Unlock Peak Performance: How Water Quality Drives Casting Cooling Process Optimization

This technical summary is based on the academic paper "Influence of Water Quality and Kind of Metal in the Secondary Cooling Zone of Casting Process" by M.Sc. Khalid Haroun Mohamed Abdalrahman, a dissertation for the Otto-von-Guericke-Universität Magdeburg (2012). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Casting Cooling Process Optimization

- Secondary Keywords: secondary cooling, water quality in casting, Leidenfrost temperature, heat transfer coefficient, ingot quality, non-ferrous metal casting, surface roughness

Executive Summary

- The Challenge: Inconsistent cooling in continuous casting leads to thermal stress, cracking, and variable product quality, but the specific influence of cooling water composition has been poorly understood.

- The Method: The researcher heated discs and sheets of various non-ferrous metals and quenched them with water jets and sprays, measuring the temperature field on the non-contact side with a high-precision infrared camera.

- The Key Breakthrough: The study established a direct, approximately linear relationship between the electrical conductivity of the cooling water and critical cooling parameters, including the Leidenfrost temperature, maximum heat flux, and DNB temperature.

- The Bottom Line: Monitoring and controlling the electrical conductivity of cooling water provides a powerful, direct method for managing the cooling rate and improving the final quality and consistency of cast metal products.

The Challenge: Why This Research Matters for HPDC Professionals

In any high-volume casting operation, the secondary cooling phase is where product quality is either secured or compromised. Uncontrolled cooling can introduce significant thermal stresses, leading to distortion and hot cracks, which directly impact yield and profitability. While engineers have long known that cooling water characteristics matter, the precise relationship between water quality and cooling rates has remained ambiguous.

Operational experiences often show that adjusting water flow rates and nozzle arrangements can improve quality, but fluctuations persist. This is often due to changes in the cooling water itself as it circulates and accumulates dissolved salts, lubricants, and other substances. This research was undertaken to move beyond anecdotal evidence and establish a scientific, measurable link between specific water properties and their direct impact on heat transfer, providing a new lever for process control.

The Approach: Unpacking the Methodology

To isolate and measure the key variables in the secondary cooling zone, a robust experimental setup was constructed.

- Materials & Samples: Discs (140 mm diameter) and sheets of various non-ferrous metals were used, including Aluminum alloy (AA6082), nicrofer, nickel, inconel, and several copper alloys. The rear (measurement) side of each sample was coated with graphite to achieve a high, stable emissivity of approximately 0.9 for accurate thermography.

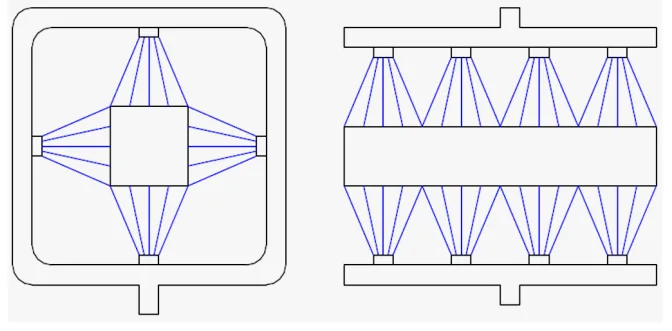

- Heating & Quenching: Samples were heated in a furnace to temperatures up to 600°C and then moved to a quenching station. Cooling was applied using either a hydraulic nozzle with a constant impingement density (3 kg/m²/s) or a segment of a casting mould with seven orifices delivering water jets.

- Data Acquisition: The temperature field on the back side of the samples was measured at high frequency using a FLIR SC3000 infrared camera. This non-contact method allowed for a detailed, time-resolved map of the cooling process.

- Key Variables Tested:

- Water Quality: Deionized water was used as a baseline and mixed with various additives, including single salts (MgSO₄, NaCl), casting lubricants (borax, graphite), surfactants, and dissolved gases (O₂, N₂, CO₂). Eight different real-world industrial water samples were also tested.

- Metal Type: The influence of the metal's intrinsic thermal properties (conductivity, heat penetration coefficient, thermal diffusivity) was analyzed.

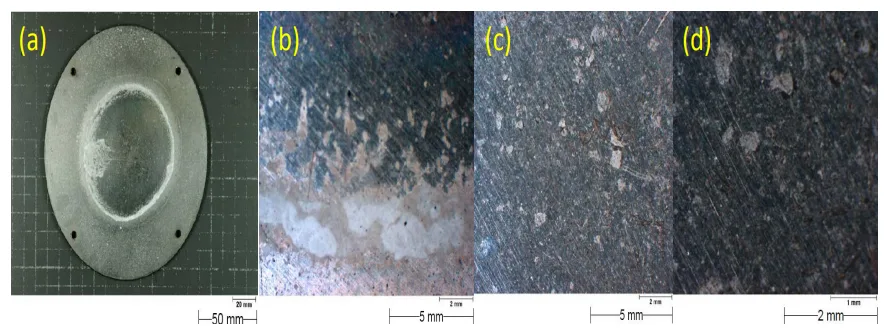

- Surface Roughness: Samples with mean roughness values from 0.2 µm to 7.7 µm, as well as real ingot surfaces, were tested.

- Jet Velocity: The outflow velocity of water jets from the mould was varied to find its effect on the cooling rate.

The Breakthrough: Key Findings & Data

The research delivered several critical insights, with the most significant being the quantifiable link between water chemistry and heat transfer efficiency.

Finding 1: Electrical Conductivity is the Master Variable for Water Quality

The study conclusively demonstrated that for water containing dissolved salts, electrical conductivity is the single most important parameter for predicting cooling performance. The addition of salts like MgSO₄ and NaCl shortened cooling times by directly influencing key heat transfer characteristics.

As shown in the paper's analysis (Figure 4.36), the Leidenfrost temperature, DNB-temperature, and maximum heat flux (MaxHF) all increase approximately linearly with the electrical conductivity of the water. For example, the Leidenfrost temperature among eight different real industrial water samples differed by as much as 200 K, a variation that correlated directly with their conductivity. In contrast, the pH value and hardness of the water showed no direct influence on the cooling rate. This finding provides a simple, reliable metric (EC) to monitor and control the cooling power of the process water.

Finding 2: Metal Properties Dictate Critical Cooling Temperatures

The type of metal being cast has a profound impact on the cooling process, specifically on the temperatures at which boiling transitions occur. The research found a clear correlation between the metal's thermal properties and its cooling behavior under identical quenching conditions.

The study concluded that the higher the heat penetration coefficient (√λρCp) and the thermal diffusivity of a metal, the lower its Leidenfrost and Departure from Nucleate Boiling (DNB) temperatures. This means that metals that can conduct heat away from the surface more effectively (like aluminum) will transition out of the inefficient film boiling regime at lower temperatures compared to metals with lower thermal properties (like nickel alloys). This insight is crucial for developing alloy-specific cooling strategies to prevent defects.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the cooling water's electrical conductivity through controlled dosing of specific salts may contribute to achieving faster, more uniform cooling, potentially reducing cycle times and defects like hot cracking. Monitoring EC in real-time could become a key process control parameter.

- For Quality Control Teams: The data in Figure 4.36 and Figure 5.14 of the paper illustrates the effect of water conductivity and metal type on the Leidenfrost temperature. This knowledge could inform new quality inspection criteria, as variations in these parameters directly influence the solidification microstructure and residual stresses in the final product.

- For Design Engineers: The findings indicate that material selection has a direct and predictable influence on the required cooling strategy. The significant differences in Leidenfrost temperatures between alloys suggest that designing components for castability should include an analysis of the material's thermal properties in relation to the plant's cooling capabilities.

Paper Details

Influence of Water Quality and Kind of Metal in the Secondary Cooling Zone of Casting Process

1. Overview:

- Title: Influence of Water Quality and Kind of Metal in the Secondary Cooling Zone of Casting Process

- Author: M.Sc. Khalid Haroun Mohamed Abdalrahman

- Year of publication: 2012

- Journal/academic society of publication: Dissertation, Fakultät für Verfahrens- und Systemtechnik, der Otto-von-Guericke-Universität Magdeburg

- Keywords: Secondary cooling, water quality, Leidenfrost temperature, heat transfer, continuous casting, non-ferrous metals, surface roughness

2. Abstract:

In the secondary cooling zone of the continuous casting of non-ferrous metals, the heat is transferred from the ingots using water sprays or water jets coming out of the mould. Unknown aspects of the heat transfer have been experimentally researched. Therefore, discs and sheets of different metals were heated in a furnace, removed and hung on a track in front of the quenching facility. The discs (140 mm diameter, 2-4 mm thickness) were cooled with a hydraulic nozzle with a constant impingement density of 3 kg/m²/s. The sheets (length 140 mm, width 70 mm, thickness 2-4 mm) were cooled with a segment of a mould consisting of seven orifices with a diameter of 2.4 mm. The water jets of the mould impinge the sheets at an angle of 30°. The temperature field of the back side of the samples was measured using an infrared camera. Therefore, the surface was coated with graphite in order to achieve a high emissivity. Its value was measured with dependence on temperature by using a specially calibrated device. The emissivity is about 0.9 and kept constant. The heat transfer was analyzed through two methods. In the first method, the temperature difference between both sides is neglected, because the Biot numbers are very small. The local heat transfer can then be calculated from a simple differential energy balance. In the second method, the temperature on the cooled side was calculated from the measured temperatures on the back side by using an inverse solution of the 2D Fourier differential equation. Both methods give similar results. At first, the influence of the water quality was researched. For this, the deionized water was used as the reference water. This water was mixed with different typical additives. The addition of salts shortens the cooling time. The maximum heat flux, the DNB-temperature in the film boiling region, and especially the Leidenfrost temperature increase approximately linearly with the concentration. The salt MgSO₄ shows the strongest effect and the salt NaCl shows the weakest effect. The salts influence the electrical conductivity of the water because they dissociate. Therefore, for the salt mixture of real water, the electrical conductivity was found as a measurement to evaluate their cooling effect. Eight different waters which are commonly used in industrial process were tested. The cooling time of the discs varied within a factor of three.

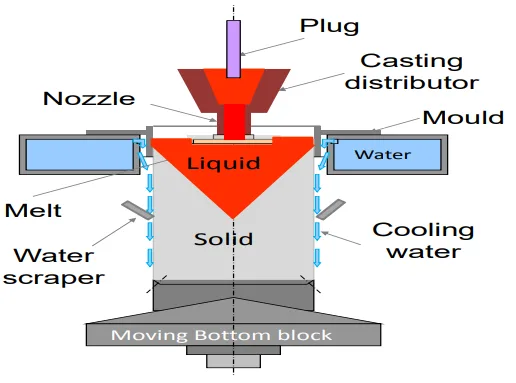

3. Introduction:

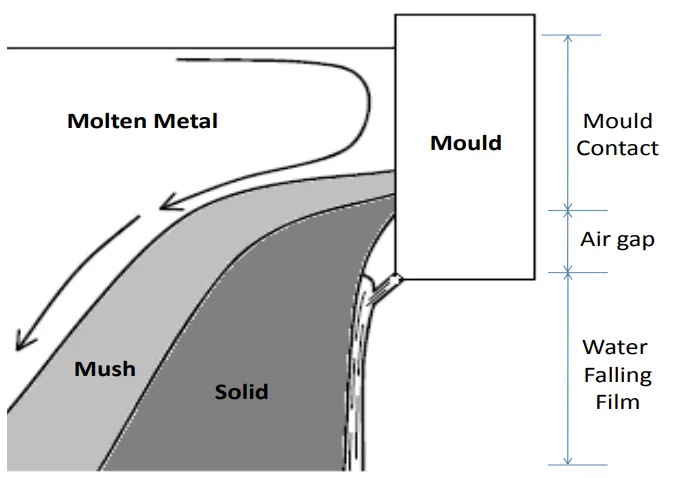

In the continuous casting of non-ferrous metals, strands must be cooled intensively with water to solidify. In the secondary cooling zone, which occurs after the strand emerges from the mould, direct water contact is used via jets or sprays. This stage has a significant influence on solidification microstructure, crack formation, and residual thermal stresses. While operational experience shows that adjusting water flow can improve ingot quality, the specific influence of water quality itself is not well understood. As cooling water is often recirculated, it accumulates dissolved salts and other pollutants, leading to quality fluctuations. This research aims to systematically investigate the influence of water quality, metal type, and surface conditions on the heat transfer rate in the secondary cooling zone to enable better process control and quality.

4. Summary of the study:

Background of the research topic:

The quality of continuously cast non-ferrous metals like aluminum and copper alloys is heavily dependent on the efficiency and uniformity of the secondary cooling stage. This stage involves complex boiling phenomena, including film boiling, transition boiling, and nucleate boiling, each with vastly different heat transfer rates.

Status of previous research:

Previous studies have developed empirical correlations for heat transfer coefficients and identified key phenomena like the Leidenfrost point (the temperature at which the insulating vapor film collapses). Research has shown that parameters like impingement density and metal properties affect cooling, but a systematic study on the combined effects of water quality (dissolved salts, lubricants, gases), metal type, and surface morphology in a single framework was lacking. The effect of real-world industrial water compositions, in particular, was not well quantified.

Purpose of the study:

The study's purpose was to experimentally quantify the influence of water quality, the type of metal, and surface properties on the heat transfer characteristics during the secondary cooling phase of a casting process. The goal was to identify key controlling parameters that could be used in an industrial setting to monitor and optimize the cooling process for improved product quality.

Core study:

The core of the study involved a series of controlled quenching experiments. Metal samples of varying types and surface roughness were heated and then cooled with water of different, precisely controlled compositions. An infrared camera was used to capture high-resolution thermal data, which was then analyzed using both a simple energy balance and an inverse heat conduction model to calculate local heat transfer coefficients and identify critical parameters like the Leidenfrost temperature, DNB-temperature, and maximum heat flux.

5. Research Methodology

Research Design:

The study used a comparative experimental design. A baseline condition was established using deionized water and a standard aluminum alloy (AA6082) sample. Key parameters were then varied one at a time to isolate their effects. These parameters included: (1) type and concentration of water additives (salts, lubricants, surfactants, gases), (2) type of metal (aluminum, nickel, inconel, copper alloys), and (3) surface roughness (from polished to real ingot surfaces).

Data Collection and Analysis Methods:

Data was collected primarily via an infrared camera (ThermaCAM SC 3000) recording at 150 Hz, capturing the temperature-time history at multiple points on the non-cooled side of the sample. This data was processed using two methods: a simple differential energy balance (assuming uniform temperature through the thin sample) and an inverse analysis of the 2D Fourier differential equation to calculate the temperature and heat flux on the cooled side.

Research Topics and Scope:

The research focused exclusively on the secondary cooling zone phenomena. The scope included:

- Water Quality: Investigating single salts, casting lubricants, surfactants, dissolved gases, water temperature, and eight real industrial water samples.

- Metal Surface Properties: Investigating different non-ferrous metals to understand the role of thermal conductivity and heat penetration coefficient, as well as the effect of surface roughness.

- Mould Jet Heat Transfer: Investigating the effect of water jet velocity from a simulated mould on the cooling mechanism and wetting front propagation.

6. Key Results:

Key Results:

- The addition of dissolved salts shortens cooling time. The Leidenfrost temperature, DNB-temperature, and maximum heat flux increase approximately linearly with the electrical conductivity of the water.

- MgSO₄ showed the strongest cooling enhancement, while NaCl showed the weakest.

- The pH value and hardness of water have no discernible influence on cooling rates.

- Casting lubricants like borax (which dissolves) increase the cooling rate, while non-dissolving lubricants like graphite have no effect. Surfactants prolong cooling time.

- The higher a metal's heat penetration coefficient and thermal diffusivity, the lower its Leidenfrost and DNB temperatures.

- Real ingot surfaces with high roughness have significantly shorter cooling times and higher Leidenfrost temperatures compared to smooth, machined surfaces.

- A previously unreported optimum jet velocity exists that provides the highest cooling rate; velocities both lower and higher than this optimum result in longer cooling times.

Figure Name List:

- Figure 4.1: Temperature profiles for MgSO4 solutions at center point

- Figure 4.2: Heat fluxes for MgSO4 solutions at 34 mm from the center

- Figure 4.3: Heat transfer coefficient for MgSO4 solutions at center point

- Figure 4.4: The calculated and measured ECs of MgSO4 solutions

- Figure 4.5: LFT, MaxHF and DNB-temperature of MgSO4 solutions at the three different positions

- Figure 5.1: Temperature distribution along the radial distance for the Nickel plate with 2 mm thickness

- Figure 5.4: Temperature profiles of metals with the thickness of 2 mm at center

- Figure 5.7: Heat flux for AA6082 at center point

- Figure 5.13: Effect of penetration factor on LFT for different metal at center point

- Figure 5.23: Temperature profile of rough AA6082 surfaces at center point

- Figure 6.2: Temperature profiles with respect to initial surface temperature

- Figure 6.21: Wetting front velocity of three different metals using IR cam

![Figure 5.31: Influence of surface temperature on the overall heat transfer coefficients with the average surface roughness [67]](https://castman.co.kr/wp-content/uploads/image-3171.webp)

7. Conclusion:

The study successfully identified several previously unknown or unquantified influences on heat transfer in the secondary cooling zone. The most critical finding for industrial application is that the electrical conductivity of cooling water serves as a robust, measurable proxy for its cooling effectiveness. Dissolved salts significantly enhance cooling by raising the Leidenfrost temperature, while surfactants and dissolved CO₂ can hinder it. The type of metal and its surface roughness also play crucial, predictable roles. An optimal jet velocity for maximum cooling was identified for the first time. These findings provide a scientific basis for optimizing casting processes by controlling water chemistry and adapting cooling strategies to specific alloys and surface conditions.

8. References:

- [1] L. Burmeister, Convective Heat Transfer. Wiley, 1983.

- [3] D. C. Weckman and P. Niessen, “A numerical simulation of the D.C. continuous casting process including nucleate boiling heat transfer,” Metallurgical Transactions B, vol. 13, no. 4, pp. 593–602, 1982.

- [4] J. Sengupta, B. Thomas, and M. WELLS, “The use of water cooling during the continuous casting of steel and Aluminium alloys,” Metallurgical and Materials Transactions A, vol. 36, pp. 187–204, 2005.

- [37] J. D. Bernardin and i. Mudawar, “The Leidenfrost Point: Experimental Study and Assessment of Existing Models,” ASME, vol. 121, pp. 894–903, 1999.

- [58] C. Huang and V. Carey, “The effect of dissolved salt on the leidenfrost transition,” Intl. J. Heat and Mass Transfer, vol. 50, pp. 269–282., 2006.

- [65] H. R. Müller and R. Jeschar, “Wärmeübertragung bei der Spritzwasserkühlung von Nichteisenmetallen,” Metallkunde, vol. 74, pp. 257–264, 1983.

- [81] H. Vu, “The Effect ofCooling Water Quality on Aluminum Ingot Casting,” Light Metals, pp. 1331–1347, 1985.

- [104] R.D.More, G.Richards, and A.Story, “Electrical Conductivity as an Indicatornof Water Chemistry of Hydrologic Process,” Streamline Watershed Management Bulletin, vol. 11, pp. 25–29, 2008.

Expert Q&A: Your Top Questions Answered

Q1: Why were two different methods used to analyze the heat transfer (simple energy balance and inverse 2D Fourier solution)?

A1: The two methods were chosen to suit different boiling regimes. The simple analysis, which neglects the temperature difference across the sample's thickness, is suitable for the film boiling region where heat transfer is lower and the Biot numbers are very small. The inverse analysis, which calculates the temperature on the cooled side, is more accurate and suitable for the nucleate boiling region, where high heat fluxes create a more significant temperature gradient through the metal. Using both provided a more robust analysis across the entire cooling curve.

Q2: The paper states that electrical conductivity is a key parameter for evaluating the cooling effect of water. Does this mean pH and water hardness are irrelevant?

A2: Yes, for the conditions tested, that is the direct conclusion. The abstract clearly states, "The pH value and the hardness of the water have no influence." The cooling effect of dissolved salts comes from their dissociation into ions, which directly increases electrical conductivity. While pH and hardness are critical for other aspects like corrosion and scaling, this research shows they are not direct indicators of the water's heat transfer capability, whereas electrical conductivity is.

Q3: How significant was the effect of dissolved gases like CO₂, O₂, and N₂ on cooling time compared to dissolved salts?

A3: The effect was present but comparatively weak. The abstract notes that dissolved CO₂ prolongs the cooling time, while O₂ and N₂ shorten it, but concludes that "The influence of the gases is comparably weak." The impact of dissolved salts, which could alter cooling times by a factor of three between different industrial waters, was far more dramatic and is the more critical parameter to control for process optimization.

Q4: The study found an optimal jet velocity for the highest cooling rate. Can you elaborate on this novel finding?

A4: This was a key discovery. The experiments showed that as water jet velocity increased from a minimum of 0.9 m/s, the cooling time initially decreased, reaching a maximum cooling rate at a velocity between 1.2 to 1.5 m/s. However, increasing the velocity further caused the cooling time to increase again. This indicates an optimal point of efficiency and challenges the assumption that simply increasing flow rate always improves cooling. This effect had not been previously reported in the literature.

Q5: What was the relationship between a metal's thermal properties, like the heat penetration coefficient, and its Leidenfrost temperature?

A5: The relationship was inverse. The study found that metals with a higher heat penetration coefficient (a measure of how quickly a material's surface temperature responds to a heat source) and higher thermal diffusivity exhibited lower Leidenfrost and DNB temperatures. This means materials that are better at conducting heat, like aluminum, maintain the insulating vapor film longer (to a lower surface temperature) compared to materials like nickel alloys under the same cooling conditions.

Q6: How did real ingot surfaces with high roughness perform compared to machined surfaces with controlled roughness?

A6: Real ingot surfaces performed significantly better. The abstract states, "Real ingot surfaces with a high roughness have a significantly shorter cooling time and therewith, a high Leidenfrost temperature and heat transfer coefficient." This is counterintuitive to some of the results with machined surfaces, where a small increase in roughness (to ~2 µm) actually prolonged cooling. The complex, multi-scale topography of a real cast surface appears to promote the collapse of the vapor film and enhance nucleate boiling, leading to much more efficient cooling.

Conclusion: Paving the Way for Higher Quality and Productivity

This foundational research demystifies the complex interplay between water, metal, and heat in the casting process. The core breakthrough—identifying electrical conductivity as a direct, measurable proxy for cooling power—provides a powerful new tool for Casting Cooling Process Optimization. By moving beyond simple flow rate adjustments and beginning to manage the chemistry of the cooling medium, manufacturers can achieve more consistent solidification, reduce defects, and improve overall product quality.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Influence of Water Quality and Kind of Metal in the Secondary Cooling Zone of Casting Process" by "M.Sc. Khalid Haroun Mohamed Abdalrahman".

- Source: Dissertation, Otto-von-Guericke-Universität Magdeburg, 2012.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.