This technical summary is based on the academic paper "Age Hardening in Martensitic/Bainitic Matrices in a Copper-Bearing Steel" published by C. N. Hsiao and J. R. Yang in Materials Transactions, JIM (2000). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Age Hardening in Copper-Bearing Steel

- Secondary Keywords: NAK 80 Steel, Martensitic/Bainitic Microstructure, Precipitation Hardening, Tempering Effect, Continuous Cooling Transformation, Microstructure-Property Relationship, Copper Precipitates

Executive Summary

- The Challenge: To optimize the age-hardening response in copper-bearing steels, it's crucial to understand how the initial matrix microstructure (martensite, bainite, or a mixture) influences the final mechanical properties.

- The Method: Researchers studied NAK 80 steel, creating various microstructures by applying different continuous cooling rates after austenitization. These samples were then subjected to isothermal aging to measure their hardness response.

- The Key Breakthrough: Contrary to common assumptions, a fully martensitic microstructure resulted in the lowest peak hardness after aging. Specimens with a mixture of martensite and bainite demonstrated a superior age-hardening response.

- The Bottom Line: The tempering (softening) of the martensite matrix during the aging process significantly hinders the hardening effect from copper precipitation. A more stable mixed microstructure with bainite provides a better foundation for achieving maximum hardness.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, low-carbon, copper-bearing, high-strength steels have been of great interest for demanding engineering applications due to their excellent combination of toughness, strength, and weldability (Ref. [1]). Strength is typically achieved not through high carbon content, but by the precipitation of fine, copper-rich particles during an aging heat treatment (Ref. [2-4]).

While much is known about copper precipitation in simple iron-copper alloys or ferrite steels, a critical knowledge gap exists for commercial steels that form more complex microstructures like bainite and martensite. In these steels, especially those with higher carbon content like the NAK 80 studied here (0.13 mass% C), the aging process becomes a competition: hardening from copper precipitates versus softening from the tempering of the matrix. This study aims to untangle these competing effects and determine how the initial microstructure, controlled by the cooling rate, dictates the ultimate age-hardened properties of the steel.

The Approach: Unpacking the Methodology

To investigate these phenomena, the researchers selected NAK 80 steel, a material known for its high hardenability, making it easy to produce bainitic structures. The core of the methodology involved:

- Controlled Cooling: Using a deformation dilatometer, specimens were austenitized at 900°C and then subjected to a wide range of continuous cooling rates, from a rapid 120°C/s to a very slow 0.05°C/s. This allowed for the precise creation of different initial microstructures, from fully martensitic to fully bainitic.

- Isothermal Aging: Three specific microstructures were selected for detailed study: 100% martensite, a mix of 58% martensite/42% bainite, and a mix of 42% martensite/58% bainite. These samples were then aged at 400, 500, and 600°C for up to 100 hours.

- Advanced Characterization: The resulting changes were meticulously analyzed using hardness measurements, optical metallography, and advanced transmission electron microscopy (TEM), including field-emission-gun TEM (FEG-TEM) to observe the extremely fine copper precipitates.

This systematic approach allowed the team to directly link the initial cooling process to the microstructure and, ultimately, to the final age-hardened performance.

The Breakthrough: Key Findings & Data

The study yielded several critical insights into the heat treatment and performance of copper-bearing steels.

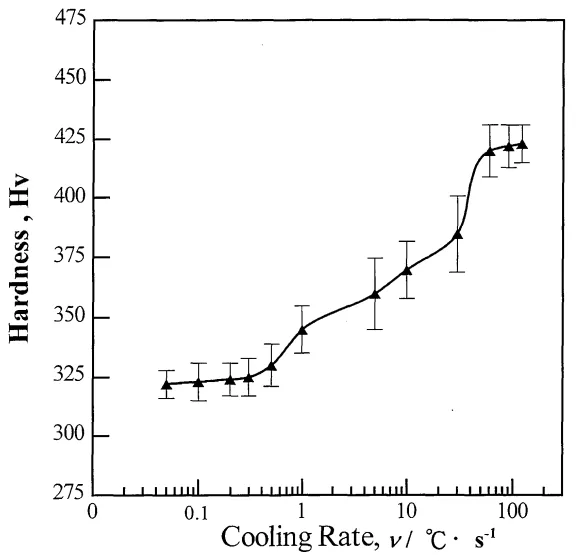

- Finding 1: Cooling Rate Dictates Microstructure: The study confirmed that the cooling rate directly controls the resulting microstructure and initial hardness. As shown in Figure 1, fast cooling rates (60-120°C/s) produce a hard, fully martensitic structure, while progressively slower rates introduce increasing amounts of bainite, leading to a lower initial hardness. The steel's high hardenability allowed for a nearly complete bainitic structure even at a slow cooling rate of 0.05°C/s.

- Finding 2: Fully Martensitic is Not Optimal for Age Hardening: The most significant and counter-intuitive finding was that the fully martensitic specimen achieved the lowest level of peak hardness after aging when compared to the mixed-phase specimens. As seen in Figure 14 and Figure 16, at aging temperatures of 400°C and 500°C, the mixed microstructures consistently reached a higher hardness value.

- Finding 3: The Tempering Effect is the Culprit: The research clearly demonstrates that the tempering of the martensitic matrix is a powerful softening mechanism that works against the hardening from copper precipitation. During aging, the highly strained martensite structure recovers and softens, a process that is less pronounced in the more thermally stable bainite. This explains why the fully martensitic matrix, despite its high starting hardness, cannot achieve its full age-hardening potential.

- Finding 4: Bainite Provides a More Stable Foundation: The two mixed-phase specimens (containing both martensite and bainite) showed nearly identical hardening behavior at 400°C and 500°C. However, at a higher aging temperature of 600°C, the matrix with a higher fraction of bainite (58%) retained a significantly higher hardness. Evidence from TEM revealed that the bainite ferrite morphology remained stable and slab-like even after prolonged aging, whereas the martensite degenerated more readily.

Practical Implications for HPDC Products

While this study focuses on a wrought steel, the fundamental principles of phase transformation and precipitation are directly relevant to tool steels used in HPDC (like NAK 80, used for plastic molds) and the heat treatment of high-performance cast components.

- For Heat Treaters & Process Engineers: This research strongly suggests that for copper-bearing steels, a "quench as fast as possible" approach to achieve 100% martensite may be counterproductive if maximum hardness after aging is the goal. A controlled, slightly slower cooling rate to produce a specific mixture of martensite and bainite could yield a component with superior final hardness and better thermal stability.

- For Materials & Design Engineers: When specifying a copper-precipitated steel, the heat treatment protocol is as critical as the alloy composition. This study proves that the microstructure before aging has a dominant effect on the final properties. Designing a process that yields a mixed martensite/bainite structure can unlock a higher performance ceiling than relying on a purely martensitic matrix.

- For Quality Control: The hardness curves presented in Figures 11, 12, and 13 provide a detailed process map. They illustrate how sensitive the final hardness is to the initial microstructure, aging temperature, and time. This data can be used to establish more precise and robust quality control windows for heat treatment operations, ensuring consistent and optimal component performance.

Paper Details

Age Hardening in Martensitic/Bainitic Matrices in a Copper-Bearing Steel

1. Overview:

- Title: Age Hardening in Martensitic/Bainitic Matrices in a Copper-Bearing Steel

- Author: C. N. Hsiao and J. R. Yang

- Year of publication: 2000

- Journal/academic society of publication: Materials Transactions, JIM, Vol. 41, No. 10

- Keywords: copper-bearing steel, continuous cooling transformation, coalescence, age hardening, copper precipitate, tempering effect, field-emission-gun transmission electron microscopy (FEG-TEM)

2. Abstract:

In order to understand the influence of matrix microstructures on age-hardening behavior in a copper-bearing steel, NAK 80, the phase transformation of austenite (during a variety of continuous cooling treatments) and the consequent precipitation of copper particles (during isothermal aging) were investigated by dilatometry, optical metallography, hardness measurement, transmission electron microscopy, and field-emission-gun transmission electron microscopy (FEG-TEM). It was found that at a wide range of cooling rates (about from 30 to 0.3°C/s) after austenitization at 900°C for 15 min, the steel produces a mixture of martensite and bainite. Three different pre-treated specimens, which had been continuously cooled at 120, 5 and 1°C/s, respectively, were studied in order to determine their response to copper age-hardening. The results show that the general level of peak hardness for the fully martensitic specimen is the lowest when compared with those of the other two specimens, which contained a mixture of nearly equal volume fractions of martensite and bainite. The findings in this work show that tempering martensite during aging drastically hinders the hardening of copper precipitates.

3. Introduction:

The use of low carbon, copper bearing, high strength, low alloy steels for applications in heavy engineering has drawn considerable interest in the last two decades because the steels can provide excellent combinations of good toughness, strength, weldability, and resistance to corrosion. Hardenability-enhancing elements such as manganese, nickel, chromium, and molybdenum are added to the steels in order to obtained relatively uniform microstructures throughout the heavy sections after they have been quenched from the austenite phase field. As a result, variations in the levels of bainite and/or martensite can produced depending on the alloying and cooling rates employed. In addition, strength is further achieved by the precipitation of copper-rich particles during aging, instead of by the precipitation of carbide particles. Researchers have reported copper precipitation in related steels during continuous cooling and isothermal aging. Little detail is known yet about the microstructural characterization of these steels, and it has not yet been established whether the copper precipitates in both bainite and martensite matrices. A great deal of early research has focused on Fe-Cu alloys and ultra-low carbon ferrite steels, and the results have provided valuable information. However, both the precipitation behavior of copper particles in the bainitic and martensitic matrices and the crystallography of precipitation in commercial steel still need to be investigated. In most age-hardened Cu-bearing steels (e.g. A710-type and HSLA 80 steels), the carbon content is not higher than 0.05 mass%; the carbide precipitation would hence have very little effect on copper age hardening. However, tempering definitely interferes with copper age hardening as the carbon concentration in steel increases. For comparison with the work by Banadkouki et al., who studied age hardening in a HSLA 80 with bainitic and martensitic matrices, the aims of this study are first, to understand the phase transformation during continuous cooling in a copper-bearing steel with 0.13 mass% carbon, and second, to investigate the effects of its various matrix microstructures on age hardening. The precipitation of copper particles in this steel has also been observed by using a field-emission-gun transmission electron microscope.

4. Summary of the study:

Background of the research topic:

Copper-bearing, high-strength, low-alloy (HSLA) steels are valued for their excellent mechanical properties, which are largely derived from the precipitation of copper-rich particles during aging. However, in commercial steels with sufficient carbon and hardenability, the matrix transforms into complex microstructures like martensite and bainite upon cooling.

Status of previous research:

Previous research has extensively studied copper precipitation in simpler Fe-Cu alloys and ferrite steels. However, there is limited understanding of the precipitation behavior within martensitic and bainitic matrices, and how the tempering of these matrices competes with the age-hardening process, especially in steels with carbon content high enough (e.g., 0.13 mass%) to cause significant tempering effects.

Purpose of the study:

This study aims to (1) understand the continuous cooling transformation behavior of a copper-bearing steel (NAK 80) with 0.13 mass% carbon, and (2) investigate how different initial microstructures (martensite, bainite, and mixtures) affect the subsequent age-hardening response from copper precipitation.

Core study:

The core of the study involves creating different initial microstructures by varying the continuous cooling rate from the austenite phase. Three specific microstructures—fully martensitic, and two different mixtures of martensite and bainite—were then isothermally aged at different temperatures (400, 500, and 600°C). The evolution of hardness was tracked over time, and the microstructures, including the fine copper precipitates, were characterized using advanced microscopy techniques to understand the underlying mechanisms.

5. Research Methodology

Research Design:

The study was designed to isolate the effect of the initial matrix microstructure on age-hardening behavior. NAK 80 steel was chosen for its high hardenability and relevant carbon content. Specimens were first homogenized and then subjected to controlled continuous cooling treatments in a dilatometer to produce a range of microstructures. Three specific pre-treated conditions (cooled at 120, 5, and 1°C/s) were then selected for a systematic isothermal aging study.

Data Collection and Analysis Methods:

Data was collected using a suite of analytical techniques:

- Dilatometry: To control and monitor the phase transformations during continuous cooling.

- Hardness Measurement: Vickers hardness tests were used to quantify the initial hardness and the response to aging.

- Optical Metallography: To observe the general microstructure of the samples.

- Transmission Electron Microscopy (TEM) and Field-Emission-Gun TEM (FEG-TEM): To examine the fine-scale features, including lath structures, retained austenite, and the morphology, size, and crystal structure of the copper precipitates.

- Energy-Dispersive X-ray Spectrometer (EDS): To perform microanalysis of the copper precipitates.Research Topics and Scope:

The research covers the continuous cooling transformation of NAK 80 steel over cooling rates from 120°C/s to 0.05°C/s. It then focuses on the isothermal precipitation hardening behavior at 400, 500, and 600°C for three distinct initial microstructures: 100% martensite, 58% martensite/42% bainite, and 42% martensite/58% bainite. The scope includes characterizing the resulting microstructures and precipitates to explain the observed hardening phenomena.

6. Key Results:

Key Results:

- At cooling rates from 30 to 0.3°C/s, the NAK 80 steel produces a mixture of martensite and bainite. A fully martensitic structure is formed at faster rates (≥60°C/s), and a nearly fully bainitic structure at very slow rates (≤0.3°C/s).

- The general level of peak hardness for the fully martensitic specimen is the lowest when compared with the two specimens containing a mixture of martensite and bainite.

- The two mixed-phase specimens (58% martensite/42% bainite and 42% martensite/58% bainite) exhibit nearly the same peak hardness when aged at 400°C and 500°C.

- At a higher aging temperature of 600°C, the matrix containing a higher fraction of bainite (58% bainite) shows a significantly higher hardness value than the matrix with less bainite.

- The study concludes that the tempering of the martensite matrix during aging is a significant softening effect that drastically hinders the hardening potential from copper precipitation. The bainitic structure is more resistant to this tempering.

- FEG-TEM analysis revealed the formation of fine, Fe-based copper precipitates. Overaging at 600°C led to the formation of rod-shaped fcc copper precipitates with a Kurdjumov-Sachs orientation relationship to the bcc matrix.

Figure Name List:

- Fig. 1 Hardness of specimens cooled at various rates.

- Fig. 2 Optical metallographs obtained from dilatometer specimens cooled at rates: (a) 120, (b) 60, (c) 30, (d) 10, (e) 5, (f) 1, (g) 0.3, and (h) 0.05°C/s.

- Fig. 3 Dilatormetric curves obtained from specimens austenitized at 900°C for 15 min and then continuously cooled at a wide range of cooling rates (120–0.05°C/s).

- Fig. 4 Illustration of the graphical method of determining the volume fraction of bainite f_b obtained at the Ms temperature from analysis of dilatometric data.

- Fig. 5 Plot of the volume fraction of bainite versus the cooling rate.

- Fig. 6 Transmission electron micrographs for illustrating the lath martensite and retained austenite obtained from the specimen cooled at 60°C/s: (a) bright field image; (b) dark field images; (c) corresponding diffraction patterns.

- Fig. 7 Transmission electron micrograph shown the bainite structures obtained from the specimen cooled at 5°C/s.

- Fig. 8 Transmission electron micrograph shown the auto-tempered martensite structure obtained from the 5°C/s cooled specimen.

- Fig. 9 Transmission electron micrograph shown the upper bainite structure obtained from the specimen cooled at 1°C/s.

- Fig. 10 Transmission electron micrograph (a) bright field image and (b) centered dark field image showing the copper precipitates in matrix obtained from the 0.1°C/s cooled specimen.

- Fig. 11 Effect of aging time and temperature on the hardness of the specimen cooled at 120°C/s.

- Fig. 12 Effect of aging time and temperature on the hardness of the specimen cooled at 5°C/s.

- Fig. 13 Effect of aging time and temperature on the hardness of the specimen cooled at 1°C/s.

- Fig. 14 Effect of aging time on hardness of various pre-treated matrices for aging at 400°C.

- Fig. 15 Hardness increment as a function of aging time at 400°C.

- Fig. 16 Effect of aging time on hardness of various pre-treated matrices for aging at 500°C.

- Fig. 17 Hardness increment as a function of aging time at 500°C.

- Fig. 18 Transmission electron micrograph showing the upper bainite structure obtained from the specimen cooled at 5°C/s and then aged at 500°C for 5 h.

- Fig. 19 FEG-TEM lattice image and cooresponding diffraction patterns for copper precipitate obtained from the specimen cooled at 5°C/s and then aged at 500°C for 5h: (a) image; (b) and (c) corresponding diffraction patterns of the copper precipitate and matrix.

- Fig. 20 Transmission electron micrograph obtained from the specimen cooled at 5°C/s and then aged at 600°C for 5 h.

- Fig. 21 Transmission electron micrograph obtained from the specimen cooled at 5°C/s and then aged at 600°C for 5 h.

- Fig. 22 Transmission electron micrograph shown the upper bainite structure obtained from the specimen cooled at 5°C/s and then aged at 600°C for 25 h.

- Fig. 23 FEG-TEM lattice image for copper precipitate obtained from the specimen cooled at 5°C/s and then aged at 600°C for 5 h.

- Fig. 24 FEG-TEM lattice image and cooresponding diffraction patterns for copper precipitate obtained from the specimen cooled at 5°C/s and then aged at 600°C for 25h: (a) image; (b) the corresponding diffraction patterns of the copper precipitate and matrix.

7. Conclusion:

An investigation has been made of the copper aging hardening response in a NAK 80 steel. Based on hardness measurement, dilatometry, optical metallography, transmission electron microscopy and field-emission-gun transmission electron microscopy, the important conclusions of this work are summarized as follows. (1) The results from dilatometry, optical metallography, and hardness measurement indicate that the hardenability with respect to bainite transformation is so good that the steel can virtually fully transform to bainite at a very slow cooling rate (0.05°C/s). At cooling rates ranging from 30 to 0.3°C/s, it gives a mixture of martensite and bainite. (2) Three various pre-treated matrices (obtained from continuous cooling at 120, 5 and 1°C/s, respectively, after austenitization at 900°C for 15 min) consist of 100% martensite (by volume fraction), 58% martensite with 42% bainite, and 42% martensite with 58% bainite separately. It is found that the general level of peak hardness for the fully martensitic matrix is lowest when compared to those for the other two matrices. (3) The two pre-treated matrices containing 58% martensite with 42% bainite and 42% martensite with 58% bainite possess nearly the same aging hardness when aged at 400 and 500°C. However, the latter matrix has a significantly higher value of hardness than the former matrix when aged at 600°C. The results reflect the fact that during aging, the tempering response is more sensitive in martensite than in bainite. The evidence from the transmission electron microscopy also reveals that bainite ferrite morphology is less affected, and retained its slab-like shape even when aged at 600°C for a long period of time. (4) Tempering by carbide formation and the resultant coarsening and modification of the substructure hinders copper precipitation hardening. Tempering of fully martensitic matrix during aging leads to a significant loss of strength and also brings about a state in which it cannot achieve the full age-hardening potential of the steel. A mixture with nearly equal volume fractions of martensite and bainite is demonstrated to exhibit superior age-hardening over a microstructure containing mainly martensite.

8. References:

- [1] I. Lemay and L. M. Shetky: Copper in Iron and Steel, John Wiley and Sons, New York, (1982), 5-43.

- [2] E. Hornbogen and R. C. Glenn: Trans. AIME, 218 (1960), 1064-70.

- [3] R. A. Depaul and A. L. Kitchen: Metall. Trans., 1 (1970), 389-393.

- [4] R. J. Jesseman and G. J. Murphy: Ind. Heat, 46(9), (1979), 27-32.

- [5] S. W. Thompson and G. Krauss: Metall. Trans., 27A (1996), 1573-1588.

- [6] S. W. Thompson, D. J. Colvin and G. Krauss: Metall. Trans., 27A (1996), 1554-1568.

- [7] S. W. Thompson, D. J. Colvin and G. Krauss: Metall. Trans., 21A (1990), 1493-1507.

- [8] Naoki Maruyama, Masaaki Sugiyama, Takura Hara and Hiroshi Tamehiro: Mater. Trans., JIM, 40 (1999), 268-277.

- [9] D. P. Dunne, S. S. Ghasemi Banadkouki and D. Yu: ISIJ International, 36 (1996), 324-333.

- [10] G. R. Speich and T. M. Scoonover: in Processing, Microstructure and Properties of HSLA Steels, A. J. DeArdo, ed., TMS, Warrendale, PA, (1988), pp. 263-286.

- [11] E. Hornbogen: Precipitation in Fe base alloys, ed. by G. R. Speich and J. B. Clark, Gordon and Breach, New York, NY, (1965), pp. 1–67.

- [12] G. R. Speich and R. A. Oriani: Trans. Metall. Soc. AIME, 233 (1965), 623-631.

- [13] S. R. Goodman, S. S. Brenner and J. R. Iow, Jr.: Metall. Trans., 4 (1973), 2371-2378.

- [14] S. R. Goodman, S. S. Brenner and J. R. Iow, Jr.: Metall. Trans., 4 (1973), 2363-2369.

- [15] P. J. Othen, M. L. Jenkins and W. J. Phythian: Phil. Mag. Lett., 64 (1991), 383-391.

- [16] K. Osamura, H. Okuda, K. Asano, M. Furusaka, K. Kishida, F. Kurosawa and R. Uemori: ISIJ International, 34 (1994), 359-365.

- [17] R. A. Ricks, P. R. Howell and R. W. K. Honeycombe: Metall. Sci., 14 (1980), 562-568.

- [18] R. A. Ricks, P. R. Howell and R. W. K. Honeycombe: Metall. Trans. A., 10A (1979), 1049-1058.

- [19] R. A. Ricks, P. R. Howell and R. W. K. Honeycombe: Metal. Sci., 15 (1980), 376-380.

- [20] Yuuji Kimura and Setsuo Takaki: ISIJ International, 37 (1997), 290-295.

- [21] S. S. Ghasemi Banadkouki, D. Yu and D. P. Dunne: ISIJ International, 36 (1996), 61-67.

- [22] J. R. Yang, C. Y. Huang and C. S. Chiou: ISIJ International, 35 (1995), 1013-1069.

- [23] C. Fossaert, G. Rees, T. Maurickx and H. K. D. H. Bhadeshia: Metall. Trans. A, 26A (1995), 21-29.

- [24] H. K. D. H. Bhadeshia: PhD thesis, Cambridge University, (1979).

- [25] L. C. Chang and H. K. D. H. Bhadeshia: Mater. Sci. Tech., 12 (1996), 233-236.

Expert Q&A: Your Top Questions Answered

Q1: Why did the fully martensitic steel show lower peak hardness after aging? A1: The fully martensitic steel showed lower peak hardness because of a competitive process. During aging, the hardening from copper precipitation was counteracted by a significant softening from the tempering of the highly strained martensite matrix. This tempering effect was so strong that it prevented the steel from reaching its full hardening potential (Source: Conclusion, point 4).

Q2: What is the ideal initial microstructure for maximizing age-hardening in this type of steel? A2: The study demonstrates that a mixed microstructure containing nearly equal volume fractions of martensite and bainite exhibits superior age-hardening compared to a fully martensitic structure. This is because the bainite component is more thermally stable and less prone to softening during the aging process, providing a better foundation for the copper precipitates to impart strength (Source: Conclusion, point 4).

Q3: How does the cooling rate affect the initial microstructure? A3: The cooling rate after austenitization is the primary control lever for the microstructure. Fast cooling rates (e.g., 120°C/s) produce 100% martensite. Intermediate rates (30 to 0.3°C/s) produce a mixture of martensite and bainite. Very slow rates (0.05°C/s) result in a nearly fully bainitic structure. This relationship is clearly shown in the hardness data in Figure 1 and the volume fraction plot in Figure 5.

Q4: What role does carbon play in this process? A4: The steel's carbon content (0.13 mass%) is high enough to make the tempering of martensite a significant factor. Unlike in very low carbon steels, where tempering is minimal, the carbon in NAK 80 allows for carbide formation and structural recovery in the martensite during aging, which leads to softening and interferes with the copper age hardening (Source: Introduction).

Q5: What are the copper precipitates like, and how do they form? A5: The copper precipitates are extremely fine. Advanced FEG-TEM analysis shows they are Fe-based with a high content of Cu (about 40 mass%). The study suggests they form as bcc clusters in the early stages and then transform in-situ to an fcc structure as they grow. In overaged conditions (e.g., 600°C for 25h), they evolve into rod-like fcc particles that have a specific Kurdjumov-Sacks orientation relationship with the surrounding steel (bcc) matrix (Source: Figure 24, page 9).

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the final properties of copper-bearing steels through intelligent heat treatment. The findings offer a clear, data-driven path toward optimizing the age-hardening response by moving beyond the traditional goal of a fully martensitic quench. By understanding and controlling the initial microstructure, manufacturers can improve strength and thermal stability.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals for tool steels or high-performance components, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "C. N. Hsiao and J. R. Yang". Based on "Age Hardening in Martensitic/Bainitic Matrices in a Copper-Bearing Steel".

- Source of the paper: https://doi.org/10.2320/matertrans1989.41.1312

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.