This introduction paper is based on the paper "Influence of Super Large Single Piece Die Casting Production to Automotive Industry" published by "The 75th World Foundry Congress".

1. Overview:

- Title: Influence of Super Large Single Piece Die Casting Production to Automotive Industry

- Author: Liu Siong Song*, Chan Kwok Keung, Qiu Ge (L.K.Machinery International Limited, Hong Kong/China)

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress (Part 10: Die-Casting Technology)

- Keywords: Super Large Single Piece die-casting, new energy vehicles new production, underbody casting

2. Abstract:

Under the motivation of the innovation idea from a new energy vehicle company in US, and the great jobs and cooperation of several parties, a new type of Super Large Single Piece die-casting production was established, which not only reduced production costs, but also accelerated production speed and further reduced the weight of the car body. In new energy vehicles, with continued explosive growth and the demand for energy conservation and emission reduction, lightweighting of new energy vehicles has become an inevitable trend, which has also promoted the faster development of Super Large Single Piece die-casting development.

Large aluminum alloy die-casting parts such as car front underbody, rear underbody, and battery trays used to be composed of up to 70+ small parts. With this new technology, they can be produced by die-casting in one shot. It is not just to amplify all the equipment can be done, but there involves many difficulties and challenges. This article starts from the perspective of the die-casting unit, through the design and process optimization of each step, and through on-site verification, to improve the performance and production efficiency of die-casting products.

The production process of the die-casting unit includes metal ladling, injection, die cooling, parts removal, spraying, parts cooling, trimming, marking, and output.

3. Introduction:

The automotive industry is constantly evolving, with technological advancements driving improvements in vehicle design, manufacturing efficiency, and overall performance. One such groundbreaking innovation is the introduction of super large single-piece die casting production. This technology has the potential to revolutionize the way vehicles are manufactured, offering numerous benefits in terms of cost, weight, strength, and production speed.

In the traditional method, the underbody of the vehicle was produced by jointing 70~100 pieces of small parts [1] together to form the whole underbody. This method has involved hundreds of robots and large space for building the assembly line. The time used is in hours basis.

On using the super large die casting machine, the front underbody, or the rear underbody can be produced in a single piece which take around 100 seconds. Space required is much less, only around 800~1000 square meter per die casting cell (around the size of two basket ball court).

Die casting is a manufacturing process that involves injecting molten metal into a die cavity under high pressure. Traditionally, this process has been used to create smaller components that are then assembled into larger structures. However, recent advancements have enabled the production of much larger components in a single piece, a process known as super large single-piece die casting. This is also called the Giga casting.

In 2019, there is 6000 ton die casting machine, and then in 2020, the 9000 ton die casting machine was announced. In 2021, the 12000 ton die casting machine was shown and in 2023 the 16000 ton die casting machine was displayed.

When the clamping force of the die casting machine become larger and larger, this has indicated that the size of a single piece casting can be bigger and bigger.

4. Summary of the study:

Background of the research topic:

The automotive industry requires continuous improvement in design, efficiency, and performance. Traditional underbody manufacturing involved assembling 70-100 small parts, a complex, time-consuming, and space-intensive process. The rise of new energy vehicles (NEVs) and the push for lightweighting created a need for more efficient production methods. An innovation idea from a US NEV company spurred the development of Super Large Single Piece (SLSP) die casting.

Status of previous research:

Previously, vehicle underbodies were made by joining many small parts using hundreds of robots over hours [1]. Die casting was typically used for smaller components. Recent advancements led to increasingly larger die casting machines: 6000 tons (2019), 9000 tons (2020), 12000 tons (2021), and 16000 tons (2023), enabling the production of much larger single-piece castings.

Purpose of the study:

This article examines SLSP die casting from the perspective of the die-casting unit. It aims to improve the performance and production efficiency of die-casting products through design and process optimization of each step, verified on-site. It also discusses the advantages and influence of this technology on the automotive industry.

Core study:

The study focuses on the SLSP die casting production process, which includes metal ladling, injection, die cooling, parts removal, spraying, parts cooling, trimming, marking, and output. It analyzes the advantages of this technology: (1) Cost Efficiency (reduced parts, assembly, labor, tooling), (2) Weight Reduction (complex geometries, optimized material), (3) Enhanced Structural Integrity (eliminates joints/weak points), (4) Increased Production Speed (single cycle vs. long assembly), and (5) Design Flexibility (complex, innovative structures). The study also discusses the impact of SLSP die casting on Electric Vehicles (EVs), overall manufacturing efficiency, supply chain simplification, and sustainability.

5. Research Methodology

Research Design:

The paper does not explicitly state a formal research design. It presents a descriptive and analytical overview of the SLSP die casting technology and its application in the automotive industry, based on industry developments and technological advancements. The abstract mentions "design and process optimization" and "on-site verification" were used to improve performance and efficiency, suggesting an empirical component, but details of the design are not provided.

Data Collection and Analysis Methods:

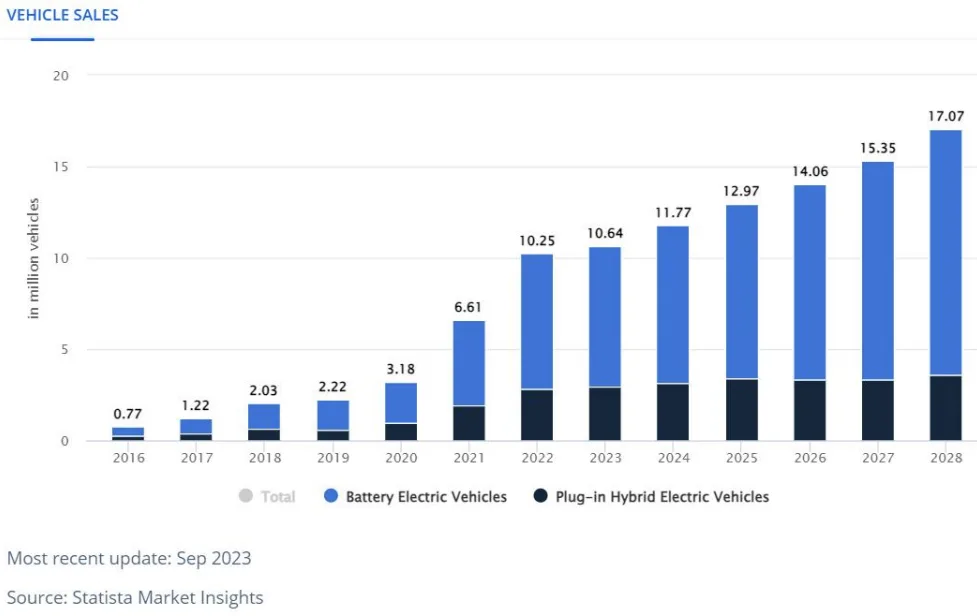

Specific data collection and analysis methods are not detailed in the paper. The study relies on describing the SLSP technology, outlining its process steps, analyzing its advantages, and discussing its impact based on industry trends (e.g., EV growth cited with reference [2] and illustrated in a figure) and technological progression (e.g., increasing machine tonnage shown in a figure). "On-site verification" is mentioned but the methodology for this verification is not elaborated upon.

Research Topics and Scope:

The research topic is the influence of Super Large Single Piece die casting production on the automotive industry. The scope covers the description of the technology, its production process (within the die-casting unit), its advantages (cost, weight, strength, speed, design), and its impact, particularly concerning new energy vehicles, manufacturing efficiency, supply chain, and sustainability. It focuses on large components like vehicle underbodies.

6. Key Results:

Key Results:

- SLSP die casting enables the production of large automotive components (e.g., front/rear underbody, battery trays), previously made of 70+ parts, in a single shot (~100 seconds).

- This technology significantly reduces manufacturing costs, labor, tooling, and factory space compared to traditional assembly methods.

- It facilitates weight reduction through optimized design and material distribution, crucial for NEV efficiency and performance.

- SLSP casting enhances structural integrity by eliminating joints from welding, bolting, or adhesives.

- Production speed is dramatically increased, allowing faster response to market demands.

- The technology offers greater design flexibility for complex and innovative vehicle structures.

- SLSP die casting positively impacts EV production, overall manufacturing efficiency, supply chain simplification (fewer parts), and sustainability (reduced waste, energy, emissions; lighter vehicles).

- The technology is applicable not only to EVs but potentially also to traditional Internal Combustion (IC) vehicles, suggesting a potential to lower overall vehicle production costs.

Figure Name List:

- Figure: Unlabeled figure under the heading "超大型首台套的创新与应用" illustrating the progression of large die casting machines developed by L.K. Machinery, showing increasing tonnage (6000t, 9000t, 12000t, 16000t) and the years they were introduced (2019, 2021, 2022, 2023 respectively - Note: The text states 9000t was announced in 2020, while the figure label under 9000t says 2021).

- Figure: Graph titled "VEHICLE SALES" showing historical (from 2016) and projected (to 2028) sales data (in million vehicles) for Total vehicles, Battery Electric Vehicles, and Plug-in Hybrid Electric Vehicles. (Source: Statista Market Insights, updated Sep 2023).

7. Conclusion:

Super large single-piece die casting represents a significant advancement in automotive manufacturing technology. Its potential to reduce costs, improve efficiency, enhance vehicle performance, and contribute to sustainability makes it a highly attractive option for automotive manufacturers. As the industry continues to evolve, the adoption of this technology is likely to play a pivotal role in shaping the future of vehicle production and design.

Since the Super Large Single Piece die casting is not only used in EV, but also possible to used for producing traditional IC vehicles. It is believed that the technology can lower the production cost of the automotive industry and thus lower the vehicle price in the coming future.

8. References:

- [1] https://x.com/tesla/status/1513886756923445254?lang=th

- [2] https://www.statista.com/outlook/mmo/electric-vehicles/worldwide#unit-sales

9. Copyright:

- This material is a paper by "Liu Siong Song, Chan Kwok Keung, Qiu Ge". Based on "Influence of Super Large Single Piece Die Casting Production to Automotive Industry".

- Source of the paper: [DOI URL not provided in the paper]

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.