Copper die casting offers high hardness, high corrosion resistance, the highest mechanical properties of alloy die casts, good wear resistance, good dimensional stability, good properties close to the strength of steel parts.

The use of forged high-conductivity copper for busbars, power cables, household wiring and overhead lines is well established.

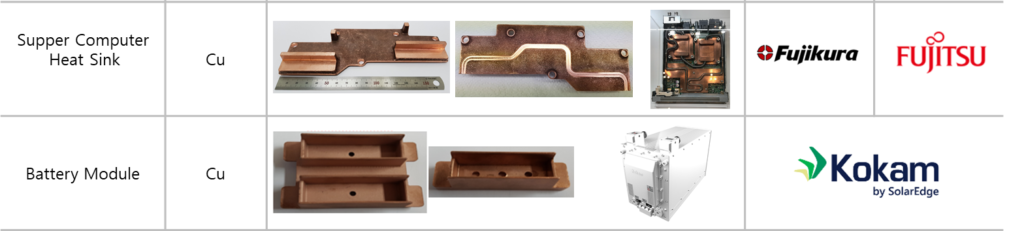

For non-standard complex shaped components, copper can be cast using the high pressure die casting method.

However, pure copper is difficult to cast and is prone to surface cracking, shrinkage and internal cavities. It is often used when castings of very high electrical conductivity are required.

Applications

- Electrode holders

- Electrode plates for process industry machinery

- Rings for process industry machinery

- Irregular shaped busbars

- Electrical switchgear

- Spot welding electrodes

- Die-cast rotors in high efficiency motors

- Stressed current-carrying parts for HF welding

- Contact mechanisms

- Die-cast battery terminals

- Terminal lugs

- High amperage circuit breakers

Copper Die-Casting Solutions

| MOLD LIFE | POROSITY | OPERATION CONDITION | |

|---|---|---|---|

| TECHNICAL ISSUE | Damage to die due to continuous exposure to thermal stress – Thermal stress due to temperature difference in die and molten metal – Melt temperature : 1,350°C, Die temperature : 2~300°C – Temperature differ – ence of approx. 1,000°CShorter die life span compared to dies for aluminum diecasting | Absence of copper die-cas-ting designsUnstable die filling due to high temperature of molten metal – Increase in shrinkage defects and porosity | Difficulty in operability due to high working temperatureAbsence of standards in copper die-casting process standardsDifficulty in building specialized equipment for copper die-casting |

| DIE LIFE EXTENSION | POROSITY REDUCTION | PROCESS OPTIMIZATION | |

|---|---|---|---|

| TECHNICAL SOLUTION | Development of surface treatment technology for die life extensionResearch and selection of die materialStructural design of dies and computer simulation | Preliminary research through computer simulationsOptimized copper die-casting designs | Optimization of copper diecasting variablesPreliminary research of copper die-casting processesStandardization of copper die-casting processes |