Part 1 — Design and mechanics

MTZ worldwide volume 71, pages20–27 (2010)Cite this article

- 131 Accesses

- Metrics

Abstract

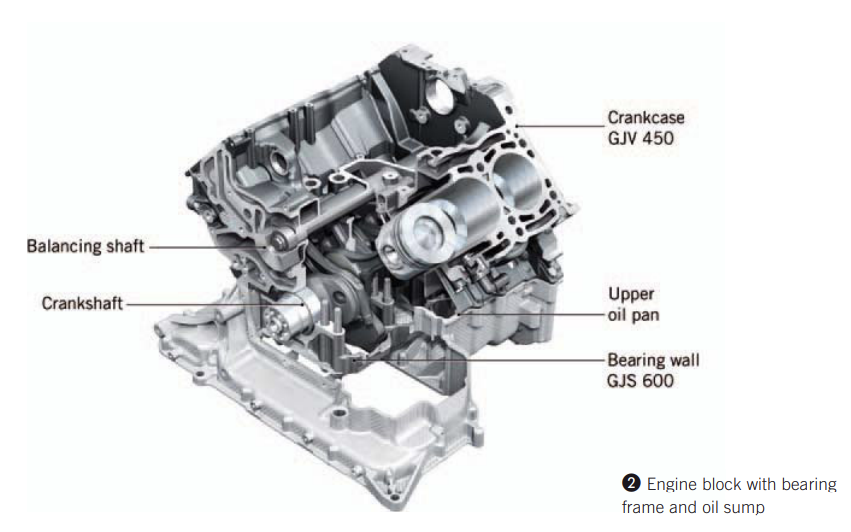

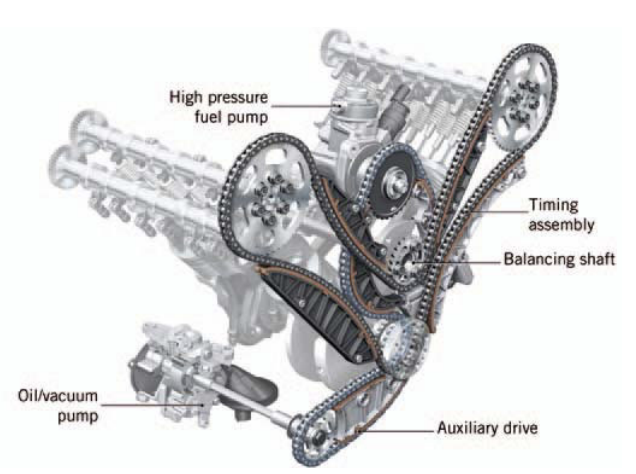

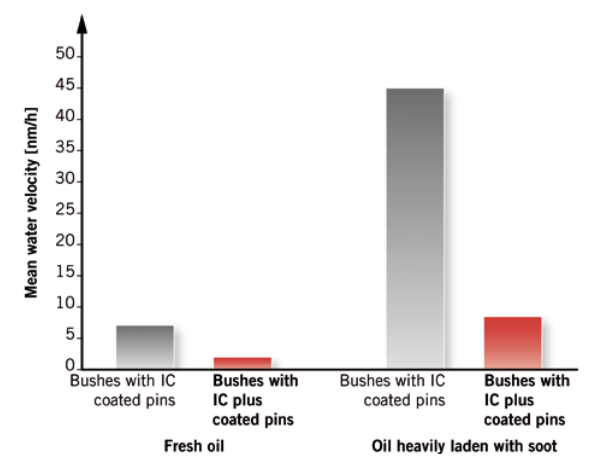

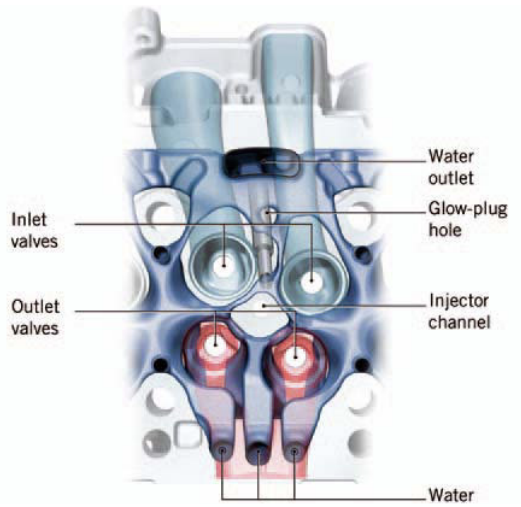

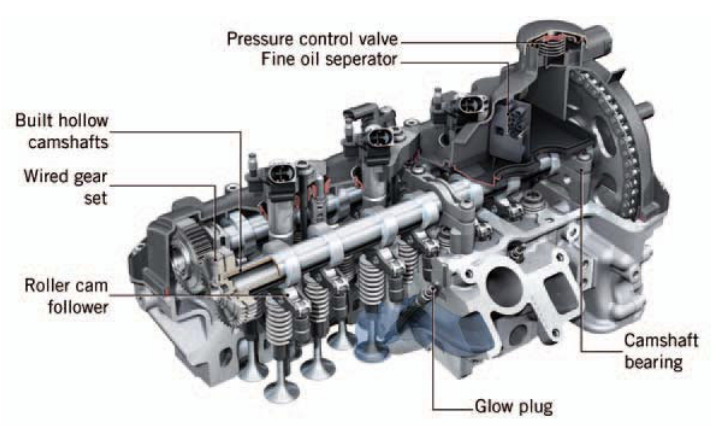

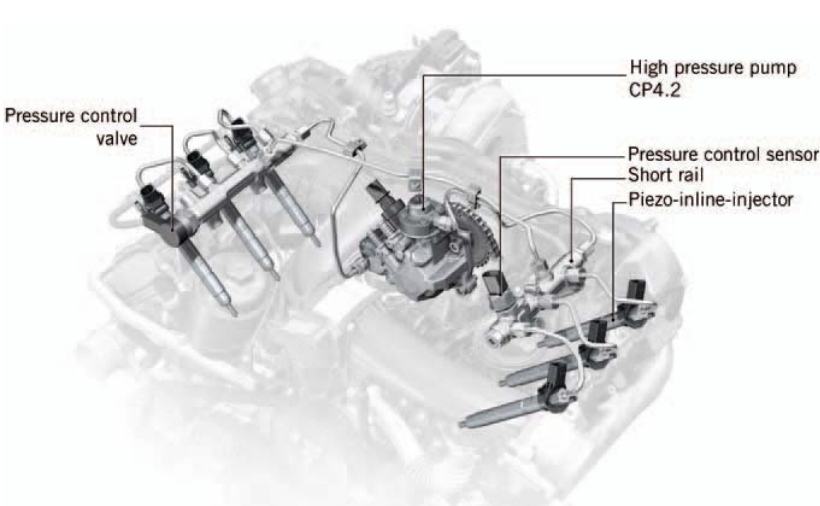

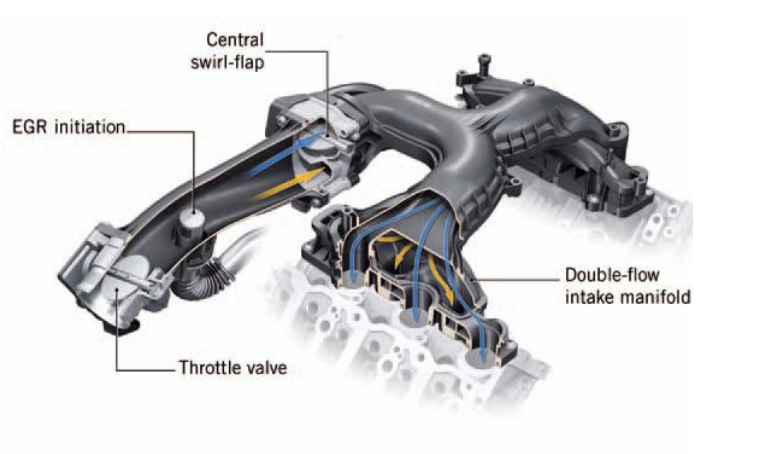

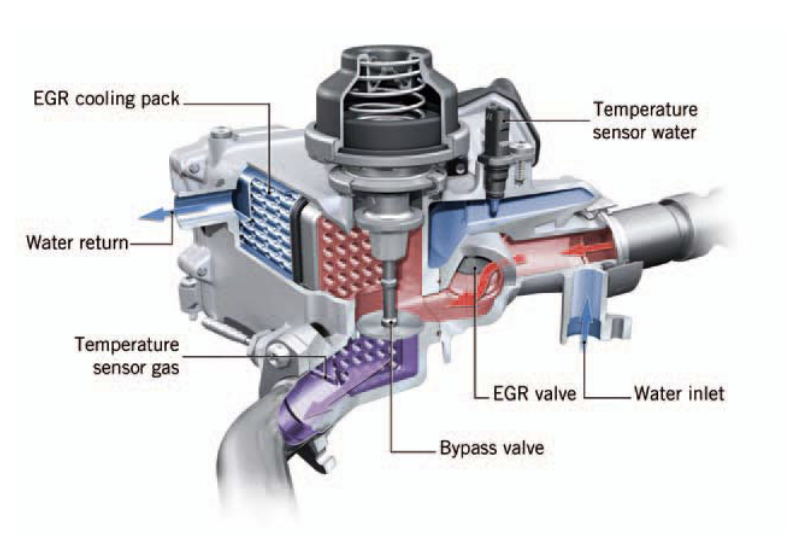

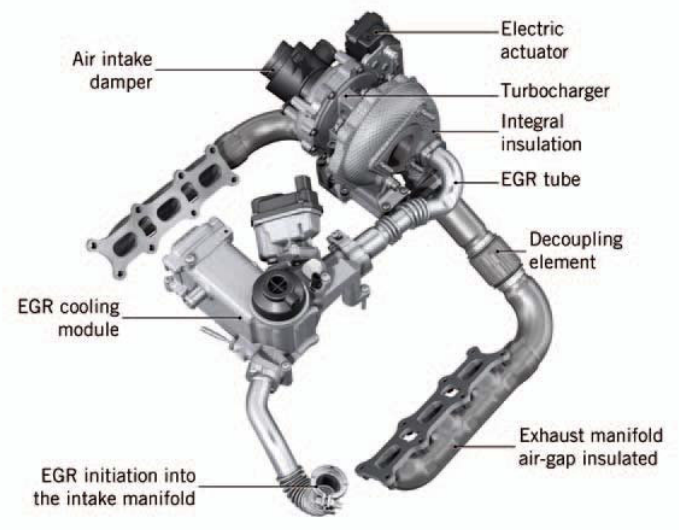

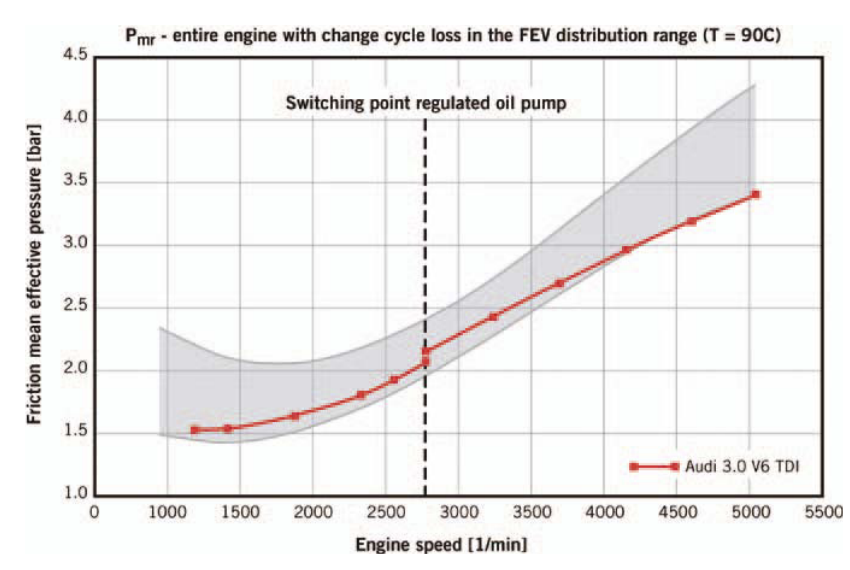

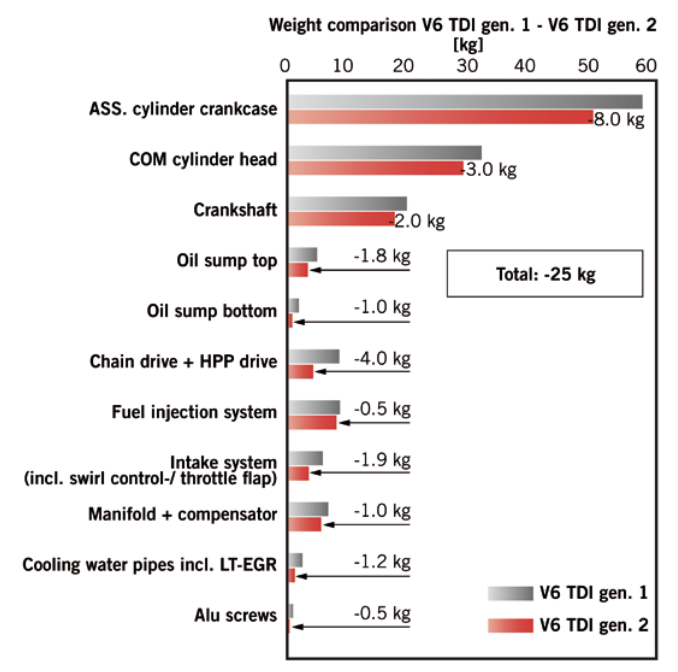

Following on from Audi’s 2003 production launch of the first generation of the 3.0 I V6 TDI engine, 2010 now marks the launch of the second generation — a completely newly developed unit successfully combining low fuel consumption, low emissions, high power output along with significantly reduced engine weight. This accomplishment is based on a large number of innovative solutions, focused particularly on minimising friction and on lightweight construction. The familiar Audi four-valve combustion method has been thermodynamically modified. The fuel injection system is an updated piezo-inline common rail unit delivering up to 2000 bar maximum rail pressure. The turbocharger has also been modified to provide enhanced spontaneity. In the following design and the mechanics of the new engine are described, the second part in the MTZ 11 deals with thermodynamics, application and exhaust treatment.

Korea Abstract

2003년 Audi의 1세대 3.0 I V6 TDI 엔진 양산에 이어 2010년에는 저연비, 저배출, 고출력을 성공적으로 결합한 완전히 새로 개발된 2세대 엔진이 출시되었습니다. 엔진 무게. 이러한 성과는 특히 마찰 최소화와 경량 구조에 중점을 둔 수많은 혁신적인 솔루션을 기반으로 합니다. 친숙한 Audi 4 밸브 연소 방식이 열역학적으로 수정되었습니다. 연료 분사 시스템은 최대 2000bar의 최대 레일 압력을 제공하는 업데이트된 피에조 인라인 커먼 레일 장치입니다. 터보차저는 또한 향상된 자발성을 제공하도록 수정되었습니다. 다음 설계와 새 엔진의 역학이 설명되어 있으며 MTZ 11의 두 번째 부분은 열역학, 적용 및 배기 처리를 다룹니다.

References

- Bauder, A.; Clos, R.; Hatz, W.; Hoffmann, H.; Pölzl, H.-W.; Reichert, H.J.: The new V-configuration engines from Audi. Vienna Engine Symposium 2002Google Scholar

- Bauder, R.; Reuss, T.; Hatz, W.; Pölzl, H.-W.: The new V6 TDI from Audi. Vienna Engine Symposium 2004Google Scholar

- Anton, C.; Bach, M.; Bauder, R.; Franzke, G.; Hatz, W.; Hoffmann, H.; Ribes-Navarro, S.: The new 3.0 I V6 TDI engine from Audi, Part 1, Design and Mechanics. In: MTZ 65 (2004) No. 7Google Scholar

- Bauder, R.; Brucker, D.; Hatz, W.; Lörch, H; Macher, A; Pamio, Z.-G; Reuss, T.; Riegger; R.; Schiffgens, H.-J.: The new 3.0 l V6 TDI engine from Audi part 2: Thermodynamics, application and exhaust treatment. In: MTZ 65 (2004) No. 9Google Scholar

- Bauder, R.; Bach, M.; Köhne, M.; Streng, C; Hofmann, H.; Rossi, D.: The new 3.0 l V6 TDI engine in the Audi Q5. In: ATZ extra — The new Audi Q5 (2008)Google Scholar

- Bauder, R.; Bach, M.; Fröhlich, A.; Hatz, W.; Helbig, J.; Kahrstedt, J.: The new generation of the 3.0 TDI engine from Audi. Vienna Engine Symposium 2010Google Scholar