Beyond the Machine: How Smart Scheduling Slashes Costs in Die Casting for NEV Motor Shells

This technical summary is based on the academic paper "Design of Automated Production Line and Optimization of Production Scheduling for Die Casting of New Energy Vehicle Motor Shell" by Yan Lu, Da-Lei Zhang, and Hao-Sheng Lu, published in Journal of Computers (2025). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Production Scheduling for Die Casting

- Secondary Keywords: New Energy Vehicle Motor Shell, Integrated Die Casting, Particle Swarm Optimization, Automated Production Line

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Effectively scheduling the production of diverse New Energy Vehicle (NEV) motor shells on parallel die-casting machines is complex, with costs arising from mold changes, storage, and equipment idle time.

- The Method: The research proposes an automated production line centered on a die-casting island and develops a mathematical model to minimize a composite cost function using an improved particle swarm optimization (PSO) algorithm.

- The Key Breakthrough: In a simulated 3-machine, 5-order scenario, the algorithm successfully scheduled production, converging at the 40th iteration to a minimum cost of 602,300 yuan and reducing the soup-changing robot's waiting time to just 1.6 seconds.

- The Bottom Line: This advanced scheduling approach provides a validated framework for reducing operational costs and improving throughput in high-volume, multi-product die-casting environments.

The Challenge: Why This Research Matters for HPDC Professionals

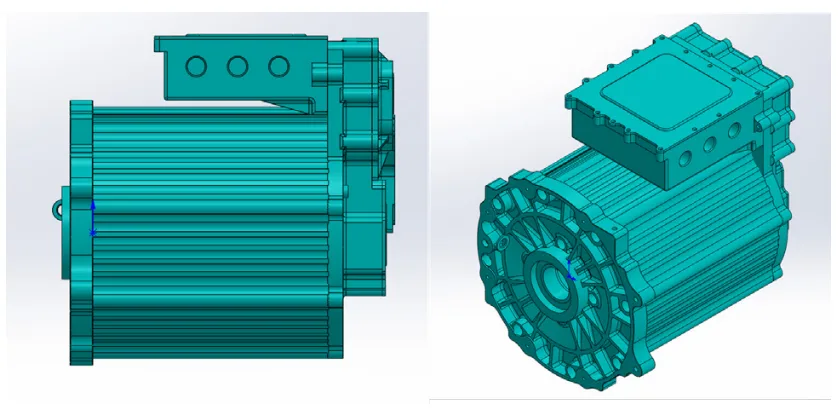

The rapid growth of the New Energy Vehicle (NEV) market has placed immense pressure on the manufacturing of core components like the drive motor. The motor housing, a critical part typically produced via die casting, must meet stringent performance requirements. With the industry trend towards lightweighting and integrated die casting—where multiple parts are combined into a single, complex casting—production efficiency has become paramount.

However, managing a modern die-casting workshop presents significant scheduling challenges. Manufacturers must juggle multiple production orders for different motor housings across several die-casting machines. This creates a complex optimization problem where minimizing costs from mold replacement downtime, in-process inventory storage, and the idle time of critical equipment like soup-changing robotic arms is essential for maintaining profitability and meeting tight delivery deadlines. This research was undertaken to design a fully automated production line and create an intelligent scheduling system to solve this multifaceted problem.

The Approach: Unpacking the Methodology

The study took a two-part approach: designing an automated production system and then developing an algorithm to optimize its operation.

1. Automated Production Line Design:

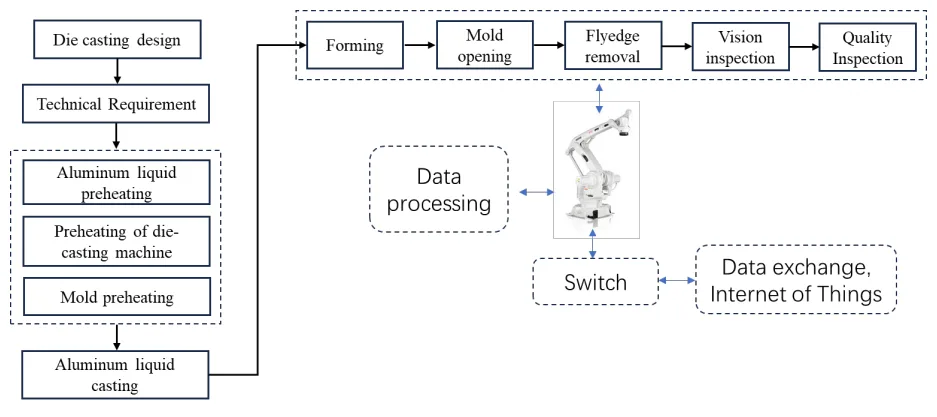

The proposed system is centered around the die-casting island. Automation is enhanced by adding robot modules for all handling and transfer processes. The complete production flow is designed as:

Die-casting → Robot parts taking → Visual system inspection → Cooling water tank → Grinding and cutting → Laser engraving → Product output.

The entire line is controlled by a Siemens S7-1200 PLC and integrated into an Industrial Internet of Things (IIoT) framework, allowing for remote monitoring and control via a cloud platform.

2. Production Scheduling Optimization:

To find the most cost-effective production sequence, the researchers established a mathematical model with the objective of minimizing a composite production cost. This cost function is composed of three key elements:

- Mold Replacement Cost: The cost associated with production downtime during mold changes between different product batches.

- Storage Cost: The cost incurred when a batch is completed before its delivery date, requiring storage.

- Robotic Arm Waiting Time: The cost equivalent of the idle time for the soup-changing robotic arm, a critical resource in the material flow.

To solve this complex optimization problem, an improved particle swarm optimization (PSO) algorithm was developed. The standard PSO was enhanced by integrating the simulated annealing (SA) algorithm to refine the search process and prevent premature convergence to a suboptimal solution.

The Breakthrough: Key Findings & Data

The effectiveness of the proposed scheduling algorithm was verified through a simulation based on a real-world production scenario involving 5 different product orders and 3 die-casting machines.

Finding 1: Effective Scheduling in a Complex Multi-Product Environment

The algorithm successfully generated a production schedule for the complex task. The total operating times for the three die-casting machines were 158.6 hours, 162.8 hours, and 192.6 hours, respectively. The simulation demonstrated the model's practical capability, showing that out of a total of 5 product orders, 4 were completed on schedule, while only 1 was delayed. This highlights the model's ability to manage production trade-offs to achieve an overall optimal result.

Finding 2: Rapid Convergence to Significant Cost and Time Savings

The performance of the optimization algorithm demonstrated both speed and effectiveness. As shown in Figure 10 of the paper, the algorithm rapidly converged to an optimal solution. By the 40th iteration, the composite production cost stabilized at a minimum value of 602,300 yuan. Simultaneously, the shortest waiting time for the soup-changing manipulator was reduced to just 1.6 seconds. This rapid convergence indicates the algorithm is efficient enough for use in dynamic production environments where schedules may need to be recalculated frequently.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the production sequence based on a holistic cost model—not just mold change time—may contribute to significantly reducing overall operational costs and equipment idle time. The impact of the soup-changing robot's waiting time is a critical factor to include in efficiency calculations.

- For Quality Control Teams: The automated line design in Figure 2 incorporates integrated visual inspection. The data from such systems can be fed back into the scheduling model to prioritize orders with higher quality yields or adjust production speeds based on real-time defect rates.

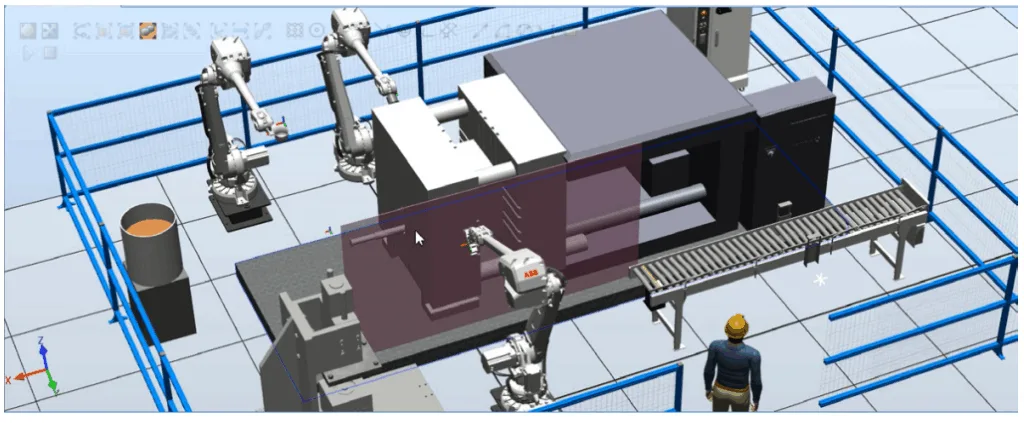

- For Plant Managers and Systems Integrators: The findings indicate that the interaction between production machines and material handling robots is a major bottleneck. The paper's conclusion highlights the importance of designing buffer zones between stations. This is a valuable consideration in the early design phase of an automated line to ensure smooth material flow and prevent costly downtime.

Paper Details

Design of Automated Production Line and Optimization of Production Scheduling for Die Casting of New Energy Vehicle Motor Shell

1. Overview:

- Title: Design of Automated Production Line and Optimization of Production Scheduling for Die Casting of New Energy Vehicle Motor Shell

- Author: Yan Lu, Da-Lei Zhang, and Hao-Sheng Lu

- Year of publication: 2025

- Journal/academic society of publication: Journal of Computers Vol. 36 No. 1

- Keywords: electric motor casing, integrated die casting, particle swarm optimization algorithm, production scheduling

2. Abstract:

For the production of drive motors for new energy vehicles, this article focuses on the die-casting island as the production core. By adding robot modules in the handling and transfer process, the automation process around the die-casting island is improved to achieve automatic loading and unloading of the overall production process. Then, based on the production order requirements, the optimization of the entire production process of the motor order is taken as the scheduling objective. Production sorting optimization is carried out through scheduling sub batches, and a composite production cost composed of mold replacement cost, storage cost, and waiting time of the soup changing robotic arm is established as the objective function for optimizing the production scheduling of the die-casting workshop. In terms of solving the optimal solution, the simulated annealing algorithm is integrated into the particle swarm algorithm, and the improved particle swarm algorithm is used to optimize the objective function. Finally, the number of die-casting machines and orders in production are simulated to verify the effectiveness of the scheduling algorithm in this paper.

3. Introduction:

New energy vehicles represent the primary direction for the transformation, upgrading, and green development of the global automotive industry. The electric drive system constitutes a vital component of new energy vehicles, with the drive motor being the core component that determines the vehicle's power performance. With the explosive growth of the market share of new energy vehicles, the industry scale of drive motors is rapidly increasing. The motor housing is the main component structure of the driving motor. Die casting has become one of the key manufacturing processes for large-scale production in the automotive industry. Therefore, based on the existing die-casting production of drive motor housing, this article designs a new energy vehicle drive motor housing die-casting production line, and studies the rationality of the production line design, as well as the improvement of production efficiency and product quality throughout the entire production process.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of the rapidly growing new energy vehicle (NEV) industry and the increasing demand for high-performance drive motors. It identifies die casting as the primary manufacturing process for motor housings and recognizes the industry's move towards integrated die casting and automation to improve efficiency and reduce costs.

Status of previous research:

The paper summarizes related work, noting that while research exists on die-casting automation and process simulation for NEV parts, there is a relative lack of research specifically on optimizing the production scheduling for these automated lines. Previous studies have looked at layout optimization, numerical simulation of material flow, and process parameter design, but this paper aims to address the holistic scheduling problem by incorporating multiple cost factors and using an advanced optimization algorithm.

Purpose of the study:

The purpose of the study is to:

1. Design an automated die-casting production line for an NEV motor housing, centered on the die-casting island and incorporating robotic automation.

2. Construct a mathematical model for the production cost, including mold replacement, storage, and the waiting time of the soup-changing robotic arm.

3. Develop and apply an improved particle swarm optimization (PSO) algorithm to solve the scheduling problem and find the optimal production sequence that minimizes total cost.

4. Verify the effectiveness of the proposed method through simulation using real-world order and machine data.

Core study:

The core of the study is the development and application of an optimization framework for production scheduling in an automated die-casting workshop. This involves creating a composite cost function that accurately reflects the key economic drivers of the production process. The study then proposes a novel solution method—an improved PSO algorithm integrated with simulated annealing—to solve this multi-objective optimization problem. The framework is then tested in a simulated environment to prove its effectiveness in reducing costs and improving efficiency.

5. Research Methodology

Research Design:

The research follows a multi-stage design. First, a physical system (an automated production line) is designed based on industry-standard components like die-casting machines, robots, and PLCs. Second, a mathematical model of the production scheduling problem is formulated, defining the objective function (minimizing composite cost) and constraints. Third, an improved optimization algorithm (PSO with SA) is developed to solve this model. Finally, a simulation experiment is designed using a case study with specific parameters (3 machines, 5 products) to validate the entire approach.

Data Collection and Analysis Methods:

The study uses simulated data based on realistic industrial scenarios for a die-casting workshop. This includes a mold change time matrix (Table 2) specifying the time required to switch between any two products, and order demand data (Table 3) which lists production quantities and machine capacities. The analysis is performed by running the improved PSO algorithm with this data as input and evaluating the objective function (total cost) and other key performance indicators like machine operating time and robot waiting time over multiple iterations.

Research Topics and Scope:

The research focuses on the operational level of a die-casting workshop for NEV motor shells. The scope is limited to the scheduling of production batches on a set of parallel die-casting machines. It specifically models the costs of mold changes, inventory storage, and the waiting time of a single soup-changing robotic arm. The study does not extend to subsequent manufacturing processes (e.g., machining, assembly) or upstream supply chain logistics.

6. Key Results:

Key Results:

- An automated production line design and control system architecture was successfully developed for die-casting NEV motor housings.

- A composite cost model was established, incorporating mold replacement, storage, and robotic arm waiting time as the objective function for production scheduling.

- An improved particle swarm optimization (PSO) algorithm was used to solve the scheduling problem for a case study with 3 die-casting machines and 5 product orders.

- The simulation resulted in a schedule where 4 out of 5 orders were completed on time, with one order delayed by over 9 hours, achieving an objective function value of 178.6 hours.

- The algorithm demonstrated efficient convergence, reaching a minimum total cost of 602,300 yuan and a minimum robot waiting time of 1.6 seconds by the 40th iteration (Figure 10).

Figure Name List:

- Fig. 1. Structure of die-casting motor

- Fig. 2. Functional layout of the overall production line

- Fig. 3. Industrial internet of things architecture framework diagram

- Fig. 4. Schematic diagram of the overall framework structure of the system

- Fig. 5. Time error table for mold replacement

- Fig. 6. Completion time, delivery date, and delay diagram

- Fig. 7. Algorithm flow chart

- Fig. 8. Production line design structure

- Fig. 9. System flow chart

- Fig. 10. Schematic diagram of algorithm iteration effect results

7. Conclusion:

This article comprehensively analyzes and proposes an optimization plan for the design and production scheduling of an automated die-casting production line for NEV motor housings. It establishes a multi-objective optimization model that considers the non-negligible role of transport equipment and proposes an improved particle swarm optimization algorithm to solve it. The improved method prevents the limitations of single particle guidance and improves search performance. However, the study identifies shortcomings for future research, including the need to optimize buffer zones, coordinate multiple robotic arms in high-demand scenarios, and integrate subsequent transportation processes into the model to prevent bottlenecks.

8. References:

- [1] J.-T. Zhai, Analysis of Development Status and Prospect of New Energy Vehicles, Automobile Applied Technology 48(20)(2023) 193-198.

- [2] X.-H. Wang, D.-X. Gao, Design of Test and Analysis System for Electric Vehicle Driving Motor, Automation & Instrumentation 38(11)(2023) 7-12.

- [3] X.-J. Bai, Z.-Y. Zhu, Driving Innovation: China's NEV Development Model and Future Outlook, China Economist 19(6)(2024) 31-57.

- [4] X.-W. Wang, M.-L. Wang, C.-Y. Kang, W.-H. Xu, L.-Y. Li, Analysis of Machining Process and Fixture Design for the Motor Case of New Energy Vehicles, Development & Innovation of Machinery & Electrical Products 37(3)(2024) 53-56.

- [5] T.-R. Luo, Z.-Z. Fan, H.-X. Hu, J.-H. Wang, Y.-Z. Tian, Research Status and Development Trend of Integrated Die-casting Aluminum Alloy for New Energy Vehicles, Special Casting & Nonferrous Alloys 43(11)(2023) 1472-1478.

- [6] L.-H. Tao, X.-C. Chi, D.-W. Gu, Optimal Scheduling of Automatic Die Casting Production Line Based on Improved PSO, Mechanical Engineer (9)(2021) 4-7+10.

- [7] H.-T. Xiao, J.-Q. Liao, W.-J. Guan, H. Liu, J.-H. Gu, Die Casting Process for the New Energy Motor Shell, Foundry Equipment & Technology (5)(2022) 8-12+25.

- [8] J. Liu, X.-M. Wang, H.-H. Liu, Z.-J. Zhou, Study on sand mold gravity gating system for box type magnesium alloy castings, World Nonferrous Metals (10)(2022) 178-180.

- [9] X.-D. Huang, T. Chang, F.-L. Wei, Design and Research of Intelligent Die Casting Unit, Foundry Equipment & Technology (6)(2019) 48-52.

- [10] F.-Z. Deng, F. Zhong, X. Zhao, J. Cai, A Kind of Optimization Design of New Energy Automobile Motor Side Shell Embedded Steel Bushing Design in the Die-casting Mould, China Southern Agricultural Machinery 53(19)(2022) 25-28.

- [11] X. Ji, L.-J. Liu, Z.-X. Jia, J.-Q. Li, D.-H. Liao, J. Fang, Numerical Simulation of Die Casting Process for Motor Housing and Prediction of Thick Wall Defects, Special Casting & Nonferrous Alloys 44(5)(2024) 708-712.

- [12] H.-Z. Li, W.-Z. Si, J.-J. Cao, Y.-S. Feng, H.-W. Zhang, H. Ruediger, Design and simulation of a handling robot for wheel-hub die casting, Manufacturing Technology & Machine Tool (8)(2021) 85-90+96.

- [13] P. Wang, H. Yu, S.-L. Zhang, Optimal Design of New Energy Vehicle Drive Motor Shell and Iron Core Interference, Auto Electric Parts (10)(2024) 16-17+21.

- [14] M. Cong, C.-Q. Lu, D. Liu, Q.-Y. Xiao, R.-D. Li, Detection method for tiny defects in casting appearance based on Refine-ACTDD, Computer Integrated Manufacturing Systems 28(9)(2022) 2815-2824.

- [15] H.-J. Zhou, Y.-T. Wu, Y.-L. Zhao, H.-Y. Liu, S. Zhang, Die Casting Process Analysis and Defect Improvement of Clutch Housing, Special Casting & Nonferrous Alloys 43(5)(2023) 717-720.

- [16] F. Tian, G.-X. Wang, J.-Q. Zhou, Study on optimization of development process for body integration structure based on high pressure die casting process, Die & Mould Industry 49(8)(2023) 17-23.

- [17] D. Gao, K. Duan, X.-C. Li, X. Wang, Analysis on Technological Characteristics of Automatic Casting Production Line, Heavy Casting and Forging (1)(2024) 18-22.

- [18] Z.-T. Liu, A Multi-machine Batch Scheduling Method Based on the Improved Particle Swarm Algorithm, Progress in Textile Science & Technology 46(5)(2024) 18-24.

- [19] X.-Y. Le, J.-G. Yu, Research on Solving Job-shop Scheduling Problem Based on Improved NSGA-II Algorithm, Mechanical & Electrical Engineering Technology 53(1)(2024) 110-114+197.

- [20] Q.-Q. Liu, H.-L. Yang, Y. Zhang, Batch production scheduling considering time window and deterioration effect, Systems Engineering-Theory & Practice 44(6)(2024) 2033-2045.

Expert Q&A: Your Top Questions Answered

Q1: Why was a composite cost function including mold replacement, storage, and robot waiting time chosen as the objective?

A1: A composite cost function was chosen to create a realistic optimization model that reflects the key operational cost drivers in a modern die-casting workshop. Simply minimizing one factor, like mold change time, could lead to increased costs elsewhere, such as higher inventory or equipment idling. By combining these three critical costs, the model seeks a globally optimal schedule that balances these competing factors for the lowest overall production cost.

Q2: What is the significance of integrating a simulated annealing (SA) algorithm into the particle swarm optimization (PSO)?

A2: Standard PSO algorithms can sometimes converge too quickly on a solution that is good but not the absolute best, a problem known as premature convergence. By integrating the SA algorithm, the model gains a powerful local search capability. The SA component allows the algorithm to occasionally accept a worse solution to escape local optima, thereby improving its ability to explore the entire solution space and find a better, more globally optimal production schedule.

Q3: The results show one order was delayed by over 9 hours. What does this imply about the scheduling model's effectiveness?

A3: This result demonstrates the model's sophisticated ability to manage trade-offs. In a complex production environment, it's not always possible to meet every deadline without incurring prohibitive costs. The algorithm determined that delaying one order was the most cost-effective overall strategy to minimize the composite cost function, likely avoiding multiple costly mold changes or extended idle periods that would have resulted from a different sequence. It reflects a realistic scheduling outcome where strategic compromises are made to optimize for the entire system's performance.

Q4: The paper identifies the lack of buffer zones as a shortcoming. How would including buffer zones impact the optimization model?

A4: Adding buffer zones would introduce new variables and constraints into the optimization model. The model would need to account for the capacity of each buffer, the time parts spend in the buffer, and the associated inventory cost. While this would make the model more complex, it would also make it more accurate by reducing the calculated waiting time for the robotic arm, as it could drop off material and proceed to its next task without waiting for the machine to finish its cycle. Optimizing buffer size itself would become another layer of the problem.

Q5: Figure 10 shows the algorithm converging around the 40th iteration. What does this rapid convergence mean for practical application?

A5: The rapid convergence is a key indicator of the algorithm's efficiency. In a real-world manufacturing setting, production plans can be disrupted by unforeseen events like machine breakdowns or urgent orders. An algorithm that can find a near-optimal solution quickly is extremely valuable, as it allows production planners to re-run the schedule and adapt to new conditions in a timely manner without significant computational delays.

Conclusion: Paving the Way for Higher Quality and Productivity

Effectively managing Production Scheduling for Die Casting is no longer just about sequencing jobs; it's about holistically optimizing a complex system of machines, robots, and inventory. This paper demonstrates that by using a composite cost model and an advanced optimization algorithm, manufacturers can find near-optimal schedules that significantly reduce costs and equipment idle time. The key breakthrough lies in quantifying and minimizing the interconnected costs of mold changes, storage, and material handling, providing a clear path toward higher productivity in the demanding NEV component sector.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Design of Automated Production Line and Optimization of Production Scheduling for Die Casting of New Energy Vehicle Motor Shell" by "Yan Lu, Da-Lei Zhang, and Hao-Sheng Lu".

- Source: doi: xx.xxxxx/199115992025023601018

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.