This introduction paper is based on the paper "Injection Parameters Optimization and Artificial Aging of Automotive Die Cast Aluminum Alloy" published by "Materials and Manufacturing Processes".

1. Overview:

- Title: Injection Parameters Optimization and Artificial Aging of Automotive Die Cast Aluminum Alloy

- Author: Zuqi Hu

- Year of publication: 2015

- Journal/academic society of publication: Materials and Manufacturing Processes

- Keywords: Aging; Aluminum; Automobile; Casting; Injection; Optimization

2. Abstract:

High-pressure die castings are expected to be used in the near future as high-duty structural components in the automotive industry. The effects of die casting parameters and aging on the tensile properties of high-performance die cast aluminum alloy are therefore investigated in this work. Our results indicate that HPDC AlMg5Si2Mn specimens (formed under an injection pressure of 100 MPa, high-level fast-shot velocity, and speed transition point location 220 mm) possess good internal quality and superb tensile properties (351.1 MPa, 200.7 MPa, 13.77%). Sample density decreased along the die filling direction due to pressure loss. After 3 h aging at 250 °C, tensile strength and yield strength were significantly increased from 351.1 and 200.7 MPa to 380.5 and 246.9 MPa, respectively. Elongation decreased initially from 13.77 to 5.5% after 1 h aging and then recovered to 11.48%. In addition, the effect of cooling methods on mechanical properties was found to be insignificant.

3. Introduction:

Light weight is an essential component in the development of modern automobiles, with die castings being well-suited for the automotive industry due to their dimensional accuracy, surface quality, and integrity. High-performance die cast aluminum alloys are required to compensate for low ductility, often caused by internal pores and Fe-rich intermetallics. Among various super-tough alloys, Magsimal-59® (AlMg5Si2Mn) is noted for its superior ductility, resulting from Mg addition and reduced Fe content, minimizing detrimental Fe-rich intermetallics. AlMg5Si2Mn is versatile, suitable for processes like forging, rheo-casting, squeeze casting, and die casting, and is recyclable with wrought aluminum alloys, making it a promising automotive material.

Injection parameters are crucial for the internal quality of die castings, as appropriate settings can eliminate defects such as inclusions, flowline cracks, and cold shut. While optimization of injection parameters has been studied for alloys like ADC12 and A380, previous research on AlMg5Si2Mn has primarily focused on its microstructure formation, tensile properties, fatigue resistance, and corrosion behavior. For instance, aging treatment was found to improve the yield strength of AlMg5Si1.5MnFe0.25Ti0.2 die castings. Studies have also elucidated surface layer formation, defect bands, and feeding mechanisms in AlMg5Si2Mn die castings, and compared corrosion resistance of gravity permanent mold versus die cast AlMg5Si2Mn. However, there has been limited research on the influence of injection parameters on the internal quality and mechanical properties of AlMg5Si2Mn die castings, a gap this study aims to address.

4. Summary of the study:

Background of the research topic:

High-pressure die castings are increasingly considered for high-duty structural components in the automotive sector. The AlMg5Si2Mn alloy is a promising candidate due to its high performance and ductility. The internal quality of such die castings is significantly influenced by injection parameters.

Status of previous research:

Previous studies on AlMg5Si2Mn alloy focused on aspects like microstructure, tensile properties, fatigue, corrosion, and the effects of aging treatment on similar alloys. The formation of surface layers, defect bands, and feeding mechanisms in AlMg5Si2Mn die castings have been investigated. While optimization of injection parameters has been performed for other die cast alloys (e.g., ADC12, A380), there was a lack of research specifically addressing the influence of injection parameters on the internal quality and mechanical properties of AlMg5Si2Mn die castings.

Purpose of the study:

The study aimed to investigate the effects of die casting injection parameters (injection pressure, fast-shot velocity, speed transition point location) and subsequent artificial aging treatments on the tensile properties and internal quality of a high-performance AlMg5Si2Mn die cast aluminum alloy.

Core study:

The core of the study involved a systematic investigation into how variations in key injection parameters—specifically injection pressure, fast-shot velocity, and the location of the speed transition point—affect the mechanical properties (tensile strength, yield strength, elongation) and density of High-Pressure Die Cast (HPDC) AlMg5Si2Mn alloy. This included microstructural analysis to understand the observed changes. Furthermore, the study examined the impact of artificial aging treatment (at 250°C for 1, 2, and 3 hours) and different cooling methods (air cooling, furnace cooling) on the mechanical properties of the optimally cast alloy.

5. Research Methodology

Research Design:

- A-type HPDC standard tension test bars were produced using a 280t horizontal cold chamber die-casting machine.

- The single-factor test method was adopted for optimizing injection parameters, meaning one parameter was varied while the other two were kept constant.

- The investigated injection parameters were:

- Injection pressure (P): 60, 80, 100, 120 MPa.

- Fast-shot velocity (v): low, medium, high levels.

- Location of speed transition points (S): 190, 220, 250 mm (moving distance of the plunger as fast-shot stage started).

- Artificial aging treatments were performed at 250°C for 1, 2, and 3 hours.

- Two cooling methods after aging were investigated: air cooling and furnace cooling.

Data Collection and Analysis Methods:

- Over 20 kg of AlMg5Si2Mn foundry ingots were melted, with pure magnesium added to achieve the target composition (compensating for ~5% mass loss of Mg). The melt was degassed for 20 min with argon gas.

- The melt was poured into the shot sleeve at 700~710°C, with the die preheated to 200°C.

- The chemical composition of the alloy (Table 1) was confirmed by optical emission spectroscopy.

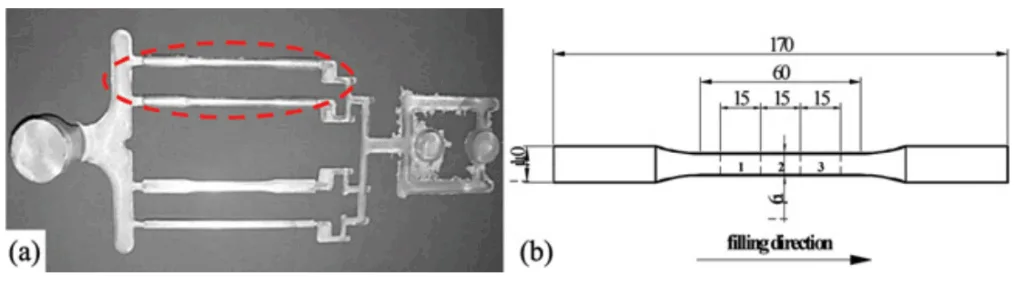

- Three groups of density samples were cut from the gauge length of tension test bars along the filling direction (Fig. 1(b)).

- Tensile tests were conducted, and results were reported as the average of five specimens for each parameter group.

- Microstructure of the die castings was analyzed to correlate with mechanical properties and processing parameters.

Research Topics and Scope:

- Material: AlMg5Si2Mn aluminum alloy (chemical composition detailed in Table 1).

- Process: High-Pressure Die Casting (HPDC).

- Variables Investigated:

- Injection pressure: 60 MPa, 80 MPa, 100 MPa, 125 MPa.

- Fast-shot velocity: low, medium, high.

- Speed transition point location: 190 mm, 220 mm, 250 mm.

- Artificial aging: 250°C for 1, 2, and 3 hours.

- Cooling method post-aging: air cooling, furnace cooling.

- Measured Outputs:

- Mechanical properties: Tensile strength (στ), yield strength (σ0.2), elongation.

- Physical properties: Sample density.

- Microstructure: Characteristics of α1-Al grains, α2-Al grains, and [Al+Mg2Si] eutectic regions.

6. Key Results:

Key Results:

- Effect of Injection Pressure:

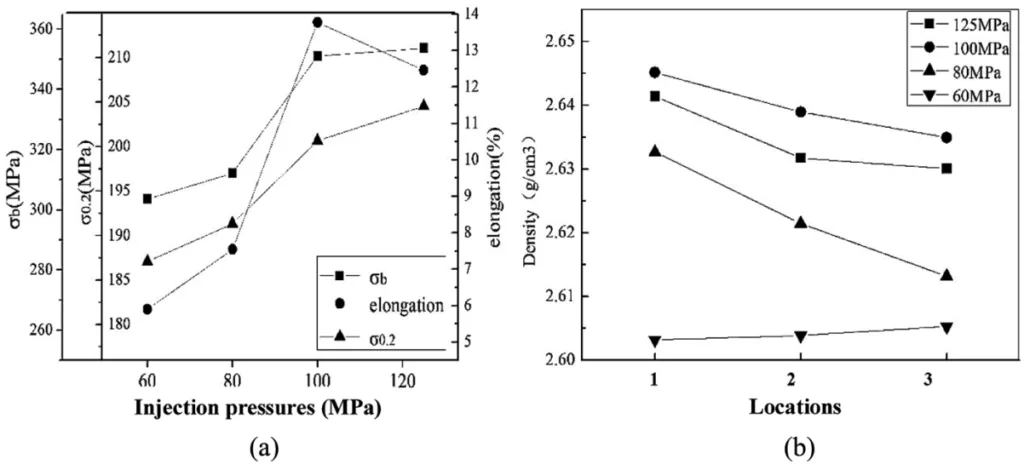

- Increasing injection pressure from 60 MPa to 100 MPa significantly improved tensile strength (στ from 303.52 MPa to 353.58 MPa), yield strength (σ0.2 from 187.08 MPa, remaining stable), and elongation (from 5.9% to 13.77%). Further increase beyond 100 MPa showed insignificant enhancement.

- Sample density increased with injection pressure up to 100 MPa, indicating reduced porosity. The highest density was achieved at 100 MPa.

- Density generally decreased along the die filling direction.

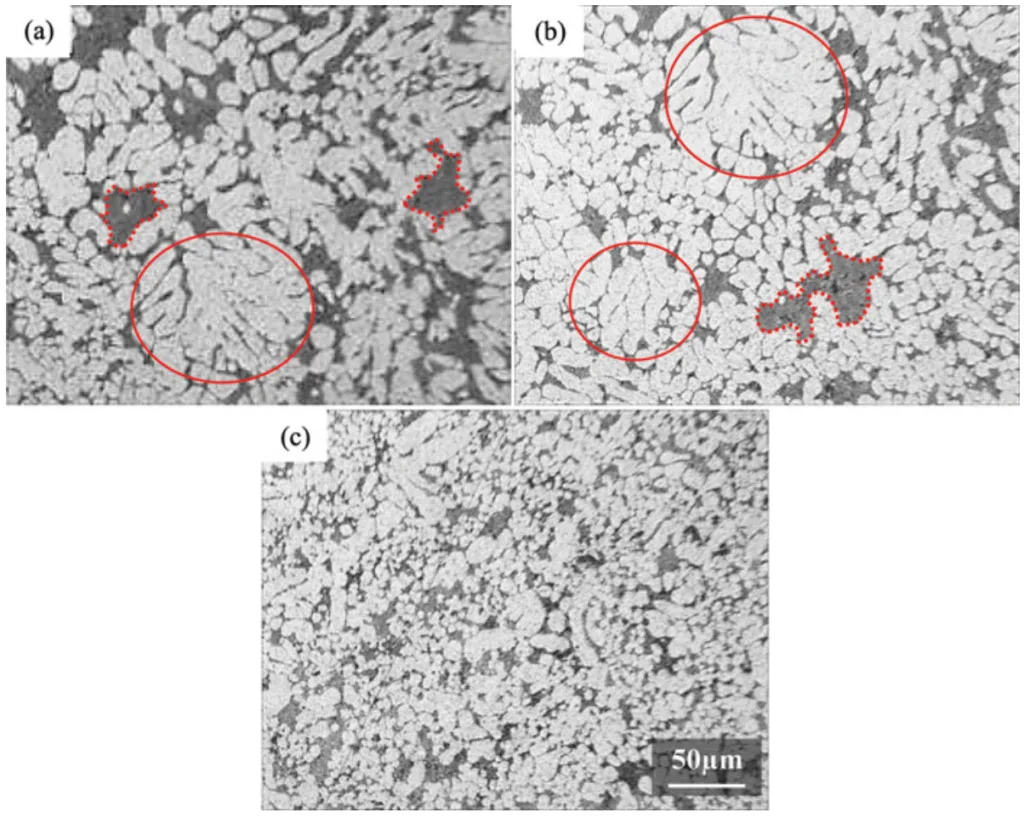

- Higher injection pressure led to an increased volume fraction of fine α2-Al grains.

- Effect of Fast-Shot Velocity:

- Tensile strength and yield strength showed minor variations (<10 MPa) with increasing fast-shot velocity.

- Elongation substantially increased from 9.73% to 13.77% as fast-shot velocity increased.

- Average sample density increased with higher fast-shot velocity.

- Increased fast-shot velocity reduced the size and volume fraction of coarse α1-Al grains and significantly increased the volume fraction of fine α2-Al grains, leading to a more compact structure with more spherical α-Al grains.

- Effect of Speed Transition Point Location:

- Mechanical properties (στ, σ0.2, elongation) initially increased and then decreased with the speed transition point location. The optimum location was found to be 220 mm, yielding στ of 351.1 MPa, σ0.2 of 200.65 MPa, and elongation of 13.77%.

- Density decreased along the filling direction when the speed transition point was at 220 mm.

- An early fast shot (S=190 mm) increased α2-Al grains but caused air entrapment. A delayed fast shot (S=250 mm) resulted in coarser α1-Al grains and non-compact structures due to prefilling.

- Optimal Injection Parameters:

- The optimal injection parameters were identified as an injection pressure of 100 MPa, a high-level fast-shot velocity, and a speed transition point location of 220 mm.

- These parameters resulted in good internal quality and superb tensile properties: 351.1 MPa (στ), 200.7 MPa (σ0.2), and 13.77% (elongation).

- Effect of Artificial Aging (at 250°C):

- After 3 hours of aging at 250°C, tensile strength and yield strength significantly increased from 351.1 MPa and 200.7 MPa to 380.5 MPa and 246.9 MPa, respectively.

- Elongation initially decreased from 13.77% to about 5.5% after 1 hour of aging, and then recovered to 11.48% after 3 hours of aging.

- The cooling method (air cooling vs. furnace cooling) after aging had an insignificant effect on mechanical properties.

- The microstructure of as-cast and age-treated specimens was found to be similar.

Figure Name List:

![FIGURE 3.—Microstructure of specimens formed by varying injection pressure: (a) 60 MPa, (b) 80 MPa, (c) 100MPa, (d) 125MPa. Brighter regions are a-Al grains and the darker regions are a mixture of empty and [Al þ Mg2Si] eutectic regions.](https://castman.co.kr/wp-content/uploads/image-2316-1024x838.webp)

- FIGURE 1.-(a) Profile of die casting samples; part within broken line was adopted in this work; (b) schematic of the rounded tensile specimens and locations of density samples (groups 1, 2, 3).

- FIGURE 2.-Effect of injection pressure on (a) mechanical properties and (b) density of the sample.

- FIGURE 3.-Microstructure of specimens formed by varying injection pressure: (a) 60 MPa, (b) 80 MPa, (c) 100 MPa, (d) 125 MPa. Brighter regions are α-Al grains and the darker regions are a mixture of empty and [Al + Mg2Si] eutectic regions.

- FIGURE 4.-Effect of fast-shot velocity on (a) mechanical properties and (b) density.

- FIGURE 5.-Microstructure of specimens formed by varying fast-shot velocity: (a) Low, (b) medium, (c) high. Coarse α1-Al dendrites and spaces between grains are respectively enclosed by solid and dotted lines in (a) and (b).

- FIGURE 6.-Effect of speed transition point locations on (a) mechanical properties and (b) density.

- FIGURE 7.-Morphology of the microstructure formed at varying speed transition points: (a) 190 mm, (b) 220 mm, (c) 250 mm.

- FIGURE 8.-Effects of aging under different cooling methods on mechanical properties: (a) air cooling, (b) furnace cooling.

7. Conclusion:

The effects of shot parameters and aging on the microstructure and mechanical properties of AlMg5Si2Mn die castings were systematically studied, and the main conclusions are now summarized.

Optimal injection parameters are pressure 100 MPa, high-level fast-shot velocity, and a speed transition point of 220 mm, and the best internal quality and mechanical properties (351.1 MPa, 200.7 MPa, and 13.77%) were obtained under those parameters. Specimen density decreased along the die filling direction, representing an effective pressure delivery process. After 3 h aging treatment under 250°C followed by cooling in air, ultimate tensile strength and yield strength gradually increased from 351.1 and 200.7 MPa to 380.5 and 246.9 MPa, respectively, while elongation decreased from 13.77 to 5.5% after 1 h aging and then increased to 11.48%.

8. References:

- [1] Cole, G.S.; Sherman, A.M. Light weight materials for automotive applications. Materials Characterization 1995, 35 (1), 3–9.

- [2] Crepeau, P.N. Effect of iron in Al-Si casting alloys: A critical review. AFS Transactions 1995, 103, 361-366.

- [3] Taylor, J.A. Iron-containing intermetallic phases in Al-Si based casting alloys. Procedia Materials Science 2012, 1 (0), 19-33.

- [4] Hielscher, U.; Koch, H.; Sternau, H.; Franke, A. Low iron content alloys for pressure die casting. Alluminio e Leghe (Italy) 1996, 8 (82), 127–129, 131-133, 135-136.

- [5] Koch, H.; Hielscher, U.; Sternau, H.; Franke, A. Magsimal-59-an AlMgMnSi type squeeze casting alloy designed for temper F. Light Metals 1996, 933-937.

- [6] Franke, R.; Dragulin, D.; Zovi, A.; Casarotto, F. Progress in ductile aluminum high pressure die casting alloys for the automotive industry. La Metallurgia Italiana 2007, 5, 21-26.

- [7] Campbell, J. Castings Practice: The Ten Rules of Castings; Elsevier Science, 2004; 102 pp.

- [8] Jin, C.K.; Kang, C.G. Fabrication by vacuum die casting and simulation of aluminum bipolar plates with micro-channels on both sides for proton exchange membrane (PEM) fuel cells. International Journal of Hydrogen Energy 2012, 37 (2), 1661-1676.

- [9] Gunasegaram, D.R.; Givord, M.; O'Donnell, R.G.; Finnin, B.R. Improvements engineered in UTS and elongation of aluminum alloy high pressure die castings through the alteration of runner geometry and plunger velocity. Materials Science and Engineering: A 2013, 559 (0), 276-286.

- [10] Ji, S.; Watson, D.; Fan, Z.; White, M. Development of a super ductile diecast Al-Mg-Si alloy. Materials Science and Engineering: A 2012, 556 (0), 824-833.

- [11] Otarawanna, S.; Gourlay, C.M.; Laukli, H.I.; Dahle, A.K. Formation of the surface layer in hypoeutectic Al-alloy high-pressure die castings. Materials Chemistry and Physics 2011, 130 (1-2), 251-258.

- [12] Otarawanna, S.; Gourlay, C.M.; Laukli, H.I.; Dahle, A.K. The thickness of defect bands in high-pressure die castings. Materials Characterization 2009, 12 (60), 1432-1441.

- [13] Otarawanna, S.; Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Feeding mechanisms in high-pressure die castings. Metallurgical and Materials Transactions A 2010, 41 (7), 1836-1846.

- [14] Hu, Z.; Wan, L.; Lü, S.; Zhu, P.; Wu, S. Research on the microstructure, fatigue and corrosion behavior of permanent mold and die cast aluminum alloy. Materials & Design 2014, 55 (0), 353-360.

- [15] Collot, J. Review of new process technologies in the aluminum die-casting industry. Materials and Manufacturing Processes 2001, 16 (5), 595-617.

- [16] Kaufmann, H.; Uggowitzer, P.J. Metallurgy and Processing of High-Integrity Light Metal Pressure Castings; Fachverlag Schiele & Schoen: Berlin, Germany, 2007; 178 pp.

- [17] Wang, B.S.; Xiong, S.M. Effects of shot speed and biscuit thickness on externaly solidified crystals of high-pressure diet cast AM60B magnesium alloy. Transactions of Nonferrous Metals Society of China 2011, 21 (4), 767–772.

- [18] Hamasaiid, A.; Wang, G.; Davidson, C.; Dour, G.; Dargusch, M.S. Interfacial heat transfer during die casting of an Al-Si-Cu alloy. Metallurgical and Materials Transactions A 2009, 40 (13), 3056-3058.

- [19] Lee, P.D.; Chirazi, A.; See, D. Modeling microporosity in aluminum-silicon alloys: A review. Journal of Light Metals 2001, 1 (1), 15-30.

- [20] Starke Jr., E.A. Aluminum Alloys: Alloy, Heat Treatment, and Temper Designation; 2001; 106-107.

- [21] Johannesson, B.; Cáceres, C.H. Effect of Si additions and heat treatment on the mechanical behaviour of an Al-5Mg cast alloy. International Journal of Cast Metals Research 2004, 17 (2), 94-98.

- [22] Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press, 2009; 61 pp.

9. Copyright:

- This material is a paper by "Zuqi Hu". Based on "Injection Parameters Optimization and Artificial Aging of Automotive Die Cast Aluminum Alloy".

- Source of the paper: https://doi.org/10.1080/10426914.2015.1004706

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.