DrissEl KhoukhiabcNicolasSaintierbFranckMorelaDanielBellettaPierreOsmondcViet-DucLeaaLAMPA, Arts et Métiers Institute of Technology, Angers, 49 035 Cedex, FrancebI2M, Arts et Métiers Institute of Technology, Talence, 33170 Cedex, FrancecGroupe PSA, Carrières-sous-Poissy, 78955 Cedex, France

Received 18 November 2020, Revised 16 March 2021, Accepted 2 May 2021, Available online 4 May 2021.

Highlights

- Point Process Theory is an efficient way to characterize the 3D spatial distribution of defects in cast alloys.

- Nearest neighbor function, Ripley's K-function and Clark-Evans tests are used to analyse the spatial distribution of defects.

- Synthetic microstructures that mimic key macroscale features of the materials are generated.

Abstract

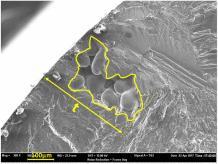

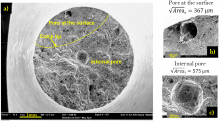

Two cast aluminium alloys fabricated by different casting processes (gravity die-casting and lost foam casting) and showing different degrees of porosity were characterized with X-ray Computed tomography. Information concerning the pore distribution inside the investigated materials is obtained in terms of pore size and the pore positions in 3D space. Subsequently, a spatial point pattern analysis is undertaken to investigate the pore distributions. Different methods, including a nearest neighbor analysis, Ripley's K-function and Clark-Evans tests developed for 3D applications, are used to analyse the observed patterns. The results show that the Homogeneous Poisson process, which provides the Complete Spatial Randomness (CSR) is suitable to approximate the spatial distribution of the pores present in the investigated alloys. Synthetic microstructures that mimic key macroscale features of the materials in terms of pore size and the 3D spatial distribution of the pores were generated. These microstructures can be used in the probabilistic modelling of fatigue behavior.

Keywords

Casting process, X-ray computed tomography, Porosity, Point pattern, Spatial statistics, Ripley's K-function, Nearest neighbor function, Poisson process, Fatigue

서로 다른 주조 공정 (중력 다이캐스팅 및 로스트 폼 주조)에 의해 제조되고 서로 다른 정도의 다공성을 보여주는 두 개의 주조 알루미늄 합금이 X 선 컴퓨터 단층 촬영으로 특성화되었습니다. 조사된 물질 내부의 기공 분포에 대한 정보는 3D 공간에서 기공 크기 및 기공 위치 측면에서 획득됩니다. 그 후, 기공 분포를 조사하기 위해 공간 점 패턴 분석이 수행됩니다.

최근 접 이웃 분석, 3D 애플리케이션 용으로 개발 된 Ripley의 K- 함수 및 Clark-Evans 테스트를 포함한 다양한 방법을 사용하여 관찰된 패턴을 분석합니다.

결과는 완전한 공간 랜덤성 (CSR)을 제공하는 Homogeneous Poisson 프로세스가 조사된 합금에 존재하는 기공의 공간 분포를 근사화하는데 적합함을 보여줍니다. 기공 크기 및 기공의 3D 공간 분포 측면에서 재료의 주요 거시적 특징을 모방한 합성 미세 구조가 생성되었습니다. 이러한 미세 구조는 피로 거동의 확률적 모델링에 사용할 수 있습니다.