This article introduces the paper 'Analysis on the Development of Light-Weight Automobile Body' published by 'ASCE'.

1. Overview:

- Title: Analysis on the Development of Light-Weight Automobile Body

- Author: Jianyou Zhao, Ling Li, Qichao Fan, and Xinyuan Zhu

- Publication Year: 2019

- Publishing Journal/Academic Society: CICTR 2019, American Society of Civil Engineers (ASCE)

- Keywords: lightweight automobile, vehicle weight reduction, lightweight vehicle body, automotive lightweight industry, China, new materials, structural optimization, NVH, economic analysis.

2. Abstracts or Introduction

The escalating demands for enhanced vehicle quality of life, coupled with growing economic and environmental consciousness, have positioned lightweight automobile development as a pivotal direction in the automotive sector. This paper, employing a literature analysis methodology, elucidates the developmental disparities in lightweight vehicles between China and developed nations. It delineates the concept of vehicle weight reduction, scrutinizes the lightweight vehicle body, its realization methodologies, performance attributes, and technical economy. Furthermore, the study explores the trajectory of China's automotive lightweight industry, encompassing critical facets such as cost, structure, and supply chain dynamics for lightweight automobiles.

3. Research Background:

Background of the Research Topic:

The rapid expansion of the automobile industry, driven by the continuous pursuit of improved living standards, has amplified the significance of economic and environmental considerations in vehicle design. This confluence of factors has propelled lightweight automobile development to the forefront as a mainstream trend in automotive engineering. As stated in the paper, "With the rapid development of the automobile industry and the continuous improvement of people's quality of life, economic, and environmental factors of vehicles have attracted people's attention, which makes lightweight automobile development an increasingly mainstream direction of automotive development."

Status of Existing Research:

Developed countries have historically been at the vanguard of lightweight vehicle design and development. The paper notes, "Developed countries have been the first to pay attention to the design and development of lightweight vehicles." Volkswagen's pioneering lightweight model in 1998 exemplified this early focus. Currently, North America leads as the largest market for automotive lightweight materials, with Europe following closely. Germany's automotive industry, characterized by its advanced manufacturing capabilities in new materials and machinery, holds a distinct advantage in promoting lightweight vehicle development. While China's lightweight industry commenced later, it is experiencing rapid acceleration, particularly with the growth of new energy vehicles. "China's lightweight industry started late, and its technology and application level lag behind developed countries such as Germany, the United States, and Japan. However, with the development of new energy vehicles, lightweight materials in China are accelerating."

Necessity of the Research:

Automotive lightweighting is presented as an indispensable strategy for achieving energy conservation and environmental protection within the automotive domain. Beyond alternative energy sources, reducing vehicle weight is crucial. Research data cited in the paper indicates that a 10% reduction in vehicle weight can yield a 6%-8% improvement in fuel efficiency. The car body, constituting approximately 30% of the vehicle's total mass, is a prime target for weight reduction. "According to the research data, the vehicle weight is reduced by 10% and the fuel efficiency will be increased by 6%-8%. The car body accounts for about 30% of the total mass of the car." Furthermore, lightweighting enhances vehicle performance parameters, including fuel economy, vehicle control stability, and collision safety. The paper emphasizes, "Therefore, the lighter body is beneficial to the fuel economy of the vehicle, vehicle control stability, and collision safety."

4. Research Purpose and Research Questions:

Research Purpose:

This study aims to comprehensively analyze the development of lightweight automobile bodies. The research objectives include: comparing the progress of lightweight vehicle development in China against developed countries; elucidating the significance of vehicle weight reduction; analyzing lightweight vehicle body design, realization methods, performance characteristics, and technical economy; and discussing the future development trajectory of China's automotive lightweight industry, considering cost, structural design, and supply chain aspects. The paper states its purpose as, "In this thesis, using the method of literature to analyze this problem, this article outlines the comparison between China and developed countries in the development of lightweight vehicles. This paper briefly describes the meaning of vehicle weight reduction, and it analyzes the lightweight vehicle body and its realization method, as well as the performance of a lightweight car body and the technical economy. Finally, the development direction of China's automotive lightweight industry and the three aspects of the cost, structure, and supply chain of China's lightweight automobiles are discussed."

Key Research:

The core research areas of this paper are:

- A comparative analysis of lightweight vehicle development between China and developed countries.

- In-depth examination of the lightweight vehicle body, encompassing its definition, implementation strategies, performance evaluation, and economic considerations.

- Exploration of the developmental direction of China's automotive lightweight industry, with a focus on cost optimization, structural innovation, and supply chain enhancement.

Research Hypotheses:

While not explicitly stated as formal hypotheses, the research operates under the implicit assumptions that:

- Lightweighting is a critical enabler for improving vehicle fuel efficiency, performance, and safety.

- The adoption of new materials and advanced manufacturing technologies is paramount for achieving effective automotive lightweighting.

- China's automotive lightweight industry faces unique challenges and opportunities in its development, necessitating tailored strategies for progress.

5. Research Methodology

Research Design:

The research employs a literature review design, synthesizing existing scholarly works and industry reports to analyze the development of lightweight automobile bodies. The paper explicitly mentions, "In this thesis, using the method of literature to analyze this problem…"

Data Collection Method:

Data collection is based on literature analysis, drawing upon published research, technical papers, and industry publications relevant to automotive lightweighting.

Analysis Method:

The analysis methods employed are primarily descriptive and comparative. The paper describes and analyzes the concepts, technologies, and trends in lightweight vehicle body development. It also compares the development status and approaches between China and developed countries.

Research Subjects and Scope:

The research focuses on the development of lightweight vehicles, specifically targeting the automobile body. The scope encompasses the technological advancements, material applications, structural designs, performance considerations, economic aspects, and future trends in lightweight automotive body engineering, with a particular emphasis on the Chinese automotive industry context.

6. Main Research Results:

Key Research Results:

The paper identifies three primary approaches to achieve automotive lightweighting:

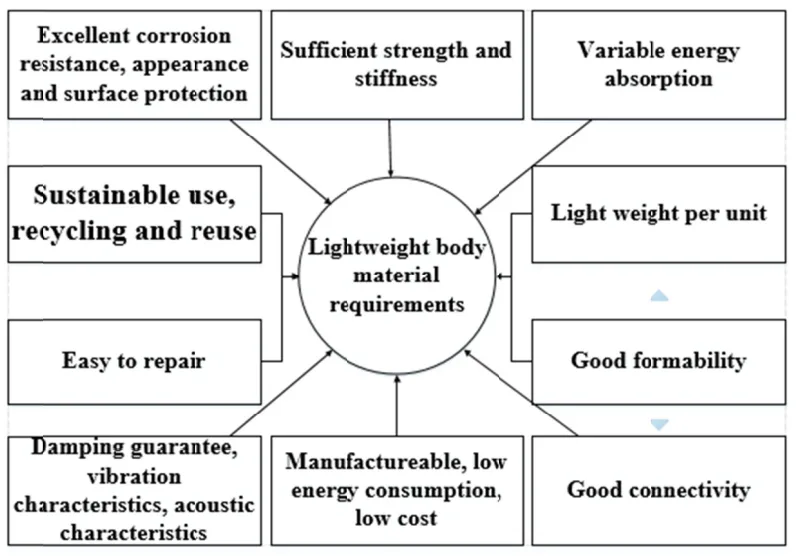

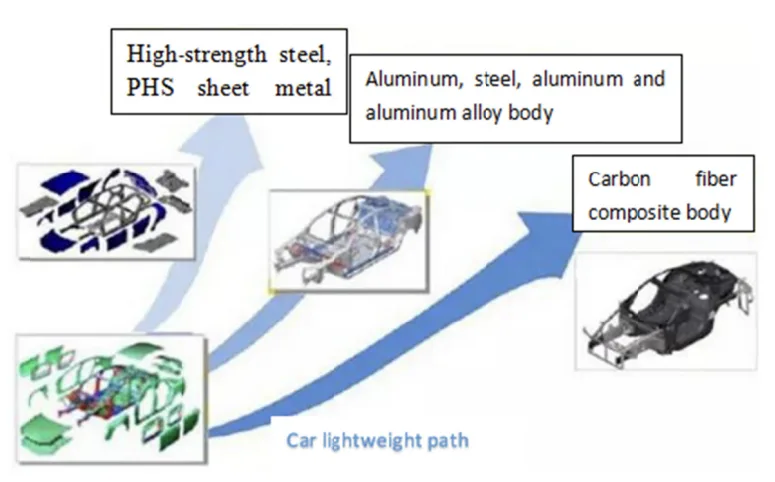

- New Materials Application: Utilizing lightweight materials that possess comparable mechanical properties to steel but with reduced density. Key material categories include high-strength steel, magnesium-aluminum alloys, and carbon fiber composites. Figure 1 outlines the requirements for lightweight materials, emphasizing factors like strength, stiffness, corrosion resistance, and manufacturability. Figure 2 illustrates the development trend of lightweight materials in automotive bodies, progressing from traditional steel to advanced composites.

- New Technology Implementation: Employing advanced manufacturing technologies to optimize material usage and structural efficiency. Hot stamping, pipe fitting hydroforming, and laser tailored blanking are highlighted as key technologies for lightweight production.

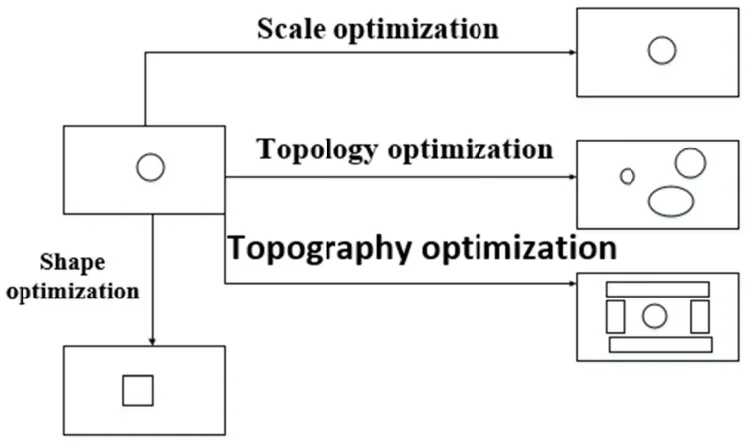

- Body Structure Optimization: Optimizing the vehicle body structure through design methodologies such as distributed structure, monolithic structure, hybrid structure, and modular structure. Four optimization schemes are presented in Figure 3: size optimization, shape optimization, topography optimization, and topology optimization. Topology optimization is recommended for conceptual design phases.

The paper further analyzes the performance of lightweight car bodies across several dimensions:

- Strength and Stiffness: Stiffness is emphasized as a critical design parameter, ensuring structural integrity and contributing to NVH (Noise, Vibration, and Harshness) and durability.

- Safety Analysis: Lightweighting must not compromise vehicle safety. The paper discusses both passive safety (collision energy absorption) and active safety (braking performance), noting that lightweight vehicles can enhance active safety due to improved braking.

- NVH Characteristics Analysis: NVH performance is a crucial aspect of vehicle quality. Lightweighting efforts must consider and mitigate potential NVH issues through material selection, structural design, and damping technologies.

- Economic Analysis of Lightweight Technology: Economic viability is a key consideration. The paper stresses the importance of economic analysis in lightweight design to balance material costs, manufacturing processes, and performance benefits.

Analysis of presented data:

- Figure 1. Requirements for lightweight materials: This figure (Figure 1 in the original paper) visually represents the multifaceted requirements for lightweight body materials. These include mechanical properties (sufficient strength and stiffness, variable energy absorption), functional attributes (excellent corrosion resistance, damping guarantee, easy to repair), manufacturing considerations (manufactureable, low energy consumption, low cost, good formability, good connectivity), and sustainability (sustainable use, recycling and reuse).

- Figure 2. Lightweight development in materials: This figure (Figure 2 in the original paper) illustrates the evolution of materials used in automotive lightweighting. It depicts a progression from traditional High-strength steel and PHS sheet metal, towards Aluminum, steel, aluminum and aluminum alloy body, and ultimately to Carbon fiber composite body, representing a pathway towards lighter materials.

- Figure 3. Four optimization schemes: This figure (Figure 3 in the original paper) outlines four distinct structural optimization schemes: Scale optimization, Shape optimization, Topology optimization, and Topography optimization. It suggests a hierarchical approach, recommending topology optimization for conceptual design and size/shape optimization for detailed design phases.

Figure Name List:

- Figure 1. Requirements for lightweight materials

- Figure 2. Lightweight development in materials

- Figure 3. Four optimization schemes

7. Conclusion:

Summary of Key Findings:

The study concludes that lightweight automobile bodies are the mainstream direction in automotive development, driven by economic and environmental imperatives. China's automotive industry is actively pursuing lightweighting technologies. Key strategies for achieving lightweighting include the application of new lightweight materials (high-strength steel, aluminum alloys, carbon fiber composites, plastics), implementation of advanced manufacturing technologies (hot stamping, hydroforming), and optimization of body structure (topology optimization). Performance analysis must encompass structural strength, stiffness, safety (passive and active), and NVH characteristics. Economic analysis is crucial for ensuring the cost-effectiveness of lightweighting solutions. The future direction for China's automotive lightweight industry involves increased adoption of all-aluminum bodies, wider use of non-metallic materials like plastics, and integration of high-tech applications such as 3D printing.

Academic Significance of the Study:

This paper provides a comprehensive handbook-level overview of lightweight automobile body development. It synthesizes existing literature to present a structured analysis of the key technologies, materials, design methodologies, and performance considerations in automotive lightweighting. The comparative perspective on China and developed countries adds valuable context to the global landscape of lightweight vehicle engineering.

Practical Implications:

The findings offer practical guidance for automotive engineers, designers, and manufacturers in pursuing lightweighting strategies. It highlights the importance of a holistic approach that considers materials, manufacturing processes, structural design, performance attributes, and economic factors. For the Chinese automotive industry, the paper underscores the need for continued innovation in materials, technologies, and supply chain development to effectively advance lightweight vehicle production.

Limitations of the Study and Areas for Future Research:

As a literature review, this study is inherently limited by the scope and availability of existing research. Empirical validation of the analyzed technologies and design methodologies through experimental studies and real-world applications would be a valuable area for future research. Further investigation into specific lightweight materials, manufacturing processes, and market dynamics within the Chinese automotive industry is also recommended. Additionally, exploring the life cycle assessment and sustainability aspects of different lightweighting approaches would be a pertinent direction for future studies.

8. References:

- Ao, B. Q. (2001). “The latest developments in lightweight automotive materials technology.” Automotive Technology and Materials, 2002(8).

- Chen, H. H., and Deng, H. J. (1998). Modern composite materials. Beijing: China Materials Publishing House.

- Chen, X. B. (2011). “Research on lightweight body based on modern design method and improving vehicle collision safety,” Doctoral dissertation, Jilin: Jilin University.

- Chen, Y. K. (2012). “Application of thermoforming process in automobile lightweighting,” Doctoral dissertation, Hunan: Hunan University.

- Li, Z. J., and Cheng, L. (2016). “Development status and implementation of automobile lightweight technology,” Doctoral dissertation, Henan: Hebi Automotive Engineering Vocational College.

- Sun, L. Y. (2011). Theory, method and engineering example of lightweight design of body structure. Beijing: National Defense Industry Press, 17-119.

- Wang, H. Y, and Chen, J. Y. (2009). Lightweight structure and lightweight materials for automobile body. Beijing: Peking University Press, 1-118.

- Wang, H. Y., and Chen, J. Y. (2009). Foundation of automobile body design [M]. Beijing: Peking University Press, 222-236.

- Wang, J. J. (2012). “Environmental impact assessment and sensitivity analysis of lightweight vehicle body life cycle,” Doctoral dissertation, Hefei: Hefei University of Technology.

- Zhang, J. S. (2016). “Automotive design based on lightweight technology,” Doctoral dissertation, Shenyang: Shenyang Aerospace University.

- Zhang, Y. R. (2006). Automotive materials. Hefei: Hefei University of Technology Press, 18-102.

- Zhu, M. T., Zhi, S. Y., and Wang, L. M. (2014). Modern design of automobile body. Beijing: National Defense Industry Press, 156-171.

9. Copyright:

- This material is "Jianyou Zhao et al."'s paper: Based on "Analysis on the Development of Light-Weight Automobile Body".

- Paper Source: DOI URL (Not available in the paper, source from ASCE library if possible).

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.