This introduction paper is based on the paper "Metal Casting: Back to Future" published by "Proceedings of the 52nd Indian Foundry Congress, Hyderabad, February 2004".

1. Overview:

- Title: Metal Casting: Back to Future

- Author: B. Ravi, G.L. Datta

- Year of publication: 2004

- Journal/academic society of publication: Proceedings of the 52nd Indian Foundry Congress, Hyderabad, February 2004

- Keywords: Ancient India, Casting, CAD/CAM, Investment Casting, Lost Wax Method, Net Shape Manufacturing, Pattern and Mould.

2. Abstract:

Future requirements of castings – thin intricate shape, minimal machining and small order quantity – can be met by going back to the time tested lost wax casting process. It was perfected in India over many centuries, but started getting ignored in the last few decades owing to other processes for mass production developed in the West, many of them with unacceptable environmental effects. In this paper, we take a comprehensive look at the ancient art of investment casting, its current state-of-the-art and some emerging computer-aided technologies relevant to wax pattern development. A hybrid methodology is proposed combining the strengths of all three (capabilities inherited from the past, resources available at present and appropriate technologies borrowed from the future), and validated by a real-life experiment. We hope this will motivate Indian foundries to critically assess their capabilities, and explore new combinations of metal, process, geometry and application to establish a niche in the global market.

3. Introduction:

Casting requirements have significantly changed due to technology push (CAD/CAE/CAM, miniaturization) and market pull (better appearance, competitive cost). Future castings are expected to be smaller, more intricate with freeform curves, thin walls, and required in net shape with minimal or no machining. Order sizes will reduce due to shorter product life-cycles, continuous design improvements, lower inventory, and mass customisation, leading to single-casting-on-demand systems. Current widely used processes like sand casting (environmental concerns, inability to produce thin walls) and die casting (suitable only for non-ferrous metals, large order quantities, cost magnification for intricate undercuts) cannot fully meet these new demands. While newer casting processes were developed in the West, they are now often procured from developing countries. India, despite its long tradition in metal casting, rich resources, large engineer pool, and IT advancements, produces only 4% of global castings with a lesser export share. The ancient lost wax or cire perdue casting method, reinvented as investment casting in the 1940s, can meet these emerging requirements. It offers high dimensional tolerance (1 micron per mm), best surface finish (1-2 micron), thinnest sections (about 1.5 mm), can produce undercuts without cores, usually requires no draft, and is flash-absent. It has no limitation on metal type and is suitable for small parts (<20 kg), though larger parts (up to 100 kg) are also produced. India is renowned for its investment casting skills (e.g., ‘Chola bronze’, ‘Dhokra iron’ art castings). This paper explores a hybrid methodology, adapting ancient investment casting to industrial needs using appropriate, economical, and nature-friendly technologies.

4. Summary of the study:

Background of the research topic:

The evolving demands in the casting industry necessitate processes capable of producing intricate, thin-walled, net-shape castings in small order quantities. Traditional methods like sand casting and die casting have limitations in meeting these modern requirements.

Status of previous research:

The paper reviews three stages of investment casting:

- Ancient Lost Wax Process: Practiced in India for over 5000 years, using natural materials and manual skill for creating intricate idols and other items. Characterized by unique patterns for single castings. (e.g., Indus Valley, Chola dynasty).

- Current Investment Casting: Industrialized process using wax injection into metal dies for pattern production, ceramic shell moulds, and controlled dewaxing and pouring. Suitable for medium order quantities and net shape parts.

- Future Technologies: Computer-aided technologies for pattern and die development, including:

- Solid modelling of intricate shapes (3D scanning, haptic modelling).

- Intelligent methoding and optimisation (e.g., AutoCAST for feeder/gating design and simulation).

- Rapid prototyping of casting patterns (e.g., FDM, Stereolithography, Thermojet, ZPrinter, LOM).

Purpose of the study:

To propose and validate a hybrid methodology for metal casting that combines the strengths of ancient techniques, current industrial practices, and emerging computer-aided technologies. This approach aims to meet the future requirements of castings, particularly for intricate shapes, minimal machining, and small order quantities, and to motivate Indian foundries to establish a niche in the global market.

Core study:

The core of the study is the development and demonstration of a hybrid approach to investment casting. This approach involves:

- Part solid modelling: Using reverse engineering or 3D modelling systems.

- Optimal methoding: Employing intelligent programs for design and simulation.

- Tooling fabrication: Using direct rapid prototyping for one-off wax patterns or RP-based routes for wax injection dies.

- Shell/mould making: Using ceramic shells or clay moulds based on casting requirements.

- Dewaxing, pouring and fettling: Using current industry best practices.

A case study involving the creation of a Ganesha idol was conducted to validate this hybrid approach. An ancient drawing was used as a reference for haptic-based 3D solid modelling. The model was then used for rapid prototyping of a wax pattern, followed by ceramic shell creation and investment casting in austenitic stainless steel.

5. Research Methodology

Research Design:

The research design involves a comprehensive review of historical, current, and emerging technologies in investment casting. Based on this review, a hybrid methodology is conceptualized. This methodology is then validated through a practical case study: the creation of an intricate Ganesha idol using the proposed hybrid steps.

Data Collection and Analysis Methods:

Data was collected from:

- Historical texts and archaeological evidence on ancient Indian casting (e.g., Shilpashastra, Indus Valley excavations).

- Current industrial practices in investment casting.

- Literature and industry information on CAD/CAM, 3D scanning, haptic modelling, casting simulation software (e.g., AutoCAST, Magma), and rapid prototyping technologies (e.g., Thermojet).

The analysis involved comparing the capabilities and limitations of each approach (ancient, current, future) to identify synergies for a hybrid model. The case study served as an experimental validation of the proposed hybrid process.

Research Topics and Scope:

The research covers:

- The historical context and techniques of ancient Indian lost wax casting.

- The current state-of-the-art in industrial investment casting processes.

- Emerging computer-aided technologies relevant to pattern development, including solid modelling of intricate shapes (3D scanning, haptic modelling), intelligent methoding and optimisation (casting simulation), and rapid prototyping of casting patterns.

- The development of a hybrid methodology combining these elements.

- A case study (Ganesha idol) to demonstrate the feasibility of the hybrid approach for producing intricate, one-off castings.

The scope is focused on meeting future casting requirements: thin intricate shapes, minimal machining, and small order quantities.

6. Key Results:

Key Results:

The study successfully demonstrated a hybrid approach to metal casting by combining ancient inspiration, modern 3D modelling techniques, rapid prototyping, and current investment casting practices.

- A complex Ganesha idol was modelled using a haptic-based solid modelling system in approximately 25 hours over 5 days, significantly less time than conventional solid modelling.

- The 3D model was converted to an STL file (approx. 200,000 facets) and used for methoding and simulation.

- A wax pattern was fabricated using a Thermojet RP system in about 12 hours.

- The wax pattern was successfully investment cast in austenitic stainless steel after creating a ceramic shell over four days.

- The proposed hybrid route is deemed economically justifiable for one-off intricate castings required urgently, such as replacement parts for critical equipment and medical prosthetics.

- The study suggests that this approach can help Indian foundries leverage their traditional skills and modern technological capabilities to compete globally.

Figure Name List:

- Fig. 1. Ancient lost wax casting method: wax model sculpting, clay covering, wire clasped mould for dewaxing, as-cast Ganesha, and finishing

- Fig. 2. Industrial investment casting process: wax injection pattern, attaching to gating, dipping in ceramic slurry, sand stuccoing, controlled drying and pouring in hot mould.

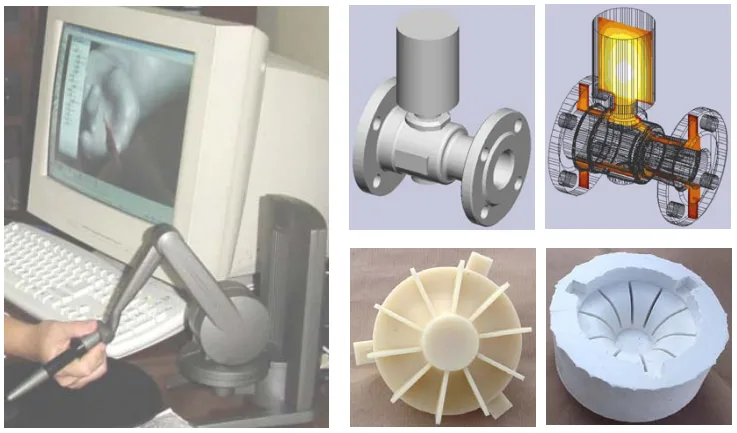

- Fig. 3. Some modern technologies relevant to investment casting of complex parts. Left- touch based solid modelling; right top- intelligent feeder design and analysis; right bottom- rapid prototyped wax model and corresponding rubber mould.

- Fig. 4. Creating a Ganesha model using a touch-based system. Top- registering the drawing, adding virtual clay and shaping; Bottom- front and side views of the final model.

- Fig. 5. Physical realisation of Ganesha: wax pattern made by rapid prototyping, followed by support structure removal and investment casting.

7. Conclusion:

India possesses proven capabilities in both ancient metal casting and modern information technologies. To excel in competitive global manufacturing, these capabilities must be combined. The paper demonstrates that emerging casting requirements (intricate, near-net, casting-on-demand) can be met by a judicious combination of technologies from the past, present, and future. A proposed route involves computer-aided design and rapid prototyping for pattern development, followed by clay-moulded (ancient) or ceramic shell (current) methods for investment casting. While currently economically viable mainly for urgent, one-off intricate castings (e.g., critical replacement parts, medical prosthetics), this hybrid approach is expected to expand its reach as system costs decrease and process efficiencies improve. Foundries are encouraged to experiment with such new routes, identify optimal combinations of application, geometry, material, and process, and specialize to establish a niche in the global market.

8. References:

- [1] Satya Pal, Ancient Indian Art Casting, Foundry, Vol.13, No.2, 13-23, 2001.

- [2] R.M. Pillai, S.G.K. Pillai and A.D. Damodaran, The Lost-Wax Casting of Icons, Utensils, Bells and Other Items in South India, Metals, Materials and Processes, Vol.13, 291-300, 2001.

- [3] B. Ravi, Investment Casting Development: Ancient and Modern Approaches, Proceedings, National Conference on Investment Casting, CMERI Durgapur, September 22-23, 2003.

- [4] G.L. Datta and Vidyut Dey, An Overview of the Status of Investment Casting Process, Proceedings, National Conference on Investment Casting, CMERI Durgapur, September 22-23, 2003.

- [5] B. Ravi, Casting Design Knowledge Management, Proceedings, 51st Indian Foundry Congress, Jaipur, January 23-25, 2003.

- [6] D. Pal, B. Ravi, L.S. Bhargava, U. Chandrasekhar, “One-off Intricate Castings using Laser Scanning and Rapid Prototyping Technology,” Proceedings, 2nd Conference of the Rapid Prototyping Society of India, Bangalore, June 2003.

9. Copyright:

- This material is a paper by "B. Ravi, G.L. Datta". Based on "Metal Casting: Back to Future".

- Source of the paper: [https://www.researchgate.net/publication/267417712_Metal_Casting_Back_to_Future] (Note: This is the ResearchGate link from the provided image, actual DOI might differ or not be present in the original proceedings.)

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.