Ren Liu1,2, Yuejin Zhao1, Xu Yang3 and Gen Wang4

Published under licence by IOP Publishing Ltd

Abstract

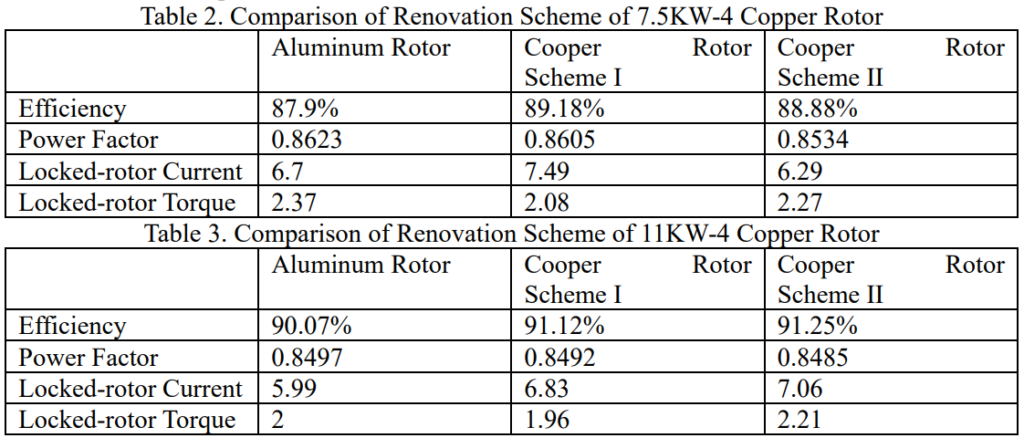

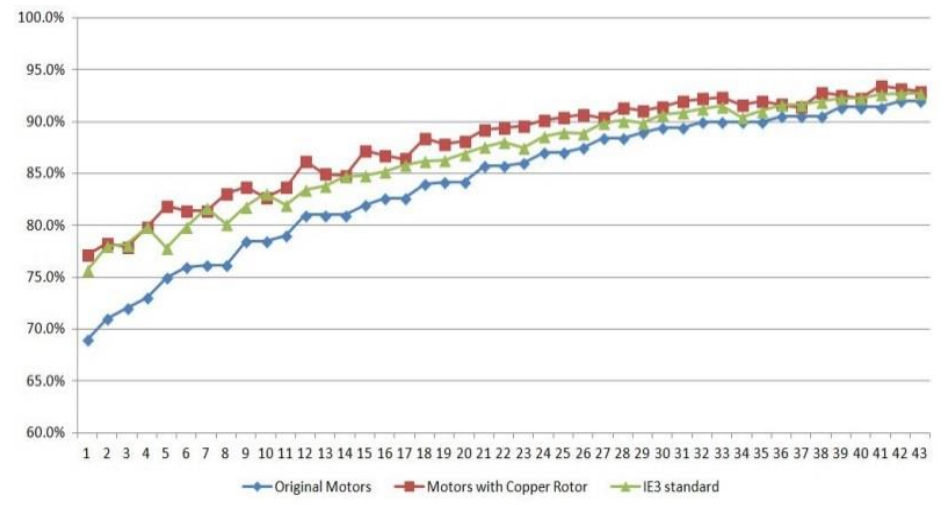

The energy conservation of electric motor system is the key of industrial energy conservation. With the implementation and acceleration of electric motor energy efficiency improvement plan, more and more electric motors are knocked out. High-efficient remanufacturing of electric motor refers to improving the efficiency of electric motor and recycling the resources by replacing the winding, iron core and other components of electric motor on the basis of the low-efficient/outdated electric motors, which conforms to China's policy of circular economy and resource recovery. The remanufacturing of electric motor not only maximizes the use of resources, but also reduces the energy consumption generated by reprocessing of cast iron, silicon steel sheet and other materials in dismantling of electric motor. However, structures and iron core materials used in design and manufacture of electric motors are different, and the degrees of wear of electric motors are also different under different operating conditions, which further result in diversified design schemes, increased remanufacturing cost and reduced remanufacturing efficiency. This paper analyzes the key process technologies for remanufacturing of electric motors are researched by analyzing the remanufacturing technologies of electric motors, and presents the feasibility to replace the cast-aluminum rotor with cast-copper rotor in high-efficient remanufacturing process of electric motor.

Korea Abstract

전기 모터 시스템의 에너지 절약은 산업 에너지 절약의 열쇠입니다. 전기 모터 에너지 효율 향상 플랜의 구현 및 가속화로 점점 더 많은 전기 모터가 노크됩니다. 전기 모터의 고효율 재생성은 전기 모터의 효율을 향상시키고 전기 모터의 권선, 철 코어 및 기타 구성 요소를 중국의 정책을 준수하는 전기 모터의 권선, 철심 및 기타 구성 요소를 교체하여 자원을 재활용합니다. 원형 경제 및 자원 회복의 전기 모터의 재생산은 자원의 사용을 극대화 할뿐만 아니라 전기 모터의 해체에서 주철, 실리콘 강판 및 기타 재료를 재 처리하여 생성 된 에너지 소비를 감소시킵니다. 그러나 전기 모터의 설계 및 제조에 사용 된 구조 및 철 코어 재료는 다르며 전기 모터의 마모도 다른 작동 조건에서 서로 다르며 다양한 설계 방식을 더욱 향상시키고, 재생산을 증가시키고 재충분 효율을 줄이고 재생 효율을 저하시킵니다. 이 논문은 전기 모터의 재 제조 기술을 분석하여 전기 모터의 재 제조 기술을 분석하여 주요 프로세스 기술을 분석하고 전기 모터의 고효율 재생산 공정에서 주조 - 구리 로터를 대체 할 수있는 타당성을 제공합니다.

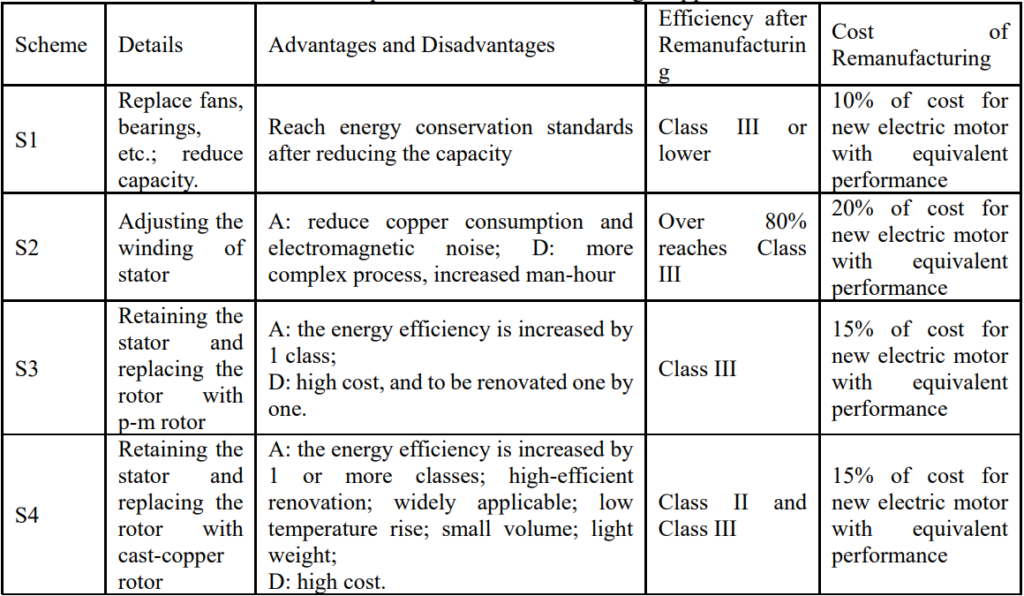

Table 1. Comparison of remanufacturing Copper Rotor

Reference

[1] Zhang S; Ding X. L. Development of Electric Motor High-efficient Remanufacturing Industry [J].

Technology & Business, 2014 (15):1 [in Chinese]

[2] Hu W.B; Discussion on Developing Automobile Remanufacturing Engineering in Chengdu [J].

Automobile Technology, 2011(5). 54-57. [in Chinese]

[3] Yang J. S. Chinese and Overseas Relative Energy Prices and Chinese Energy Efficiency [J].

Economist, 2009 (4): 90-97. [in Chinese]

[4] Chen P, Chen Y, Li J. Y. Energy Efficiency Monitoring and Energy Conservation and Emission

Reduction Measures for Industrial Boiler [J]. Energy Conservation and Environmental Protection,

2013 (6): 66-67. [in Chinese]

[5] Wang S. W. Potential Analysis of China Industry’s Energy-saving and Some Suggestions [J].

Industrial Boiler. 2005 (1): 1-16. [in Chinese]

[6] Zhao Q. X, Zhou Q. L. Solutions, Questions and Status of China’s Industrial Boiler [J]. Industrial Boiler, 2010 (1): 1-6. [in Chinese]

[7] Wang C. J. Energy-saving Way Analysis of Small-medium Coal-fired Industrial Boilers [J]. Clean Coal Technology, 2016, 22 (1): 109-113. [in Chinese]

[8] Chen Y.T. Solutions, Questions and Status of China’s Industrial Boiler [J]. Low Carbon World, 2016 (17). [in Chinese]