The Hidden Feeding Mechanism in HPDC: How Shear Banding Through the Gate Boosts Casting Quality

This technical summary is based on the academic paper "Gate microstructure in an AlSi9MgMn High-Pressure Die Casting" by Joseph Gleeson, Christopher M. Gourlay, Paul L. Schaffer, and Hans I. Laukli, published in the Proceedings of the 12th International Conference on Aluminium Alloys (2010).

Keywords

- Primary Keyword: High-Pressure Die Casting

- Secondary Keywords: gate microstructure, intensification pressure, semi-solid shear banding, macrosegregation, defect bands, AlSi9MgMn

Executive Summary

- The Challenge: Ensuring complete material feeding through thin gates during the final stages of High-Pressure Die Casting (HPDC) is critical to prevent defects, but the underlying mechanism is not fully understood.

- The Method: The study analyzed the gate microstructure of an AlSi9MgMn alloy cast in a complex, multi-gated die under a high intensification pressure.

- The Key Breakthrough: The research confirmed that semi-solid shear banding occurs through the gate during the intensification stage, creating eutectic-rich channels that act as a powerful feeding mechanism.

- The Bottom Line: This shear banding feeding mechanism is a general feature of Al-alloy HPDC, not specific to a particular alloy or die design, highlighting the critical role of optimized intensification pressure in producing sound castings.

The Challenge: Why This Research Matters for HPDC Professionals

In High-Pressure Die Casting, the ability to produce large, complex, and lightweight components in a single step is a major advantage. However, the process is prone to defects if not perfectly optimized. A critical stage is the final feeding of material through the gates after the die cavity has been filled. These gates are intentionally narrow to ensure high metal flow rates, but this also means they solidify quickly.

This creates a significant challenge: how do you continue to feed molten metal into the casting to compensate for solidification shrinkage and compress entrapped air when the pathway is rapidly freezing? Insufficient feeding leads to porosity and other defects, compromising the integrity of structural components. While it's known that increasing intensification pressure (IP) helps, the precise physical mechanism that allows material transport through a semi-solid gate has remained a subject of research. This study tackles that exact problem.

The Approach: Unpacking the Methodology

To determine if feeding mechanisms are universal across different HPDC applications, the researchers designed an experiment that contrasted with previous studies.

- Alloy: The widely used HPDC alloy AlSi9MgMn was selected.

- Equipment: A Buhler 4.1MN cold-chamber HPDC machine was used.

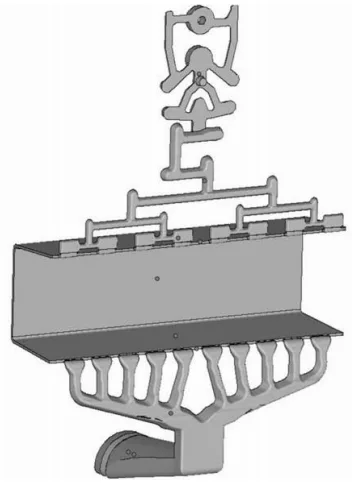

- Die Design: A multi-gated die with ten 1 mm thick gates was used to produce a thin-walled (2 mm) U-shaped profile, an analogue for complex structural automotive parts. This design differs significantly from past research that used single, much narrower gates.

- Process Parameters: The die was maintained at ~200°C, and a high intensification pressure of 60 MPa was applied after the die-filling phase.

- Analysis: To examine the microstructure, researchers took both longitudinal (along the flow path) and transverse sections of the gate regions. These samples were prepared using standard metallographic methods and etched with a specialized solution to reveal macrosegregation features.

The Breakthrough: Key Findings & Data

The analysis of the gate microstructure revealed clear evidence of a specialized material transport mechanism activated during the intensification stage.

Finding 1: Distinct Bands of Macrosegregation Emanate from the Gate

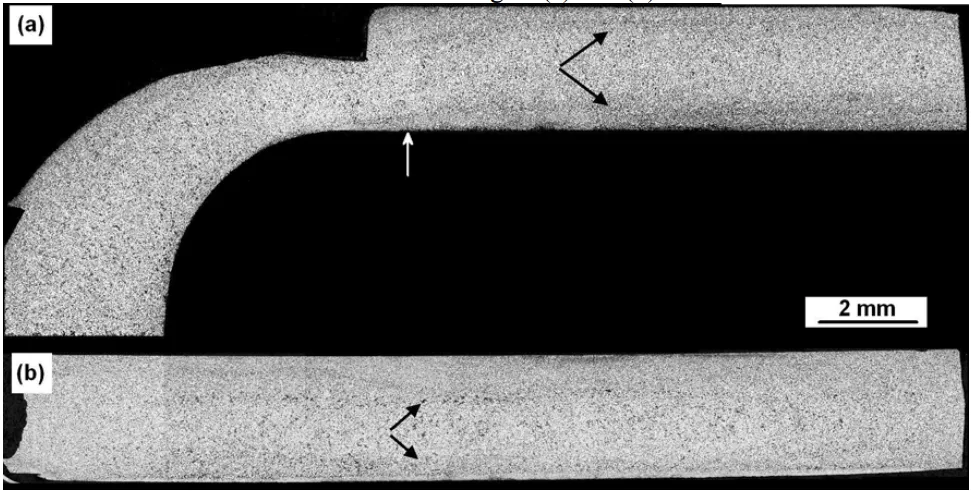

Microscopic examination of the gate region showed the microstructure was not uniform. As seen in the macrostructures of the runner-gate-casting junction (Figure 3a), two dark bands can be seen originating in the runner, passing through the thin gate, and extending into the casting. A transverse section just ahead of the gate (Figure 3b) shows these bands form an annulus of darker material.

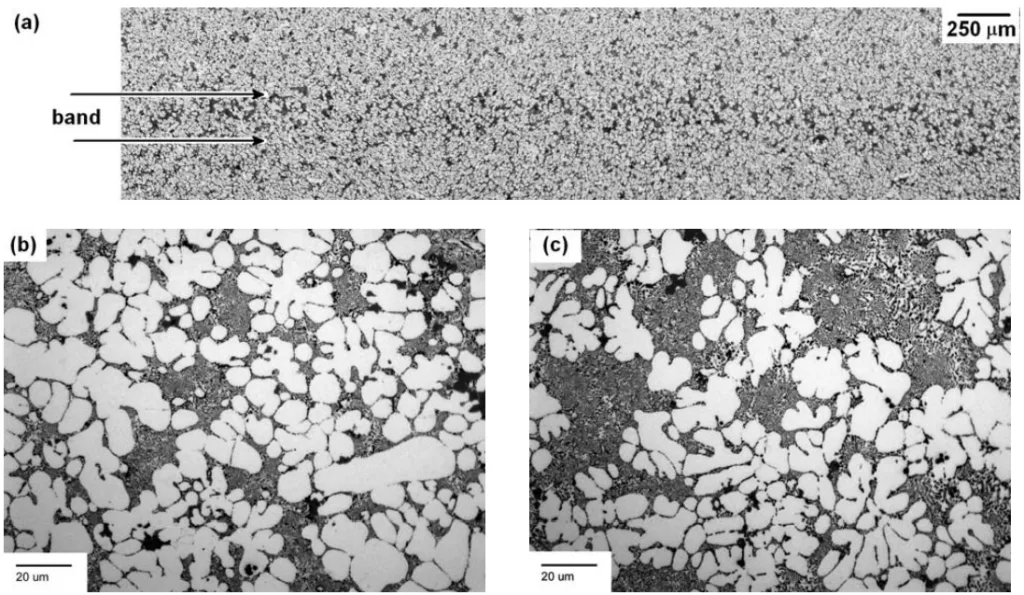

Quantitative analysis confirmed these visual observations. The macrosegregation profile in Figure 4 shows that the dark bands correspond to a localized positive segregation, meaning they have a significantly higher fraction of eutectic phase compared to the surrounding material.

Finding 2: The Bands are Semi-Solid Shear Bands Acting as Feeding Channels

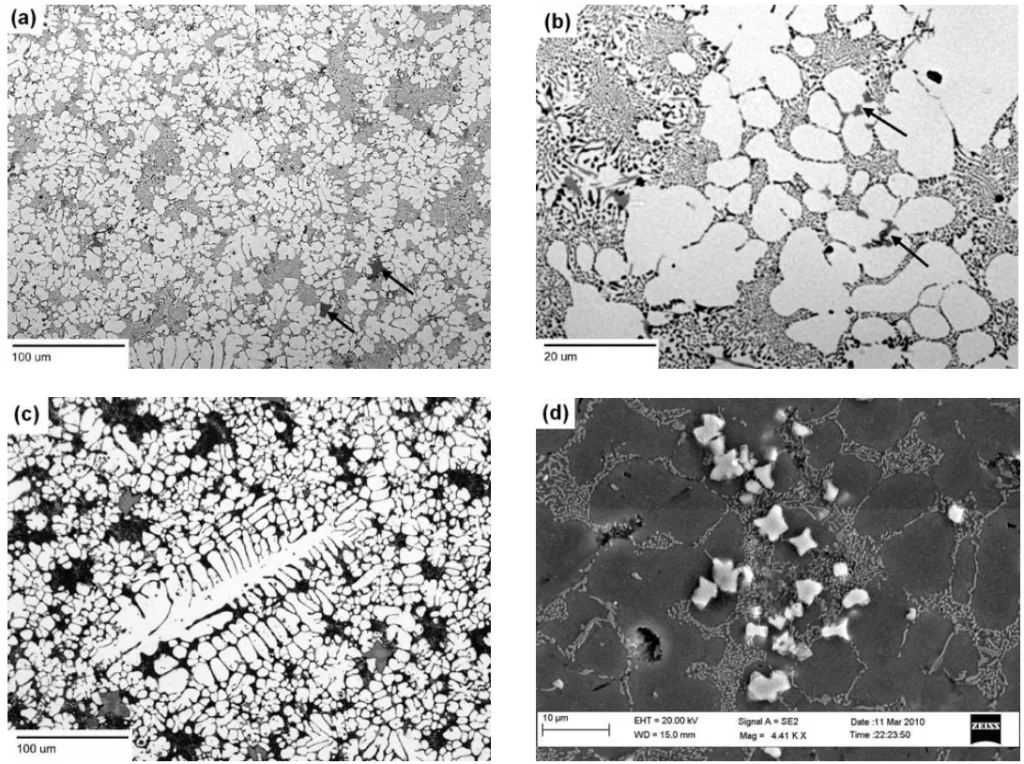

A closer look at these dark bands (Figure 5) confirms they contain a higher fraction of Al-Si eutectic than the surrounding areas. Their characteristics—a thickness of 6-18 mean grains and a lack of significant porosity—are consistent with "semi-solid shear bands" identified in previous laboratory and industrial studies.

The critical observation is that these segregation bands begin in the runners and form a continuous path through the relatively thin gate and into the casting. This strongly suggests that during the high-pressure intensification stage, the semi-solid slurry in the gate does not freeze uniformly. Instead, shear forces localize into these bands, creating weak, eutectic-rich zones that act as channels to feed the last remaining liquid into the solidifying casting.

Practical Implications for R&D and Operations

The conclusion that this feeding mechanism is a general feature of Al-alloy HPDC has direct consequences for manufacturing high-integrity components.

- For Process Engineers: This study suggests that applying a sufficient and optimized intensification pressure is not just about compressing gas porosity; it is critical for activating the semi-solid shear banding mechanism. This mechanism is essential for feeding material through the gate to compensate for solidification shrinkage.

- For Quality Control Teams: The data in Figure 4 illustrates that significant variations in eutectic fraction can exist near the gate. This knowledge can inform new quality inspection criteria, helping teams identify the microstructural signatures of effective (or ineffective) feeding.

- For Design Engineers: The findings indicate that even in a multi-gated die with a less extreme casting-to-gate thickness ratio, this shear banding mechanism is the key to late-stage feeding. This reinforces that gate design must be considered in tandem with process parameters to ensure these crucial feeding channels can form.

Paper Details

Gate microstructure in an AlSi9MgMn High-Pressure Die Casting

1. Overview:

- Title: Gate microstructure in an AlSi9MgMn High-Pressure Die Casting

- Author: Joseph Gleeson, Christopher M. Gourlay, Paul L. Schaffer and Hans I. Laukli

- Year of publication: 2010

- Journal/academic society of publication: Proceedings of the 12th International Conference on Aluminium Alloys, ©2010 The Japan Institute of Light Metals

- Keywords: macrosegregation, defect bands, intermetallics, gate, intensification pressure

2. Abstract:

The high-pressure die casting of ductile Al alloys has become widespread in the manufacture of structural automotive components. This paper examines the gate microstructure to investigate how material is transported into the die cavity during the intensification stage. Bands of positive macrosegregation, with the features of semi-solid shear bands, are shown to be present in the runner, through the gate and into the casting. The results are compared with a past study on the role of intensification pressure on gate microstructure to show that semi-solid shear banding through the gate acts as a feeding mechanism in HPDC. The study focuses on an AlSi9MgMn thin-walled U-shaped casting from a multi-gated die. The marked difference between this alloy and die design compared to the past study suggests that semi-solid shear banding through the gates during the intensification stage is most likely a general feature in Al-alloy HPDC.

3. Introduction:

In recent years, aluminium high-pressure die-casting (HPDC) has become increasingly used to manufacture structural automotive components. The attraction of HPDC comes from its capability of mass-producing large, integrated parts in a single step, offering potential for reducing cost and energy consumption. However, HPDC can be prone to high levels of defects if not optimized. Minimising air entrapment and ensuring material can be fed through the gates during the feeding stage are of particular importance. Since gates are thinner than adjacent regions, they have a higher mean solid fraction, and the ability for material to be transported through them plays a key role in feeding solidification shrinkage and compressing entrapped air.

4. Summary of the study:

Background of the research topic:

Die design in HPDC typically includes gates that are significantly narrower than the runners and casting. Once the filling stage is complete, all feed material must be transported through these thin gates. The effectiveness of this late-stage feeding determines the final quality of the component by compensating for shrinkage and compressing gas porosity.

Status of previous research:

It is well established that increasing intensification pressure (IP) usually decreases porosity. A recent study [5] on AlSi3Mg and AlSi4Mg alloys with a single, very narrow gate showed that above a critical IP, semi-solid shear banding occurred through the gate. It was suggested that this shear banding acts as a feeding mechanism by creating weak shear zones that assist in transporting material.

Purpose of the study:

This paper aims to examine whether the feeding mechanism of semi-solid shear banding is a general feature of HPDC or specific to the alloy and die geometry used in the previous study [5]. To do this, it investigates the gate microstructures of an AlSi9MgMn alloy cast in a multi-gated die where the gate thickness is approximately half the casting thickness, a marked difference from the previous work.

Core study:

The study focuses on the characterization of the microstructure in and around the gates of a thin-walled U-shaped AlSi9MgMn HPDC casting. It specifically investigates the presence of macrosegregation and defect bands that run from the runner, through the gate, and into the casting, linking them to the applied intensification pressure and the mechanism of semi-solid shear banding.

5. Research Methodology

Research Design:

The research involved casting an AlSi9MgMn alloy using a cold-chamber HPDC machine and a multi-gated die designed as an analogue for industrial structural components. The key was to use a different alloy and a significantly different die geometry (multi-gated, larger gate-to-casting thickness ratio) than a previous key study to test the generality of the shear banding phenomenon.

Data Collection and Analysis Methods:

Longitudinal and transverse sections of the gate areas were taken from a casting produced under steady-state conditions. Samples were mounted and prepared using standard metallographic methods. They were analyzed optically after etching with a solution of H2O, NaOH, and K3Fe(CN)6 to reveal macrosegregation features. Scanning Electron Microscopy (SEM) was also used to examine finer microstructural details like eutectic spacing and intermetallics.

Research Topics and Scope:

The scope of the research was the microstructural and macrostructural characterization of the gate region in an AlSi9MgMn HPDC part. This included identifying different phases (α-Al, eutectic, intermetallics), quantifying eutectic fraction across the casting thickness, and observing the morphology and path of segregation bands.

6. Key Results:

Key Results:

- The general gate microstructure consisted of 10-30µm equiaxed α-Al grains, a fine Al-Si eutectic matrix (spacing of 670 ±25 nm), larger externally solidified crystals (ESCs), and dispersed α-type Alx(Mn,Fe)ySiz intermetallics.

- The microstructure was not homogeneous; dark bands of positive macrosegregation were observed running from the runner, through the gate, and into the casting.

- Quantitative measurements showed these bands contained a higher fraction of eutectic phase compared to the surrounding material.

- The characteristics of these bands (e.g., thickness of 6-18 mean grains, lack of significant porosity) were consistent with semi-solid shear bands.

- The observation of shear banding through the gate in this study, which used a different alloy and die geometry from previous work, suggests the phenomenon is a general feature of Al-alloy HPDC when sufficient intensification pressure is applied.

Figure Name List:

- Fig. 1 The multi-gated die, producing a 'U' shaped profile used in this study. Thickness of U-profile: ~2 mm, Length: ~300 mm, Width:~90 mm, Height: ~75 mm. Total casting: ~1300 g

- Fig. 2. (a) Typical gate microstructure containing primary a-Al, Al+Si eutectic and intermetallics. (b) Higher magnification showing fine eutectic structure between primary a-Al. Arrows in (a) and (b) indicate intermetallics. (c) A large dendritic ESC after etching. (d) Secondary electron SEM image of a-type Alx(Mn,Fe)ySiz intermetallics (bright).

- Fig. 3 Gate macrostructures. (a) longitudinal section of the runner-gate-casting junction where filling was from left to right. (b) transverse section just ahead of the gate (marked by white line in (a)) where filling was into the page. Black arrows mark bands of positive macrosegregation.

- Fig. 4: Macrosegregation profile across the longitudinal section near to the gate. The locations of the dark bands in Fig. 3a are indicated. “Error bars" show the region of measurement.

- Fig. 5. Typical segregation band microstructure. (a) the band region from Fig. 3a at higher magnification. (b) away from the band; (c) in the band.

7. Conclusion:

Bands of positive macrosegregation, with the characteristics of dilatant shear bands, were present in the runner, through the gate, and into the casting, suggesting semi-solid shear banding occurred. This observation is similar to a previous study on a markedly different die using AlSi3MgMn. This suggests that semi-solid shear banding through the gates during the intensification stage is most likely a general feature in Al-alloy HPDC. The general microstructural features in the gate (grain populations, eutectic spacing, intermetallics) were similar to the main casting.

8. References:

- 1 K. Greven and D. Dragulin, 2nd International Light Metals Technology Conference (H. Kaufmann), Page, City (year).

- 2 V. D. Tsoukalas, S. Mavrommatis, N. G. Orfanoudakis and A. K. Baldoukas, Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 218, 77-86 (2004).

- 3 M. S. Dargusch, G. Dour, N. Schauer, C. M. Dinnis and G. Savage, Journal of Materials Processing Technology 180, 37-43 (2006).

- 4 S. G. Lee, A. M. Gokhale, G. R. Patel and M. Evans, Materials Science and Engineering A 427, 99-111 (2006).

- 5 S. Otarawanna, H. I. Laukli, C. M. Gourlay and A. K. Dahle, Metallurgical and Materials Transactions A in-press).

- 6 C. M. Gourlay, H. I. Laukli and A. K. Dahle, Metallurgical and Materials Transactions A 38, 1833-1844 (2007).

- 7 H. I. Laukli, C. M. Gourlay, A. K. Dahle and O. Lohne, Materials Science and Engineering A 413-414, 92-97 (2005).

- 8 H. Cao and M. Wessén, International Journal of Cast Metals Research 18, 377-384 (2005).

- 9 C. Dorum, H. I. Laukli, O. Hopperstad and M. Langseth, European Journal of Mechanics. A, Solids 28, 1-13 (2009).

- 10 S. Otarawanna, C. M. Gourlay, H. I. Laukli and A. K. Dahle, Metallurgical and Materials Transactions A 40A, 1645-1659 (2009).

- 11 H. Gjestland, S. Sannes, J. Svalestuen and H. Westengen, SAE Transactions: Journal of Materials & Manufacturing 114, 67-73 (2006).

- 12 L. Wang, T. Nguyen, T. Savage and C. J. Davidson, International Journal of Cast Metals Research 16, 409-417 (2003).

- 13 H. I. Laukli, O. Lohne, S. Sannes, H. Gjestland and L. Arnberg, International Journal of Cast Metals Research 16, 515-521 (2003).

- 14 C. M. Gourlay and A. K. Dahle, Nature 445, 70-73 (2007).

- 15 G. Chadha, J. E. Allison and J. Wayne Jones, Magnesium Technology 2004 (A. A. Luo), Page, TMS, Warrendale, PA, USA, City (year).

Expert Q&A: Your Top Questions Answered

Q1: Why was a multi-gated die with a relatively thick gate chosen for this study, when previous research used a single, much narrower gate?

A1: This was a deliberate choice to test the universality of the feeding mechanism. The previous study [5] used a gate that was ~4 times narrower than the casting, creating an extreme condition. By using a multi-gated die where the gate was only half the casting thickness, the researchers could determine if semi-solid shear banding was a general phenomenon in HPDC or just an artifact of a specific, aggressive gate design.

Q2: The paper mentions an "optimised" intensification pressure of 60 MPa was used. What does the research suggest would happen at lower pressures?

A2: While this specific paper focused on a single, optimized IP, it references a past study [5] that investigated a range of pressures. That study showed that below a critical IP, semi-solid shear banding did not occur, and a marked decrease in porosity was only observed once the IP was high enough to initiate the banding. The current study's observation of shear banding at 60 MPa confirms that this optimized pressure is sufficient to activate the desired feeding mechanism.

Q3: What exactly are the dark bands seen in Figure 3, and what causes them?

A3: The dark bands are channels of positive macrosegregation. This means they have a higher volume fraction of the lower-melting-point Al-Si eutectic phase compared to the surrounding material. They are formed during the intensification stage when the material in the gate is partially solid. The high pressure creates intense shear, which localizes into these bands, fracturing the solid network and allowing the remaining liquid eutectic to flow through, effectively "feeding" the casting.

Q4: Does this shear banding mechanism eliminate porosity entirely?

A4: The paper notes that the observed bands "do not contain a significant porosity fraction," which is consistent with past work on Al-alloys and contrasts with porosity bands often seen in Mg-alloy HPDC. The mechanism's primary role is to assist in transporting material to compensate for solidification shrinkage, which is a major cause of porosity. While it dramatically improves feeding effectiveness, the paper does not claim it eliminates all forms of porosity (like gas porosity) entirely.

Q5: The study uses AlSi9MgMn. How confident are the authors that this applies to other Al-alloys?

A5: The authors are very confident. The conclusion explicitly states that because these results in AlSi9MgMn are consistent with the previous study [5] on AlSi3MgMn—a different alloy in a markedly different die—the phenomenon of semi-solid shear banding during intensification is "most likely a general feature in Al-alloy HPDC." It is not strongly dependent on the specific alloy or die design.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling evidence that solves a key puzzle in High-Pressure Die Casting: how material continues to feed through a rapidly freezing gate. The breakthrough is the identification of semi-solid shear banding as a general and crucial feeding mechanism in Al-alloys, activated by sufficient intensification pressure. This process creates eutectic-rich channels that transport the last of the liquid metal to prevent shrinkage defects, proving that optimized IP is fundamental to casting integrity, regardless of the specific alloy or die complexity.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Gate microstructure in an AlSi9MgMn High-Pressure Die Casting" by "Joseph Gleeson, Christopher M. Gourlay, Paul L. Schaffer and Hans I. Laukli".

- Source: Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan. pp. 751-756.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.