Boosting Die Casting Quality: A Six Sigma and Data Mining Approach to Defect Reduction

This technical summary is based on the academic paper "IMPLEMENTATION SIX SIGMA AND DATA MINING TO IMPROVE DIE CASTING PRODUCTION PROCESS AT PT. AB" by Rina Fltriana, Johnson Saragih, and Sitta Sarasaty, published in the Proceeding 7th International Seminar on Industrial Engineering and Management. It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Die Casting Quality Improvement

- Secondary Keywords: Six Sigma in Die Casting, Data Mining for Manufacturing, Defect Reduction, FMEA, Cylinder Component Casting, Process Control

Executive Summary

- The Challenge: A motorcycle cylinder component manufacturing line was experiencing a defect rate of 5.06%, significantly above the specified limit of 3.36%, leading to costly rework and production inefficiencies.

- The Method: The research applied the structured Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology, integrating Failure Mode and Effect Analysis (FMEA) and data mining (decision trees) to identify and address root causes.

- The Key Breakthrough: The study successfully identified "flow line" as the most dominant defect and pinpointed its primary causes, leading to targeted improvements that increased the process sigma level from 3.66 to 3.71.

- The Bottom Line: Integrating Six Sigma with data mining provides a powerful, data-driven framework for achieving tangible Die Casting Quality Improvement, reducing defects, and establishing standardized, repeatable process controls.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive motorcycle manufacturing industry, quality is paramount. This research addresses a common and critical challenge faced by die casting operations: high defect rates that inhibit production and increase costs. A specific manufacturer, PT. AB, was struggling with its KYZ cylinder component, a high-volume part. The actual percentage of defects was 16.8%, a figure drastically higher than the company's allowed minimum standard of 3.36%. This discrepancy necessitated significant rework, which not only inflated production costs but also slowed down the entire manufacturing process. The study focused on the die casting stage, as historical data from August to October 2012 clearly indicated it was the primary source of these costly defects. This scenario highlights the urgent need for a systematic methodology to identify defect types, determine root causes, and implement effective, sustainable improvements.

The Approach: Unpacking the Methodology

The study employed the well-established Six Sigma DMAIC framework to systematically tackle the quality issues. This five-phase approach provided a clear roadmap for investigation and improvement:

- Define: The project scope was defined by identifying the KYZ cylinder component as the product with the highest defect percentage (5.06% in one month). The casting process was pinpointed as the main source of these defects.

- Measure: The initial process capability was quantified. The baseline performance was calculated at a DPMO (Defects Per Million Opportunities) of 15,356, which corresponds to a sigma level of 3.66—well below the industry target of 6 sigma.

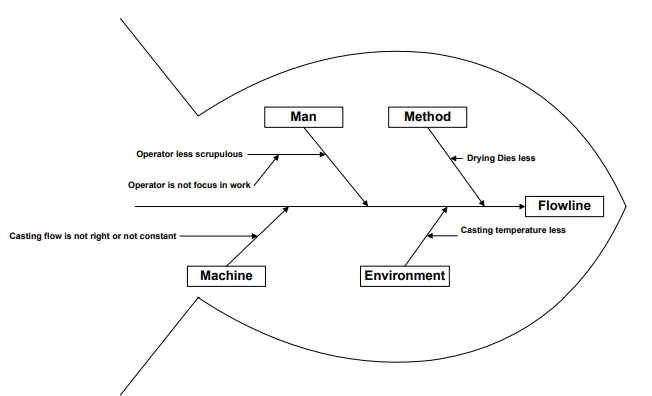

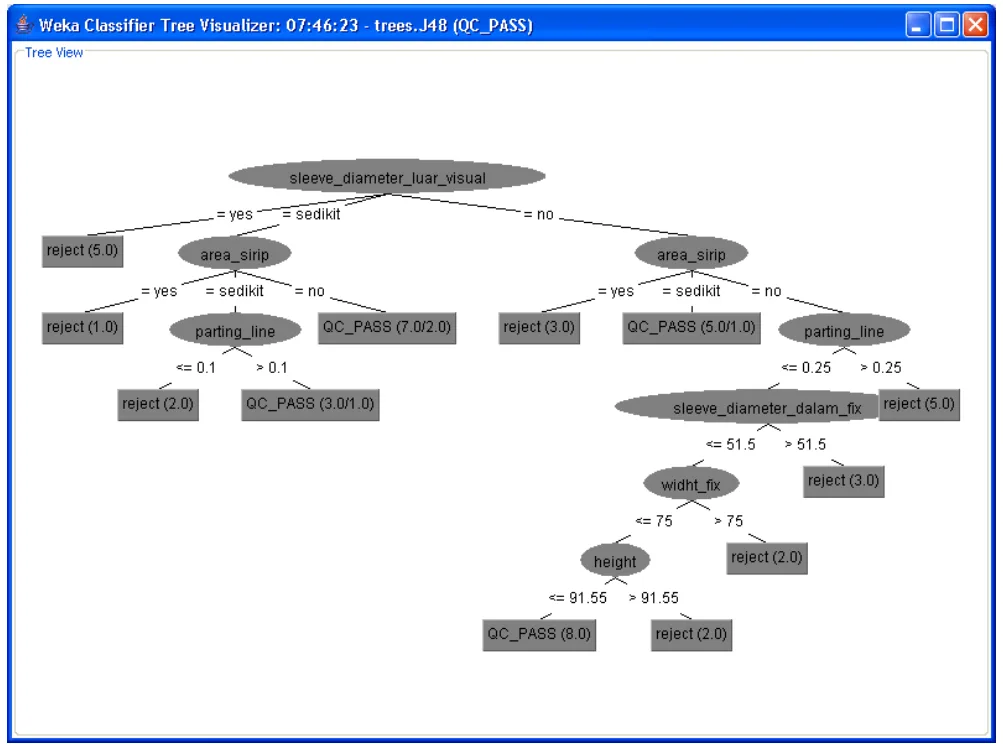

- Analyze: To uncover the root causes of the defects, the team used a combination of analytical tools. A cause-and-effect (Ishikawa) diagram was developed for the most dominant defect type, "flow line." This was followed by a Failure Mode and Effect Analysis (FMEA) to prioritize potential failure modes based on their risk. Finally, data mining was used to create a decision tree, identifying the most critical parameters influencing product quality.

- Improve: Based on the analysis, targeted solutions were developed. These included conducting specific operator training, creating standardized operating procedures (SOPs), and, critically, standardizing the Quality Control (QC) PASS criteria using "if-then" rules derived from the data mining model.

- Control: To ensure the improvements were sustained, the process was monitored post-implementation. Control maps (p and u charts) were used to compare results, and a new DPMO and sigma level were calculated to verify the project's success.

The Breakthrough: Key Findings & Data

The structured DMAIC approach yielded concrete, data-driven findings that directly guided the improvement efforts.

Finding 1: Prioritizing Failures with FMEA

The FMEA was crucial in focusing efforts on the most critical failure modes. For the "Flow line" defect, the analysis identified several causes, but the Risk Priority Number (RPN) calculation highlighted the most significant contributors. As shown in Table 4, the cause "Temperature Casting Less" had the highest RPN of 384, followed by "Improper casting flow and constant" with an RPN of 320. This data provided a clear directive to the engineering team: stabilizing casting temperature and ensuring consistent molten metal flow were the top priorities for reducing "Flow line" defects.

Finding 2: Quantifiable Improvement in Process Capability

The ultimate success of the project was measured by the tangible improvement in quality metrics. Before the improvement phase, the process had a DPMO of 15,356 and a sigma level of 3.66. After implementing the new SOPs, operator training, and data-driven QC standards, the process was re-evaluated. The results showed a reduction in DPMO to 13,221 and an increase in the sigma level to 3.71. This represents a total increase in the sigma level of 0.05, confirming that the implemented changes had a positive and measurable impact on Die Casting Quality Improvement.

Practical Implications for R&D and Operations

This study offers valuable, actionable insights for various roles within a die casting facility.

- For Process Engineers: This study suggests that adjusting startup procedures for temperature settings and ensuring consistent casting flow may contribute to significantly reducing "Flow line" defects. The FMEA in Table 4 provides a template for prioritizing process parameter optimization.

- For Quality Control Teams: The data in Figure 6 (Proposal Decision Tree) illustrates the effect of specific conditions (e.g.,

sleeve_diameter_luar_visual,parting_line) on the final QC PASS/FAIL outcome. This decision tree model could inform new, standardized quality inspection criteria, reducing human subjectivity and improving consistency. - For Design Engineers: The findings indicate that factors influenced by part design, such as those affecting molten metal flow ("Improper casting flow"), could influence "Flow line" defect formation during solidification, suggesting this is a valuable consideration in the early design phase.

Paper Details

IMPLEMENTATION SIX SIGMA AND DATA MINING TO IMPROVE DIE CASTING PRODUCTION PROCESS AT PT. AB

1. Overview:

- Title: IMPLEMENTATION SIX SIGMA AND DATA MINING TO IMPROVE DIE CASTING PRODUCTION PROCESS AT PT. AB

- Author: Rina Fltriana, Johnson Saragih, Sitta Sarasaty

- Year of publication: [The paper is from the "Proceeding 7th International Seminar on Industrial Engineering and Management". The specific year is not mentioned, but the study data is from 2012-2013.]

- Journal/academic society of publication: Proceeding 7th International Seminar on Industrial Engineering and Management

- Keywords: Six Sigma, FMEA, Decision Tree.

2. Abstract:

PT. AB is well known as a manufacturing industry which operates in motorcycle industry. The quality measurement has become the most important substance in this industry. As a result, the purposes of this research are improving the quality control and reducing the defect percentages in die casting production. This research using Six Sigma methods, which have 5 Steps. There are: Measure, Analyze, Improvement, and Control (DMAIC). In the define phase, obtained that the production per month which has the largest percentage of defects in PT. AB is a cylinder component KYZ which have 5.06%, while its specified limits only 3.36%. Therefore, further treatment is needed. The second phase is measure, which does the calculation control map p and u. The results of the measurements obtained for 15,356 DPMO value with sigma level of 3.66. In the Analyse phase, the analysis used to use cause and effect diagrams, Failure Mode and Effect Analysis (FMEA), and data mining for decision tree. The most dominant issue is form of disability flow line. For the improvement stage, the results obtained for the response of each of these failures by conducting operator training, Standard Operating Procedure (SOP) and the standardization of QC PASS by using data mining method, which obtained if then rule that can be received in the Quality Control (QC). This implementation should be obeyed by casting machine operators. In the control phase, the calculation of control maps p and u done to compare the results after implementation. Sigma level after doing the implementation. The results of the measurements obtained DPMO values of 13 221 and sigma level of 3.71. The increase in sigma level is 0.05.

3. Introduction:

PT. AB is a company engaged in the motor industry in Indonesia. This company is a manufacturing and distribution of motorcycles. From all the products, the largest production with the highest percentage of disability is die casting production process with product type KYZ cylinder component. To produce good quality, PT. AB should be able to reduce the percentage of defects generated. Repairs were carried out by PT. AB is an attempt to satisfy customers by producing products according to demand and in a shorter period of time with the best results. To improve the quality of this, the use of six sigma approach method that aims to minimize variation and control processes and make continuous improvement. PT. AB die casting production process is done at the beginning of the production process. The study starts from January to early February 2013 the number of samples taken on the product type KYZ cylinder component of 84 541 units. The issue at PT. ABM is due to the high occurrence of disability is 14 281 units on the type of product components KYZ cylinder in the month of January - beginning of February 2013. It had need rework and lead to higher production costs thus inhibiting the production process. Minimum standards flaw allowed the company is 3.36%, while the actual percentage of defects that occur at 16.8%. Companies need to make improvements with six sigma method to identify the type of defect and determine the factors causing high so as to reduce the disability occurs. The purpose of this study is to search the level of sigma company before and after doing the implementation.

4. Summary of the study:

Background of the research topic:

A motorcycle component manufacturer, PT. AB, was experiencing high defect rates in its die casting process for the KYZ cylinder component, leading to increased costs and production delays. The actual defect rate of 16.8% was significantly higher than the allowed 3.36%.

Status of previous research:

The paper references Jang (2009) who proposed a six sigma methodology based on data mining for processing massive data, which was applied in a Korean Steel Company. This study applies a similar combined approach to the die casting industry.

Purpose of the study:

The primary purposes were to improve quality control, reduce defect percentages in the die casting production of the KYZ cylinder component, and measure the company's sigma level before and after implementing improvements.

Core study:

The study implemented the five-step Six Sigma DMAIC methodology. It involved defining the problem with the KYZ component, measuring the initial sigma level (3.66), analyzing root causes using tools like FMEA and data mining, implementing improvements such as operator training and standardized QC rules, and controlling the process to verify the improvement to a new sigma level of 3.71.

5. Research Methodology

Research Design:

The research followed the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) project methodology. This is a systematic, data-driven approach for process improvement.

Data Collection and Analysis Methods:

Data was collected from historical production records at PT. AB from August 2012 to February 2013. The analysis methods included:

- Process flowcharts and SIPOC diagrams.

- Calculation of DPMO and sigma level.

- Cause-and-effect (Ishikawa) diagrams.

- Failure Mode and Effect Analysis (FMEA) to calculate Risk Priority Numbers (RPN).

- Data mining using a decision tree algorithm (J48 in WEKA software) to generate "if-then" rules for quality control.

- Control charts (p and u) for process monitoring.

Research Topics and Scope:

The research was focused on the die casting production process for the KYZ cylinder component at PT. AB. The scope was limited to identifying and improving the factors causing the highest percentage of defects within this specific process.

6. Key Results:

Key Results:

- The initial process performance was measured at a DPMO of 15,356, corresponding to a sigma level of 3.66.

- The most dominant defect type was identified as "Flow line".

- FMEA analysis pinpointed "Temperature Casting Less" (RPN 384) and "Improper casting flow and constant" (RPN 320) as the highest-risk causes for the Flow line defect.

- A decision tree model was created to standardize QC PASS criteria based on measurable parameters.

- After implementing improvements (training, SOPs, standardized QC), the DPMO was reduced to 13,221, and the sigma level increased to 3.71.

- The total increase in the sigma level was 0.05.

Figure Name List:

- Figure 3. Project Charter Declaration Produk Cylinder Component KYZ

- Figure 4. Diagram SIPOC (Supplier – Input – Process – Output - Customer) Produk Cylinder Component KYZ

- Figure 5. Cause-effect Diagram Flowline Defect

- Figure 6. Proposal Decision Tree In WEKA Software

7. Conclusion:

Based on the research, processing and analysis, it can be concluded that the DPMO value generated prior to implementation was 15,357 and the sigma level was 3.66. Results of observation and analysis led to a proposal to reduce defects caused by the use of a decision tree for the "flowline" defect. After implementation, the DPMO improved to 13,221 and the sigma level to 3.71.

8. References:

- (a) Gaspersz, Vincent. 2002. Pedoman Implementasi Program Six Sigma. Jakarta: PT. Gramedia Pustaka Utama.

- (b) Manggala, D. 2005. Menerapkan Konsep Lean dan Six Sigma di Sektor Publik. IPOMS Newsletter, Vol 1/1/4-5 Agustus 2005.

- (c) Jang Gill-Sang, Jeon Jong-Hag. 2009. A Six Sigma Methodology Using Data Mining : A Case Study on Six Sigma Project for Heat Efficiency Improvement of Hot Stove System in Korean Steel Manufacturing Company. Springer-Verlag Berlin Heidelberg.

- (d) Pande, Peter S., dkk. 2002. The Six Sigma Way. Yogyakarta: Andi.

- (e) Kusrini, Emha TL. 2009. Algoritma Data Mining. Yogyakarta:Andi.

- (f) Tan, Steinbach Kumar. 2006. Introduction to Data Mining. Pearson Education, Inc. Addison Wesley

Expert Q&A: Your Top Questions Answered

Q1: Why was the KYZ cylinder component chosen for this study over other products?

A1: The KYZ cylinder component was selected because, among all products manufactured by PT. AB, it had the highest production volume combined with the highest percentage of defects. This combination made it the most critical product to improve from both a quality and cost perspective, ensuring the project would have the maximum impact.

Q2: The paper identifies "Flow line" as the most dominant defect. What were the key contributing factors according to the cause-and-effect diagram (Figure 5)?

A2: The cause-and-effect diagram in Figure 5 breaks down the root causes into four categories. Key factors included: Man (operator not focused or less scrupulous), Method (drying dies less), Machine (casting flow not right or not constant), and Environment (casting temperature less). This analysis showed that the defect was not caused by a single issue but a combination of human, procedural, and equipment factors.

Q3: How did the FMEA analysis prioritize the improvement efforts?

A3: The FMEA prioritized efforts by calculating a Risk Priority Number (RPN) for each potential cause of failure. As seen in Table 4, the cause "Temperature Casting Less" received the highest RPN of 384, while "Improper casting flow and constant" had an RPN of 320. These high scores signaled that these two causes posed the greatest risk to product quality and should be addressed first.

Q4: What was the specific role of data mining in the 'Improve' phase?

A4: In the Improve phase, data mining was used to create the decision tree shown in Figure 6. This model's primary role was to standardize the QC inspection process. It generated objective "if-then" rules based on actual product measurements (like sleeve_diameter, parting_line, height). This replaced subjective operator judgment with a data-driven standard for what constitutes a "QC PASS," ensuring consistency and reliability in quality checks.

Q5: The sigma level improvement was from 3.66 to 3.71. While positive, this is a modest gain. What does this suggest for the company?

A5: The modest gain suggests that the initial improvements were effective in addressing some of the primary root causes and successfully validated the Six Sigma and data mining methodology. However, it also indicates that achieving higher levels of quality is an ongoing process. This initial project serves as a foundation for continuous improvement, where the same DMAIC framework can be reapplied to further refine the process, tackle secondary causes of defects, and drive the sigma level closer to the industry goal of 6.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demonstrates how a structured combination of Six Sigma and data mining can diagnose and remedy persistent quality issues in a high-pressure die casting environment. By moving from broad problem statements to specific, data-backed root causes like improper temperature control and inconsistent material flow, the team was able to implement targeted, effective solutions. The result was a measurable Die Casting Quality Improvement, proven by the reduction in DPMO and the increase in the process sigma level. This study serves as a powerful case for adopting data-driven methodologies to enhance process control, reduce waste, and boost overall productivity.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "IMPLEMENTATION SIX SIGMA AND DATA MINING TO IMPROVE DIE CASTING PRODUCTION PROCESS AT PT. AB" by "Rina Fltriana, Johnson Saragih, Sitta Sarasaty".

- Source: [A specific DOI/URL is not provided in the document. The source is the "Proceeding 7th International Seminar on Industrial Engineering and Management".]

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.