This article introduces the paper ['Development of creep-resistant magnesium casting alloys for high temperature automotive applications'] presented at the ['WIT Transactions on The Built Environment, Vol 97, 2008 WIT Press']

1. Overview:

- Title: Development of creep-resistant magnesium casting alloys for high temperature automotive applications

- Author: L. Han, H. Hu & D. O. Northwood

- Publication Year: 2008

- Publishing Journal/Academic Society: WIT Transactions on The Built Environment, Vol 97, WIT Press

- Keywords: magnesium alloy, calcium addition, creep resistance, solid solution hardening, dispersion hardening.

2. Research Background:

Background of the Research Topic:

Magnesium alloys, owing to their low specific gravity, are highly desirable in automotive and aerospace sectors. Conventional Mg casting alloys, primarily Mg-Al based systems with additions of Zn, Mn, or Si such as AZ91 alloy (Mg-9.0Al-1.0Zn, wt.%), exhibit excellent castability, mechanical properties, and corrosion resistance, leading to their widespread use in the automotive industry. However, the application of these conventional alloys is restricted to components operating below 150 °C due to the rapid degradation of mechanical properties, particularly creep resistance, at elevated temperatures. The development of new creep-resistant Mg casting alloys is imperative for applications in transmission cases (up to ~175 °C), engine blocks (~250 °C), and pistons (~300 °C).

Status of Existing Research:

The addition of Calcium (Ca) to Mg-Al alloys has been explored as a cost-effective and density-efficient method to enhance both room-temperature and elevated-temperature mechanical properties. In Mg-Al-Ca alloys, Ca-containing eutectic phases progressively replace the β-Mg17Al12 phases, resulting in improved mechanical properties attributed to microstructural refinement with increasing Ca content. Prior research has identified the eutectic compounds in Mg-Al-Ca alloys as Al₂Ca, Mg2Ca, (Al, Mg)2Ca, or mixtures thereof, due to their crystallographic similarities. However, a detailed investigation into the microstructural dependence on the level of Ca addition was lacking.

Necessity of the Research:

A comprehensive study on the influence of Calcium addition on the microstructure and creep resistance of Mg-Al-Ca alloys is crucial for the advancement of high-performance creep-resistant alloys. Understanding the microstructural evolution and its correlation with mechanical properties is essential for tailoring alloys for demanding high-temperature automotive applications.

3. Research Purpose and Research Questions:

Research Purpose:

The primary research purpose is to develop high performance creep-resistant magnesium alloys suitable for elevated temperature automotive applications. This objective is pursued through the microstructural design of cast alloys to effectively prevent grain boundary sliding and restrict the motion of lattice dislocations within the primary α-Mg grains. Specifically, this paper describes the development of Mg-Al-Ca casting alloys as a promising approach.

Key Research:

This research focuses on investigating the effect of Calcium (Ca) content on the microstructural evolution and creep resistance of permanent mold (PM) cast Mg-Al-Ca alloys. The study aims to characterize the microstructure and mechanical behavior of AM50 base alloy and Mg-5.0 wt.% Al alloys with 1.0 wt.% and 2.0 wt.% Ca additions.

Research Hypotheses:

It is hypothesized that the addition of Calcium to Mg-Al alloys will lead to:

- Refinement of the microstructure, characterized by a reduction in grain size and secondary dendrite arm spacing (SDAS).

- Alteration of eutectic phases from discontinuous β-Mg17Al12 to a continuous network of Ca-containing eutectic phases.

- Enhancement of creep resistance through mechanisms including grain refinement, solid solution hardening, and dispersion hardening attributed to nanoscale eutectic phases.

- Increased thermal stability of eutectic phases, with (Al, Mg)2Ca phase exhibiting higher stability compared to β-Mg17Al12 phase.

4. Research Methodology

Research Design:

This research employs an experimental design focused on comparative alloy development. Two levels of Calcium addition (1.0 and 2.0 wt.%) were introduced to the AM50 base alloy to produce PM Mg-Al-Ca alloys. The microstructural and mechanical properties of these alloys were then systematically compared to the AM50 base alloy.

Data Collection Method:

- Microstructural Characterization: Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) were utilized to characterize the microstructure. Samples were prepared by polishing and chemical etching using Glycol etchant. SEM (JEOL JSM-5800LV) was used for morphological and microchemical characterization. TEM (JEOL 2010) equipped with Energy Dispersive X-ray Spectrometer (EDS) was employed for detailed phase analysis at an operating voltage of 200 keV.

- Mechanical Property Evaluation: Vickers microhardness was measured using a Buehler microhardness tester with a load of 200 g. Nano-indentation creep tests were conducted using a Hysitron Ubi®1 nanomechanical test instrument with a Berkovich indenter at room temperature.

Analysis Method:

- Quantitative Image Analysis: Image analysis was performed to measure the secondary dendrite arm spacing (SDAS) and the volume fraction of secondary eutectic phases.

- Microscopy Analysis: SEM micrographs were analyzed to observe the microstructural evolution and phase distribution. TEM was used for high-resolution imaging and phase identification, complemented by EDS for elemental analysis.

- Mechanical Testing Data Analysis: Microhardness values were compared to assess the effect of Ca content on alloy hardness. Nano-indentation creep curves were analyzed to evaluate the creep resistance of different alloys.

Research Subjects and Scope:

The research subjects were permanent mold (PM) cast AM50 (Mg-5.0Al-0.3Mn, wt.%) alloy and Mg-Al-Ca alloys with compositions Mg-5.0Al-1.0Ca and Mg-5.0Al-2.0Ca (wt.%). The scope of the research was limited to the investigation of microstructure and creep resistance at room temperature, focusing on the effect of Calcium addition within the specified compositional range.

5. Main Research Results:

Key Research Results:

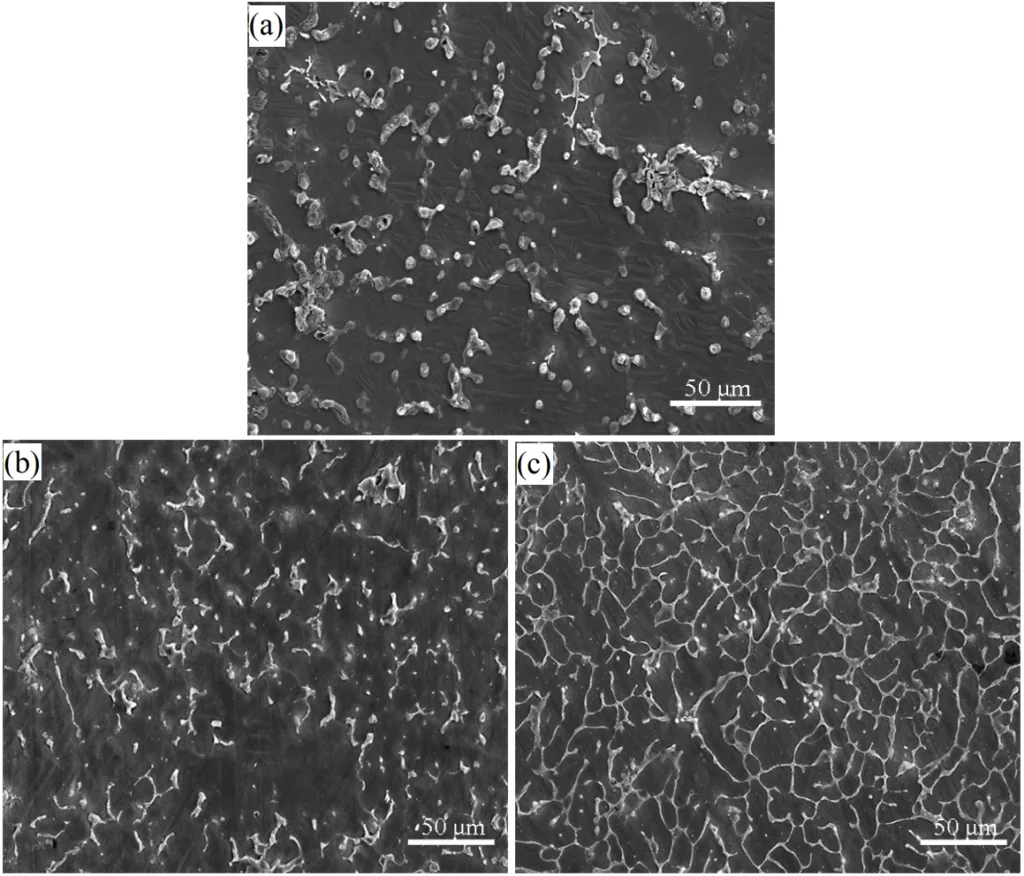

- Grain Refinement: The addition of Calcium significantly refined the grain structure of the Mg-Al alloy. A marked grain refining effect was observed with increasing Ca content, as shown in Figure 1.

- Secondary Dendrite Arm Spacing (SDAS) Reduction: Quantitative image analysis revealed a substantial reduction in SDAS with increasing Ca content. SDAS values decreased from 39.1 ± 6.4 µm at 0.0 wt.% Ca to 9.8 ± 3.1 µm at 2.0 wt.% Ca.

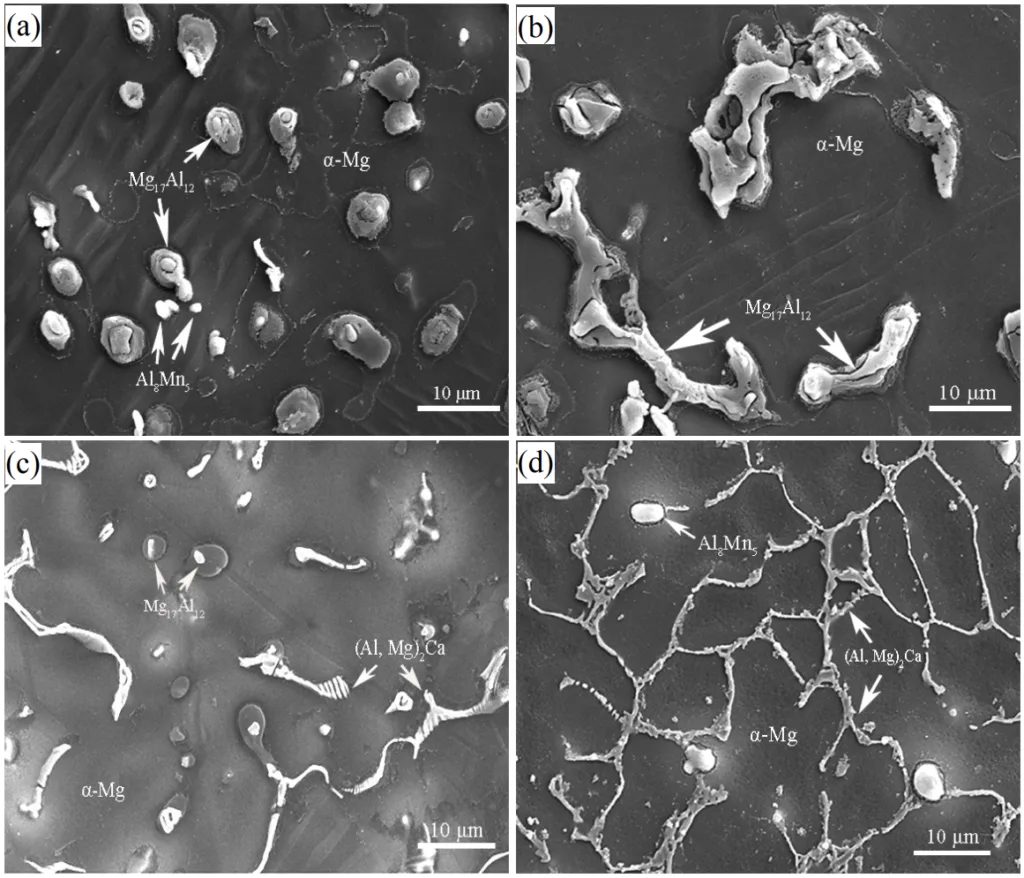

- Eutectic Phase Evolution: The morphology of eutectic phases transformed from completely divorced, discontinuous eutectic phases in the AM50 alloy to a continuous network of eutectic phases with increasing Ca content (Figure 1).

- Phase Transformation: At 2.0 wt.% Ca addition (AC52 alloy), the β-Mg17Al12 phase was completely replaced by Ca-containing phases. The Al-rich eutectic α-Mg phase, typically present in die-cast Mg-Al-Mn alloys, disappeared in the PM AC52 alloy.

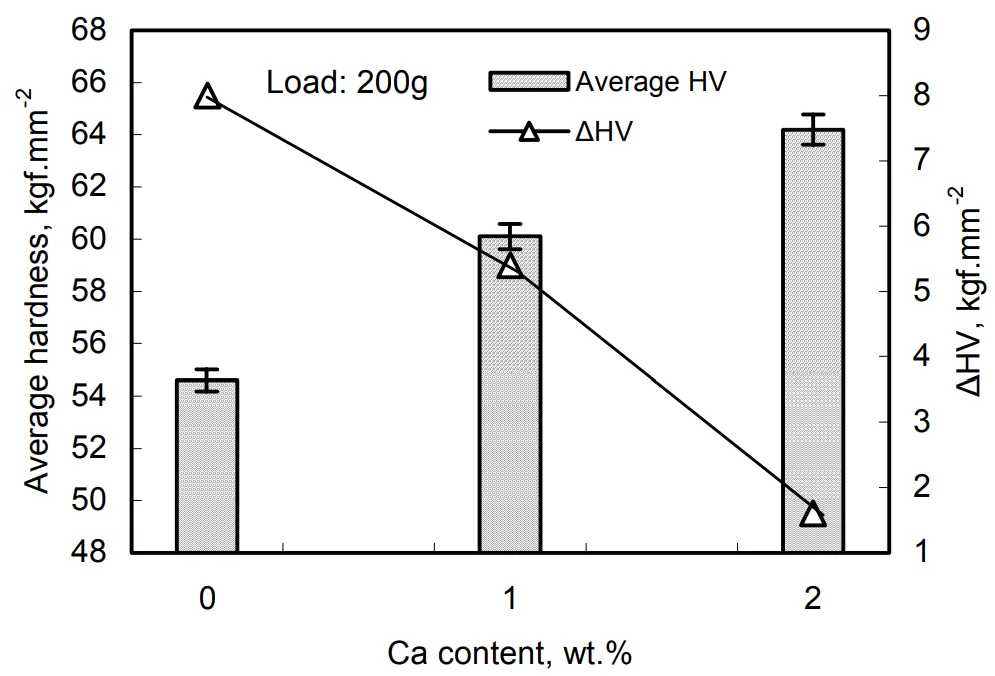

- Hardness Improvement: The average hardness across the casting thickness increased with increasing Ca content. Compared to the PM AM50 alloy with an average hardness of 54.6 kgf.mm², the PM AC52 alloy exhibited a significantly increased average hardness of 9.6 kgf.mm². (Figure 5)

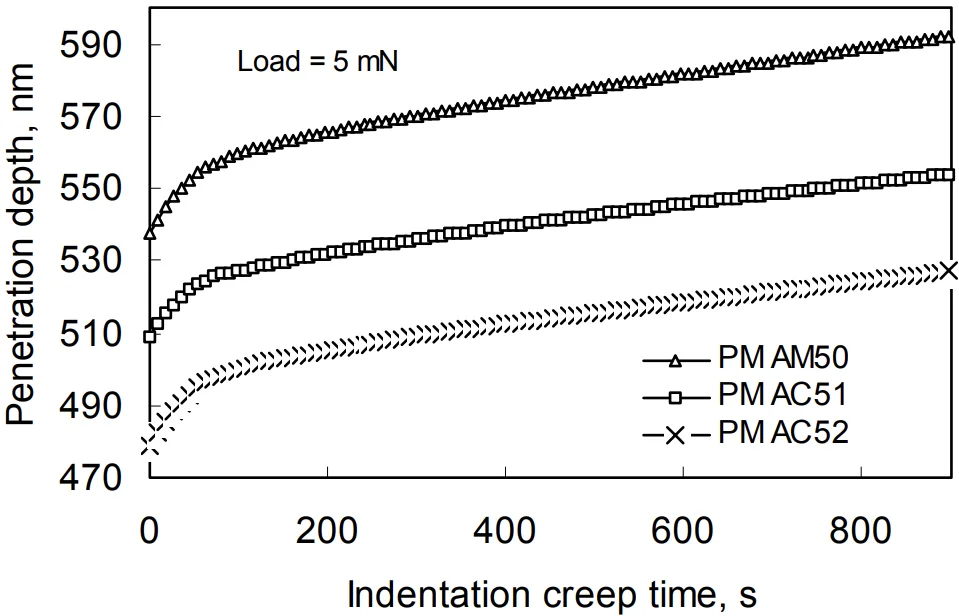

- Enhanced Creep Resistance: Nano-indentation creep tests demonstrated that the PM AC52 alloy exhibited lower penetration depths compared to PM AM50 and AC51 alloys at the same indentation time, indicating superior creep resistance. (Figure 6)

- Nanoscale Precipitates: TEM micrographs revealed nanoscale Ca-containing precipitates dispersed within the primary α-Mg grains of the AC52 alloy (Figure 4).

Data Interpretation:

The observed grain refinement and reduction in SDAS are attributed to the grain refining effect of Calcium addition. The transformation of eutectic phases and the formation of a continuous network of Ca-containing phases along grain boundaries contribute to the improved mechanical properties. The increased hardness and creep resistance are attributed to a combination of precipitation hardening, solid solution hardening from Ca addition, and dispersion hardening from nanoscale eutectic phases. The higher thermal stability of the (Al, Mg)2Ca phase, which replaces β-Mg17Al12 at higher Ca levels, further contributes to enhanced creep resistance at elevated temperatures.

Figure Name List:

- Figure 1: SEM micrographs of the microstructural evolution of the PM Mg-Al-Ca alloys with different Ca contents: (a) 0.0, (b) 1.0 and (c) 2.0 (wt.%).

- Figure 2: SEM micrographs of the PM AM50 alloy in: (a) skin region, and (b) central region, and the PM AC51 alloy in: (c) central region and the PM AC52 alloy in: (d) central region.

- Figure 3: SEM micrographs of precipitation phases in: (a) skin region and (b) central region of the PM AC52 alloy.

- Figure 4: TEM micrograph of dispersed eutectic phases in the AC52 alloy.

- Figure 5: Average hardness values across the casting thickness and the hardness difference between the skin and central regions for the three PM Mg-Al and Mg-Al-Ca alloys.

- Figure 6: Indentation creep curves for PM AM50, AC51 and AC52 alloys at an applied load of 5 mN at room temperature.

6. Conclusion:

Summary of Main Results:

The addition of Calcium to Mg-Al alloys effectively refines the microstructure, transitioning from coarse, discontinuous eutectic phases in PM AM50 alloy to fine (Al, Mg)2Ca eutectic phases with increasing Ca content. Quantitative image analysis confirmed a significant reduction in SDAS and an increase in the volume fraction of eutectic phases with Ca addition. At 2.0 wt.% Ca, the β-Mg17Al12 phase is completely replaced by the (Al, Mg)2Ca phase, which exhibits enhanced thermal stability at higher temperatures compared to β-Mg17Al12. Consequently, the hardness and creep resistance of the Mg-Al-Ca alloys are significantly improved.

Academic Significance of the Research:

This research provides a detailed microstructural and mechanical characterization of Mg-Al-Ca alloys, elucidating the critical role of Calcium addition in enhancing creep resistance. The study contributes to the fundamental understanding of phase transformations and strengthening mechanisms in magnesium alloys, particularly the influence of Ca on eutectic phase morphology and stability.

Practical Implications:

The development of creep-resistant Mg-Al-Ca alloys, as demonstrated in this study, offers significant practical implications for the automotive industry. These alloys are promising candidates for high-temperature applications such as transmission cases, engine blocks, and pistons, potentially expanding the utilization of magnesium die castings in critical automotive components.

Limitations of the Research

The creep resistance evaluation in this study was primarily conducted at room temperature. Further investigations at elevated temperatures relevant to automotive applications are necessary to fully validate the high-temperature creep performance. The research focused on a limited range of alloy compositions based on AM50 with specific Ca additions. Exploring a broader compositional range and incorporating other alloying elements could further optimize alloy performance.

7. Future Follow-up Research:

- Directions for Follow-up Research

Future research should focus on:- Evaluating the creep behavior of Mg-Al-Ca alloys at elevated temperatures (175-300 °C) to simulate actual automotive operating conditions.

- Investigating a wider range of Calcium content and exploring the synergistic effects of other alloying additions to further enhance creep resistance and other mechanical properties.

- Conducting long-term creep tests to assess the long-term stability of the microstructure and creep performance.

- Areas Requiring Further Exploration

Further exploration is required in:- Fatigue behavior and other critical mechanical properties of Mg-Al-Ca alloys for automotive applications.

- Optimization of permanent mold casting parameters to achieve desired microstructure and mechanical properties in Mg-Al-Ca alloys.

- Detailed investigation of phase transformation kinetics and thermodynamic modeling to predict and control phase evolution in these alloys.

8. References:

- [1] Hu H., Yu A., Li N. & Allison J. E., Potential magnesium alloys for high temperature die cast automotive applications: A review. Materials and Manufacturing Processes, 18(5), pp. 687–717, 2003.

- [2] Yuan G., Wang Q. & Ding W., High temperature deformation behavior of permanent casting AZ91 alloy with and without Sb addition. Journal of Materials Science, 37 (1), pp. 127–132, 2002.

- [3] Moreno I. P., Nandy T. K., Jones J. W., Allison J. E. & Pollock T. M., Microstructural stability and creep of rare-earth containing magnesium alloys. Scripta Materialia, 48(8), pp. 1029–1034, 2003.

- [4] Hu H., Shang R. & Li N., Effect of Ca addition on grain microstructure development of Mg alloy AM60. AFS Transactions, 111, pp. 1019–1029, 2003.

- [5] Ozturk K., Zhong Y., Luo A. & Liu Z., Creep resistant Mg-Al-Ca alloys: Computational thermodynamics and experimental investigation. JOM, 55(11), pp. 40–44, 2003.

- [6] Luo A. & Powell R., Tensile and compressive creep of magnesium-aluminum-calcium based alloys. Magnesium Technology 2001, TMS Annual Meeting, pp. 137–144, 2001.

- [7] Suzuki A., Saddock N. D., Jones J. W. & Pollock T. M., Structure and transition of eutectic (Mg, Al)2Ca Laves phase in a die-cast Mg-Al-Ca base alloy. Scripta Materialia, 51(10), pp. 1005–1010, 2004.

- [8] Luo A. A., Balogh M. P. & Powell B. R., Creep and microstructure of magnesium-aluminum-calcium based alloys. Metallurgical and Materials Transactions A, 33A(3), pp. 567–574, 2002.

- [9] Kim Y. K., Son H. T., Lee J. S., Oh I. H., Kim H. J. & Bae J. C., Microstructure and mechanical properties of Mg-Al-Ca alloys with yttrium addition. Key Engineering Materials, 345–346, pp. 73–76, 2007.

- [10] Zhong Y., Luo A., Sofo J. O. & Liu Z., Laves phases in Mg-Al-Ca alloys. Magnesium Technology 2004, TMS Annual Meeting, pp. 317–323, 2004.

- [11] Gertsman V. Y., Jian L., Su X., Thomson J. P. & Mahi S., Microstructure and second-phase particles in low- and high-pressure die-cast magnesium alloy AM50. Metallurgical and Materials Transactions A, 36A(8), pp. 1989-1997, 2005.

- [12] Lee S. G., Patel G. R. & Gokhale A. M., Macro-segregation in high-pressure die-cast AM60 alloy. Magnesium Technology 2005, TMS Annual Meeting, pp. 377-380, 2005.

- [13] Yao J. & Liu Z., Influence of AZ91 die-casting on its microstructure and mechanical properties. Rare Metals, 21(SUPPL.), pp. 69–74, 2002.

- [14] Zhou M., Li N. & Hu H., Effect of section thicknesses on tensile behavior and microstructure of high pressure die cast magnesium alloy AM50. Materials Science Forum, 475–479, pp. 463–468, 2005.

- [15] Han L., Hu H., Northwood D. & Li N., Microstructure and nano-scale mechanical behavior of Mg-Al and Mg-Al-Ca alloys. Materials Science and Engineering A, 473(1-2), pp. 16-27, 2008.

- [16] Han L., Hu H. & Northwood D., Effect of Ca additions on microstructure and microhardness of an as-cast Mg–5.0 wt.% Al alloy. Materials Letters, 62 (3), pp. 381-384, 2008.

- [17] Han, L., Microstructure characterization and micro- and nano-scale mechanical behavior of Mg-Al and Mg-Al-Ca alloys, PhD Thesis, University of Windsor, 2007.

- [18] Huang Y. D., Hort N., Leil T. A., Kainer K. U. & Y. L. Liu, Effect of microstructural inhomogeneity on creep response of Mg-Sn alloys. Key Engineering Materials, 345–346, pp. 561–564, 2007.

9. Copyright:

- This material is "L. Han, H. Hu & D. O. Northwood"'s paper: Based on "Development of creep-resistant magnesium casting alloys for high temperature automotive applications".

- Paper Source: doi:10.2495/HPSM080061

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.