furthermore, Rheo-HPDC leads to a more homogeneous and uniform microstructure while reducing porosity. The paper concludes that this technique has high productivity and is reliable for producing excellent casts with great precision. For sand casting, it suggests that tapioca flour is a potentially preferable binder to bentonite for achieving higher strength in dry conditions.

8. References:

- [List the references exactly as cited in the paper, Do not translate, Do not omit parts of sentences.]

- H. Sudjana, Teknik Pengecoran Logam Jilid 2 Untuk SMK (Jakarta: Direktorat Pembinaan Sekolah Mengengah Kejuruan, Direktorat Jenderal Manajemen Pendidikan Dasar dan Menengah, Departemen Pendidikan Nasional: 2008).

- T. Surdia and K. Chijiwa, Teknik Pengecoran Logam (Jakarta: PT Pradnya Paramita: 1980).

- P. Puspitasari and Khafididin, Analisa Hasil Pengecoran Logam AL-SI Menggunakan Lumpur Lapindo Sebagai Pengikat Pasir Cetak (Malang: Universitas Negeri Malang: 2014).

- H. Mae, X. Teng, Y. Bai, and T. Wierzbicki, International Journal of Solids and Structures, 45, No. 5: 1430 (2008). https://doi.org/10.1016/j.ijsolstr.2007.10.016

- C. Saikaew and S. Wiengwiset, Applied Clay Science, 67-68: 26 (2012). https://doi.org/10.1016/j.clay.2012.07.005

- W. B. Parkes, Clay-Bonded Foundry Sand (London: Applied Science Publishers: 1971).

- S. K. Singha and S. J. Singh, International Journal of Research in Engineering and Technology, 4, No. 5: 24 (2015).

- P. Hackney and R. Wooldridge, Procedia Manufacturing, 11: 457 (2017). https://doi.org/10.1016/j.promfg.2017.07.136

- S. Shahria, Tariquzzaman, H. Rahman, A. Amin, and A. Rahman, International Journal of Mechanical Engineering and Applications, 5, No. 3: 155 (2017). https://doi.org/10.11648/j.ijmea.20170503.13

- U. Patwari, S.I. Chowdhury, H. Rashid, and G.R. Mumtaz, Annals of the Faculty of Engineering Hunedoara, 14, No. 1: 143 (2016).

- T. Surdia, Metal Casting Techniques (Jakarta: Pradnya Paramita: 2000) .

- S. Slamet, Komposisi Distribusi Butir Pasir Cetak Terhadap Tingkat Produktifitas Akibat Cacat Produk Cor (Gondang Manis Bae Kudus: Universitas Muara Kudus: 2015).

- J.W. Dika, Analisis Variasi Holding Time Peleburan Terhadap Kekuatan Impak, Cacat Makro, dan Struktur Mikro Pada Pengecoran Logam Al-Si (Malang: Universitas Negeri Malang: 2016).

- T. Purbowo and S. Tjitro, Jurnal Teknik Mesin, 5, No. 2: 43 (2003).

- I.M. Astika, D.N.K.P. Negara, and M.A. Susantika, Jurnal Energi dan Manufaktur, 4, No. 2: 132 (2010).

- P.O. Atanda, O.E. Olorunniwo, K. Alonge, and O.O. Oluwole, International Journal of Materials and Chemistry, 2, No. 4: 132 (2012).

- D.M. Gilson, Transactions of the American Foundrymen's Society, 101: 491 (1993).

- M. Stancliffe, J. Kroker, and X. Wang, Modern Casting, 97, No. 3: 40 (2007).

- Y. Umardani and E. Sudrajat, Rotasi, 9, No. 3: 10 (2007).

- J.J. Sobczak, R. Purgert, A. Balinski, P. Darlak, The Use of Fly Ash As an Aggregate for Foundry Sand Mold and Core Production (Final Report. Combustion by Products Research Consortium) (Ohio: The Energy Industries of Ohio: 2002).

- S. Tjitro and Hendri, Seminar Nasional Teknik Mesin 4 (Surabaya: UK Petra Surabaya: 2009), p. 196.

- P. Puspitasari, Tuwoso, and E. Aristiyanto, Jurnal Teknik Mesin, 23, No. 1: 21 (2015).

- Tempo.co, Letusan 2014 Paling Besar dalam Sejarah Kelud (Jakarta: Tempo Media Group: 2014).

- A.S. Suryani, Info Singkat Kesejahteraan Sosial Kajian Singkat Terhadap Isu-Isu Terkini, VI, No. 04: 9 (2014).

- Y. Umardani, Rotasi, 17, No. 1: 52 (2015). https://doi.org/10.14710/rotasi.17.1.52-56

- N.T. Herwido, P. Murdanto, and P. Puspitasari, Jurnal Teknik Mesin, 24, No. 1: 1 (2016).

- A. Andoko, R. Nurmalasari, M.A. Mizar, R. Wulandari, P. Puspitasari, and A.A. Permanasari, Journal of Mechanical Engineering Science and Technology, 1, No. 1: 32 (2017). https://doi.org/10.17977/um016v1i12017p032

- A. Andoko, P. Puspitasari, A.A. Permanasari, and D.Z. Lubis, Journal of Mechanical Engineering Science and Technology, 1, No. 2: 49 (2017). https://doi.org/10.17977/um016v1i22017p049

- A.H. Zuhri, Pengaruh Penggunaan Calcium Carbonate Sebagai Bahan Pengikat Pada Pasir Cetak Terhadap Kualitas dan Fluiditas Hasil Pengecoran Logam Aluminium (Malang: Universitas Negeri Malang: 2014).

- S. Tata and S. Saito, Pengetahuan Bahan Teknik (Jakarta: PT Pradnya Paramita: 1999).

- Mugiono, Lagiyono, and Rusnoto, Jurnal Teknik Mesin, Juli: 1 (2013).

- K.G. Budinski, Engineering Materials Properties and Selection (New Delhi: PHI: 2001).

- A. Fuad, Traksi, 10, No. 1: 44 (2010).

- T.M. Radchenko, V.A. Tatarenko, and H. Zapolsky, Solid State Phenomena, 138: 283 (2008). https://doi.org/10.4028/www.scientific.net/SSP.138.283

- D.S. Leonov, T.M. Radchenko, V.A. Tatarenko, and Yu.A. Kunitsky, Defect and Diffusion Forum, 273–276: 520 (2008). https://doi.org/10.4028/www.scientific.net/DDF.273-276.520

- T.M. Radchenko, V.A. Tatarenko, H. Zapolsky, and D. Blavette, Journal of Alloys and Compounds, 452, No. 1: 122 (2008). https://doi.org/10.1016/j.jallcom.2006.12.149

- M. Gupta and S. Ling, Journal of Alloys and Compounds, 287, Nos. 1-2: 284 (1999). https://doi.org/10.1016/S0925-8388(99)00062-6

- H.S. Dai and X.F. Liu, Materials Characterization, 59, No. 11: 1559 (2008). https://doi.org/10.1016/j.matchar.2008.01.020

- Y.G. Yang, Process and Quality Control of Aluminum Die-Casting (Beijing: Chemical Industry Press: 2009).

- R. Franke, D. Dragulin, A. Zovi, and F. Casarotto, Metallurgia Italiana, 5, No. 5: 21 (2007).

- M.F. Qi, Y. Kang, B. Zhou, and H.H. Zhang, The Chinese Journal of Nonferrous Metals, 25, No. 8: 2029 (2015).

... (and all subsequent references up to 88)

Expert Q&A: Your Top Questions Answered

Q1: Why is slurry preparation so critical in the Rheo-HPDC process?

A1: According to the paper, "slurry serves a very significant role in producing high-quality castings, and thus proper preparation is necessary before rheo-HPDC." The core of the Rheo-HPDC process consists of first, the preparation of the slurry, and second, the forming process. This initial preparation step is what distinguishes it from conventional HPDC and is directly responsible for the improvements in final product quality.

Q2: The paper mentions several slurry-making methods. Which one is presented as the most advanced?

A2: The paper identifies the self-inoculation method (SIM) as the most advanced. It is described as "the latest innovation among all slurry-making processes" and "the latest system and able to improve the quality of the cast products." This suggests that for achieving the highest quality outcomes with Rheo-HPDC, the SIM process is the current state-of-the-art.

Q3: How exactly does Rheo-HPDC reduce porosity compared to conventional HPDC?

A3: The mechanism for porosity reduction is related to the viscosity of the metal. The paper explains that "slurry has a higher viscosity than molten or liquid metal. This leads to the less entrapped gas contained in the materials and hence a final product with no porosity defects." By injecting a thicker, semi-solid material instead of a fully liquid one, the turbulent flow that traps air and gas is minimized.

Q4: Can you quantify the improvement in ultimate tensile strength (UTS) achieved with Rheo-HPDC according to the data presented?

A4: Yes, the data is very specific. According to Table 6, "The ultimate tensile strength of specimen cast using the conventional HPDC was 217 MPa, while that of products cast by rheo-HPDC was up to 261 MPa." This represents an improvement of up to 44 MPa, or approximately 20%, demonstrating a substantial increase in material strength.

Q5: What is the main difference in the microstructure between a part made with Rheo-HPDC and one made with conventional HPDC?

A5: The paper highlights a clear difference using Figure 25. The microstructure in the Rheo-HPDC product (Fig. 25a) is described as "much better and clearer" than the conventional HPDC image (Fig. 25b). The key features of the superior Rheo-HPDC structure are "the clearly visible grain boundaries and the homogeneity of the spherical microstructure," which support its superior mechanical properties.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of overcoming internal defects like porosity in High-Pressure Die Casting has long been a barrier to achieving maximum component performance. This review of Rheo-HPDC technology demonstrates a clear and proven path forward. By integrating semi-solid slurry preparation into the casting process, manufacturers can produce components with demonstrably superior mechanical properties, lower porosity, and a more refined microstructure. The continuous innovation in slurry-making techniques, culminating in the self-inoculation method, further solidifies Rheo-HPDC as a smart, reliable manufacturing process for the modern era.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "CASTING QUALITY ENHANCEMENT USING NEW BINDERS ON SAND CASTING AND HIGH-PRESSURE RHEO-DIE CASTING" by "P. Puspitasari and J.W. Dika".

- Source: https://doi.org/10.15407/ufm.20.03.396

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.