Unlocking Higher Production Rates: A New Model for Irregular Cooling Channel Design in HPDC

This technical summary is based on the academic paper "Determination of Heat Transfer Coefficients Using a 1-D Flow Model Applied to Irregular Shaped Cooling Channels in Pressure Diecasting" published by L. D. Clark, K. Davey, I. Rosindale, and S. Hinduja in the Journal of Manufacturing Science and Engineering (2000). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Cooling Channel Design for HPDC

- Secondary Keywords: Heat Transfer Coefficient (HTC), Boiling Heat Transfer, Pressure Diecasting Simulation, 1-D Flow Model, Boundary Element Method (BEM), Die Thermal Management, Productivity Improvement in Die Casting

Executive Summary

- The Challenge: Accurately predicting and applying heat transfer conditions in complex, irregularly shaped cooling channels is a major hurdle in die casting simulation, often leading to suboptimal die designs and lower production rates.

- The Method: Researchers developed a novel mesh partitioning strategy using a shortest path algorithm. This allows a 1-D flow model to be applied to complex channels, accurately calculating coolant temperature, pressure, and velocity, and accounting for boiling.

- The Key Breakthrough: A "novel die" designed using this method to exploit boiling heat transfer achieved a 75% increase in production rate (from 42 to 70 cycles per minute) compared to a conventional die, without producing defective castings.

- The Bottom Line: This advanced simulation technique enables the design of highly efficient, conformal cooling channels, leading to more uniform die temperatures, better part quality, and significantly higher productivity.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-pressure die casting process, controlling the thermal state of the die is paramount. Cooling channels are the primary tool for extracting heat, but their effectiveness depends on accurately understanding the heat transfer from the die to the coolant. Local variations in heat transfer can be large, especially when the channel surface temperature is high enough to cause boiling (Ref. [2]).

For decades, engineers have faced a dilemma. Simple, straight-drilled cooling channels are easy to model but are often inefficient at cooling complex die cavities uniformly. Irregular, conformal cooling channels that follow the shape of the part are theoretically superior, but modeling the fluid flow and heat transfer within them is extremely difficult. The channel's axis and cross-section are not easily defined, making it challenging to apply standard 1-D flow models. This often forces engineers to rely on computationally expensive 3-D fluid dynamics models or to make simplifying assumptions that compromise the accuracy of the thermal analysis. Inaccurate thermal predictions can lead to poor die performance, defects like blistering, and lower-than-expected production rates.

The Approach: Unpacking the Methodology

To overcome this challenge, the researchers developed a multi-step strategy that combines the strengths of different modeling techniques:

- Mesh Partitioning: The core innovation is a strategy to analyze the boundary element mesh of an irregular cooling channel. It uses Dijkstra's algorithm, a method for finding the shortest path between nodes in a graph, to define a central "seam path" along the length of the channel (Figure 2a).

- Defining Cross-Sections: From this seam path, a series of circumferential paths are defined, effectively slicing the channel into discrete, manageable sections (Figure 2b). For each section, the model calculates an axial point, cross-sectional area, and wetted perimeter.

- 1-D Flow and Thermal Modeling: With the channel now defined as a series of connected sections, a 1-D Bernoulli-type flow model is applied. This model calculates the changes in the coolant's bulk temperature, pressure, and velocity as it flows through the channel, accounting for friction and losses at bends.

- Boiling Heat Transfer: This detailed coolant information is then fed into a sophisticated boiling model (Figure 4). This model calculates the effective heat transfer coefficient (HTC) at the die/coolant interface, accounting for forced convection, nucleate boiling, and transitional film boiling.

- Iterative Solution: The calculated HTCs are applied as boundary conditions to a 3-D steady-state thermal model of the entire die. The process is run iteratively: the thermal model calculates die temperatures, which are used to refine the boiling model and HTCs, which are then fed back into the thermal model until a stable, converged solution is reached.

This approach cleverly bypasses the need for a full 3-D fluid simulation of the coolant while still capturing the critical physics of flow and boiling in complex geometries.

The Breakthrough: Key Findings & Data

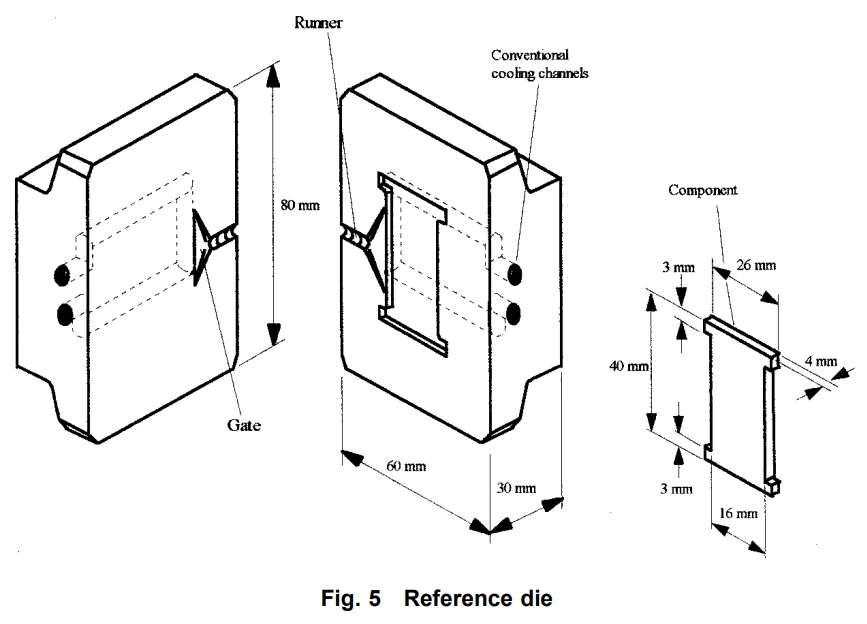

The researchers validated their model by manufacturing and testing two dies: a "reference die" with conventional cooling and a "novel die" with irregular channels designed using their new methodology.

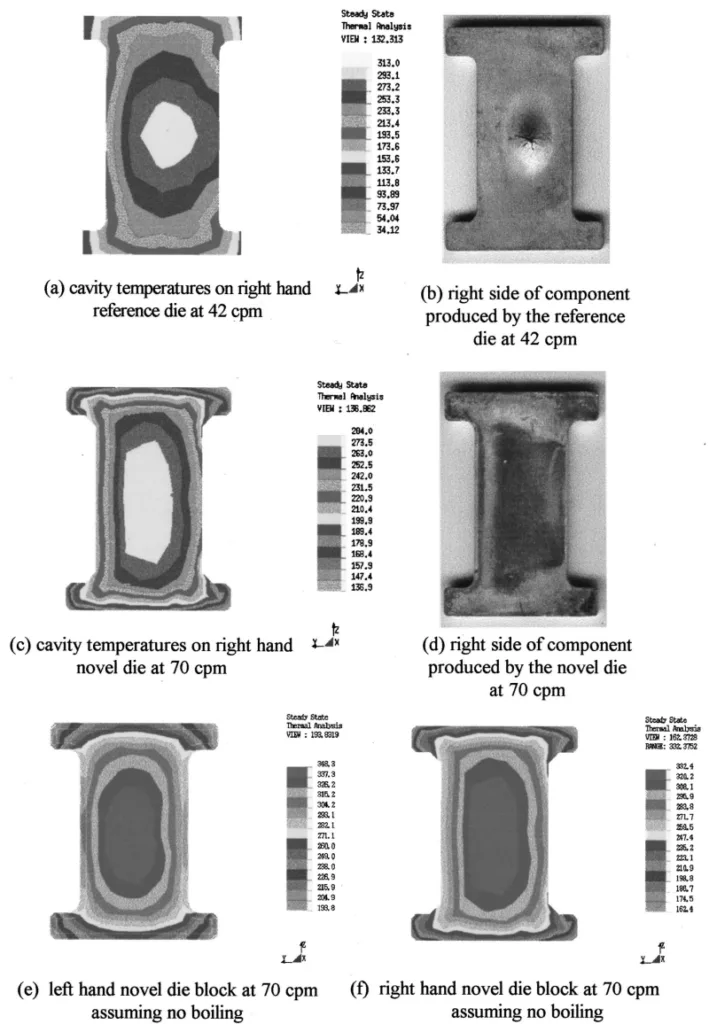

- Dramatic Productivity Increase: The reference die began producing blistered, defective castings at 42 cycles per minute (cpm). The novel die, however, ran flawlessly up to the machine's speed limit of 70 cpm—a 75% increase in productivity. The castings from the novel die showed no signs of blistering and had a good surface finish (Figure 8d).

- Accurate Temperature Prediction: The simulation's predictions for channel surface temperatures in the novel die were in excellent agreement with experimental thermocouple readings, showing a mean absolute error of just 4.5% across six different operating conditions (Figure 9). Coolant outlet temperature predictions also showed strong agreement, with a mean absolute error of 8% (Figure 10).

- The Critical Role of Boiling: The model predicted that for some runs, boiling was responsible for nearly 39% of the total heat extracted by the coolant (Table 1, Run 1). A simulation of the same run that ignored boiling predicted a maximum cavity temperature 50°C higher, which would have inevitably led to scrapped castings (Figure 8e, 8f). This proves that accurately modeling boiling is not just an academic exercise—it is essential for designing high-performance dies.

- Improved Thermal Uniformity: The novel die, designed with conformal channels, produced a much more uniform temperature distribution across the casting cavity compared to the conventional die, which showed a distinct hot spot that led to part failure (Figure 8a, 8c).

Practical Implications for HPDC Products

This research provides a clear, data-driven framework for improving die casting operations.

- For Process Engineers: The findings in this paper suggest that by accurately modeling and deliberately exploiting boiling heat transfer, you can safely increase production rates far beyond what conventional analysis would suggest. The model provides a tool to understand the limits of your process and avoid defects like blistering.

- For Die Design: This study liberates designers from the constraints of simple drilled cooling lines. The methodology allows for the confident design of complex, irregular, or conformal cooling channels that are optimized for the specific geometry of a part. This leads to more uniform die temperatures, which directly translates to better part quality and reduced cycle times.

- For Quality Control: The strong correlation shown between the predicted peak die temperature and casting defects (Figure 8) demonstrates how this simulation tool can be used proactively. By designing dies to operate within a stable and uniform thermal window, you can significantly improve process consistency and reduce scrap rates.

Paper Details

Determination of Heat Transfer Coefficients Using a 1-D Flow Model Applied to Irregular Shaped Cooling Channels in Pressure Diecasting

1. Overview:

- Title: Determination of Heat Transfer Coefficients Using a 1-D Flow Model Applied to Irregular Shaped Cooling Channels in Pressure Diecasting

- Author: L. D. Clark, K. Davey, I. Rosindale, S. Hinduja

- Year of publication: 2000

- Journal/academic society of publication: ASME, Journal of Manufacturing Science and Engineering, Vol. 122

- Keywords: Mesh partitioning, 1-D flow model, heat transfer coefficients, boiling, pressure diecasting, boundary element method

2. Abstract:

A mesh partitioning strategy is presented which facilitates the application of boundary conditions to irregular shaped cooling channels in the pressure diecasting process. The strategy is used to partition a boundary element mesh, but can also be applied to the surface of a cooling channel bounded by a finite element mesh. The partitioning of the mesh into a series of element packs enables a one-dimensional flow model to be applied to the coolant. The flow model is used in conjunction with a steady-state thermal model which initially assumes that no boiling is taking place on the die/coolant interface. Values of bulk temperature, pressure, and velocity in the coolant are thus ascertained. This information, together with die temperatures, is then used in empirical relationships which model the various heat transfer mechanisms, including nucleate and transitional film boiling, between die and coolant. Effective heat transfer coefficients are calculated and applied at the die/coolant interface. The steady-state thermal code and the empirical boiling model are then used iteratively until stable values for the effective heat transfer coefficients are obtained. The models are tested by casting a small thin component using a die with conventional cooling channels and also using a novel die with irregular shaped cooling channels running on a hot chamber proprietary die casting machine. Simulation results are shown and experimental results using the hot chamber pressure die casting machine are reported.

3. Introduction:

In the pressure diecasting process a steel die receives an injection of molten alloy. The die is chilled by cooling channels machined into it. The thermal process can be modelled using the boundary element method (BEM) as demonstrated by Davey et al. [1,2], in which case the cooling channel surfaces themselves form part of the die boundary mesh. Local variations in the rate of heat transfer, from these surfaces to the coolant, can be relatively large [2]. This is due to the nonuniform application of the heat flux, with the cooling channel surface nearest to the casting cavity receiving a greater applied heat flux. The heat transfer mechanism can also vary because the channel surface temperature is often sufficient to sustain subcooled nucleate boiling and transitional film boiling, as well as forced convection. In order to accurately apply boundary conditions to these surfaces, variation in the bulk coolant temperature, flow velocity and pressure need to be ascertained along the channel. One way to achieve this is by using a one-dimensional Bernoulli type model which could be applied to a finite element mesh of the cooling channel domain. An alternative strategy is proposed which requires that the existing boundary element mesh of the cooling channels be partitioned along the axis of the conduit, and the elements packaged into discrete parcels of contiguous elements to which a 1-D flow model can be applied. For channels with irregular cross sections and complex shape, a solution is not so readily apparent. This paper presents a method which utilizes a shortest path algorithm to define the location of a sequence of axial points and partition the boundary mesh into an axial sequence of element groups.

4. Summary of the study:

Background of the research topic:

The study addresses the challenge of accurately modeling heat transfer in cooling channels for pressure die casting, particularly for channels with irregular shapes. Standard modeling approaches are often insufficient because they cannot easily account for variations in coolant properties (temperature, pressure, velocity) along complex paths, nor can they easily model the significant effects of boiling.

Status of previous research:

Previous work by Davey et al. [1,2] established the use of the Boundary Element Method (BEM) for modeling the thermal process. However, applying accurate boundary conditions to cooling channels, especially those with complex geometries where boiling occurs, remained a significant challenge. Existing methods were either too simplistic or computationally prohibitive.

Purpose of the study:

The purpose was to develop and validate a new methodology that allows a 1-D flow model to be applied to irregularly shaped cooling channels. This would enable the accurate determination of local heat transfer coefficients, including the effects of boiling, which could then be used in a 3-D thermal analysis of the die. The ultimate goal was to use this improved modeling capability to design more efficient dies that could increase productivity.

Core study:

The core of the study is the development of a "mesh partitioning strategy." This strategy uses a shortest path algorithm to define an axis and cross-sections along an irregular channel mesh. This allows a 1-D flow model to calculate local coolant conditions. These conditions are then used in an empirical boiling model to find effective heat transfer coefficients (HTCs). The HTCs are applied to a 3-D BEM thermal model of the die. The process is iterated until the HTC values stabilize. The model was tested experimentally by comparing a conventional die with a novel die featuring irregular channels designed using the new method.

5. Research Methodology

Research Design:

The research involved both computational modeling and physical experimentation. A computational framework was developed combining a mesh partitioning algorithm, a 1-D fluid flow model, a boiling heat transfer model, and a 3-D steady-state thermal BEM model. To validate this framework, two physical test dies were designed and manufactured: a "reference die" with conventional straight cooling channels and a "novel die" with irregular channels.

Data Collection and Analysis Methods:

A thin, flat zinc component was cast using a hot chamber die casting machine. For the experimental part, thermocouples were installed in the novel die to measure channel surface temperatures at five locations (Figure 7). Coolant inlet and outlet temperatures were also recorded. The performance of the two dies was compared based on the maximum defect-free production rate. The collected experimental data (temperatures, production rates) were then compared against the predictions generated by the simulation model.

Research Topics and Scope:

The research is focused on the steady-state thermal analysis of the pressure die casting process. It is limited to thin castings where the assumption of complete solidification before ejection is valid. The study specifically investigates the determination of heat transfer coefficients in cooling channels, including the effects of forced convection and boiling, and the application of these coefficients to a 3-D thermal model of the die.

6. Key Results:

Key Results:

- A novel die designed with the new model achieved a 75% higher production rate (70 cpm) than a conventional die (42 cpm) without casting defects.

- The simulation model predicted channel surface temperatures with a mean absolute error of 4.5% and a maximum error of 13% compared to experimental measurements.

- The model predicted the rise in coolant temperature with a mean absolute error of 8% and a maximum error of 16%.

- Boiling was found to be a significant heat transfer mechanism, accounting for up to 38.6% of the total heat removed by the coolant in one of the test runs (Table 1).

- Simulations that ignored boiling effects incorrectly predicted die temperatures to be 50°C higher, which would have resulted in scrapped parts (Figure 8).

- The novel die design resulted in a more uniform cavity surface temperature distribution compared to the conventional design (Figure 8).

Figure Name List:

- Fig. 1 Portion of a boundary element mesh and its representation as a complete digraph

- Fig. 2 Partitioning and packaging of a cooling channel surface mesh

- Fig. 3 The two possible path orientations and the corresponding sign of their area value

- Fig. 4 Model boiling curve

- Fig. 5 Reference die

- Fig. 6 Novel die

- Fig. 7 Thermocouple positions in the novel die

- Fig. 8 Cavity surface temperatures and casting results

- Fig. 9 Channel surface temperatures

- Fig. 10 Coolant temperatures

- Fig. 11 Effect of 1-D flow model on temperature predictions

7. Conclusion:

A shortest path algorithm can be successfully applied to the surface mesh of irregular cooling channels to approximate cross-sectional area and axial length. This enables a 1-D flow model to be applied to ascertain coolant velocity, temperature, and pressure along the channel. This information, used with a boiling heat transfer model, allows for the determination of effective heat transfer coefficients for a 3-D thermal analysis. Experimental results from a test die confirmed the model's accuracy, predicting channel surface temperatures with a mean absolute error of 4.5%. The study demonstrated the potential benefits of designing dies to exploit boiling, achieving a 75% increase in productivity with a test die. This shows that optimizing cooling channel shapes can further increase productivity and improve surface finish by ensuring a more uniform cavity surface temperature distribution.

8. References:

- [1] Davey, K., and Hinduja, S., 1990, "Modeling the Pressure Diecasting Process With the Boundary Element Method: Steady State Analysis," Int. J. Numer. Methods Eng., 30, pp. 1275-1299.

- [2] Clark, L. D., Rosindale, I., Davey, K., and Hinduja, S., 1997, "Predicting Heat Extraction Caused by Boiling in Cooling Channels During the Pressure Diecasting Process," forwarded to Proc. IMechE Part C, J. Mech. Eng. Sci.

- [3] Brebbia, C. A., 1978, The Boundary Element Method for Engineers, Pentech Press, London, Halstead, New York.

- [4] Dijkstra, E. W., 1959, "A Note on Two Problems in Connection With Graphs," Numer. Math., 1, pp. 269-271.

- [5] Swamee, P. K., and Jain, A. K., 1976, "Explicit Equations for Pipe-Flow Problems," J. Hydraul. Div., Am. Soc. Civ. Eng., 102, pp. 657-664.

- [6] Kays, W. M., and Perkins, H. C., 1973, reprint from Standards of the Hydraulic Institute, in Handbook of Heat Transfer, 7-18, Rohsenow, W. M., and Hartnett, J. P., eds., McGraw-Hill, New York.

- [7] Lapple, C. E., 1949, "Velocity Head Simplified Flow Computation," Chem. Eng., 56, pp. 91-138

- [8] Dittus, F. W., and Boelter, L. M. K., 1930, "Heat Transfer in Automobile Radiators of the Tabular Type," University of California-Berkeley, Pub. Eng. 2, p. 443.

- [9] Bergles, A. E., and Rohsenow, W. M., 1964, "The Determination of Forced-Convection Surface-Boiling Heat Transfer," ASME J. Heat Transfer, 86, pp. 365-372.

- [10] Gambill, W. R., 1962, Generalized prediction of burnout heat flux for flowing subcooled, wetting liquids, AIChE Preprint 17, 5th Nat. Heat Transfer Conf., Houston.

- [11] Rohsenow, W. M., 1952, "A Method of Correlating Heat Transfer Data for Surface Boiling of Liquids," Trans. ASME, 74, pp. 969-976.

- [12] Henry, R. E., 1974, "Correlation for the Minimum Film Boiling Temperature," AIChE Symp. Ser., 70, pp. 81-90.

- [13] Hammer, P. C., and Stroud, A. H., 1956, "Numerical Integration Over Simplexes," Math. Tables Aids Comp., 10, pp. 137-139.

- [14] Eckert, E. R. G., and Drake, Jr. R. M., 1959, Heat and Mass Transfer, McGraw-Hill, New York.

Expert Q&A: Your Top Questions Answered

Q1: Why is this modeling approach better than just using a standard simulation package?

A1: Standard packages may struggle to efficiently model irregularly shaped channels. They might require a full, computationally expensive 3-D CFD analysis of the coolant or use simplified assumptions that ignore critical physics. This paper's method provides a "best of both worlds" approach: it's computationally efficient like a 1-D model but captures the essential details of flow and, crucially, boiling heat transfer in complex geometries, which is often the dominant mode of heat extraction (Table 1).

Q2: What is the real-world benefit of this complex modeling? A 75% productivity increase seems almost too good to be true.

A2: The 75% increase is a direct result of superior thermal management. The novel die, designed with this model, could extract heat much more effectively and uniformly. This prevented the formation of hot spots that caused defects in the conventional die (Figure 8). By keeping the entire die cavity within the optimal thermal window, it was possible to drastically reduce the cycle time without compromising part quality.

Q3: How does this model account for boiling, and why is that so important?

A3: The model uses the calculated local die surface temperature and coolant properties (pressure, velocity, temperature) to predict the heat transfer regime using empirical correlations (Figure 4). It can distinguish between forced convection, nucleate boiling, and film boiling. This is critical because, as the results show, boiling can account for over a third of the total heat removal (Table 1). Ignoring it leads to a massive underestimation of cooling capacity and incorrect predictions of die temperatures and part defects (Figure 8e, 8f).

Q4: How accurate is this simulation method?

A4: The study provides strong experimental validation. The model's predictions for die surface temperatures at five different locations matched the physical thermocouple measurements with a mean absolute error of only 4.5% across six different production runs (Figure 9). This level of accuracy gives engineers high confidence in the model's ability to predict real-world die performance.

Q5: Does this mean I can design cooling channels of any shape?

A5: This methodology significantly expands design freedom. It allows engineers to move beyond simple straight-drilled lines and design complex, conformal channels that follow the contours of the part. The model provides the analytical power to verify that these complex designs will perform as intended. While there are still manufacturing constraints, this simulation approach removes a major analytical barrier to creating more effective and efficient cooling layouts.

Conclusion & Next Steps

This research provides a valuable roadmap for fundamentally rethinking cooling channel design in high-pressure die casting. By enabling the accurate analysis of irregular channels and the deliberate use of boiling heat transfer, the findings offer a clear, data-driven path toward improving quality, dramatically increasing productivity, and optimizing the entire casting process.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "L. D. Clark, K. Davey, I. Rosindale, S. Hinduja". Based on "Determination of Heat Transfer Coefficients Using a 1-D Flow Model Applied to Irregular Shaped Cooling Channels in Pressure Diecasting".

- Source of the paper: http://manufacturingscience.asmedigitalcollection.asme.org/ on 02/23/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.