This technical summary is based on the academic paper "Sustainable production of copper components using concentrated solar energy in material extrusion additive manufacturing (MEX-CSE)" published by Antonio Cañadilla Sánchez, Gloria Rodríguez, Ana Romero, Miguel A. Caminero, and Oscar J. Dura in Sustainable Materials and Technologies (2023). It was analyzed and summarized for manufacturing experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Sustainable Copper Component Manufacturing

- Secondary Keywords: Concentrated Solar Energy (CSE), Material Extrusion (MEX), Solar Sintering, Additive Manufacturing Copper, Thermal Debinding, Metal 3D Printing, Sustainable Manufacturing Technology

Executive Summary

- The Challenge: Conventional additive manufacturing of metal components involves highly energy-intensive thermal processes (debinding and sintering), which are costly and environmentally burdensome.

- The Method: Researchers developed a novel "Printing-Debinding-Solar Sintering" (PDSS) process. This method uses a low-cost Fresnel lens to concentrate solar energy, providing a clean, renewable heat source for the critical thermal debinding and sintering stages of 3D-printed copper parts.

- The Key Breakthrough: The use of concentrated solar energy (CSE) dramatically reduced the thermal processing time from approximately 25 hours in a conventional furnace to just 1 hour. It also lowered the required sintering temperature from 1075°C to 975°C.

- The Bottom Line: This sustainable approach successfully produced high-quality, dense (96% relative density) pure copper parts with excellent thermal and electrical properties, proving that renewable energy can be directly integrated into advanced manufacturing to create superior components more economically and sustainably.

The Challenge: Why This Research Matters for Manufacturing Professionals

In the quest for more efficient and sustainable production, the manufacturing industry is increasingly turning to additive manufacturing (AM) for its ability to create complex, customized metal parts with minimal waste [Ref. 3, 4]. However, a significant bottleneck for indirect AM technologies like Material Extrusion (MEX) is the post-processing stage. After a part is printed (the "green" part), it must undergo thermal debinding to remove a polymer binder and then be sintered at high temperatures to fuse the metal particles into a dense, solid component.

These thermal stages are traditionally performed in electric furnaces, consuming vast amounts of energy and leading to long production cycles and high operational costs. For a material like copper, which is critical for thermal and electrical applications, finding a more efficient and environmentally friendly manufacturing route is a major challenge [Ref. 11, 12]. This study directly addresses this challenge by exploring a radical new way to power these critical thermal processes.

The Approach: Unpacking the Methodology

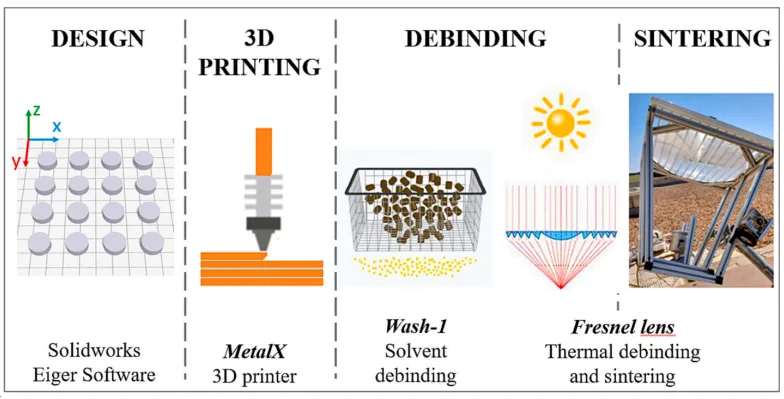

To create a more sustainable manufacturing pathway, the researchers developed and validated a novel three-stage process they termed Printing-Debinding-Solar Sintering (PDSS).

The methodology involved:

- Printing: Standard cylindrical and square copper components were designed in CAD software and fabricated using a commercial MetalX 3D printer. The printer used a filament composed of pure copper powder (~95 wt%) held together by a polymer binder system [Ref. 47].

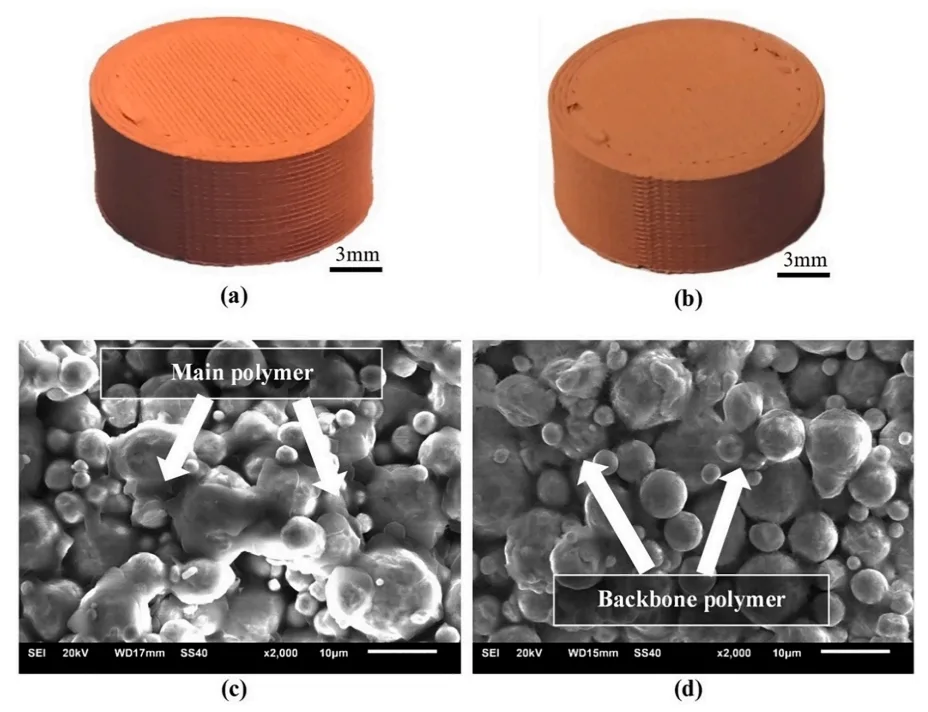

- Debinding: The printed "green parts" first underwent a chemical debinding step, where they were immersed in a solvent to remove the main binder component. This created an open-pore structure necessary for the next stage.

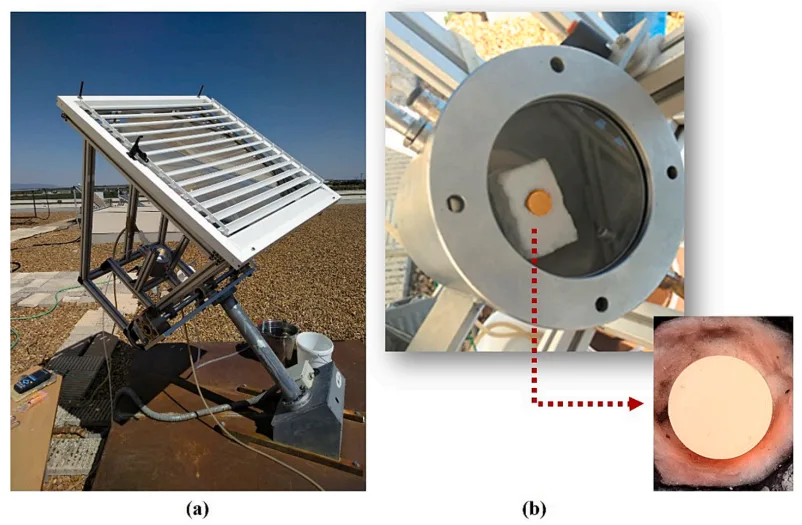

- Solar Thermal Debinding & Sintering: This is the core innovation. Instead of an electric furnace, the "washed parts" were placed in a reaction chamber under a large Fresnel lens. The lens concentrated direct sunlight, creating a high-intensity focal spot to heat the components. This solar energy was precisely controlled to first perform a final thermal debinding (removing the remaining "backbone" polymer) and then sinter the copper particles into a solid, dense part in a protective N₂-5%H₂ atmosphere (Figure 3).

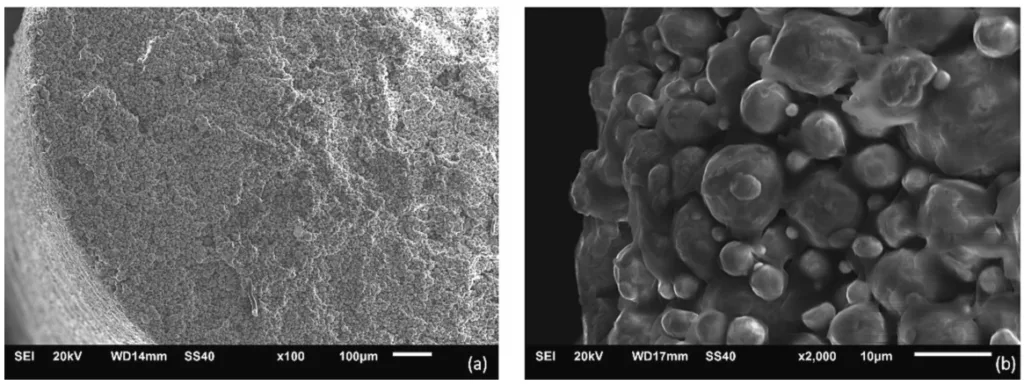

Throughout the process, the team conducted extensive analysis, including thermogravimetric analysis (TGA) to understand binder decomposition, scanning electron microscopy (SEM) to observe microstructural changes, and rigorous testing of the final parts' density, hardness, and thermal/electrical conductivity.

The Breakthrough: Key Findings & Data

The results of the PDSS process were remarkable, demonstrating significant advantages over conventional furnace-based methods.

- Drastic Reduction in Process Time and Temperature: The most significant finding was the massive efficiency gain. The entire thermal debinding and sintering cycle using solar energy was completed in approximately 1 hour. This is a stark contrast to the ~25 hours required in a conventional electric furnace. Furthermore, optimal densification was achieved at a sintering temperature of 975°C, a full 100°C lower than the 1075°C needed in the conventional process (Table 2).

- Excellent Final Part Density and Microstructure: The optimized solar sintering process (975°C for 15 minutes) produced copper parts with a final relative density of 96.0%. This is slightly higher than the 95.25% achieved with conventional methods. The resulting microstructure showed well-defined, equiaxed grains with minimal, isolated microporosity, confirming effective and complete sintering (Figure 10, Figure 11c).

- Competitive Mechanical and Conductive Properties: The solar-sintered parts exhibited a Vickers hardness of ~62 HV, comparable to conventionally processed parts. Critically for copper's primary applications, the components demonstrated excellent conductivity:

- Electrical Conductivity: 49 x 10⁶ S/m, equivalent to 84.5% of the International Annealed Copper Standard (IACS).

- Thermal Conductivity: 350 W/m·K, equivalent to 89.5% of the IACS value for pure copper. These values are on par with, or even slightly better than, those from conventional MEX processing (Table 2).

- Homogeneous Material Properties: Hardness measurements taken across the part's cross-section, from the solar-exposed top surface to the bottom, showed no significant variation. This confirms that the solar heating and subsequent heat transfer through the part were sufficient to create uniform metal bonding and homogeneous properties throughout the entire component (Figure 12).

Practical Implications for Advanced Manufacturing

While this research focuses on a specific AM process, its principles have broader implications for the future of metal component production.

- For Process Engineers: The study provides a powerful proof-of-concept for using direct renewable energy in thermal processing. This suggests that for any manufacturing process involving high-temperature furnaces (e.g., heat treatment, brazing, sintering), exploring concentrated solar energy could be a viable strategy to slash cycle times, reduce energy costs, and decrease dependence on the electrical grid.

- For R&D and Strategy Managers: This technology represents a tangible step toward decarbonizing manufacturing. By integrating a free and abundant energy source directly into the production line, companies can significantly lower their carbon footprint and operational expenditures. This enhances sustainability credentials and builds resilience against fluctuating energy prices.

- For Component Design: The ability to create complex, net-shape copper parts with high thermal and electrical conductivity opens new doors for high-performance applications. This is especially relevant for designing intricate cooling channels in molds and dies, advanced heat sinks for electronics, and complex conductors for aerospace and automotive systems—all areas where HPDC also plays a key role. This research expands the toolbox for creating optimized thermal management solutions.

Paper Details

Sustainable production of copper components using concentrated solar energy in material extrusion additive manufacturing (MEX-CSE)

1. Overview:

- Title: Sustainable production of copper components using concentrated solar energy in material extrusion additive manufacturing (MEX-CSE)

- Author: Antonio Cañadilla Sánchez, Gloria Rodríguez, Ana Romero, Miguel A. Caminero, Oscar J. Dura

- Year of publication: 2023 (Available online 16 December 2023)

- Journal/academic society of publication: Sustainable Materials and Technologies

- Keywords: Concentrated solar energy, Material extrusion, Additive manufacturing, Copper, Solar sintering

2. Abstract:

Material extrusion is a suitable technology for the additive manufacturing of complex components from any family of materials. The processing of metallic parts involves a three-stage methodology known as PDS (Printing-Debinding-Sintering). In the printing stage, filaments made of metallic powder and a polymeric binder system are used. After printing, the binder must be removed, and the parts sintered to obtain densified metal components with the final properties. These last two stages, in particular sintering, require high temperatures, and are thus high-energy demanding processes. The use of the Concentrated Solar Energy (CSE) is increasingly the focus of research in materials science as it is a clean, non-polluting, renewable energy resource, which is highly efficient for high temperature materials processing. This is the first study to analyse the feasibility of using CSE in the thermal debinding and sintering stages in the production of metallic components via Printing-Debinding-Solar Sintering (PDSS) technology. The objective is to develop a new sustainable process for producing metallic components by combining additive manufacturing and solar energy. In this study, pure copper cylindrical parts were produced and sintered in a low-cost Fresnel lens. The results revealed that solar sintering occurred at lower temperature (975 °C) and much shorter time (~1 h) than in the conventional process, enhancing the economic and environmental efficiency of the conventional manufacturing process.

3. Introduction:

One of the major current challenges in materials processing focuses on developing more energy efficient technologies that reduce waste generation and the use of natural resources. Specifically, the manufacturing industry needs to incorporate more sustainable technologies without compromising the final quality of the products. In this context, technologies based on additive manufacturing (AM) are going to play a crucial role in the shaping of materials by optimizing the efficiency of material and energy resources. Additive manufacturing, although originally developed for the rapid prototyping and processing of polymeric materials, currently enables functional parts to be processed from a broad spectrum of materials. This technology can be potentially used for manufacturing customized metal products by joining material layer by layer to obtain light-weight parts, complex shapes, and tailored mechanical, medicinal, thermal, and electrical properties for various applications [1]. AM has significant advantages compared to traditional manufacturing techniques, such as the ability to efficiently produce geometrically complex parts with high design freedom, high flexibility in customization, short production cycle time, and highly potential automated fabrication without tool changes [2]. Moreover, AM is considered a promising solution to achieve environmentally friendly and sustainable manufacturing thanks to fewer raw material requirements, which yields less waste [3,4]. Hence, AM is a rapidly evolving technology in academic and industrial research win the last 20 years and has been actively adopted in many industrial sectors for automotive [5], aerospace [6], and medical applications [7]. Among the numerous metals processed by AM, pure copper could benefit from being processed by this technique [8–10].

4. Summary of the study:

Background of the research topic:

The additive manufacturing of metal parts via material extrusion (MEX) requires a three-stage Printing-Debinding-Sintering (PDS) process. The final two stages, debinding and sintering, are energy-intensive as they require high-temperature furnaces. Concentrated Solar Energy (CSE) presents a clean, renewable, and efficient alternative for high-temperature materials processing.

Status of previous research:

Previous research has demonstrated the use of MEX for producing copper parts and the application of CSE for various metallurgical processes like surface hardening, welding, and sintering of other alloys. However, few studies have explored CSE for sintering pure copper, and none have combined it with the MEX additive manufacturing process. Conventional copper sintering typically requires temperatures around 1075°C and long processing times.

Purpose of the study:

This study is the first to analyze the feasibility of using CSE for the thermal debinding and sintering stages in the production of metallic components via a novel Printing-Debinding-Solar Sintering (PDSS) technology. The objective was to develop a new, sustainable process for producing high-quality pure copper components by combining additive manufacturing with solar energy.

Core study:

The core of the study was to fabricate pure copper parts using MEX, then use a Fresnel lens to concentrate solar energy for the thermal debinding and sintering steps. The researchers optimized the solar processing parameters (temperature and time) to achieve maximum density and the best material properties. The final parts were characterized and compared to those produced by conventional furnace-based methods to evaluate the efficiency, sustainability, and quality of the new PDSS process.

5. Research Methodology

Research Design:

The study followed an experimental design to develop and validate the PDSS process. It involved fabricating copper parts using a commercial MEX system, followed by a two-part debinding process (chemical and solar-thermal), and a final solar sintering stage. Key process parameters for solar debinding and sintering, such as temperature and holding time, were systematically varied to find the optimal conditions.

Data Collection and Analysis Methods:

- Material: A commercial filament from Markforged containing ~95 wt% pure copper powder in a polymer binder was used.

- Equipment: A MetalX 3D printer, a Wash-1 solvent station, and a custom-built solar installation featuring a 900 mm diameter Fresnel lens and a hermetic reaction chamber were used.

- Analysis: Thermogravimetric Analysis (TGA) was used to characterize the binder system. Scanning Electron Microscopy (SEM) was used to analyze the microstructure. The Archimedes method was used to measure density. Vickers microhardness tests were performed to assess mechanical properties. The Van Der Pauw method and laser flash analysis were used to determine electrical and thermal conductivity, respectively.Research Topics and Scope:

The research focused on the sustainable production of pure copper components. The scope included:

- 3D printing of copper parts via MEX.

- Characterization of the filament's binder system.

- Optimization of the solar thermal debinding process.

- Optimization of the solar sintering process to maximize density and part quality.

- Full characterization (microstructural, mechanical, thermal, electrical) of the final solar-sintered copper parts.

- Comparison of the novel PDSS process with the conventional PDS process in terms of processing time, temperature, and final part properties.

6. Key Results:

Key Results:

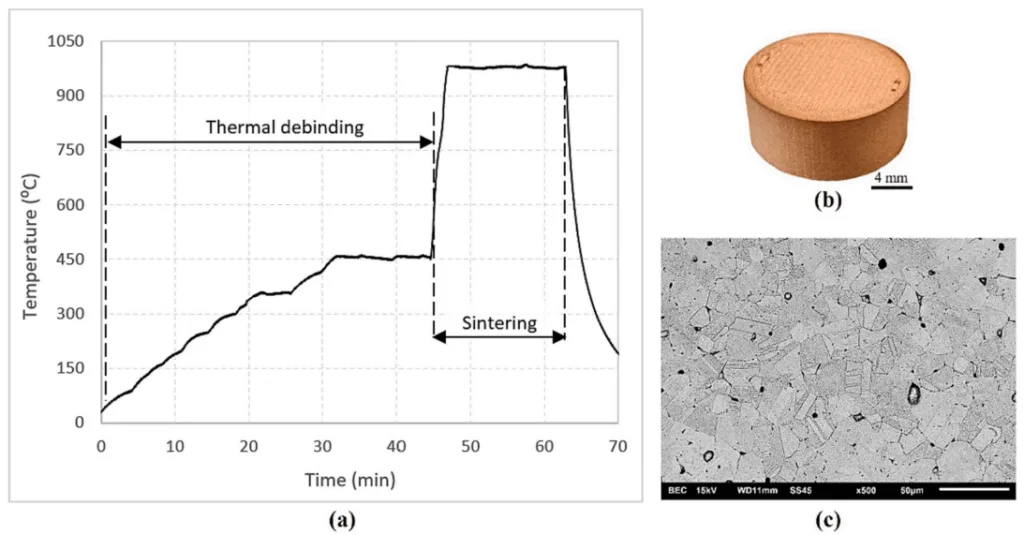

- The optimized solar thermal debinding cycle was a two-stage process: a plateau at 350°C for 5 min, followed by a second plateau at 450°C for 12.5 min.

- The optimal solar sintering parameters were found to be a temperature of 975°C with a holding time of 15 minutes.

- This process achieved a maximum relative density of 96.0%, which is superior to the 95.25% from conventional furnace sintering.

- The total thermal processing time was reduced from ~25 hours to ~1 hour.

- The final parts showed a Vickers hardness of 62.23 HV, thermal conductivity of 350 W/m·K (89.5% IACS), and electrical conductivity of 49 x 10⁶ S/m (84.5% IACS). These properties are comparable or superior to those achieved through conventional methods (Table 2).

- The microstructure was homogeneous, with well-bonded grains and small, isolated pores, indicating high-quality sintering.

Figure Name List:

- Fig. 1. Stages of the Metal Extrusion Additive Manufacturing technique combined with solar sintering.

- Fig. 2. SEM micrographs of the copper filament. Details of (a) cylindrical filament, and (b) spherical copper powder and binder coating.

- Fig. 3. (a) Fresnel lens. (b) Set-up of the test sample.

- Fig. 4. Cylindrical components in (a, c) green state, and (b, d) washed state after solvent debinding.

- Fig. 5. (a) TGA of copper filament, and (b) TGA of a washed part after solvent debinding.

- Fig. 6. Weight loss in the second plateau of the thermal debinding of copper parts. (a) Influence of temperature. (b) Influence of time at 450 °C.

- Fig. 7. (a) Solar thermal-debinding cycle, (b) Cylindrical brown part, and (c) SEM image of brown part after thermal debinding.

- Fig. 8. Solar sintering cycles at 925, 950 and 975 °C.

- Fig. 9. (a) Copper relative density as a function of solar sintering temperature. (b) Cross section micrographs of sintered copper parts at (1) 925 °C, (2) 950 °C, and (3) 975 °C.

- Fig. 10. (a) Relative density for sintering at 975 °C as a funtion of the sintering time, and (b) Microstructure of copper part sintered at 975 °C for 15 min.

- Fig. 11. (a) Complete solar thermal cycle. (b) Final solar sintered copper part. (c) SEM micrograph of final copper material.

- Fig. 12. Vickers microhardness measurements as a function of the distance from the surface where concentrated solar energy is incising.

- Fig. 13. Measured electrical and thermal conductivities as a function of the temperature of the test.

7. Conclusion:

The manufacturing of pure copper components was achieved by the Material Extrusion Additive Manufacturing technique using concentrated solar energy for thermal debinding and sintering steps. The main accomplishments are outlined below:

- Solar thermal debinding stage was optimized in a two-stage cycle (a first plateau at 350 °C for 5 min, and a second plateau at 450 °C for 12.5 min) achieving and adequate backbone polymer mass loss of ~2.1 wt%.

- Final copper parts were obtained after solar sintering at 975 °C for 15 min, achieving a relative density of 96% and similar properties or even better than those obtained by the conventional MEX technique. Concentrated solar energy reduced the conventional furnace sintering time (from ~25 h to ~1 h) and sintering temperature (from 1075 °C to 975 °C). Time savings were attributed to the higher heating and cooling rates, up to 120 °C/min. Moreover, a photo-activating effect of solar energy occurs on the diffusional processes that results in a decrease in temperature and especially sintering time.

- Thermal and electrical conductivity of copper parts sintered by solar energy were 350 W/m·K (~90% IACS) and 49.10⁶ S/m (~85% IACS), respectively. Both conductive properties were similar to those obtained in other indirect additive manufacturing techniques using conventional electrical furnaces. The overall optimized manufacturing process applied in this study enabled the fabrication of high-quality and dense pure copper parts with competitive relative density, electrical, and thermal properties in shorter time and at lower temperature due to the use of concentrated solar energy. This approach is an innovation in materials science and additive manufacturing fields that promotes a broad range of applications of direct solar energy in metal thermal treatment and 3D printing industry. In short, MEX technology combined with solar energy can be oriented to the fabrication of complex 3D printed copper parts with applications in functional and/or structural devices reducing costs and environmental impact of the processing.

8. References:

- [List of 81 references exactly as cited in the paper is omitted for brevity but is available in the source document.]

Expert Q&A: Your Top Questions Answered

Q1: What is the main advantage of using solar energy over a conventional furnace for this process? A1: The primary advantages are drastic reductions in both time and energy. The thermal processing time was cut from about 25 hours in a conventional furnace to just 1 hour using concentrated solar energy. This is due to much faster heating and cooling rates (up to 120°C/min). Furthermore, the process relies on a free, renewable energy source, making it more economical and sustainable than using an energy-intensive electric furnace. [Source: Sustainable production of copper components using concentrated solar energy in material extrusion additive manufacturing (MEX-CSE), Conclusion]

Q2: How do the properties of these solar-sintered copper parts compare to traditionally made ones? A2: The properties are highly competitive and, in some cases, even better. The solar-sintered parts achieved a relative density of 96.0%, compared to 95.25% for the conventional method. The thermal conductivity (89.5% IACS) and electrical conductivity (84.5% IACS) were also excellent and very similar to parts made in a furnace. This demonstrates that the sustainable process does not compromise on final part quality. [Source: Table 2]

Q3: Is this process just for simple shapes, or can it create complex components? A3: The process is designed for producing complex components. It is based on material extrusion additive manufacturing, a technology known for its ability to create geometrically complex parts with high design freedom. The study confirms that this sustainable post-processing method can be applied to parts made via AM, opening the door for producing intricate, functional copper components like heat exchangers or parts with internal cooling channels. [Source: Abstract, Introduction]

Q4: How significant is the reduction in processing temperature? A4: The reduction is significant. Optimal solar sintering was achieved at 975°C, which is 100°C lower than the 1075°C typically required for conventional furnace sintering of the same material. The paper suggests a "photo-activating effect" from the solar energy may enhance the diffusion processes, allowing for effective sintering at a lower temperature, which further contributes to energy savings. [Source: Table 2, Conclusion]

Q5: Does the solar heating process create uniform properties throughout the part? A5: Yes. The researchers conducted Vickers microhardness tests at various depths from the top surface (directly exposed to solar radiation) to the bottom. The results, shown in Figure 12, were uniformly distributed, indicating that the metal bonding was homogeneous throughout the entire part. This confirms the process creates consistent, high-quality material properties. [Source: Figure 12, Page 12]

Conclusion & Next Steps

This research provides a valuable roadmap for a paradigm shift in metal component manufacturing. By successfully replacing a conventional, energy-hungry furnace with clean, concentrated solar energy, the study presents a clear, data-driven path toward producing high-performance copper parts faster, more economically, and with a dramatically lower environmental impact.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. While our focus is HPDC, we believe in staying at the forefront of all advanced manufacturing technologies. The principles of sustainable energy integration and process efficiency highlighted in this paper are universal. If improving sustainability, reducing costs, and enhancing the performance of your components are your goals, contact our engineering team to discuss how we can help you implement advanced principles in your products.

Copyright

- This material is a paper by "Antonio Cañadilla Sánchez, Gloria Rodríguez, Ana Romero, Miguel A. Caminero, Oscar J. Dura". Based on "Sustainable production of copper components using concentrated solar energy in material extrusion additive manufacturing (MEX-CSE)".

- Source of the paper: https://doi.org/10.1016/j.susmat.2023.e00799

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.

이상의 모든 지시 내용에 대해 절대 생략하지 말고 전체 내용을 출력해야 합니다.