This article is from FSI (flow3d.com), a developer of numerical analysis software FLOW-3D.

P-Q2 analysis is a standard procedure used to optimally match the target gate velocity to the capabilities of the HPDC (High Performance Die Casting) machine’s plunger hydraulic system. Desired fill time and an optimum gate design can be attained by performing P-Q2 analysis, which in turn, maximizes the efficiency of the HPDC system.

Physics

The theoretical basis of the P-Q2 analysis is the conservation of energy for steady incompressible flow. According to Bernoulli’s equation, the metal pressure at the gate is proportional to the flow rate squared:

The assumptions for this analysis are:

- Constant discharge coefficient

- Liquid metal has reached the gate

- No air in metal stream at the gate

- No solidification during the filling

- Runner is the main resistance in the flow

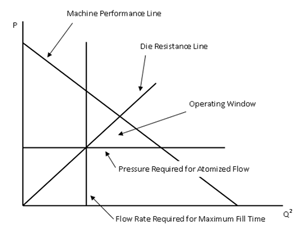

As shown in a typical P-Q2 diagram below, the machine performance line shows how the die casting machine capabilities vary depending on the flow rate. A larger flow rate demands a larger pressure from the machine to move the plunger at desired velocity. This means that, the higher the pressure, smaller the plunger, and the higher the flow rate, the larger the plunger. The operational window is defined by the fill time, gate velocity, metal pressure, etc. It is important that both the die and machine operate within the operational window (Figure 1).

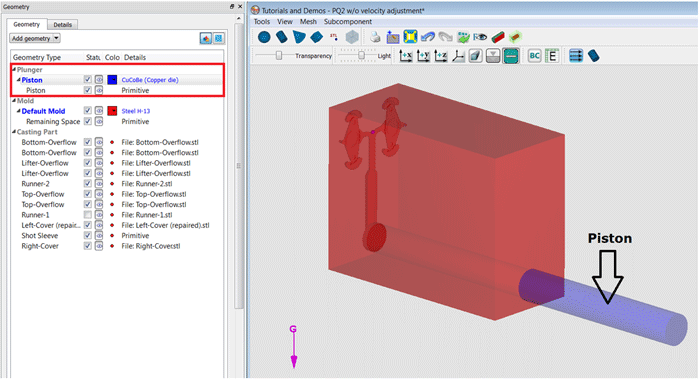

P-Q2 analysis in FLOW-3D

P-Q2 analysis in FLOW-3D is performed in the following way.

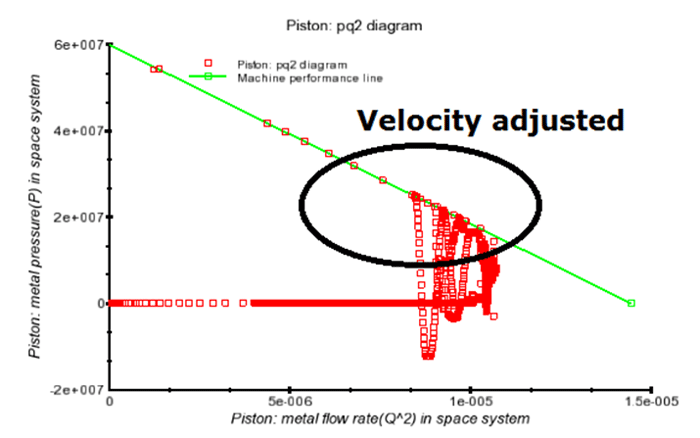

Custom process parameters may not be optimal at the design stage. For example, the resulting pressure exceeds the machine performance. If so, you can adjust the speed, etc. so that the piston speed automatically adjusts to match the machine performance.

Conclusion

FLOW-3D Cast allows you to perform P-Q2 analysis that helps achieve desired fill time and optimum gate design. The analysis data can be viewed and processed in FLOW-3D POST, an integrated post-processor that comes with the FLOW-3D Cast installation.