The 80/20 Rule in Action: Prioritizing Casting Repair Work for Maximum Impact

This technical summary is based on the academic paper "The Analysis Cause of Casting Repair Work with Pareto Chart in Project X" by Ryobi Irfanto, published in Jurnal Teknik Sipil (2022). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Casting Repair Work

- Secondary Keywords: Pareto Chart, Casting Defects, Quality Control, Concrete Casting, Grouting, Chipping, Construction Projects

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: The unique nature of construction projects makes quality control difficult, often leading to costly and time-consuming casting repair work that can account for up to 30% of total construction expenses.

- The Method: The study applied a Pareto chart analysis to field data from a large-scale construction project to identify the frequency and root causes of defects requiring casting repair.

- The Key Breakthrough: The analysis revealed that just two dominant types of defects—cracks and unevenness—were responsible for over 76% of all required casting repair work.

- The Bottom Line: By focusing quality control and repair efforts on preventing and correcting cracks and unevenness, project teams can address the vast majority of issues, significantly improving efficiency and reducing costs.

The Challenge: Why This Research Matters for HPDC Professionals

In any large-scale construction project, maintaining the quality of concrete casting is a persistent challenge. The unique management and variable conditions of each project make it difficult to achieve consistent results, leading to defects that require rework. This isn't just a minor inconvenience; according to Tetteh (2020), the cost of concrete repair work can swell to 25-30% of a project's total construction expenditure.

Identifying which defects cause the most significant impact is critical for effective project management. Without a systematic approach, teams can waste valuable time and resources fixing minor issues while the most impactful problems continue to drain the budget. This research was undertaken to apply a proven statistical technique, the Pareto chart, to analyze the causes of casting repair work on a major construction project ("Project X"), providing a clear roadmap for prioritizing quality control efforts.

The Approach: Unpacking the Methodology

The research employed a qualitative case study method based on direct field observation at "Project X," an 8-story office building with two basement levels in Central Jakarta. The structure was predominantly concrete, with casting work accounting for 44.3% of the total project value.

The methodology followed these key steps:

1. Data Collection: Researchers conducted field observations to identify and record the frequency of every instance that required repair work on cast concrete components (columns, beams, slabs, retaining walls, etc.).

2. Categorization: Initially, 11 distinct types of repair jobs were identified. These were then consolidated into six main categories based on the nature of the defect (e.g., "cracks in columns" and "cracks in beams" were grouped into the "Cracks" category).

3. Pareto Analysis: The frequency of each defect category was calculated and plotted on a Pareto chart. This tool visually organizes issues from most to least frequent, allowing for the identification of the "vital few" causes that create the majority of the problems, in line with the 80/20 principle.

The Breakthrough: Key Findings & Data

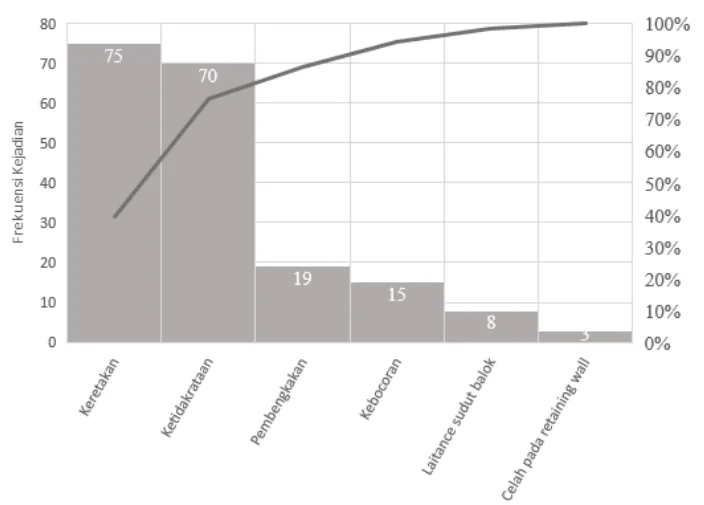

The Pareto analysis provided a clear, data-driven hierarchy of the most common casting defects requiring repair. Out of 190 total recorded incidents, two issues were overwhelmingly dominant.

Finding 1: Cracks and Unevenness are the "Vital Few" Defects

As detailed in Table 3, "Cracks" were the single most frequent defect, occurring 75 times and accounting for 39.47% of all repair incidents. "Unevenness" was a close second, with 70 occurrences representing 36.84% of the total. Combined, these two issues alone were responsible for 76.32% of all casting repair work on the project. This finding powerfully illustrates the Pareto principle, where a small number of causes (33% of the categories) led to a large majority of the effects.

Table 3. Results of Pareto Chart Calculation Data Processing

| No | Type of Work | Frequency | Cumulative Frequency | Percentage | Cumulative Percentage |

| :--- | :--- | :--- | :--- | :--- | :--- |

| 1 | Cracks | 75 | 75 | 39.47% | 39.47% |

| 2 | Unevenness | 70 | 145 | 36.84% | 76.32% |

| 3 | Swelling | 19 | 164 | 10.00% | 86.21% |

| 4 | Leakage | 15 | 179 | 7.89% | 94.21% |

| 5 | Laitance on beam corners | 8 | 187 | 4.21% | 98.42% |

| 6 | Gaps in retaining wall | 3 | 190 | 1.58% | 100.00% |

Finding 2: The Pareto Chart Visually Confirms Repair Priorities

The Pareto chart in Figure 4 provides an immediate visual representation of these findings. The steep rise of the cumulative percentage line for the first two bars (Cracks and Unevenness) clearly separates them from the "trivial many" defects that follow. For any quality control manager or engineer, this chart instantly communicates where to focus attention and resources for the greatest return on investment. The remaining four defect categories—swelling, leakage, laitance, and gaps—collectively made up less than 24% of the required repairs.

Practical Implications for R&D and Operations

- For Process Engineers: The study identifies specific repair methods for the most common defects. The

chippingmethod is recommended for repairing porous concrete or leveling swollen areas, while thegroutingmethod (injecting a cement and water mixture) is effective for filling cracks and the results of chipping. Mastering these two techniques is essential for efficient repair operations. - For Quality Control Teams: The data in Table 3 and Figure 4 demonstrates that the Pareto chart is a simple yet powerful tool for quality analysis. Teams can adopt this methodology to move beyond anecdotal evidence and use frequency data to pinpoint and prioritize the most critical quality issues in their own projects, ensuring that limited resources are allocated effectively.

- For Project Managers: The finding that over 76% of rework stems from just two causes provides a strong business case for proactive investment. Focusing on improving the root causes of cracks (e.g., curing process, load management) and unevenness (e.g., proper vibrator use, formwork design) during the initial casting phase can yield substantial savings in repair costs and project timelines.

Paper Details

THE ANALYSIS CAUSE OF CASTING REPAIR WORK WITH PARETO CHART IN PROJECT X

1. Overview:

- Title: THE ANALYSIS CAUSE OF CASTING REPAIR WORK WITH PARETO CHART IN PROJECT X

- Author: Ryobi Irfanto

- Year of publication: 2022

- Journal/academic society of publication: Jurnal Teknik Sipil, Volume 18, Number 1

- Keywords: Cause of Repair, Pareto Chart, Casting Repair

2. Abstract:

Construction projects are inseparable from their unique management. The unique management of construction projects makes it difficult to maintain their quality. One of the tools to measure quality in project management is the Pareto chart. Pareto chart is a statistical technique that is usually used for decision making based on the frequency of events compared to the causes of events. This research was conducted to analyze the causes of repair work on project X by using Pareto chart. The conceptual framework used in this study is based on two approaches, namely literature and field observations. The main literature for analysis is the Pareto chart then field data collection on each component first which is then categorized based on the type of work. After the data is categorized, a Pareto chart will be made from the data. The processing results obtained two dominant types of errors in the casting work, namely cracks and unevenness of the casting results. Cracks and unevenness of the casting results can be overcome by the chipping method then followed by grouting if necessary. The chipping method is used to repair porous concrete or flatten the casting if it swells, and the grouting method to fill cracks and chipping results with a mixture of cement and water until the surface becomes flat and the casting work results are better.

3. Introduction:

Construction projects are unique from one project to another and also have a certain time limit (Project Management Institute, 2008). The uniqueness of the project makes project management difficult. Project management also depends on three aspects, namely cost, quality, and time. (Setiawan, Dwivania, & Sunaris, 2019). According to Behnam (2017) one of the tools to measure quality in organizational management is the Pareto chart. A Pareto chart is a statistical technique that is usually used for decision making based on the frequency of events compared to the cause of the event. The Pareto chart that has been created is then analyzed and used for the selection of several causes that will have a significant impact (Talib, 2010). Some types of Pareto charts on the project are 80% of events caused by 20% of causes. Concrete structures are the most commonly used building materials because of their good durability, which has been used to build a large number of constructions from houses to bridges for many years. Concrete structures that are often used are also inseparable from repair work due to various factors such as errors in initial calculations or planning, human error during implementation, cost factors, and natural disasters (Agustinus & Lesmana, 2019). In the last few years, the increasing need for structural repairs has led to cost overruns. The cost of concrete repair is estimated to be up to 25-30% of the total expenditure on construction work (Tetteh, 2020). Sjafei Amri (2006) explains that the definition of repair is an effort to restore the performance of a building or component to its original state, to meet a predetermined standard so that the quality of the resulting building is good. This concrete repair work is carried out in order to maintain the structural strength of the building and maintain the final result so that its quality is maintained.

4. Summary of the study:

Background of the research topic:

The study addresses the high cost and frequency of repair work required for concrete casting in construction projects. Given that concrete structures are ubiquitous and repair costs can account for 25-30% of total construction expenditures, there is a significant need for a systematic method to identify and prioritize the root causes of these repairs to improve quality and manage costs effectively.

Status of previous research:

Previous studies have utilized Pareto analysis in construction to identify productivity constraints (Durdvey and Ismail, 2012) and critical issues in the industry like budget mismatches and improper casting techniques (Hedaoo, dkk., 2021). However, this study specifically focuses on applying the Pareto chart to categorize and quantify the causes of post-casting repair work, providing a focused analysis on rework and its primary drivers.

Purpose of the study:

The purpose of this research is to apply the Pareto chart to analyze the causes of repair work in concrete casting on a specific construction project (Project X). The goal is to identify the most dominant types of errors, thereby providing a data-driven basis for prioritizing repair efforts and suggesting effective remediation methods.

Core study:

The core of the study involved observing and recording the frequency of 11 different types of required repairs on the cast concrete elements of Project X. This raw data was then categorized into 6 broader types of defects. A Pareto analysis was performed on this categorized data to determine the "vital few" defects that accounted for the majority of repair incidents. The study found that cracks and unevenness were the two dominant causes, together accounting for 76.32% of all repairs. The paper concludes by recommending chipping and grouting as appropriate repair methods for these common defects.

5. Research Methodology

Research Design:

The study used a qualitative research method with a case study observation approach. The research was conducted on Project X, an office building construction site in Central Jakarta. The process involved identifying the problem (the need for repair work), conducting a literature review on Pareto charts, collecting field data through observation, processing and categorizing the data, creating a Pareto chart, and analyzing the results to draw conclusions and recommend solutions.

Data Collection and Analysis Methods:

Data was collected through direct field observation, where researchers recorded the frequency of each type of error in the cast concrete that necessitated repair. This frequency data was first compiled into a detailed list (Table 1) and then grouped into broader categories (Table 2). The analysis involved calculating the frequency, cumulative frequency, percentage, and cumulative percentage for each category to construct a Pareto chart (Table 3 and Figure 4), which visually identified the most significant problems.

Research Topics and Scope:

The research was focused on the repair work performed on the cast concrete results of Project X. The scope was limited to identifying the frequency of different types of defects requiring repair, such as cracks, unevenness, swelling, leakage, and others, across various structural components like columns, beams, slabs, and retaining walls. The study analyzed the causes of the repair work itself, not the initial casting process, and proposed appropriate repair methods based on the findings.

6. Key Results:

Key Results:

- The study identified 11 specific types of repair work, which were then consolidated into 6 main categories for analysis: Cracks, Unevenness, Swelling, Leakage, Laitance, and Gaps.

- Out of a total of 190 repair incidents, Cracks were the most frequent defect (75 occurrences, 39.47%), followed closely by Unevenness (70 occurrences, 36.84%).

- These two dominant categories, Cracks and Unevenness, collectively accounted for 76.32% of all required casting repair work, identifying them as the "vital few" problems according to the Pareto principle.

- The remaining four categories (Swelling, Leakage, Laitance, Gaps) were identified as the "trivial many," making up less than 24% of the total issues combined.

- The study concludes that repair methods such as

chippingandgroutingare effective for addressing the two most dominant types of defects found.

Figure Name List:

- Gambar 1. Contoh Pareto Chart

- Gambar 2. Kerangka Konseptual Penelitian.

- Gambar 3. Diagram Alir Metode Penelitian

- Gambar 4. Pareto chart Penyebab Perbaikan Pekerjaan Pengecoran

7. Conclusion:

The results obtained from this study is the identification of the causes of repair work on the results of casting with a Pareto chart conducted on Project X shows that there are two causes of repair work, namely cracks and unevenness of the casting results. These two causes have a percentage of 76.32% of the total overall frequency of errors in the casting results. These two causes also show that out of 6 categories of causes of repair work, only 2 categories dominate or 33.33% of the categories. Cracks and unevenness can be repaired by the chipping method and then continued with grouting so that the casting results are better.

8. References:

- Agustinus, S., & Lesmana, C. (2019). Perbandingan Analisis Perkuatan Struktur Pelat dengan Metode Elemen Hingga. Jurnal Teknik Sipil Universitas Kristen Maranatha Volume 15 Nomor 1, 1-25.

- Alfredo, D., Hutomo, K., Sudjarwo, P., & Buntoro, J. (2014). Analisa Penyebab dan Metode Perbaikan yang Tepat pada Beton yang disebabkan oleh Faktor Non- Struktural. Jurnal Dimensi Pratama Teknik Sipil, 1-5.

- Amri, S. (2006). Teknologi Audit, Repair dan Retrofit untuk Rumah dan Bangunan. Jakarta: Yayasan John Hi-Tech.

- Durdyev, S., & Ismail, S. (2012). Pareto analysis of on-site productivity constraints and improvement techniques in construction industry. Scientific Research and Essays Vol. 7(7), 824-833.

- Five Star Product Inc. (2012). A Professional's Guide to Grouting and Concrete Repair. Five Star Product Inc.

- Hedaoo, D. N., Jain, H., Kabra, M., & Chhajed, S. (2021). Identifying Critical Issues in Construction Industry Using Pareto Analysis. International Journal for Science and Advance Research in Technology Volume 7 Issue 1, 1-4.

- Moon, S., Lopez, R., Forlani, J., Xu, S., & Wang, X. (2015). Applying Pareto Principle to Process Control in Construction. International Conference on Innovative Production and Construction, (pp. 129-132). Perth.

- Neyestani, B. (2017). Seven Basic Tools of Quality Control: The Appropriate Quality Techniques for Solving Quality Problem in the Organization. doi: 10.5281/zenodo.400832.

- Project Management Institute. (2008). A Guide to Project Management Body of Knowledge 4th Ed.

- Setiawan, A. F., Dwivania, N., & Sunaris, M. L. (2019). Analisis Keterlambatan Pengiriman Material Beton (Studi Kasus Proyek Breeze Tower, Bintaro PT. Tatamulia Nusantara Indah). Jurnal Teknik Sipil Universitas Kristen Maranatha Volume 15 Nomor 1, 26-35.

- Sunarto, & Nugroho, H. S. (2020). Buku Saku Analisis Pareto. Surabaya: Prodi Kebidanan Magetan Politekkes Kemenkes.

- Tague, N. R. (2005). The Quality Toolbox (2nd Edition). Milaukee, Wisconsin: ASQ Quality Press.

- Talib, F. R. (2010). Pareto analysis of total quality management factors critical to success for service industries. International journal for quality research Vol. 2, 155-168.

- Tetteh, A. R. (2020). Repair of Cracks on Concrete Structures. International Journal of Science and Research, Vol. 9 Issue 4, 82-92.

Expert Q&A: Your Top Questions Answered

Q1: Why was the Pareto chart chosen for this analysis over other quality control tools?

A1: The paper explains that a Pareto chart is a statistical technique specifically used for decision-making based on the frequency of events compared to their causes. Its primary strength, and the reason it was suitable here, is its ability to distinguish the "vital few" problems from the "trivial many," aligning with the 80/20 principle. This makes it ideal for prioritizing actions where multiple types of defects occur, ensuring that efforts are focused where they will have the most significant impact.

Q2: The paper combines different types of defects like "cracks in columns" and "unevenness of retaining walls" into single categories. What was the rationale for this?

A2: The study's objective was to identify the dominant types of errors in the casting work, not just their locations. By consolidating data as shown in the transition from Table 1 to Table 2, a clearer pattern emerged. This approach revealed that "Cracks" and "Unevenness" were systemic problems occurring across various structural components, a critical insight that might have been obscured if the data remained fragmented by location.

Q3: What specific repair methods were identified for the top two defects, cracks and unevenness?

A3: The paper proposes a two-step process. First, the chipping method is used to repair porous concrete or to flatten areas that are swollen or uneven. Second, the grouting method is applied. This involves filling the cracks and any areas repaired by chipping with a mixture of cement and water until the surface is flat and the overall quality of the casting work is improved.

Q4: What does the paper suggest are the root causes of these cracks and unevenness (voids)?

A4: The paper cites Daniel Alfredo (2014) to explain the causes. For non-structural cracks, it points to potential causes like errors in the curing process, excess load during casting, and weather factors. For unevenness, also known as voids, the cause is typically due to inadequate compaction (improper use of a vibrator) or formwork-rebar spacing that is too narrow, preventing mortar from properly filling the space between coarse aggregates.

Q5: The study focuses on one specific project ("Project X"). How applicable are these findings to other projects?

A5: While the exact frequency of defects (76.32% from cracks and unevenness) is specific to Project X, the methodology is universally applicable. The key takeaway is not the specific defects themselves, but the power of the Pareto analysis method. Any project team can use this same approach of data collection, categorization, and analysis to identify their own unique "vital few" problems and make data-driven decisions to improve quality and reduce repair costs.

Conclusion: Paving the Way for Higher Quality and Productivity

This study effectively demonstrates that not all defects are created equal. By moving beyond simple defect lists and applying a structured Pareto analysis, project teams can gain profound clarity on where to focus their quality improvement efforts. For Project X, the critical insight was that tackling just two issues—cracks and unevenness—could resolve over three-quarters of the required Casting Repair Work. This data-driven approach transforms quality control from a reactive, scattered effort into a strategic, high-impact initiative.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "The Analysis Cause of Casting Repair Work with Pareto Chart in Project X" by "Ryobi Irfanto".

- Source: https://doi.org/10.28932/jts.v18i1.4485

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.