Unlocking Flawless Welds: How Dynamic Beam Oscillation Transforms Laser Welding for Die Casting

This technical summary is based on the academic paper "Enhanced process understanding for laser welding of copper and aluminum alloys with dynamic beam oscillation" by Stephan Börner et al., published in Lasers in Manufacturing Conference 2023. It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Laser Welding for Die Casting

- Secondary Keywords: dynamic beam oscillation, copper welding, aluminum welding, e-mobility manufacturing, weld seam quality, keyhole stability, porosity reduction

Executive Summary

- The Challenge: Instability, defects (spatter, pores), and blowouts limit the use of conventional laser welding for joining copper and aluminum die-cast components in e-mobility applications.

- The Method: Researchers used dynamic beam oscillation with in-situ X-ray imaging and high-speed video to analyze the influence of key parameters, particularly beam path speed, on weld quality.

- The Key Breakthrough: An optimal beam path speed (30-100 m/min) significantly stabilizes the welding process, creating an expanded keyhole that reduces porosity and defects in difficult-to-weld materials like aluminum die-cast.

- The Bottom Line: Optimizing beam path speed during dynamic beam oscillation is a critical strategy for achieving high-quality, reliable welds in challenging materials used in HPDC applications.

The Challenge: Why This Research Matters for HPDC Professionals

The rapid growth of e-mobility and other advanced propulsion systems demands efficient and reliable manufacturing processes for components made from copper and aluminum alloys. However, joining these materials, especially in high-volume production, is fraught with challenges. Conventional laser beam welding often suffers from low process stability, leading to defects like blowouts, spatter, and porosity (as seen in Fig. 1a of the paper). These flaws compromise the structural integrity and performance of critical components. For manufacturers working with aluminum die-cast parts, which can contain entrapped gases, the risk of porosity is even higher. This research was necessary to develop a deeper process understanding and identify crucial factors to overcome these limitations and enable high-quality, stable joining technologies.

The Approach: Unpacking the Methodology

To investigate the process, the research team employed a sophisticated experimental setup designed for high-resolution analysis.

- Equipment: The trials were conducted using a 5000 W single mode fiber laser combined with a galvanometric scanning optics system capable of oscillation frequencies up to 4000 Hz.

- Materials: The primary samples were made of Cu-OF (oxygen-free copper), with findings later transferred to aluminum die-cast.

- Key Variables: The study explored a wide parameter range, including laser power (1000-3000 W), welding speed (1.5-6 m/min), circular oscillation amplitude (0.05-0.4 mm), and frequency (250-4000 Hz).

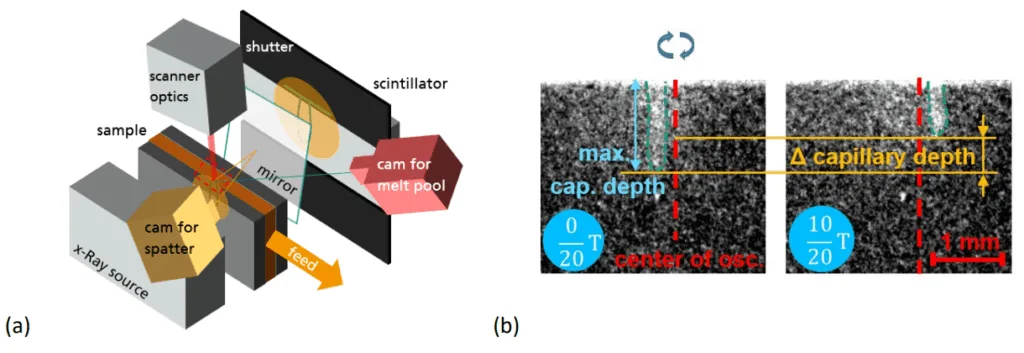

- Advanced Diagnostics: To capture the complex physics of the interaction zone, the team used a combination of high-spatial and temporal resolution diagnostics. This included X-ray analysis at up to 10 kHz to visualize the vapor capillary and melt pool dynamics, supplemented by high-speed cameras to detect spatter and melt ejections (Fig. 2a).

This comprehensive approach allowed for a direct correlation between process parameters and the resulting weld quality, both on the surface and internally.

The Breakthrough: Key Findings & Data

The study delivered crucial insights into optimizing dynamic beam oscillation, highlighting the dominant role of beam path speed and its transferability to aluminum die-cast.

Finding 1: The Critical Role of Beam Path Speed in Weld Quality

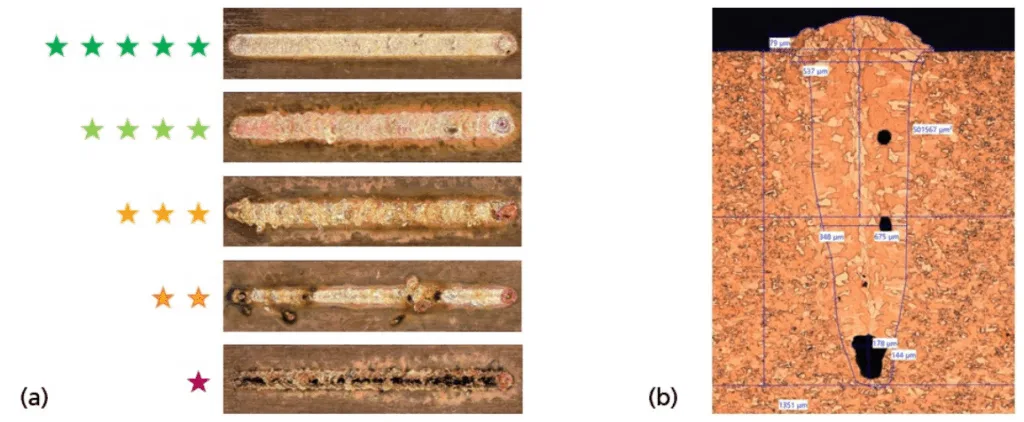

The most significant finding is that the resulting weld seam quality is directly and strongly influenced by the beam path speed—the combined velocity of the welding feed and the superimposed oscillation. As shown in Figure 4, there is a distinct process window for achieving high-quality welds.

- Optimal Range (30-100 m/min): In this range, the process stability is significantly increased, leading to a sharp decrease in spatter and pore formation. Welds rated as acceptable (three stars) to very high quality (five stars) were consistently produced. The stabilized capillary at these higher speeds is a key reason for the improved quality.

- Low Speed Range (< 30 m/min): At beam path speeds below 30 m/min, the proportion of low-quality trials (one or two stars) increases significantly due to unstable processes and insufficient overlap of the beam path.

- High Speed Range (> 200 m/min): When the beam path speed exceeds 200 m/min, the process shifts towards a remote laser cutting regime. The high intensity and low interaction time lead to increased melt ejections and low-quality welds.

Finding 2: Expanded Keyhole Welding for Porosity Reduction in Aluminum Die Cast

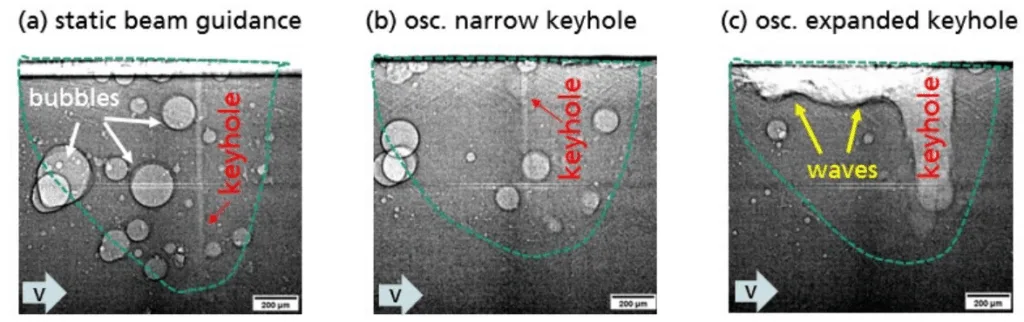

The principles discovered in copper welding were successfully transferred to aluminum die-cast, a material notoriously difficult to weld due to entrapped gases. Synchrotron X-ray recordings revealed that beam path speed is a critical factor here as well.

As shown in Figure 8, static beam guidance (Fig. 8a) results in large bubbles forming in the melt pool, which become trapped as pores. In contrast, dynamic beam oscillation at a high beam path speed creates an "expanded keyhole" (Fig. 8c). This expanded, stable keyhole, along with induced waves in the melt pool, pushes bubbles toward the keyhole, allowing them to degas efficiently before the weld solidifies. This demonstrates that dynamic beam oscillation is a powerful solution for producing high-quality welds in gas-prone die-cast materials.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting oscillation frequency and amplitude to achieve a beam path speed between 30 and 100 m/min may contribute to significantly stabilizing the welding process and reducing spatter and porosity.

- For Quality Control Teams: The data in Figure 4 of the paper illustrates the direct effect of beam path speed on weld seam quality, which could inform new in-process monitoring and quality inspection criteria for welded die-cast assemblies.

- For Design Engineers: The findings indicate that the expanded keyhole created by high-speed oscillation can effectively mitigate porosity in aluminum die-cast. This suggests that designing joints to be accessible for this type of welding process is a valuable consideration in the early design phase to ensure component integrity.

Paper Details

Enhanced process understanding for laser welding of copper and aluminum alloys with dynamic beam oscillation

1. Overview:

- Title: Enhanced process understanding for laser welding of copper and aluminum alloys with dynamic beam oscillation

- Author: Stephan Börner, Dirk Dittrich, Joseph Barrios Larrañaga, Andreas Wetzig, Michael Sawannia, Eveline N. Reinheimer, Andreas Heider, Reiner Ramsayer

- Year of publication: 2023

- Journal/academic society of publication: Lasers in Manufacturing Conference 2023

- Keywords: laser beam welding; copper; beam oscillation; beam path speed; expanded keyhole; X-ray

2. Abstract:

The increasing electrification of automotive application require high quality and efficient joining processes for copper and aluminum alloys. Dynamic beam oscillation is suitable to cover the wide range of joining application for copper (thin to thick sheets) through the possibility of adapted energy distribution by one optical setup. However, amount of welding parameters increases strongly, which results in higher complexity of influencing factors. Deeper process understanding and the identification of crucial process factors is necessary to overcome existing limitations in joint quality such as formation of blowouts, spatters and pores. Therefore, comprehensive insights in the welding process by X-ray imaging, high-speed video-recordings are combined with metallographic analysis. In this paper, the impact of the beam path speed on the process regime and the weld seam quality will be presented. Moreover, the transferability to applications and other difficult to weld materials like aluminum die-cast will be illustrated.

3. Introduction:

In the ongoing engagement against climate change, alternative propulsion systems such as e-mobility need to be further improved and the manufacturing process for components made more efficient. In e-mobility, there is a large field of different applications and a wide range of geometries as well. Processing of materials like copper and aluminum for those application within serial production is essential. For reliable and flexible joining processes, laser beam welding shows high potential to face these challenges. Due to low stability of conventional welding processes with regard to blowouts, spatters and pores, there is a need of adapted joining technologies. Beam oscillation increases flexibility and enables an adaption of the energy distribution in the process zone. To achieve high quality weld seams, it is essential to know how different parameters influence the welding process and how irregularities develop.

4. Summary of the study:

Background of the research topic:

The automotive industry's shift to e-mobility requires high-quality joining of copper and aluminum alloys. Conventional laser welding is often unstable for these materials.

Status of previous research:

Approaches like using different laser wavelengths (515 nm or 450 nm) or power modulation have been explored. Beam oscillation has been identified as an efficient way to stabilize welding processes, but the increased number of parameters complicates optimization.

Purpose of the study:

The goal is to present the influence of the beam path speed (vB) on the quality of the weld seam in copper and to demonstrate the transferability of these findings to other difficult materials like aluminum die-cast.

Core study:

The study systematically varied laser power, welding speed, and circular oscillation parameters (amplitude, frequency) to create a process map. Using advanced diagnostics like X-ray imaging and high-speed video, the researchers analyzed the capillary dynamics, melt pool behavior, and defect formation mechanisms. They identified a clear correlation between beam path speed and weld quality and investigated specific phenomena like humping and the formation of an expanded keyhole.

5. Research Methodology

Research Design:

The study used an experimental approach with systematic parameter variation. Welding trials were performed on Cu-OF samples, and the results were evaluated using a five-star quality assessment scale based on microscopy and metallographic analysis according to DIN EN ISO standards.

Data Collection and Analysis Methods:

Data was collected using in-situ process diagnostics, including X-ray imaging (up to 10 kHz) to observe the vapor capillary and high-speed cameras for melt pool and spatter detection. Post-process analysis involved creating metallographic cross-sections to measure penetration depth, seam width, and internal defects like pores.

Research Topics and Scope:

The research focused on laser welding of copper with dynamic beam oscillation. The scope included identifying optimal process windows, understanding the physical mechanisms behind defect formation (spatter, pores, humping), and demonstrating the transferability of the core findings to aluminum die-cast welding.

6. Key Results:

Key Results:

- The beam path speed is a dominant factor influencing weld seam quality. An optimal process window exists between 30 and 100 m/min, where process stability is high and defects are minimized.

- Beam path speeds below 30 m/min lead to process instabilities, while speeds above 200 m/min result in a cutting-like process with excessive melt ejection.

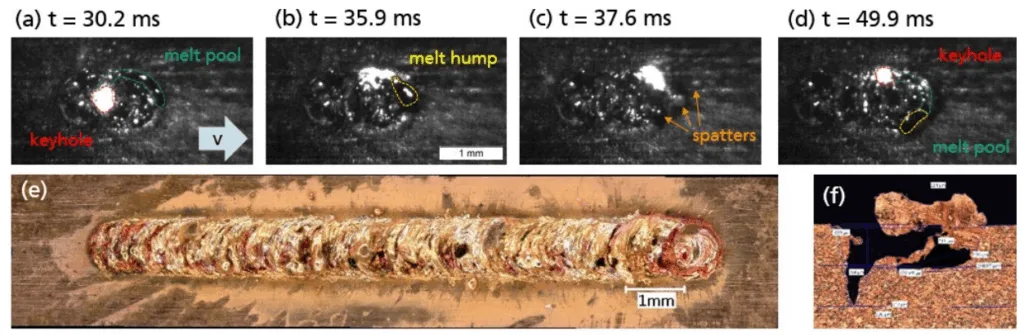

- A specific defect, "humping phenomena," was identified at low laser power and high amplitude/frequency, caused by high melt flow. This can be solved by reducing the oscillation amplitude or frequency.

- The findings are transferable to aluminum die-cast. High beam path speeds create an "expanded keyhole," which promotes the degassing of the melt pool and significantly reduces porosity.

Figure Name List:

- Fig. 1. Comparison of copper weld seam surfaces for same energy per unit length with (a) typical failures during static beam guidance; (b) unsuitable oscillation parameters; (c) adapted oscillation parameters

- Fig. 2. (a) Schematic experimental setup for welding trials with dynamic beam oscillation welding of copper at the X-ray laboratory of IFSW in Stuttgart, Germany; (b) Cumulated X-ray images from two different positions during an oscillation period T.

- Fig. 3. (a) Characteristic seam appearance for five star quality assessment; (b) cross section of a bead on plate welding with measurements of weld seam geometry and welding defects like pores

- Fig. 4. Influence of the beam path speed on the resulting weld seam quality for different energy per unit length for dynamic beam oscillation welding of copper

- Fig. 5. (a) Maximum capillary depth and its maximum capillary depth difference during one period with circular beam oscillation as a function of amplitude and; (b) frequency. Determined from X-ray images. Qualitatively, the number of spatters and pores is also plotted. Green = less spatters and red = many spatters and pores. For Cu-OF at a welding speed of 5 m/min and a laser power of 2000W.

- Fig. 6. (a-d) Sequence of humping phenomena during beam oscillation welding of copper; (e) surface of weld seam; (f) cross section

- Fig. 7. Possible solutions to avoid humping phenomena during dynamic beam oscillation welding of copper – high speed recording of melt pool, picture of seam surface and cross section for (a) reduction of process interaction zone/amplitude and (b) reduction of beam path speed/frequency

- Fig. 8. Synchrotron X-ray recordings for different beam bath speeds and keyhole shapes during aluminum die cast welding (a) static beam guidance; (b) oscillated narrow keyhole with low beam path speed; (c) oscillated expanded keyhole due to high beam path speed

7. Conclusion:

Dynamic beam oscillation is a key technology for improving the quality of laser-welded copper and aluminum components. The beam path speed was identified as a major influencing factor. By analyzing and understanding process limitations, it is possible to counteract their causes and expand the stable process window. The successful transfer of these principles to aluminum die-cast demonstrates the potential of this technology to solve critical joining challenges in e-mobility and other industries.

8. References:

- Börner, S., Dittrich, D., Mohlau, P., Leyens, C., García-Moreno, F., Kamm, P., Neu, T., Schlepütz, C., 2021. In situ observation with x-ray for tentative exploration of laser beam welding processes for aluminum-based alloys. Journal of Laser Applications. 33. 012026. 10.2351/7.0000315.

- Dittrich, D., Börner, S., Liebscher, J., Standfuß, J., Jahn, A., 2018. Laserstrahlschweißen hochreflektierender Werkstoffe – neue Möglichkeiten mit 515 nm im Leistungsbereich bis 1 kW, DVS Berichte, Band: 344, ISBN: 978-3-96144-036-8

- Dittrich, D., Jahn, A., Standfuss, J., Beyer, E., 2017. Laser beam welding of atmosphere aluminium die cast material using high frequency beam oscillation and brilliant beam sources, J. Laser Appl. 29, 022425

- Franco, D.F., 2017. Wobbling laser beam welding of copper. Dissertation, Universidade Nova de Lisboa

- Heider, A., 2018. Erweitern der Prozessgrenzen beim Laserstrahlschweißen von Kupfer mit Einschweißtiefen zwischen 1 mm und 10 mm, Dissertation, Universität Stuttgart, ISBN 978-3-8316-4738-5

- Heider, A.; Stritt, P., Heß, A.; Weber, R., Graf, T., 2011. Process Stabilization at welding Copper by Laser Power Modulation, In: Physics Procedia 12, p. 81-87

- Liebl, S., Wiedenmann, R., Ganser, A., Schmitz, P., Zaeh, M.F., 2014. Laser Welding of Copper Using Multi Mode Fiber Lasers at Near Infrared Wavelength. Physics Procedia 56, p.591-600

- Mahrle, A., Beyer, E., 2007. Modeling and simulation of the energy deposition in laser beam welding with oscillatory beam deflection. 26th International Congress on Applications of Lasers and Electro-Optics, ICALEO 2007 - Congress Proceedings. 10.2351/1.5061037.

- Musiol, J. D., 2015. Remote-Laserstrahl-Abtragschneiden, Dissertation, Technische Universität München, ISBN 978-3-8316-4523-7

- Pricking, S., Dold, E., Kaiser, E., Klausmann, K., Zaske, S., Brockmann, R., 2019. High-performance welding of copper with green multi-kW continuous wave disk lasers. 28. 10.1117/12.2509925.

- N.N., 2021. Electron and laser-beam welded joints - Requirements and recommendations on quality levels for imperfections - Part 2: Aluminium, magnesium and their alloys and pure copper (ISO 13919-2:2021); German version EN ISO 13919-2:2021

- N.N., 2014. Welding - Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded) - Quality levels for imperfections (ISO 5817:2014); German version EN ISO 5817:2014

- Reinheimer, E. N., Weber, R., Graf T, 2022. Influence of the capillary geometry on the weld seam quality during high-speed laser welding. Procedia CIRP 111, p. 431-434

- Zediker, M., Fritz, R., Finuf, M., Pelaprat, JM, 2019. Stable keyhole welding of 1 mm thick copper with a 600 W blue laser system. Journal of Laser Applications. 31. 022404. 10.2351/1.5096092.

Expert Q&A: Your Top Questions Answered

Q1: Why is beam path speed a more critical parameter than just welding speed or oscillation frequency alone?

A1: Beam path speed is the resultant velocity of the laser spot, combining the linear feed motion with the circular oscillation motion. It represents the actual speed at which the laser interacts with the material at any given moment. This is more critical because it directly governs the energy deposition per unit area and the interaction time, which are the primary drivers of keyhole stability and melt pool dynamics. A specific welding speed and frequency can result in very different beam path speeds depending on the oscillation amplitude, making it the more comprehensive parameter for process control.

Q2: The paper mentions a "humping phenomena" in Figure 6. What causes this and how is it mitigated?

A2: The humping phenomenon observed in the paper is caused by a combination of factors at low laser power: a narrow melt pool formed along the oscillation track and a high beam path speed (approx. 75 m/min). This leads to high melt flow rates that build up a "hump" at the rear of the melt pool, which the laser then interacts with on its next pass, causing melt ejection. As shown in Figure 7, this can be mitigated in two ways: by reducing the oscillation amplitude to concentrate the energy in a smaller zone, or by reducing the frequency (and thus the beam path speed) to decrease the melt flow velocity and shorten the melt pool.

Q3: How does the "expanded keyhole" shown in Figure 8c actually help reduce porosity in aluminum die-cast?

A3: In aluminum die-cast, entrapped gases form bubbles in the melt pool during welding. With static or slow welding, these bubbles have a long lifetime and often get trapped as pores. The high beam path speed creates an "expanded keyhole" that is wider and more stable. This, combined with the waves it generates in the melt pool, actively pushes the bubbles toward the keyhole's surface. The keyhole then acts as a vent, allowing the entrapped gases to escape (degas) before the molten metal solidifies, thereby significantly reducing final porosity.

Q4: Figure 5 shows a complex relationship between amplitude/frequency and capillary depth. What's the practical takeaway for process setup?

A4: The data in Figure 5 demonstrates that there are optimal windows for amplitude and frequency to balance weld quality and stability. For the tested conditions (2000 W power, 5 m/min speed), an amplitude of 0.3 mm and a frequency between 750-1000 Hz provided the best results. This range was high enough to stabilize the capillary and reduce spatter but not so high as to cause excessive pore formation from capillary pinching or low beam path overlap. The practical takeaway is that these parameters require careful tuning; simply maximizing frequency or amplitude does not guarantee better results.

Q5: The study primarily used copper samples. How confident can we be that these findings, especially the optimal beam path speed, directly apply to aluminum die-cast?

A5: While the exact numerical values for the optimal beam path speed may require adjustment due to differences in material properties (thermal conductivity, absorptivity), the fundamental physical principles are highly transferable. The core finding is that stabilizing the keyhole and managing melt pool dynamics via high-speed beam movement is key to defect reduction. Figure 8 provides direct evidence of this transferability, showing that a high beam path speed creates the beneficial "expanded keyhole" in aluminum die-cast, effectively solving the critical issue of porosity.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing defect-free welds in copper and aluminum alloys is a significant hurdle in high-performance manufacturing. This research demonstrates that dynamic beam oscillation, when properly understood and controlled, offers a powerful solution. The key breakthrough is the identification of beam path speed as the dominant factor for process stability. By operating within an optimal window of 30-100 m/min, manufacturers can dramatically reduce spatter and porosity. Furthermore, the successful application of these principles to Laser Welding for Die Casting highlights a clear path toward mitigating porosity in aluminum components, a critical advancement for the e-mobility and electronics industries.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Enhanced process understanding for laser welding of copper and aluminum alloys with dynamic beam oscillation" by "Stephan Börner, Dirk Dittrich, Joseph Barrios Larrañaga, Andreas Wetzig, Michael Sawannia, Eveline N. Reinheimer, Andreas Heider, Reiner Ramsayer".

- Source: Lasers in Manufacturing Conference 2023

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.