Mastering Dendritic Structure Control: The Key to Stronger, More Reliable As-Cast Aluminium Alloys

This technical summary is based on the academic paper "Parameters Influencing Dendritic Structure to Improve the Properties of As-Cast Aluminium Alloys" by Nisheeth Kr. Prasad, P. Kranthi Kumar, Ashok Sharma, and M. K. Bhargava, published in the Indian Foundry Journal (2014).

Keywords

- Primary Keyword: Dendritic Structure Control

- Secondary Keywords: As-Cast Aluminium Alloys, Secondary Dendrite Arm Spacing (SDAS), Mechanical Properties, Grain Refinement, MCAST, ALPROP Model

Executive Summary

- The Challenge: The mechanical properties of as-cast aluminium alloys are fundamentally limited by their dendritic microstructure, which can lead to performance inconsistencies and premature component failure.

- The Method: The study analyzes the relationship between Secondary Dendrite Arm Spacing (SDAS), cooling rates, and mechanical properties, and investigates the MCAST (melt conditioning by advanced shear technology) process for physical grain refinement.

- The Key Breakthrough: Decreasing SDAS through faster cooling rates and applying the MCAST process significantly improves tensile strength, hardness, and fatigue life in Al-Si alloys.

- The Bottom Line: Precise control over solidification conditions, particularly cooling rate and melt shearing, is a critical and effective strategy for enhancing the performance of as-cast aluminium components in demanding automotive and aerospace applications.

The Challenge: Why This Research Matters for HPDC Professionals

In casting processes for most alloys, solidification occurs under conditions far from equilibrium, leading to the formation of dendritic microstructures. This process can trap solute-rich liquid between the growing dendrite arms, resulting in a "banded" microstructure. For engineers and managers in the HPDC industry, this is a critical issue. This micro-segregation directly impacts the final mechanical properties of the component, including tensile strength, hardness, and fatigue life. Without a deep understanding and control of these dendritic structures, achieving consistent, high-performance, and reliable lightweight components for critical applications remains a significant challenge.

The Approach: Unpacking the Methodology

The paper reviews and applies several methods to understand and control dendritic structures in as-cast aluminium alloys.

Method 1: Microstructural Analysis and Property Estimation

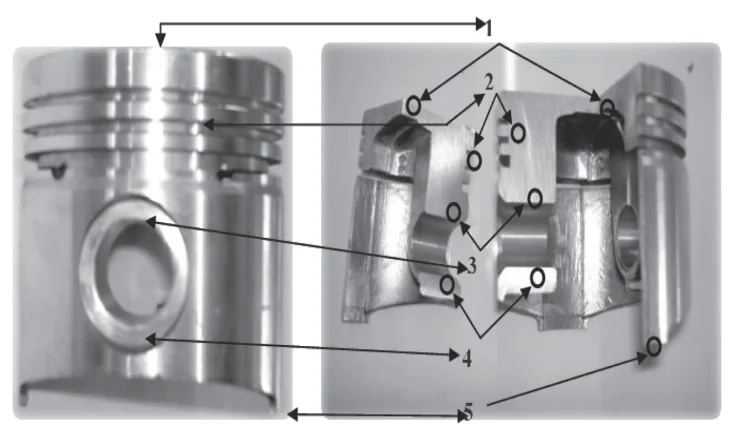

A commercial automotive engine piston, cast from a near-eutectic aluminium-silicon alloy, was systematically analyzed. Researchers studied five distinct regions of the piston (top, ring, top pin, down pin, and skirt) as shown in Figure 5. In each region, the Secondary Dendrite Arm Spacing (SDAS) was quantified using an image analyzer and the formula SDAS=d/nM. These empirical SDAS values were then used in a predictive model (UTS = -1.4399*SDAS + 340 [MPa]) to estimate the local ultimate tensile strength, demonstrating the direct link between microstructure and mechanical performance.

Method 2: Predictive Modeling with ALPROP

The study references the ALPROP model, a semi-empirical tool designed to calculate the tensile properties and hardness of AlSiMg(Fe) foundry alloys. The model takes chemical composition, dendrite arm spacing (DAS), and heat treatment parameters as inputs. It utilizes a Ludvig stress-strain law (UTS = YS + Kεn) to predict the ultimate tensile stress, establishing a clear mathematical relationship where strain hardening increases with higher magnesium content and decreasing DAS.

Method 3: Physical Grain Refinement via MCAST

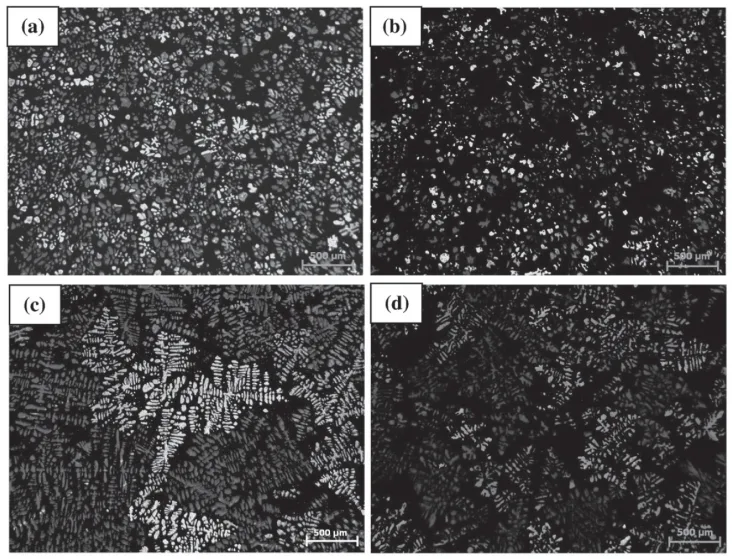

The research highlights a novel physical grain refinement process called MCAST (melt conditioning by advanced shear technology). This method applies a high shear rate and intense turbulence to the molten metal during processing. The study compares the microstructure of an Al-10.2%Si alloy cast conventionally versus the same alloy processed with the MCAST unit at different pouring temperatures (590°C and 650°C) to evaluate the effectiveness of this mechanical approach to grain refinement.

The Breakthrough: Key Findings & Data

The research provides compelling data that links process parameters directly to microstructural features and, consequently, to improved mechanical properties.

Finding 1: An Inverse Relationship Between SDAS and Mechanical Strength

The analysis of the engine piston revealed a direct and significant correlation between local cooling rates, SDAS, and predicted strength. As shown in Figure 6, the SDAS decreased progressively from the slower-cooling top position (46.98 µm) to the faster-cooling skirt position (23.64 µm). This nearly 50% reduction in SDAS corresponded to a significant increase in calculated ultimate tensile strength, which rose from 202.36 MPa at the top to 235.97 MPa at the skirt, as detailed in Table 1. This confirms that finer dendritic structures, achieved through higher cooling rates, result in stronger material.

Finding 2: The MCAST Process Dramatically Refines Grain Size Without Chemical Additives

The MCAST technology proved to be a highly effective method for physical grain refinement. Figure 9 shows that for an Al-10.2%Si alloy, the MCAST-sheared material produced a grain size of approximately 200-400 µm, which is drastically finer than the 600-1000 µm grain size observed in conventionally cast, non-sheared material. This remarkable refinement was achieved across a range of casting temperatures and, crucially, without any chemical grain refiner additions. The optical micrographs in Figure 8 provide a clear visual confirmation, showing a fine, equiaxed grain structure in the sheared samples compared to the large, dendritic grains in the conventional samples.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting cooling rates through mould design, strategic placement of cooling channels, or the use of chills can be a powerful tool to control SDAS and directly improve mechanical properties like tensile strength and hardness. Furthermore, the MCAST process presents a viable, chemical-free alternative for achieving fine-grained structures, potentially reducing reliance on and variability from Al-Ti-B and other refiners.

- For Quality Control Teams: The data in Table 1 and Figure 6 illustrates the strong effect of SDAS on ultimate tensile strength. This relationship suggests that SDAS measurement can serve as a powerful, localized, and predictive indicator of mechanical properties, which could inform new, more precise quality inspection criteria for critical cast components.

- For Design Engineers: The findings indicate that solidification thermal gradients across a component significantly influence local microstructure and properties. This is a valuable consideration in the early design phase, as part-component geometry and thickness variations can be optimized to promote favorable cooling conditions and ensure critical areas achieve the desired fine dendritic structure for maximum performance.

Paper Details

Parameters Influencing Dendritic Structure to Improve the Properties of As-Cast Aluminium Alloys

1. Overview:

- Title: Parameters Influencing Dendritic Structure to Improve the Properties of As-Cast Aluminium Alloys

- Author: Nisheeth Kr. Prasad, P. Kranthi Kumar, Ashok Sharma+ and M. K. Bhargava*

- Year of publication: 2014

- Journal/academic society of publication: Indian Foundry Journal (Vol 60, No. 10, October 2014)

- Keywords: Dendritic solidification, Dendrite Arm Spacing (DAS), Secondary Dendrite Arm Spacing (SDAS), Mushy Zone, Micro-Segregation, As-Cast Aluminium Alloys, ALPROP Model, MCAST, Grain Refinement, Mechanical Properties.

2. Abstract:

Dendritic microstructures are formed in most alloys during processes such as casting and welding. A semi-empirical model named ALPROP has been developed for the calculation of tensile properties and hardness in AlSiMg (Fe) foundry alloys. With chemical composition, dendrite arm spacing (DAS) and heat treatment parameters as input, the model calculates tensile properties and hardness for material in as-cast, solid-solution, heat-treated and in artificially-aged condition. It is seen that with decrease in dendritic arm spacing, the tensile strength, hardness and fatigue life increases. However, there is not much effect found on the yield strength. The present study makes an estimation of an automotive engine piston mechanical properties and fatigue life based on some characteristics of metallurgical microstructure. Alloy systems such as, Al-Si and Al-Si-Mg are taken to discuss the dentritic structure. Secondary dendritic arm spacing (SDAS) and grain size have great bearing on mechanical properties. Hence along with SDAS, more emphasis should also be given on the grain refinement to get better mechanical properties in the as-cast structure. The present study describes the effects of grain refinement in Al-10.2%Si using a newly developed process called as MCAST (melt conditioning by advanced shear technology). As a result, understanding the mechanisms for morphological selection of dendritic structures will be a key in the development of next-generation light-weight alloys used in automotive and aerospace applications.

3. Introduction:

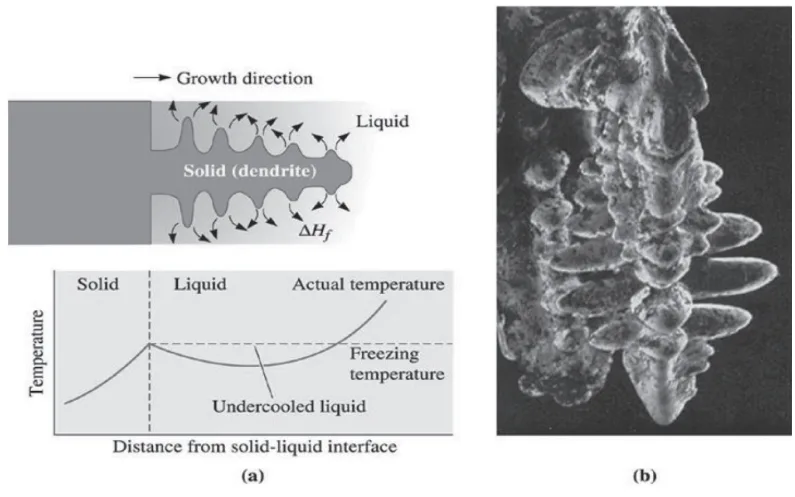

Dendritic solidification is a frequent occurrence under non-equilibrium conditions typical of casting and welding. This process can lead to the entrapment of solute-rich liquid between dendrite arms, which subsequently solidifies into solute-rich solid regions. This micro-segregation results in a "banded" microstructure, particularly after subsequent mechanical processing. The formation of dendrites occurs in a liquid-solid region known as the mushy zone, situated between the fully solid zone at the mould surface and the fully liquid zone at the center of the casting. The width of this mushy zone is influenced by the alloy's freezing range and the thermal gradient. The dendritic structures within this zone are often highly ramified and complex, arising from the growth of primary, secondary, and higher-order branches.

4. Summary of the study:

Background of the research topic:

The mechanical properties of as-cast aluminium alloys, which are widely used in automotive and aerospace industries, are critically dependent on their metallurgical microstructure. Dendritic structures, formed during solidification, and features such as secondary dendrite arm spacing (SDAS) and grain size, have a significant bearing on the final performance characteristics, including tensile strength, hardness, and fatigue life.

Status of previous research:

Previous work includes the development of the semi-empirical ALPROP model for predicting mechanical properties in AlSiMg(Fe) alloys based on composition and DAS. Various researchers have proposed relationships to estimate tensile strength from microstructural features. Bernsztejn proposed a linear function of silicon volume fraction, Mandal correlated strength with silicon particle size, and other models have linked tensile strength to SDAS and the size of silicon lamellas in interdendritic regions.

Purpose of the study:

The study aims to review the key parameters that influence dendritic structures in as-cast aluminium alloys. It seeks to establish the relationship between dendritic arm spacing and mechanical properties. A further objective is to estimate the mechanical properties of an automotive engine piston by analyzing its local microstructure and to describe the grain refinement effects of a newly developed process, MCAST (melt conditioning by advanced shear technology), in an Al-Si alloy.

Core study:

The core of the study is a multi-faceted review and analysis. It examines the fundamentals of dendritic solidification, the formation of the mushy zone, and micro-segregation. It then applies an empirical model to a case study of a commercial engine piston, correlating measured local SDAS values with calculated ultimate tensile strength. Finally, it presents experimental results demonstrating the efficacy of the MCAST process as a method for physical grain refinement in an Al-10.2%Si alloy, comparing its outcomes against conventional casting.

5. Research Methodology

Research Design:

The study employs a combination of a literature review, a case study analysis, and a presentation of experimental data. It synthesizes established models (ALPROP), empirical formulas, and new experimental findings (MCAST) to provide a comprehensive overview of the factors controlling dendritic structures and their impact on material properties.

Data Collection and Analysis Methods:

For the engine piston case study, microstructural analysis was performed on five distinct locations. Secondary Dendrite Arm Spacing (SDAS) was quantified using the line intercept method via an image analyzer (SDAS=d/nM). The ultimate tensile strength (UTS) was then calculated using the empirical relation: UTS = -1.4399*SDAS + 340 [MPa]. For the grain refinement study, optical microscopy was used to compare the grain size and morphology of Al-10.2%Si alloy samples produced by conventional casting and by the MCAST process at casting temperatures of 590°C and 650°C.

Research Topics and Scope:

The research focuses on as-cast aluminium alloys, particularly Al-Si and Al-Si-Mg systems. The scope includes the mechanisms of dendritic solidification, the influence of SDAS and grain size on mechanical properties (tensile strength, hardness, fatigue life), predictive modeling of properties, and methods of grain refinement, with a specific focus on the physical MCAST process.

6. Key Results:

Key Results:

- A decrease in dendritic arm spacing is correlated with an increase in tensile strength, hardness, and fatigue life. The effect on yield strength is reported to be minimal.

- In a case study of an automotive piston, SDAS was found to vary significantly with location, from 46.98 µm at the top position to 23.64 µm at the skirt. This variation is attributed to different local cooling rates.

- The calculated Ultimate Tensile Strength (UTS) for the piston increased from 202.36 MPa to 235.97 MPa as the SDAS decreased from the top to the skirt position.

- An inverse relationship was observed between the SDAS and the volume fraction of the eutectic phase within the piston's microstructure.

- The MCAST process (melt conditioning by advanced shear technology) was shown to produce a significantly finer and more equiaxed grain structure in an Al-10.2%Si alloy compared to conventional casting, without the use of chemical grain refiners.

- The grain refinement achieved by MCAST is substantial even at higher superheat casting temperatures, where conventional casting produces very large dendritic grains.

Figure Name List:

- Fig.1: (a) If the liquid is under-cooled, a protuberance on the solid-liquid interface may grow rapidly as a dendrite. (b) Scanning electron micrograph of dendrites in steel.

- Fig. 2: Formation of a mushy zone.

- Fig.3: Residual segregation index δ vs. dimensionless homogenisation parameter for low alloy steel (T. Z. Kattamis and M. C. Flemings, Transaction of the Metallurgical Society of AIME, 233,998,1965).

- Fig.4: Microstructure Analysis.

- Fig. 5: Regions of piston studied: 1-top position, 2- piston ring position, 3- top pin position, 4- down pin position, 5- skirt position

- Fig. 6: Secondary dendrite arm spacing.

- Fig. 7: Volume fraction of eutectic and α-aluminium dendrite phase.

- Fig. 8: Optical micrographs of specimen (a), (c) conventional and (b), (d) sheared, pouring temperature (a), (b) 590°C and (c), (d) 650 °C.

- Fig. 9: Variation of the grain size as a function of casting temperature for Al-10.2%Si alloy cast (with sheared and non-sheared).

7. Conclusion:

This paper reviews the various parameters affecting dendritic structure and the relationship between dendritic arm spacing and mechanical properties in aluminium alloys. Secondary dendrite arm spacing decreases with an increasing cooling rate during solidification. As SDAS decreases, the hardness, tensile strength, percentage elongation, and impact energy of the alloys increase. The improved mechanical characteristics are attributed largely to the shorter wavelength of microsegregation periodicity. The study also notes that finer grain structure, as obtained using the MCAST process in an Al-10.2%Si alloy, offers additional benefits such as refinement of intermetallic phases and their uniform distribution, leading to better overall properties in the final as-cast product.

8. References:

- Gurevich S., Amoorezaei M., Provatas N., Phys Rev E 2010, 82, p.160-166.

- Amoorezaei M., Gurevich S., Provatas N., Acta Mater 2010, 58, p.6115-6124.

- Haxhimali T., Karma A., Gonzales F., Rappaz M., Nat Mater 2006, 5, p.660-664.

- Amoorezaei M., Gurevich S., Provatas N., Acta Materialia 2012, 60, p.657-663.

- Martin E. Glicksman, Mechanism of Dendritic Branching, Metallurgical and Materials Transaction A, volume 43A, February 2012, p.391-404.

- S. P. Marsh, M. E. Glicksman, Metallurgical and Materials Transactions A, Volume 27 Issue 3, March 1996, p. 557-567.

- Masakazu Ikeda, Heat Flow and Dendritic Growth, January 1971, p.12-13.

- Aluminum Properties, a Model for Calculating Mechanical Properties in AlSiMgFe-Foundry Alloys. STIG BRUSETHAUG et al, Hydro Aluminum, R&D Materials Technology, Material Science and Technology. Vol. 18(1) 2000, p.3-7.

- Mechanical Resistance as a Function of Local Properties, George Chirita, Delfim Soares, The Annals of University Dunarea De Jos of Galati Fascicle viii, 2007 (xiii), ISSN 1221-4590 Tribology.

- Goulart, P.R., Spinelli, J.E., Osorio, W.R., Garcia, A., 2006, Mechanical Properties as a Function of Microstructure and Solidification Thermal Variables of Al-Si Castings, Materials Science and Engineering A 421, p. 245-253.

- Haque, M. M., Maleque, M. A., 1998, Effect of Process Variables on Structure and Properties of Aluminum-Silicon Alloy, Journal of Materials Processing Technology 77, p.122-128.

- Haque, M. M., Sharif, A., 2001, Study on Wear Properties of Aluminum-Silicon Piston Alloy, Journal of Materials Processing Technology 118, p. 69-73.

- Han, S.W., Kumai, S., Sato, A., 2002, Effects of Solidification Structure on Short Fatigue Crack Growth in Al-7%Si-0.4%Mg Alloy Casting, Materials Science and Engineering A332, p. 56-63.

- Shabestari, S.G., Moemeni, H., 2004, Effect of Copper and Solidification Conditions on the Microstructure and Mechanical Properties of Al-Si-Mg Alloys, Journal of Materials ProcessingTechnology, 153-154, p.193-198.

- Wang, Q.G., 2003, Microstructural Effect on the Tensile and Fracture Behaviour of Aluminium Casting Alloy A 356/357, Metallurgical and Materials Transaction, Vol. 34 A, December, p. 2887-2899.

- Bernsztejn, L., Zajmowskij, W.A., 1973 Struktura i własnos cimechanicznemetali (Structure and Mechanical Properties of Metals), Wyd. Naukowo-Techniczne, Warsaw.

- Mandal, P., Saha, A., Chakraborty, M., 1991, Size of Primary Silicon Particles and Mechanical Properties of As-cast High Silicon Al Alloys, AFS Trans. p.99, 33.

- Takahashi, T., Sugimura, Y., Sasaki, K., 2004, Thermal Plastic-Elastic Analysis in Consideration of Metallurgical Microstructure, Journal of Manufacturing Science and Engineering, Vol.126, p. 25-32.

- Radjai A., Miwa K., Metal Mat Trans 2000, A31, 755-762.

- Fan, Z., Bevis, M.J., Ji, S., PCT Patent, WO 01/21343 A1, 1999.

- Fan Z., Wang Y., Xia M., Arumuganathar S., Acta Mater 2009, 57, 4891-4901.

- Fan Z., Wang Y., Zhang Z.F., Xia M., Li H.T., Xu J., Gránásy L., Scamans Inter GM. J Cast Met Res 2009, 22(1-4), p.318-322.

- Das A., Liu G., Fan Z., Mater Sci Eng. 2006, A419, p.349-356.

- Das A., Ji S., Fan Z., In: Tsutsui Y., Kiuchi M., Ichikawa K., Editors, Proceedings of the 7thS2P, Advanced Semi-solid Processing of Alloys and Composites, 2002, Tsukuba, Japan.

- H.R. Kotadia, N. Hari Babu, H. Zhang, Z. Fan, Microstructural Refinement of Al-10.2%Si Alloy by Intensive Shearing, Materials Letter, (2010), p. 1-3.

Expert Q&A: Your Top Questions Answered

Q1: Why does the ALPROP model use a fixed value of n=0.5 in the Ludvig stress-strain law for its calculations?

A1: The paper states that the value of n=0.5 is "prescribed as a typical value for n in aluminium alloys." This suggests that for the semi-empirical model's purpose of predicting tensile properties in these specific alloy systems, using a standardized, representative value for the strain hardening exponent provides a reliable and practical estimation without requiring complex experimental determination for every case.

Q2: The paper states that decreasing dendritic arm spacing increases tensile strength and hardness, but has little effect on yield strength. Why is this the case?

A2: The paper's abstract makes this observation directly, but does not provide a detailed metallurgical explanation for the phenomenon. It states, "It is seen that with decrease in dendritic arm spacing, the tensile strength, hardness and fatigue life increases. However, there is not much effect found on the yield strength." This finding highlights that the mechanisms enhanced by finer microstructures, such as resistance to crack propagation and dislocation movement during plastic deformation, have a more pronounced impact on ultimate strength and hardness than on the initial point of yielding.

Q3: What is the primary mechanism by which the MCAST process refines grain structure without chemical additives?

A3: The MCAST process induces grain refinement through intense physical forces. The paper explains that the MCAST unit provides a "high shear rate and high intensity turbulence." This promotes the primary phase to grow into a globular, rather than dendritic, morphology. Additionally, the intensive shearing disperses and breaks up oxide films and inclusion clusters into fine, uniformly distributed particles, which can serve as potent nucleation sites for new grains during solidification.

Q4: How was the Secondary Dendrite Arm Spacing (SDAS) specifically measured in the piston study?

A4: The paper details that the SDAS was quantified by first identifying and measuring small groups of well-defined secondary dendrite arms on the screen of an image analyser. The final value was then calculated using the line intercept method formula: SDAS=d/nM, where 'd' is the length of the line drawn across the measured arms, 'M' is the magnification of the image, and 'n' is the number of dendrite arms that the line crosses.

Q5: The study of the engine piston showed an inverse relationship between SDAS and the volume fraction of the eutectic phase. What is the significance of this finding?

A5: The paper highlights this as an interesting observation: "the region with higher values of the SDAS has small amount of eutectic phase." This suggests that the solidification conditions that lead to coarser dendrites (slower cooling) also result in a lower volume fraction of the final eutectic phase to solidify. While the paper does not elaborate on the deeper implications, this correlation is valuable for metallurgists, as it links thermal history not only to the scale of the primary phase (dendrites) but also to the proportion of the constituent phases in the final microstructure.

Conclusion: Paving the Way for Higher Quality and Productivity

The research summarized here provides a clear and actionable framework for improving the properties of as-cast aluminium alloys. The core challenge—inconsistent mechanical properties due to uncontrolled dendritic growth—can be met with a focused strategy of Dendritic Structure Control. By managing cooling rates to reduce Secondary Dendrite Arm Spacing (SDAS) and employing advanced physical refinement techniques like MCAST, manufacturers can significantly enhance the tensile strength, hardness, and fatigue life of their components. These findings offer a direct path to producing lighter, stronger, and more reliable parts for the most demanding applications.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Parameters Influencing Dendritic Structure to Improve the Properties of As-Cast Aluminium Alloys" by "Nisheeth Kr. Prasad, P. Kranthi Kumar, Ashok Sharma, and M. K. Bhargava".

Source: Indian Foundry Journal, Vol 60, No. 10, October 2014, pp. 23-28.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.