This introduction paper is based on the paper "The Summarize of High Power LED Headlamps Cooling Design of Automobile" published by "Applied Mechanics and Materials".

1. Overview:

- Title: The Summarize of High Power LED Headlamps Cooling Design of Automobile

- Author: Chenyang Liu, Mo Yin, Xufeng Cheng, Guodong Yin and Xiaoquan Zheng

- Year of publication: 2014

- Journal/academic society of publication: Applied Mechanics and Materials

- Keywords: White LED, automotive headlamp, heat dissipation.

2. Abstract:

With the luminous flux of high-power white LED has been further improved, LED will gradually replace incandescent lamp and halogen lamp, and become the “fourth generation light" source of automotive lighting. Now there are still a number of technical difficulties in LED application for automotive headlamp, one more difficult to overcome of which is the heat dissipation problem of LED headlamp. In this paper, the current LED headlamps heat dissipation solutions are introduced; and the future direction of improving the heat dissipation is given.

3. Introduction:

The white LED has become the better choice for the new generation of automotive light source technology, because of its advantages such as small volume, long service life, low energy consumption, resistance to vibration, fast startup time, environmental protection and so on. There are many unique advantages to use LED as a light source for the automotive headlamp. Besides the characteristics like almost no startup time and low voltage electrical safety, long service life, In particular, it can be composed of several LED lanterns; this can make the appearance of LED lamps plastic greatly. China is in the period of great development of the car, it is great significance to promote the development of automobile industry that develop the LED headlamp.

4. Summary of the study:

Background of the research topic:

The development of LED headlamps faces several key issues. A significant portion of electrical energy in LEDs, about 70%, is converted into heat energy, while only 10% - 30% becomes light. For high-power LED car headlamps operating for extended periods without an effective heat-cooling system, the LED temperature can rise. If the temperature exceeds 125 °C, it can lead to a loss of luminous efficiency or even failure of the LED. Therefore, researching better heat-dissipation systems is crucial for the widespread adoption of LEDs in automobile headlamps.

Heat-dissipation is identified as the primary obstacle in the development of LED headlamps, particularly for high power LEDs (defined as a single chip achieving more than 1 w). If heat is not dissipated in time, the LED chip junction temperature rises rapidly, potentially causing silicon carbide to turn yellow, reducing the LED's service life, or leading to failure.

Other critical aspects include:

- The LED headlamp Driving-power: The optical-electrical characteristics of high power LEDs mean luminous intensity is determined by drive current, and small voltage fluctuations can cause large current variations, affecting brightness. Driving-power design must ensure constant current output, heat dissipation, efficiency, power factor, and various protections.

- Optical design: Good optical design is necessary for standard brightness and efficient energy use, which in turn reduces heat generation.

- The LED luminous efficiency: Low luminous efficiency and electro-optic conversion efficiency are critical issues. Improvements require research into semiconductor materials, chip structure design, and manufacturing processes.

Status of previous research:

The paper summarizes existing LED headlamp cooling solutions and current research developments:

Existing Solutions and Analysis (Thermal Issue):

The LED headlamp temperature is generally required to be below 80°C. Current cooling solutions include:

- Fin and fan combination [1]: A common method using a finned heat-dissipation area and a fan for forced convective heat transfer. Suitable for less than 100 w/m2 heat flow density, but reliability and stability can be low.

- Liquid-cooled thermal radiation [2]: Typically water cooling, reducing heat sink size without needing additional air flow. However, it may not be suitable for harsh environments (high temperature, vibration) and is mostly conceptual.

- Heat-pipe dissipation technology [3]: Uses heat conduction and rapid heat transfer properties of a cooling medium to quickly dissipate heat. It has high heat transfer efficiency but often needs to be combined with other methods, increasing cost.

- Micro-channel cooling technology [4]: Tuckerman and Pease reported this in the 1980s. Goodson developed an electro-osmosis pump using liquid electro-osmosis drive, which has no moving parts and low consumption. For a heat flux of 200 W, it can reduce temperature by 20°C with pump power consumption less than 1 W.

- Semiconductor refrigeration technology [5]: Uses the Peltier effect. The optimal coefficient of thermoelectric refrigeration materials is about 2.45*10-3/K, but refrigeration efficiency is relatively low (about 10% of Carnot cycle efficiency).

- Other technologies like Ultrasonic refrigeration and superconducting refrigeration exist but are limited by cost, application occasions, and low heat-dissipating capacity for automotive LED headlamps.

Current Research (Domestic and Foreign Cooling Technologies):

- In 2006, Lai [6] reported an LED headlamp cooling scheme (Fig. 1) using a liquid-cooled system for 37.5 W total heat power, showing LED chip temperature rise of less than 5 °C.

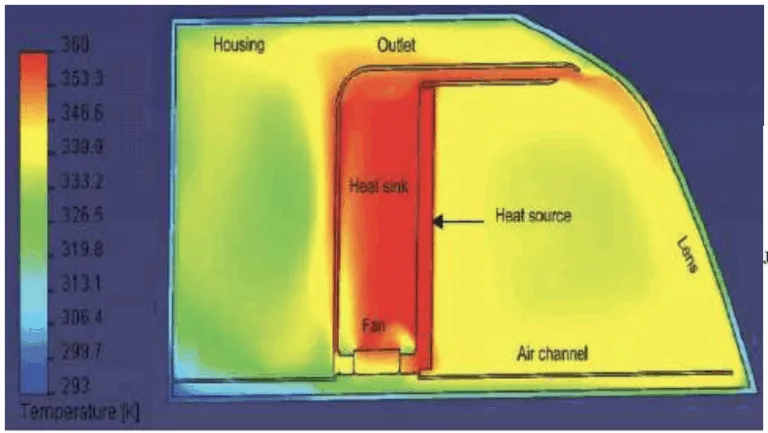

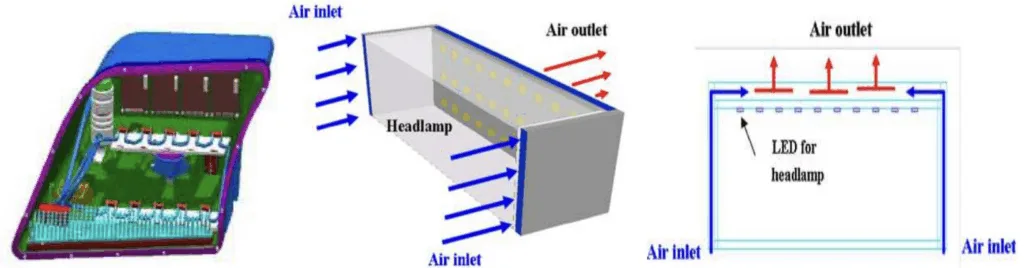

- In 2008, Sunho Jang [7] designed a system with 30 LEDs (1W each) using ventilation channels in the lamp shell (Fig. 2). Calculated highest LED chip temperature was 34 °C.

- Schefenacker company [8] proposed a cooling pattern with an internal fan to uniformize air temperature within the lamp body, preventing fogging (figure 3).

- In 2006, Professor Luo Xiaobing [9] reported experimental results on using micro-spray to cool high power LED arrays (figure 4). The system could handle a 220W LED array, achieving an LED bottom temperature of 69.4°C at 30.8 °C room temperature, with 5.8 W power consumption for fan and micro pump.

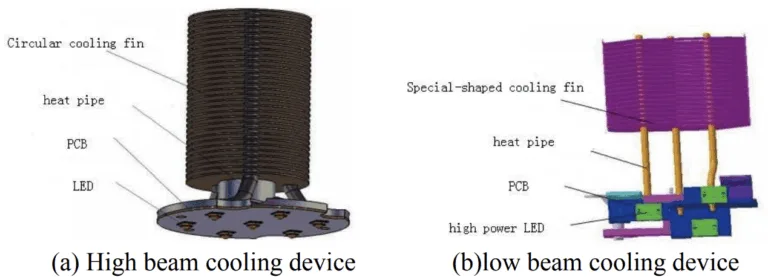

- In 2010, Luo jing [10] designed an LED headlamp cooling system with heat pipe and heat-dissipation fin (Fig. 5). For an 18W high beam, LED temperature reached 65°C, and low beam LED temperature reached 80°C under a 50 °C simulated environment.

Development Overview of LED Headlamp Domestic and Foreign Patent Technologies:

- Benz Corp Company [11]: Designed a double-deck structure for the lamp back, which is evacuated to prevent heat from high-temperature air in the lamp and engine bay (Figure 6).

- German Stanley [12]: A radiating device composed of high heat conductivity plates (14,15), connecting plate (16), and bracket to enlarge radiation area and distribute temperature (Figure 7).

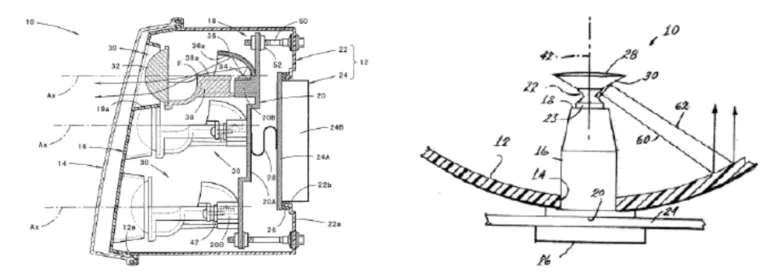

- Koito [13]: A Japanese manufacturer, designed a system where heat from LED(34) is transmitted via a metal seat, flexible heat pipe, and radiating fin (Figure 8).

- Osram [14]: LED devices are placed on a high thermal conductivity metal block (23), connected to a metal thermal column, conducting heat to a heat sink (24) (Figure 9).

- China's "11th five-year plan" included research topics like "automotive LED light source system development" [15]. An LED headlamp based on the BenTeng B50 car was developed (fig.10), using a heat sink for cooling (fig. 11). The B50 headlamp has five LED sources (3 for low beam, 2 for high beam, 15W each).

Purpose of the study:

The purpose of this paper is to introduce the current LED headlamps heat dissipation solutions and to provide future directions for improving heat dissipation. The study emphasizes the importance of designing high-efficiency heat dissipation technology to ensure LED headlamps operate below 80 °C.

Core study:

The core study involves a comprehensive review and summarization of existing heat dissipation technologies applicable to high-power LED automotive headlamps. This includes an analysis of various cooling methods, an overview of recent research advancements both domestically and internationally, and a survey of patented technologies from major automotive lamp providers and manufacturers. The paper synthesizes this information to highlight key challenges and propose future directions for enhancing LED headlamp cooling performance.

5. Research Methodology

Research Design:

The study employs a literature review methodology. It systematically gathers, synthesizes, and discusses information from existing academic papers, conference proceedings, patents, and technical reports related to LED headlamp cooling technologies.

Data Collection and Analysis Methods:

Data was collected from published scientific and technical literature. The analysis involved categorizing different cooling solutions, summarizing key findings from various research efforts and patented designs, and identifying common challenges and trends in the field of LED headlamp thermal management. The paper does not involve primary empirical research or new experimental data generation but rather provides a descriptive and analytical overview of the state-of-the-art.

Research Topics and Scope:

The primary research topic is the heat dissipation challenges and solutions for high-power LED automotive headlamps. The scope covers:

- Fundamental issues of heat generation in LEDs.

- Various cooling technologies (e.g., fin-fan, liquid cooling, heat pipes, micro-channels, thermoelectric cooling).

- Specific examples of research and development in LED headlamp cooling systems from academic and industrial sources.

- Patented cooling designs from automotive manufacturers.

- Future strategies for improving LED headlamp thermal performance.

6. Key Results:

Key Results:

- Heat dissipation is the primary technical difficulty hindering the application of high-power LEDs in automotive headlamps. Efficient thermal management is critical to maintain performance and lifespan, with a target operating temperature below 80°C.

- A variety of cooling solutions exist, each with specific advantages and disadvantages:

- Fin and fan: Common, but reliability can be low.

- Liquid cooling: Reduces heat sink size, but may not suit harsh environments.

- Heat pipes: High efficiency, but often require combination with other methods.

- Micro-channel cooling: Effective for high heat flux, with potential for compact designs.

- Semiconductor refrigeration: Low relative efficiency.

- Specific research examples (e.g., Lai [6], Sunho Jang [7], Schefenacker [8], Luo Xiaobing [9], Luo jing [10]) and patented technologies (e.g., Benz [11], Stanley [12], Koito [13], Osram [14]) demonstrate ongoing efforts and diverse approaches to LED headlamp cooling.

- China has actively pursued research in LED headlamps, exemplified by the BenTeng B50 LED headlamp.

- Future improvements in LED headlamp performance depend on two main approaches:

- LED own improvement:

- Enhancing LED encapsulation technology to reduce internal thermal resistance.

- Improving LED electro-optic conversion efficiency to reduce heat generation.

- Developing new LEDs that can tolerate higher temperatures, reducing the difficulty of thermal design.

- Reasonable heat dissipation device design:

- Selecting appropriate cooling systems (heat pipe, fan, water cooling, etc.) for different headlamp structures, ensuring rapid heat emission and stable operation.

- Optimizing fin structure (shape, size) to ensure sufficient heat dissipation area and better cooling effect.

- LED own improvement:

Figure Name List:

- Fig. 1 The LED headlamp cooling system of Lai

- Fig. 2 The LED headlamp system of Sunho Jang

- Fig. 3 The LED headlamp cooling system of Schefenacker company

- Fig. 4 The Micro-jet cooling system

- Fig. 5 The LED headlamp cooling system of Luojing

- Fig. 6 The LED headlamp of Bens

- Fig. 7 The LED headlamp of Stanley

- Fig. 8 The LED headlamp of Koito

- Fig. 9 The LED headlamp of OSRAM

- Fig.10 The LED headlamp of Benteng B50

- Fig. 11 The B50 LED headlamp cooling device

7. Conclusion:

Many key problems are introduced about LED headlamp application existed in the home and abroad in the above article; especially problems about heat dissipation of LED headlamps are introduced. And some different heat dissipation ways of a few car headlamp and LED headlamp patent are listed at present, As well as improving direction is discussed in the future. It is essential to make the LED headlamps work below 80 °C by the way that how to design the high efficiency of heat dissipation technology, it is the meaning of this study part.

8. References:

- [1] Hetsroni G, Mosyak A, Segal Z, et al:International Journal of Heat and Mass Transfer, Vol. 5 (2002), No.16, p.3275-3286.

- [2] Cohen A B: IEEE Transaction on Componets, Hybrids and Manufacturing Technology, 1987, Vol. 10 (1987), No.2, p.159-175.

- [3] Nguyen T, Mochizuki M, Mashiko K, et. al. Use of heat pipe/heat sink for thermal managenlent of high performance CPUs. in: Proceeding of Sixteenth IEEE Semi-Thermtm Symposium. San Jose, USA, 2000, p.76-79.

- [4] Lee D Y, Vafai K: International Journal of Heat and Mass Transfer, Vol. 42 (1999), No.9, p.1555-1568.

- [5] Disalvo F J. Thermoelectric cooling and power generation. Science, Vol. 285 (1999), p.703-706

- [6] Lai Y, Cordero N, Barthel F, et al. Liquid cooling of bright LEDs for automotiveapplications. in: Proceedings of the 12th International Workshop on Thermal Investigationof ICs and Systems, Nice, France, 2006. p.80-85

- [7] Sunho Jang and Moo Whan Shin: Member: Device and Materials Reliability, Vol. 8 (2008), No.3, p.561-564.

- [8] Information on http://www.ledsmagazine.com.

- [9] Luo X B, Liu S: A closed micro jet cooling system for high power LEDs. in: Electronic Packaging Technology, ICEPT '06. 7th International Conference on China, 2006.p.592-598.

- [10] Luo Jing: Automotive engineer, Vol. 3 (2011), p.27-28.

- [11] Wakabayashi N, Yamauchi S: Lighting device for use in automotive headlight, hasloop-type heat pipe with heat receiving portion thermally connected to light source and heat releasing portion thermally connected to connecting portion of housing. JP, A, 2006164967, 2004.11.12.

- [12] Ui K. LED lamp e.g. headlamp of motor vehicle, consists of thermally conductive aluminum plates fixed at upper and lower sides of lamp unit in resin case. JP, A, 2006302753, 2006.11.2.

- [13] Inoue T, Yagi S. Vehicle lamp e.g. headlamp, for forming low-beam distribution pattern, has metal bracket tiltably supported by lamp body with heat sink, where heat sink and bracket are connected by flexible heat pipe with high thermal conductivity. US, A1, US 2007025105, 2007.2.1.

- [14] Coushaine C M. LED light source for e.g. headlight has electrical conductors, each with tension reliever that compresses when printed circuit boards are assembled to central heat conductor, and heat sink in thermal contact with one board. US, B2, 7075224, 2006.7.11.

- [15] Information on http://club.autohome.com.cn/bbs/thread-c-632-8773997-1.html.

- [16] Chenyang Liu: The design for high-power LED headlamps research, master degree thesis, Northeastern university,China,2013.

9. Copyright:

- This material is a paper by "Chenyang Liu, Mo Yin, Xufeng Cheng, Guodong Yin and Xiaoquan Zheng". Based on "The Summarize of High Power LED Headlamps Cooling Design of Automobile".

- Source of the paper: doi:10.4028/www.scientific.net/AMM.494-495.32

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.