This introduction paper is based on the paper "Mega and Giga Casting: A New Technological Paradigm for Die Material and Design" published by "The 75th World Foundry Congress".

1. Overview:

- Title: Mega and Giga Casting: A New Technological Paradigm for Die Material and Design

- Author: Isaac Valls, Thibault Le Bourdiec*, Anwar Hamasaiid (ROVALMA S.A., C/ Collita 1-3, 08191 Rubí, Spain; *Corresponding address: e-mail: tlebourdiec@rovalma.com)

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress (Part 13: Additive Manufacturing)

- Keywords: Not explicitly listed in the provided text.

2. Abstract:

The sociotechnological transition to electric mobility requires much lighter, more economic and more sustainable life cycle Electric Vehicles (EVs). To meet with these conditions, the technological ecosystem of the automotive industry needs to develop and shape new light materials, complex and large geometries as well as functionally and compositionally graded components, at reduced cost. Aluminium based alloys are among the choice candidates to meet these requirements considering their high formability and recyclability features, as well as good combination of density, mechanical and physical properties.

3. Introduction:

According to a study carried out for the European Aluminium Association [1], the aluminium content of passenger vehicles in Europe will increase from 205 kg in 2022 to 256 kg in 2030. Very similar forecasts are also cited for American vehicles [2]. Accordingly, the decrease in demand for castings associated with the combustion engine will be largely counterweighed by the demand for new aluminium based components for EVs, such as for motor housings, BEV and PHEV battery enclosure assemblies and different structural parts. The demand for automotive structural parts, manufactured by die casting, is expected to increase sharply from 8.2 million in 2021 to 25 million in 2030 [3]. The cited studies agree that more than 50% of the projected aluminium based parts will be shaped by die casting methods in particular High Pressure Die Casting (HPDC). In these studies, the fast uptake of Mega and Giga high pressure die casting was not taken into consideration. Hence, yet much higher demand for HPDC parts can be expected than forecasted in the coming years.

The geometries of these new parts, the new aluminium alloys, and the size of the components are significantly changing the technological paradigm of the die casting process in particular die making processes. There are indisputable needs to new die design, cooling strategies, die materials, die machining and die life management technology in order to address the challenges related to the three Key Technological Enablers (KTEs) of Mega and Giga casting which are i) durability of the expensive dies and the related die components, ii) the productivity of the process (scrap rate, cycle time, production stability, etc.) and iii), the part and process quality and the related monitoring and controlling technologies.

In this paper, three innovative technologies, with significant potential to address the challenges related to the above mentioned three KTEs will be presented and discussed.

4. Summary of the study:

Background of the research topic:

The sociotechnological transition to electric mobility necessitates lighter, more economic, and sustainable Electric Vehicles (EVs). This drives the need for new light materials, complex and large geometries, and functionally graded components, often produced using Aluminium based alloys due to their favorable properties. The demand for large aluminium die-cast components, particularly for EVs through High Pressure Die Casting (HPDC), is significantly increasing with the advent of Mega and Giga casting, posing new challenges for die materials, design, and manufacturing processes.

Status of previous research:

Previous studies [1, 2, 3] have forecasted increased aluminium use in vehicles and growth in HPDC structural parts, but these did not fully incorporate the impact of Mega and Giga casting. Current State of Art (SoA) Metal Additive Manufacturing (MAM) technologies often have limitations regarding cost, the thermo-mechanical properties of manufactured tools, material selection (especially for carbon-based tool steels), and the production of large components. For example, EN-DIN 1.2709 maraging steel, commonly used in SoA MAM, exhibits low thermal conductivity (14-18 W/m.K) and poor abrasive wear resistance for die casting applications.

Purpose of the study:

This paper aims to present and discuss three innovative technologies designed to address the challenges associated with the three Key Technological Enablers (KTEs) of Mega and Giga casting. These KTEs are: i) the durability of expensive dies and related components, ii) the productivity of the process (including scrap rate, cycle time, and production stability), and iii) the quality of parts and processes, along with related monitoring and controlling technologies.

Core study:

The study focuses on three innovative technologies:

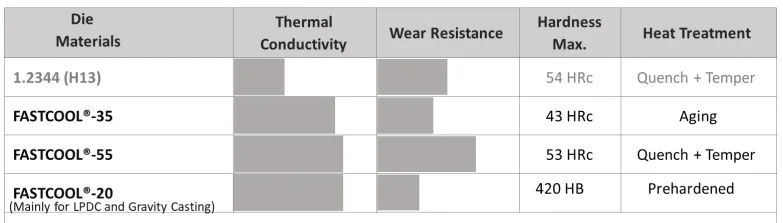

- High Thermal Conductivity Tool Steels (HTCS): Introduction of HTCS grades (FASTCOOL®-55, FASTCOOL®-20, and FASTCOOL®-35) with very high thermal conductivities (up to 55-62 W/mK) compared to conventional tool steels (20-29 W/mK). FASTCOOL®-35 is highlighted for its precipitation hardening capability, simplifying heat treatment and reducing die making time.

- ROVALMA® MAM (Metal Additive Manufacturing): A disruptive MAM method capable of printing high-performance die components from HTCS and conventional carbon-based tool steels. This technology can produce large parts (up to 600 x 700 x 2200 mm) at competitive speeds and costs, offering flexibility for advanced conformal cooling designs beyond current SoA MAM.

- Advanced Embedded Sensors: The integration of the aforementioned technologies with advanced multirole sensors for measuring the temperatures of the injected alloy and the die. This facilitates performant thermal management and monitoring to enhance die lifespan, minimize scrap, and optimize overall productivity.

5. Research Methodology

Research Design:

The paper utilizes a descriptive and comparative methodology. It introduces novel technologies (HTCS, ROVALMA® MAM, and embedded sensors) and elaborates on their features, benefits, and potential applications in tackling the challenges of Mega and Giga casting. This is often achieved by contrasting these innovations with conventional materials, manufacturing methods, and existing SoA MAM technologies.

Data Collection and Analysis Methods:

The paper presents material property data, such as a table comparing thermal conductivity, wear resistance, maximum hardness, and heat treatment for FASTCOOL® series tool steels against conventional EN-DIN 1.2344 / H13. The paper states that the advantages of these technologies will be further highlighted through "several industrial use cases" and "different uses cases." An illustrative example of temperature data acquired by an embedded multirole sensor in a die during a die casting operation is also mentioned and shown in a figure.

Research Topics and Scope:

The research topics addressed include:

- Novel die materials, with a focus on high thermal conductivity tool steels (HTCS).

- Advanced die manufacturing techniques, emphasizing the ROVALMA® MAM technology for producing large die components with conformal cooling.

- Process monitoring and control through the application of embedded sensor technology for effective thermal management in die casting.

The scope is centered on resolving the challenges presented by Mega and Giga casting processes used in the production of automotive components, especially for Electric Vehicles (EVs).

6. Key Results:

Key Results:

- New high thermal conductivity tool steel grades, specifically FASTCOOL®-55, FASTCOOL®-20, and FASTCOOL®-35, have been developed. These steels exhibit thermal conductivities up to 55-62 W/mK, a significant improvement over conventional tool steels like EN-DIN 1.2344 / H13 (typically 20-29 W/mK). FASTCOOL®-35 can be hardened via a simple age hardening process, which can reduce die making time by over two weeks, increase productivity, and lower scrap rates by minimizing hot spots.

- ROVALMA® MAM technology facilitates the additive manufacturing of large (up to 600 x 700 x 2200 mm), high-performance die components using materials such as HTCS and conventional carbon-based tool steels. This method is presented as cost-effective and competitive with traditional machining, while also enabling the creation of advanced conformal cooling channels that surpass the capabilities of current State of Art (SoA) MAM. This addresses issues like low thermal conductivity and durability associated with materials like 1.2709 steel, often used in other AM processes.

- The synergy of these advanced materials and MAM technology with embedded multirole sensors enables precise measurement of both injected alloy and die temperatures. This capability leads to improved thermal management, extended die life, reduced scrap, and optimized productivity in Mega and Giga casting. An example cited involves temperature measurement in a die for Al-9Si-3Cu (A380) alloy on a 1650T cold chamber die casting machine.

Figure Name List:

- Table: Comparison of properties (Thermal Conductivity, Wear Resistance, Hardness Max., Heat Treatment) for Die Materials 1.2344 (H13), FASTCOOL®-35, FASTCOOL®-55, and FASTCOOL®-20 (Mainly for LPDC and Gravity Casting).

- Figure: Temperature measured by a multirole sensor embedded in a die for Al-9Si-3Cu (A380) alloy during a die casting process on a 1650T cold chamber die casting machine.

7. Conclusion:

The transition to electric mobility is driving significant advancements in die casting, especially for large structural components produced via Mega and Giga casting. This paper introduces three pivotal innovative technologies to meet the ensuing challenges:

- High thermal conductivity tool steels (HTCS), such as the FASTCOOL® series, enhance productivity and extend die life.

- ROVALMA® MAM technology provides a cost-effective means to produce large, high-performance dies with sophisticated conformal cooling, utilizing a broader spectrum of materials including HTCS.

- Embedded sensor technology allows for superior thermal management and process monitoring.

The integration of these innovations—advanced die materials, disruptive additive manufacturing, and advanced sensor technology—establishes a new technological paradigm for die material and design. This holistic approach pushes the current boundaries of cooling systems and die design, proving essential for prolonging die life, minimizing scrap, and sustaining optimized productivity in the demanding environment of Mega and Giga casting for automotive applications.

8. References:

- [1] Ducker Research & Consulting, Aluminium Content in Passenger Vehicles (Europe) 2022 assessment and outlook 2026, 2030, public summary, April 2023.

- [2] Svendsen A., Aluminium Continues Unprecedented Growth in Automotive Applications, Light Metal Age Magazine, 2020.

- [3] Roos H.J., Lagler M. et Quintana L: Whitepaper: The Future of Structural Components in HPDC. Bühler AG, 2019.

9. Copyright:

- This material is a paper by "Isaac Valls, Thibault Le Bourdiec, Anwar Hamasaiid". Based on "Mega and Giga Casting: A New Technological Paradigm for Die Material and Design".

- Source of the paper: [DOI URL not provided in the source document]

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.