Achieving First-Time-Right Castings: A Deep Dive into Multiphysics Casting Process Simulation

This technical summary is based on the academic paper "Multiphysics CAE Simulations of Casting Process for the First Time Right Product Development" by Mir Mehdi Hussain, Ramanathan SV, and Raj C Thiagarajan, published in the Proceedings of the 2015 COMSOL Conference in Pune. It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Casting Process Simulation

- Secondary Keywords: Multiphysics CAE, Solidification Modeling, Aluminum Alloy Wheel Casting, Coupled Flow, Heat Transfer, First Time Right Development

Executive Summary

- The Challenge: The casting industry faces low quality, defects, and metal wastage due to the complex, coupled physical effects inherent in the process, often called a "process of uncertainty."

- The Method: Researchers used Multiphysics CAE to model the coupled laminar flow, heat transfer, and phase change solidification process for an aluminum alloy wheel.

- The Key Breakthrough: The simulation successfully visualized the liquid-solid transition phase and temperature profile over time, providing a clear picture of the solidification process at 15 and 60 seconds.

- The Bottom Line: Physics-based Casting Process Simulation enables virtual product development that can optimize processes, reduce defects, and achieve first-time-right products, especially for complex components like automotive wheels.

The Challenge: Why This Research Matters for HPDC Professionals

Casting is a 6000-year-old manufacturing process, yet it continues to present significant challenges for modern industry. Foundries often experience issues with low quality, low productivity, and material wastage. This is due to the involvement of numerous process parameters and coupled physical effects—from material flow and process temperature to solidification, shrinkage, and residual stress. Even in tightly controlled environments, defects can occur, leading to the casting process being known as a "process of uncertainty."

For manufacturers of high-value components, particularly in the automotive sector where cast aluminum wheels are standard, the pressure is immense. Global competition and faster model turnaround times demand the ability to develop quality products faster. This research addresses the core need for a reliable method to predict and control casting outcomes, moving from trial-and-error to a physics-based, predictive approach for first-time-right product development.

The Approach: Unpacking the Methodology

To investigate and optimize the casting of an aluminum alloy wheel, the researchers employed a multiphysics Casting Process Simulation using COMSOL Multiphysics software. The study focused on the most critical stages: die filling and solidification.

The methodology involved creating a simplified, axisymmetric Finite Element Analysis (FEA) model of a typical alloy wheel. The simulation coupled several physical phenomena:

- Laminar Fluid Flow: To model the movement of the molten aluminum alloy as it fills the die, governed by the Navier-Stokes equations for fluid velocity (u) and pressure (p).

- Phase Change Heat Transfer: To simulate the solidification process, accounting for the significant latent heat released as the molten alloy transitions from liquid to solid.

- Material Properties: The model incorporated appropriate material properties for the aluminum alloy wheel and the steel die.

A transient simulation was performed to study the solidification process over time. Key performance indicators such as flow velocity, pressure, temperature, and the volume fraction of the phase change were monitored to evaluate the process performance and identify potential issues like turbulent flow.

The Breakthrough: Key Findings & Data

The simulation provided detailed, time-dependent visualizations of the solidification process, offering critical insights into how the alloy wheel cools and solidifies within the mold.

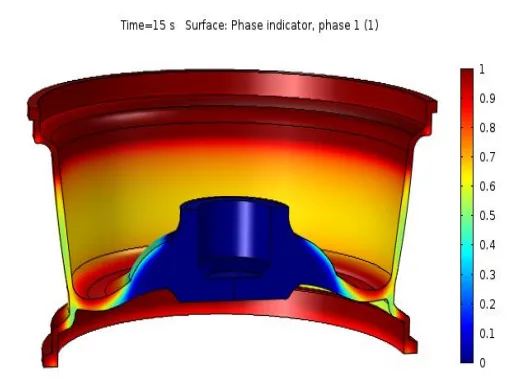

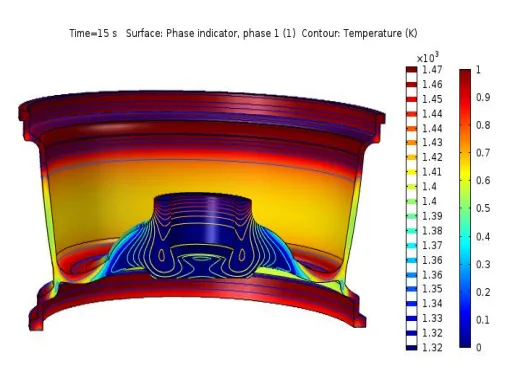

Finding 1: Solidification State at 15 Seconds

The simulation shows the initial phase of solidification. As shown in Figure 3, after 15 seconds, the volume fraction of the liquid phase (represented by the color scale from 0/blue for solid to 1/red for liquid) indicates that solidification has begun at the outer surfaces in contact with the die, while the core and thicker sections remain fully molten. Figure 5 combines this with the temperature profile, showing temperatures ranging from approximately 1320 K to 1470 K, illustrating the initial temperature gradients driving the solidification.

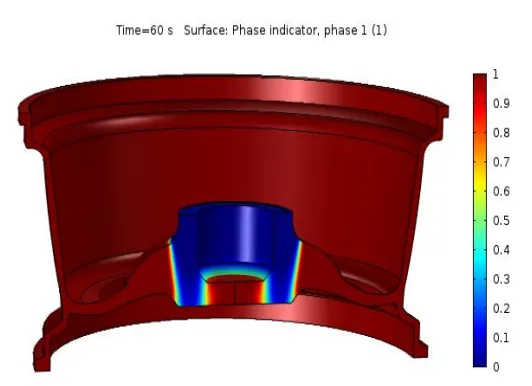

Finding 2: Solidification Progression at 60 Seconds

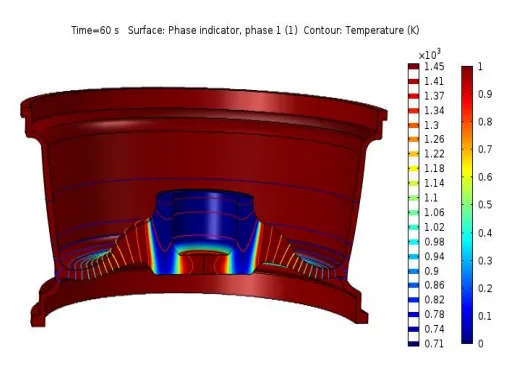

After 60 seconds, the solidification has progressed significantly. As shown in Figure 4, the solid (blue) regions have expanded considerably, moving inward from the mold surfaces. The remaining liquid (red/yellow) is now concentrated in the central hub and the thickest parts of the spokes. Figure 6 shows a much wider temperature distribution at this stage, from around 710 K to 1450 K, highlighting the large thermal gradients across the part as it continues to cool and solidify. This visualization is critical for predicting where defects like shrinkage porosity are likely to form.

Practical Implications for R&D and Operations

The findings from this Casting Process Simulation offer actionable insights for various engineering roles involved in manufacturing.

- For Process Engineers: This study suggests that adjusting process parameters like melt/pouring temperature, pressure build-up, and cooling duration can be directly correlated to the solidification pattern. The flow front animation helps identify and control flow velocity to minimize turbulent flow, a common cause of defects.

- For Quality Control Teams: The data in Figure 5 and Figure 6 of the paper illustrates the effect of cooling time on the temperature and solidification fronts. This information can be used to predict the final microstructure and mechanical properties, informing new quality inspection criteria focused on areas identified as last to solidify.

- For Design Engineers: The findings indicate that the geometry of the wheel directly influences the solidification pattern. The simulation can be used in the early design phase to optimize part geometry and rigging design to ensure directional solidification, minimize hot spots, and reduce the likelihood of shrinkage porosity.

Paper Details

Multiphysics CAE Simulations of Casting Process for the First Time Right Product Development

1. Overview:

- Title: Multiphysics CAE Simulations of Casting Process for the First Time Right Product Development

- Author: Mir Mehdi Hussain, Ramanathan SV, and Raj C Thiagarajan

- Year of publication: 2015

- Journal/academic society of publication: Excerpt from the Proceedings of the 2015 COMSOL Conference in Pune

- Keywords: Casting, product development, physics based modeling, Coupled flow, Heat Transfer, phase change Solidification

2. Abstract:

Casting is a manufacturing processes used to produce complex components with lower costs. Casting of ferrous, non ferrous, Aluminum Alloy, graded cast iron, ductile iron and Steel materials are used for automobiles, railways, aerospace and industrial applications. In a casting process, liquid material is usually poured into a mould of the desired shape, and then allowed to solidify. Casting product performance depends on material, flow, Process Temperature, Solidification, Shrinkage and residual stress. In a casting process, not all available resources are utilized effectively which results in low quality of casting, defects and metal wastage. Physics based modeling is increasingly used to optimize product performance, improve quality and reduce defects of casting products. In this paper, phase change solidification process of alloy wheel is investigated for process performance and optimization. Coupled flow, heat transfer and phase change solidification process modeling of casting process of Aluminum alloy wheel is detailed. Multiphysics CAE of casting process will enable first time right casting product development.

3. Introduction:

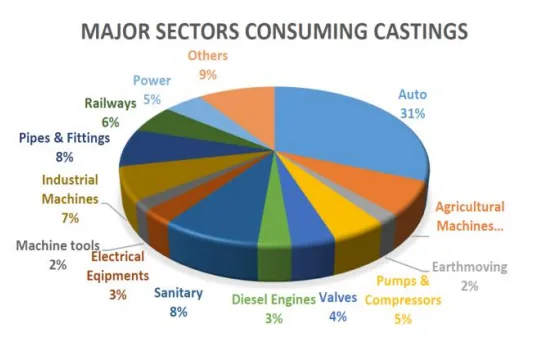

Casting is a 6000 years old and widespread manufacturing processes used to produce complex components with lower costs. Casting/Foundry industry experiences, low quality and productivity issues, due to involvement of number of casting process parameters and coupled physical effects. Even in completely controlled process, defect in casting are observed and hence casting process is also known as process of uncertainty. CAE simulations are increasingly used to provide physics based solution and methods for process control and for eliminating casting defects [1-5]. Figure 1 shows the consumption distribution of casting products. Automobile is one of the major end user of casting products. Cast Aluminum wheels are becoming standard configuration for passenger Cars. The wheel manufacturers are under pressure to develop quality products faster, due to global competition and faster turnaround of models. Multiphysics CAE of casting process can enable virtual product development for the first time right wheel development in compliance with automobile manufacturer's requirement. In this paper, coupled laminar flow, phase change heat transfer and structural analysis is explored for aluminum alloy wheel casting process simulation.

4. Summary of the study:

Background of the research topic:

Casting is a widespread manufacturing process for complex components, but it suffers from low quality, defects, and productivity issues due to its complexity and the interaction of numerous physical effects. The automotive industry, a major consumer of cast products like aluminum wheels, requires faster development of high-quality products.

Status of previous research:

The paper notes that CAE simulations are increasingly being used to provide physics-based solutions for process control and the elimination of casting defects, citing references [1-5].

Purpose of the study:

The purpose is to investigate the phase change solidification process of an aluminum alloy wheel to optimize its performance. The paper details the modeling of coupled flow, heat transfer, and solidification to enable "first time right" product development.

Core study:

The core of the study is the multiphysics CAE simulation of the casting process for an aluminum alloy wheel. It explores coupled laminar flow, phase change heat transfer, and structural analysis to model the filling and solidification stages, with the goal of correlating process parameters to final product quality.

5. Research Methodology

Research Design:

The study utilized a simplified, axisymmetric model of a typical alloy wheel for Finite Element Analysis. A transient simulation was designed to study the solidification process over time by monitoring key physical variables.

Data Collection and Analysis Methods:

The simulation was performed using the COMSOL Multiphysics software package, specifically leveraging the Heat Transfer module with Phase Change physics, along with laminar flow and structural analysis modules. Data on flow velocity, pressure, temperature, and volume fraction of phase change were collected and visualized as contour plots at different time intervals (15 and 60 seconds) for performance evaluation.

Research Topics and Scope:

The research focuses on the die filling and solidification stages of the low-pressure die casting process for an aluminum alloy wheel. The scope includes modeling the coupled physics of fluid flow and heat transfer to understand and optimize the process, with an eye towards predicting mechanical properties through further coupled structural analysis.

6. Key Results:

Key Results:

- The simulation successfully modeled the liquid-solid transition phase of an aluminum alloy wheel during casting.

- Contour plots at 15 seconds (Figure 3, Figure 5) show the initial solidification at the mold-metal interface and the corresponding temperature distribution.

- Contour plots at 60 seconds (Figure 4, Figure 6) show significant progression of the solidification front, with the liquid phase concentrated in the thicker, hotter sections of the wheel.

- The study identified key process parameters (melt/pouring temperature, process time, pressure build-up, cooling duration) for optimization to minimize defects like porosity and wastage.

Figure Name List:

- Figure 1. Casting products vs industry distribution

- Figure 2 CAD geometry with FEA mesh of typical Automobile Aluminum Alloy Wheel

- Figure 3. Contour plots of liquid solid transition phase Volume fraction at 15 seconds.

- Figure 4. Contour plots of liquid solid transition phase Volume fraction at 60 seconds.

- Figure 5. Contour plots of liquid solid transition phase Volume fraction and temperature profile at 15 seconds

- Figure 6. Contour plots of liquid solid transition phase Volume fraction and temperature profile at 60 seconds

7. Conclusion:

A brief overview of casting process was given. The problem formulation and simulation details related to coupled phase change heat transfer, laminar flow and structural analysis was given. An aluminum alloy wheel from automobile industry was considered for representative casting process simulation. The COMSOL modeling details were provided. The simulation results related to solidification process and phase change flow front were reported. The correlation potential of process parameters such as, melt temperature, process time, pressure build-up, cooling duration to Process optimization to minimize filling path, wastage, porosity was highlighted. Further, coupled structural analysis will be used for mechanical property prediction. The model will be developed as an online application with COMSOL server backend for cost, process, and performance optimization of casted products.

8. References:

- [1] Chougule, R.G., and Ravi, B., 2003, casting process planning using case based reasoning. Transactions of American Foundry Society, 111, 2003.

- [2] Vijayan T G, "Numerical Simulations of casting Solidification in permanent metallic molds", 26 September 2005, Journals of material processing technology 178(2006) 29-33, 2006.

- [3] Rajkolhe R, Khan J G,"Defects, Causes and Their Remedies in Casting Process: A Review ", International Journal of Research in Advent Technology, Vol.2, No.3, March 2014 E-ISSN: 2321-9637

- [4] Ravi B, "Metal casting: Computer-aided Design and analysis", PHI, New Delhi, ISBN: 81-203-2726-8, 2005-2008, Fourth print, 2008.

- [5] Flori M, Milostean D, Heat Transfer Simulation in Mold During Die Casting of Steel, ACTA Technica Corviniensis Bulletin of Engineering, ISSN: 2067-3809, Vol VI, No 4, Oct-Dec, 2013.

- [6] COMSOL Multiphysics, Introduction to COMSOL Multiphysics and Heat transfer and Fluid flow and Structural analysis manual, version 5.1, 2015.

Expert Q&A: Your Top Questions Answered

Q1: What specific physics were coupled in this simulation to model the casting process?

A1: The study used a multiphysics approach that coupled laminar fluid flow, phase change heat transfer, and structural analysis. This combination allows the simulation to accurately model the filling of the mold with molten metal, the solidification process as it cools, and provides a foundation for predicting residual stresses and mechanical properties in the final part.

Q2: Why was an aluminum alloy wheel chosen for this particular study?

A2: An aluminum alloy wheel was chosen as a representative component from the automobile industry. The paper highlights that automobiles are a major end-user of casting products and cast aluminum wheels are a standard configuration for passenger cars. Their complex geometry and the high-quality demands from manufacturers make them an ideal and challenging case for validating the effectiveness of Casting Process Simulation.

Q3: What do the volume fraction plots in Figures 3 and 4 actually represent?

A3: The volume fraction plots visualize the state of the metal at a specific point in time. A value of 1 (shown in red) represents 100% liquid metal, while a value of 0 (shown in blue) represents 100% solid metal. By comparing Figure 3 (15 seconds) and Figure 4 (60 seconds), engineers can track the progression of the solidification front and identify which areas of the casting solidify last, which are often prone to defects.

Q4: The paper mentions a "Numerical Design of experiment." What was its purpose?

A4: The purpose was to correlate key process parameters with casting outcomes. The paper states that parameters such as melt/pouring temperature, process time, pressure build-up, and cooling duration were analyzed to find the optimal settings for minimizing the filling path, material wastage, and porosity. This moves beyond a single simulation to a systematic optimization of the entire process.

Q5: What software and version were used to perform this analysis?

A5: The paper explicitly states that the simulation was conducted using COMSOL Multiphysics, version 5.1, as referenced in citation [6]. The specific modules leveraged were for heat transfer, fluid flow, and structural analysis.

Q6: How does this simulation approach help achieve "first time right" product development?

A6: This simulation enables virtual product development. By accurately predicting how a component will solidify before any physical tooling is made, engineers can optimize the part design and the casting process (e.g., rigging, cooling circuits) on the computer. This significantly reduces the need for expensive and time-consuming pre-production sampling and physical trials, allowing manufacturers to meet quality requirements from the very first run.

Conclusion: Paving the Way for Higher Quality and Productivity

The persistent challenges of defects and uncertainty in casting can be overcome with modern analytical tools. This research effectively demonstrates that a multiphysics Casting Process Simulation provides the deep insights needed to master the complex interplay of fluid flow and heat transfer during solidification. By visualizing the process second-by-second, manufacturers can move from reactive problem-solving to proactive process optimization, ensuring higher quality and achieving first-time-right product development.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Multiphysics CAE Simulations of Casting Process for the First Time Right Product Development" by "Mir Mehdi Hussain, Ramanathan SV, and Raj C Thiagarajan".

- Source: Excerpt from the Proceedings of the 2015 COMSOL Conference in Pune

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.