This introduction paper is based on the paper "Strengthening behavior and thermal conductivity of Cu/Al composite with penetration architecture" published by "Transactions of Nonferrous Metals Society of China".

1. Overview:

- Title: Strengthening behavior and thermal conductivity of Cu/Al composite with penetration architecture

- Author: Xiao-ling CHEN, Zhi-qing CHEN, Bo HU, Long YAN, Jing-ya WANG, Tao YING, Xiao-qin ZENG

- Year of publication: 2024

- Journal/academic society of publication: Transactions of Nonferrous Metals Society of China

- Keywords: Cu/Al composites; compressive strength; squeeze casting technology; thermal conductivity

2. Abstract:

To improve the strength of Al alloys without severely deteriorating the thermal conductivity, the Cu/Al bimetallic composite comprising penetration architecture was artificially designed and fabricated via the additive manufacturing combined with the squeeze casting. The composite exhibited a good balance of the strength (~340 MPa) and thermal conductivity (200 W/(m·K)), outperforming the traditional Al alloys. High thermal conduction is attributed to the geometrical Cu scaffold, which provides a rapid pathway for the electron conduction. Simultaneously, the good metallurgical bonding is attained by the formation of the Al2Cu eutectic phase along the interfaces, which effectively enhances the strength of the Cu/Al composite.

3. Introduction:

Cu/Al composites are extensively appealing for the electrical and thermal conductor components in the heat dissipation, aviation, communications and automotive applications [1-3]. They perfectly take advantage of the excellent thermal conductivity of Cu, combined with light weight and low cost of Al. The Cu/Al bimetallic composites can reduce 40% mass and 60% expense, yet offers the equivalent electrical and thermal conductivity. However, most fabrication techniques are restricted to manufacturing Cu/Al composites with simple shapes, which severely constrains their widespread application in complex components. Another limitation of traditional Cu/Al composites arises from the trade-off between mechanical strength and thermal conductivity, which are mutually exclusive properties. Generally, traditional strengthening approaches are inevitably detrimental to thermal conductivity. This paper proposes a novel strategy involving an artificially designed penetration architecture for Cu reinforcement, accomplished by a feasible manufacturing approach, to address these issues.

4. Summary of the study:

Background of the research topic:

There is a growing demand for materials with both high mechanical strength and excellent thermal conductivity for applications in heat dissipation, aviation, and communications. Cu/Al composites are promising candidates due to their potential to combine the high thermal conductivity of Cu with the light weight and low cost of Al [1-4].

Status of previous research:

Numerous techniques have been developed to fabricate Cu/Al composites, including welding [5-7], extrusion, rolling, and compound casting [11-15]. However, these methods often result in simple geometries and face a critical trade-off: enhancing mechanical strength typically degrades thermal conductivity. For instance, Al-50vol.%Cu composites showed high hardness but low thermal conductivity (130 W/(m·K)), while other methods achieved improved thermal conductivity (322 W/(m·K)) but with lower tensile strength (102 MPa).

Purpose of the study:

The study aimed to develop a novel Cu/Al composite with an artificially designed penetration architecture to achieve a good balance between mechanical strength and thermal conductivity. The goal was to overcome the limitations of existing fabrication techniques and the inherent property trade-offs in conventional Cu/Al composites, thereby extending their applicability to complex components.

Core study:

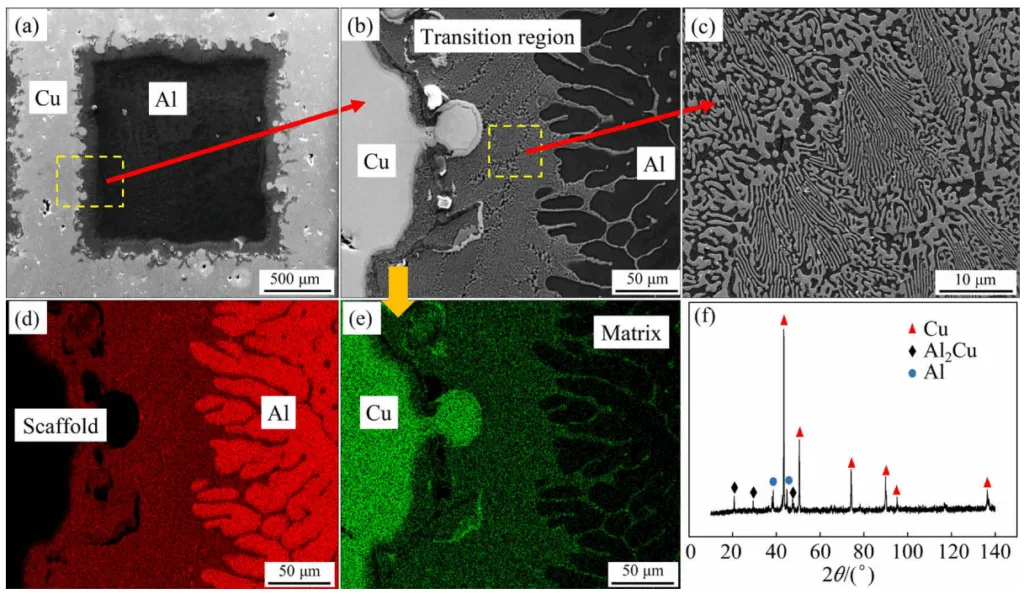

The core of this study involved the design and fabrication of a Cu/Al bimetallic composite with a unique penetration architecture. This was achieved by first creating a complex Cu scaffold using selective laser melting (SLM), an additive manufacturing technique. Subsequently, pure Al was infiltrated into this scaffold using squeeze casting under high pressure and temperature. The research then focused on characterizing the microstructure, particularly the Cu-Al interface, using SEM, EDS, and XRD, and evaluating the formation quality through XCT. Finally, the mechanical properties (Vickers hardness, compressive strength) and thermal properties (thermal diffusivity, thermal conductivity) of the fabricated composite were systematically investigated and compared with the constituent materials and existing literature data. The study highlighted the formation of a single Al₂Cu eutectic layer at the interface, contributing to good metallurgical bonding and enhanced mechanical strength, while the penetration architecture of the Cu scaffold ensured efficient thermal conduction.

5. Research Methodology

Research Design:

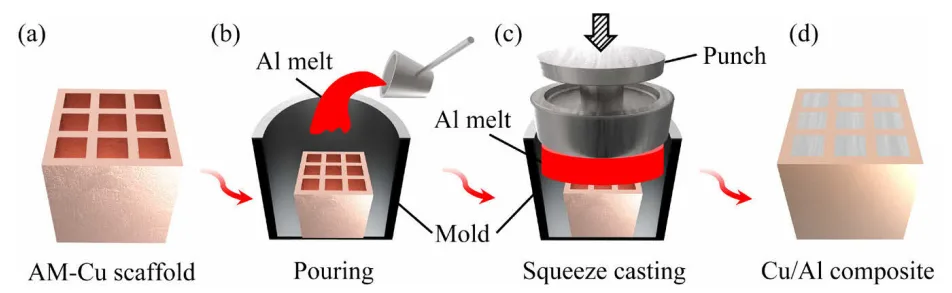

A novel design concept was developed, focusing on a penetration architecture for the Cu reinforcement within an Al matrix. The Cu scaffold was designed with thoroughly penetrated square holes (1.5 mm × 1.5 mm) using Solidworks software. The fabrication process combined additive manufacturing (SLM) for the Cu scaffold and squeeze casting for Al infiltration.

Data Collection and Analysis Methods:

The Cu scaffold was fabricated by SLM, with specific parameters like layer thickness (50 µm), laser power (300 W), and preheating (200 °C). Pure Al was melted and poured into the AM-Cu scaffold at 720 °C under a pressure of ~100 MPa. Microstructure characterization involved optical microscopy, SEM with EDS, XRD, and XCT. Mechanical properties were assessed through Vickers hardness tests and quasi-static uniaxial compression tests. Thermal properties were determined by measuring thermal diffusivity using the laser flash method, from which thermal conductivity was calculated using the formula λ=αρε.

Research Topics and Scope:

The research focused on the fabrication, microstructure characterization, and evaluation of mechanical and thermal properties of the novel Cu/Al composite. The scope included:

- Fabrication of a 3D Cu scaffold via SLM.

- Infiltration of Al into the scaffold via squeeze casting.

- Characterization of the Cu/Al interface and phase composition (Al₂Cu eutectic phase).

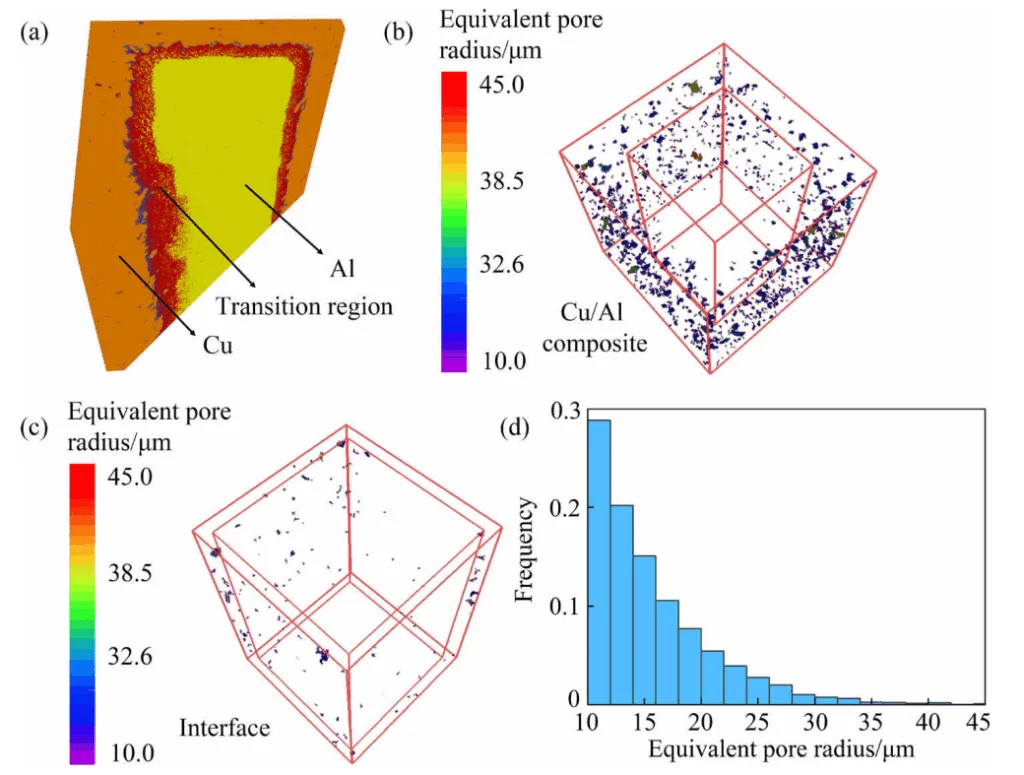

- Analysis of defect distribution and formation quality.

- Measurement of Vickers hardness, compressive strength, and thermal conductivity.

- Comparison of properties with constituent materials and literature values.

6. Key Results:

Key Results:

The fabricated Cu/Al composite with penetration architecture exhibited a good balance of compressive strength (~340 MPa) and thermal conductivity (200 W/(m·K)). This performance surpassed traditional Al alloys. High thermal conduction was attributed to the geometrical Cu scaffold providing a rapid pathway for electron conduction. Good metallurgical bonding was achieved through the formation of an Al₂Cu eutectic phase at the interface, enhancing the composite's strength. The interfacial microstructure was free of pores or microcracks, with a single IMC layer of ~120 µm width. The composite had a low porosity of ~0.57%. The novel penetration architecture and fabrication process effectively mitigated the trade-off between strength and thermal conductivity.

Figure Name List:

![Fig. 8 Thermal conductivity versus compressive strength for Cu/Al composite, AM-Cu and cast Al measured in this work, compared with those from Cu alloys and Al alloys in literature [28,30,31]](https://castman.co.kr/wp-content/uploads/image-2437.webp)

- Figure 1 Schematic of formation process of Cu/Al composite: (a) AM-Cu scaffold; (b) Pouring of Al melt; (c) Squeeze casting processing; (d) Fabricated Cu/Al composite

- Figure 2 Schematic diagrams of sample used for compression test (a) and thermal analysis (b)

- Figure 3 SEM images (a–c), distribution of alloying elements (d, e) and XRD pattern (f) of Cu/Al composite

- Figure 4 Al–Cu phase diagram calculated by Pandat software

- Figure 5 Defect distribution from top view side (a), 3D visualization of defects in AM-Cu (b) and along interface (c), and equivalent pore radius distribution in composite (d)

- Figure 6 Vickers hardness in various regions of composite (a), and corresponding indent imprints (b)

- Figure 7 Compressive engineering stress-strain curves of Cu/Al composite, AM-Cu and pure cast Al cut from excess of Cu/Al composite

- Figure 8 Thermal conductivity versus compressive strength for Cu/Al composite, AM-Cu and cast Al measured in this work, compared with those from Cu alloys and Al alloys in literature

7. Conclusion:

(1) The Cu/Al composite with an artificially designed penetration architecture was developed and fabricated by squeeze casting Al melt in the additive-manufactured Cu scaffold. Good metallurgical bonding was obtained without obvious defects and microcracks along the interface. [Conclusion 1]

(2) An excellent balance between thermal conductivity (200 W/(m·K)) and compressive strength (~340 MPa) was achieved, which was attributed to the artificially designed structure and excellent metallurgical bonding, accomplished by the novel formation approach. [Conclusion 2]

(3) This study offers a promising strategy for the design and fabrication of high-performance Cu/Al composites, utilizing the advantages of the geometrical structure and the feasible formation approach. [Conclusion 3]

8. References:

- MAVHUNGU S T, AKINLABI E T, ONITIRI M A, VARACHIA F M. Aluminum matrix composites for industrial use: Advances and trends [J]. Procedia Manufacturing, 2017, 7: 178–182.

- LING J M, XU T, CHEN R, VALENTIN O, LUECHINGER C. Cu and Al–Cu composite-material interconnects for power devices [C]//Proceedings of the 2012 IEEE 62nd Electronic Components and Technology Conference. IEEE, 2012: 1905–1911.

- DANILENKO V N, SERGEEV S N, BAIMOVA J A, KORZNIKOVA G F, NAZAROV K S, KHISAMOV R K, GLEZER A M, MULYUKOV R R. An approach for fabrication of Al–Cu composite by high pressure torsion [J]. Materials Letters, 2019, 236: 51–55.

- SHENG L Y, YANG F, XI T F, LAI C, YE H Q. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling [J]. Composites Part B: Engineering, 2011, 42: 1468–1473.

- WEI Y N, CHEN Y, NIU R, YANG Q, LUO Y G, ZOU J T. Study on the thermal conductivity of Cu/Al joints with different interfacial microstructures [J]. Advances in Materials Science and Engineering, 2022, 2022: 7040685.

- MEHTA K P, BADHEKA V J. Effects of tilt angle on the properties of dissimilar friction stir welding copper to aluminum [J]. Materials and Manufacturing Processes, 2016, 31: 255–263.

- ALROUBAIY A O, NABAT S M, BATAKO A D. Experimental and theoretical analysis of friction stir welding of Al–Cu joints [J]. The International Journal of Advanced Manufacturing Technology, 2014, 71: 1631–1642.

- LEE T H, LEE Y J, PARK K T, NERSISYAN H H, JEONG H G, LEE J H. Controlling Al/Cu composite diffusion layer during hydrostatic extrusion by using colloidal Ag [J]. Journal of Materials Processing Technology, 2013, 213: 487–494.

- WANG T, LI S, REN Z K, HAN J C, HUANG Q X. A novel approach for preparing Cu/Al laminated composite based on corrugated roll [J]. Materials Letters, 2019, 234: 79–82.

- ASEMABADI M, SEDIGHI M, HONARPISHEH M. Investigation of cold rolling influence on the mechanical properties of explosive-welded Al/Cu bimetal [J]. Materials Science and Engineering A, 2012, 558: 144–149.

- BAKKE A O, ARNBERG L, LI Y J. Achieving high-strength metallurgical bonding between A356 aluminum and copper through compound casting [J]. Materials Science and Engineering A, 2021, 810: 140979.

- JIANG W M, GUAN F, LI G Y, JIANG H X, ZHU J W, FAN Z T. Processing of Al/Cu bimetal via a novel compound casting method [J]. Materials and Manufacturing processes, 2019, 34: 1016–1025.

- TAVASSOLI S, ABBASI M, TAHAVVORI R. Controlling of IMCs layers formation sequence, bond strength and electrical resistance in AlCu bimetal compound casting process [J]. Materials & Design, 2016, 108: 343–353.

- YUAN H, CHEN Y Q, LI L HU H D, ZHU Z A. Microstructure and properties of Al/Cu bimetal in liquid–solid compound casting process [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1555–1563.

- CHEN S Y, CHANG G W, YUE X D, LI Q C. Solidification process and microstructure of transition layer of Cu–Al composite cast prepared by method of pouring molten aluminum [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 2247–2256.

- BURGER N, LAACHACHI A, FERRIOL M, LUTZ M, TONIAZZO V, RUCH D. Review of thermal conductivity in composites: Mechanisms, parameters and theory [J]. Progress in Polymer Science, 2016, 61: 1–28.

- KIM K, KIM D, PARK K, CHO M, CHO S, KWON H. Effect of intermetallic compounds on the thermal and mechanical properties of Al–Cu composite materials fabricated by spark plasma sintering [J]. Materials, 2019, 12: 1546.

- LEE T H, LEE Y J, PARK K T, JEONG H G, LEE J H. Mechanical and asymmetrical thermal properties of Al/Cu composite fabricated by repeated hydrostatic extrusion process [J]. Metals and Materials International, 2015, 21: 402–407.

- MOISY F, GUEYDAN A, SAUVAGE X, GUILLET A, KELLER C, GUILMEAU E, HUG E. Influence of intermetallic compounds on the electrical resistivity of architectured copper clad aluminum composites elaborated by a restacking drawing method [J]. Materials & Design, 2018, 155: 366–374.

- ZHANG M Y, YU Q, LIU Z Q, ZHANG J, TANG Q, JIAO D, ZHU W J, LI S J, ZHANG Z F, YANG R. 3D printed Mg–NiTi interpenetrating-phase composites with high strength, damping capacity, and energy absorption efficiency [J]. Science Advances, 2020, 6: eaba5581.

- GUAN F, JIANG W M, LI G Y, JIANG H X, ZHU J W, FAN Z T. Interfacial bonding mechanism and pouring temperature effect on Al/Cu bimetal prepared by a novel compound casting process [J]. Materials Research Express, 2019, 6: 096529.

- DAI W, WU S S, LÜ S L, LIN C. Effects of rheo-squeeze casting parameters on microstructure and mechanical properties of AlCuMnTi alloy [J]. Materials Science and Engineering A, 2012, 538: 320–326.

- SUN S H, LI J, ZHAO Y W, ZHAO H L, XU R, LIU R P. Study on eutectic transformation in Al–Cu alloys under 5 GPa pressure condition [J]. Physical Testing Chemical Analysis Part A, 2008, 44(9): 465–466. (in Chinese)

- LIU T, WANG Q D, SUI Y D, WANG Q G, DING W J. An investigation into interface formation and mechanical properties of aluminum–copper bimetal by squeeze casting [J]. Materials & Design, 2016, 89: 1137–1146.

- YUE T M, CHADWICK G A. Squeeze casting of light alloys and their composites [J]. Journal of Materials Processing Technology, 1996, 58: 302–307.

- WANG J, GUO Z P, JIAO X Y, XIONG S M. On the formation mechanism of the ring-like microstructure of high-pressure die-cast A390 alloy [J]. Materials Characterization, 2018, 140: 179–188.

- FERREIRA I L. On the heat capacity of pure elements and phases [J]. Materials Research, 2021, 24(2): e20200529.

- SABERI Y, OVEISI H. Development of novel cellular copper–aluminum composite materials: The advantage of powder metallurgy and mechanical milling approach for lighter heat exchanger [J]. Materials Chemistry and Physics, 2022, 279: 125742.

- PADAP A K, YADAV A P, KUMAR P, KUMAR N. Effect of aging heat treatment and uniaxial compression on thermal behavior of 7075 aluminum alloy [J]. Materials Today: Proceedings, 2020, 33: 5442–5447.

- DAVIS J R. Aluminum and aluminum alloys [M]. The United States of America: ASM international, 1993.

- DAVIS J R. Copper and copper alloys [M]. The United States of America: ASM international, 2001.

9. Copyright:

- This material is a paper by "Xiao-ling CHEN, et al.". Based on "Strengthening behavior and thermal conductivity of Cu/Al composite with penetration architecture".

- Source of the paper: https://doi.org/10.1016/S1003-6326(23)66394-0

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.

Summarize:

This paper details the development of a Cu/Al bimetallic composite featuring a novel penetration architecture, produced by combining additive manufacturing (for the Cu scaffold) with squeeze casting (for Al infiltration). The research aimed to enhance the strength of Al alloys without significantly compromising their thermal conductivity. The resulting composite achieved a desirable balance, exhibiting a compressive strength of approximately 340 MPa and a thermal conductivity of 200 W/(m·K), outperforming traditional Al alloys. This improved performance is attributed to the unique design, where the Cu scaffold facilitates rapid electron conduction, and the formation of an Al₂Cu eutectic phase at the interface ensures strong metallurgical bonding and enhanced mechanical properties.

Key questions and answers about the research:

This paper introduces a Cu/Al bimetallic composite with a novel penetration architecture, fabricated using additive manufacturing for the Cu scaffold followed by squeeze casting of Al. The research aimed to improve the strength of Al alloys without severely deteriorating thermal conductivity. The resulting composite demonstrated a good balance of strength (~340 MPa) and thermal conductivity (200 W/(m·K)), outperforming traditional Al alloys due to its unique design and good metallurgical bonding.

Q1. What was the primary motivation for designing the Cu/Al composite with a penetration architecture?

A1. The primary motivation was to improve the strength of Al alloys without severely deteriorating their thermal conductivity, addressing the common trade-off between these properties in traditional Al alloys. (Source: Abstract, Introduction)

Q2. What fabrication method was used to create the Cu/Al composite, and what were its key components?

A2. The composite was fabricated via additive manufacturing (selective laser melting) to create a Cu scaffold, followed by squeeze casting to infiltrate the scaffold with Al. (Source: Abstract, Section 2.1 Fabrication)

Q3. What were the achieved compressive strength and thermal conductivity of the new Cu/Al composite?

A3. The composite exhibited a compressive strength of approximately 340 MPa and a thermal conductivity of 200 W/(m·K). (Source: Abstract, Section 3.3 Mechanical and thermal properties)

Q4. How does the penetration architecture contribute to the composite's thermal conductivity?

A4. The geometrical Cu scaffold in the penetration architecture provides a rapid pathway for electron conduction, effectively utilizing the high thermal conductivity of copper. (Source: Abstract, Section 3.3 Mechanical and thermal properties)

Q5. What was observed at the interface between the Cu scaffold and Al matrix, and how did it affect the composite's strength?

A5. A good metallurgical bonding was attained by the formation of an Al₂Cu eutectic phase along the interfaces, which effectively enhanced the strength of the Cu/Al composite. (Source: Abstract, Section 3.1 Microstructure)

Q6. How did the properties of this novel Cu/Al composite compare to traditional Al alloys and other Al-Cu composites?

A6. The composite outperformed traditional Al alloys by achieving a better balance of strength and thermal conductivity, and also showed superior combined properties compared to conventional Al-Cu composites and novel cellular copper-aluminum materials mentioned in the literature. (Source: Abstract, Section 3.3 Mechanical and thermal properties, Figure 8)