From CAD to Cycles: A Guide to FEA-Based Fatigue Analysis for Aluminum Alloy Wheels

This technical summary is based on the academic paper "Fatigue Analysis of Aluminum Alloy Wheel Under Radial Load" by N. Satyanarayana & Ch.Sambaiah, published in International Journal of Mechanical and Industrial Engineering (IJMIE) (2012).

Keywords

- Primary Keyword: Aluminum Alloy Wheel Fatigue Analysis

- Secondary Keywords: FEA, A356.2, S-N Curve, Radial Load, CATIA, ANSYS, Low Pressure Die Casting

Executive Summary

- The Challenge: Predicting the fatigue life of aluminum alloy wheels with complex geometries is a time-consuming and costly process that traditionally relies on extensive physical testing.

- The Method: The researchers developed a 3D model of an A356.2 aluminum alloy wheel and used Finite Element Analysis (FEA) to simulate total deformation, stress distribution, and fatigue life under a static radial load.

- The Key Breakthrough: The study successfully determined the wheel's fatigue life, safety factor, and damage using an S-N curve approach, identifying critical stress points and predicting a maximum life of 1.7667e6 cycles at an alternating stress of 100 MPa.

- The Bottom Line: This research validates FEA simulation as a reliable and efficient method for predicting the fatigue performance of alloy wheels, enabling manufacturers to optimize designs for durability and weight before committing to physical prototypes.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, the demand for lightweight, high-performance, and stylistically complex alloy wheels is constantly growing. However, ensuring the structural integrity and durability of these components is paramount. Traditional design and development cycles are often long and expensive, requiring numerous physical prototypes and iterative testing to validate fatigue performance.

The key challenge lies in the quality of the casting. Defects such as blow holes, porosity, and shrinkage can compromise the integrity of the final product. While manufacturing processes like low-pressure die casting have improved control over these issues, accurately predicting how a new design will perform under millions of cycles of real-world road stress remains a significant hurdle. This research was undertaken to demonstrate a more efficient, computer-aided engineering (CAE) approach to shorten development time and reduce the need for costly physical tests by accurately simulating fatigue life.

The Approach: Unpacking the Methodology

The study employed a robust simulation-based methodology to analyze the wheel's performance.

- Material: The wheel was modeled using Aluminum Alloy A356.2, a common material for alloy wheels known for its good casting characteristics. Key material properties included a Young's Modulus of 69000 MPa, a Tensile Yield Strength of 229 MPa, and a Tensile Ultimate Strength of 279 MPa.

- Modeling: A 3-dimensional model of a 17"x6" wheel was designed in CATIA and then imported into the ANSYS FEA software package.

- Meshing: The 3D model was discretized into a finite element mesh using 10-node tetrahedron solid elements, resulting in a total of 212,319 nodes and 117,243 elements. This high-density mesh allows for a detailed and accurate analysis of stress concentrations.

- Boundary Conditions: To simulate a radial load test, the model was constrained in all degrees of freedom at the pitch circle diameter (PCD) and hub portion. A pressure of 2.8653 MPa was applied to the rim of the wheel.

- Analysis: A static structural analysis was performed to determine total deformation and stress distribution. Subsequently, a fatigue analysis was conducted using the stress results and an S-N curve specific to the A356.2 material to predict the wheel's life, safety factor, and damage under cyclic loading.

The Breakthrough: Key Findings & Data

The FEA simulation yielded precise, actionable data on the wheel's structural and fatigue performance.

Finding 1: Stress Distribution and Deformation Under Load

The static analysis revealed the precise areas of stress and deformation. The maximum total deformation of the wheel was 0.2833mm, occurring at the rim where the load was applied. The maximum equivalent stress was found to be 163.97 MPa. The analysis also showed that the maximum shear stress was 48.195 MPa, while the minimum was -48.241 at the hub, indicating the complex stress state within the component.

Finding 2: S-N Curve Based Fatigue Life Prediction

By applying the S-N curve data for A356.2 (as detailed in Table 2 of the paper), the researchers were able to predict the fatigue life at various stress levels. The simulation predicted a maximum wheel life of 1,766,700 cycles. The analysis also identified the critical areas for fatigue damage, noting that the damage was highest "at a cross sectional area of wheel spokes," a common failure point. This confirms that the simulation accurately models real-world failure mechanisms.

Practical Implications for R&D and Operations

The findings from this paper offer valuable insights for engineering and manufacturing teams involved in producing cast components.

- For Process Engineers: This study validates a simulation methodology that can be used to assess the impact of design changes on durability without the need for immediate physical testing. It provides a framework for front-loading analysis to catch potential fatigue issues early in the development cycle.

- For Quality Control Teams: The analysis, which identifies high-stress regions like the rim and spoke junctions, can help prioritize areas for non-destructive testing and quality inspection on finished parts, ensuring that the most critical areas meet stringent standards.

- For Design Engineers: The S-N curve approach combined with FEA is a powerful tool for design optimization. Engineers can use this method to confidently explore lighter-weight designs or more complex aesthetics, while simultaneously verifying that the proposed changes will not compromise the wheel's fatigue life and safety.

Paper Details

Fatigue Analysis of Aluminum Alloy Wheel Under Radial Load

1. Overview:

- Title: Fatigue Analysis of Aluminum Alloy Wheel Under Radial Load

- Author: N. Satyanarayana & Ch.Sambaiah

- Year of publication: 2012

- Journal/academic society of publication: International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No. 2231-6477, Vol-2, Issue-1

- Keywords: Aluminum Alloy Wheel, A356.2, FEA, CATIA, ANSYS

2. Abstract:

In this paper a detailed "Fatigue Analysis of Aluminum Alloy Wheel under Radial Load". During the part of project a static and fatigue analysis of aluminum alloy wheel A356.2 was carried out using FEA package. The 3 dimensional model of the wheel was designed using CATIA. Then the 3-D model was imported into ANSYS using the IGES format. The finite element idealization of this modal was then produced using the 10 node tetrahedron solid element. The analysis was performed in a static condition. This is constrained in all degree of freedom at the PCD and hub portion. The pressure is applied on the rim. We find out the total deformation, alternative stress and shear stress by using FEA software. And also we find out the life, safety factor and damage of alloy wheel by using S-N curve. S-N curve is input for a A.356.2 material.

3. Introduction:

Alloy wheels were first developed in the 1960s for performance and styling. The market has grown steadily, with alloy wheels now being a de-facto standard. The quality of an alloy wheel depends on the casting process, with methods like sand and gravity casting being less controllable and prone to defects. Low-pressure die casting offers precise control, reducing cavities and porosity, and is considered the state-of-the-art technology for manufacturing alloy wheels. This process is amenable to large-scale production and is used by leading OEM suppliers.

4. Summary of the study:

Background of the research topic:

Automotive wheels have complex geometries and must meet criteria for style, weight, manufacturability, and performance. Reducing wheel weight is a major industry concern to improve driving comfort and reduce material costs. Traditionally, wheel design is time-consuming, requiring multiple tests and iterations. Computer-aided engineering (CAE) has become a useful tool to shorten development time and reduce testing.

Status of previous research:

Fatigue as a technical problem was recognized in the mid-19th century. Historical reviews by Peterson (1950) and Timoshenko (1954) highlighted the importance of stress concentrations around notches and the development of experimental stress analysis techniques. This foundational work led to the modern understanding of fatigue performance in mechanical components.

Purpose of the study:

The purpose of this study is to estimate the fatigue life of an aluminum alloy wheel under a radial load by conducting a static and fatigue analysis using an FEA package. The goal is to compare simulation results with established testing procedures and validate the use of FEA with an S-N curve approach for predicting wheel durability.

Core study:

The core of the study involves creating a 3D model of an A356.2 aluminum alloy wheel, performing a finite element analysis in ANSYS to determine stress and deformation under a simulated radial load, and then using these results along with material-specific S-N data to predict the fatigue life, safety factor, and damage locations on the wheel.

5. Research Methodology

Research Design:

The research follows a computational simulation design. A 3D model of a wheel with specific dimensions (17" diameter, 6" width) was created. A static structural analysis was performed, followed by a fatigue analysis.

Data Collection and Analysis Methods:

The 3D model was created in CATIA. The analysis was performed using the ANSYS FEA software. The model was meshed with 10-node tetrahedral solid elements. Boundary conditions involved constraining the hub and PCD and applying pressure to the rim. The fatigue analysis utilized the stress-life (S-N) approach, with material data for A356.2 used as input.

Research Topics and Scope:

The scope is limited to the fatigue analysis of a specific A356.2 aluminum alloy wheel design under a static radial load condition. The analysis includes total deformation, alternating stress, shear stress, fatigue life, safety factor, and damage.

6. Key Results:

Key Results:

- The maximum total deformation of the wheel is 0.2833mm.

- The maximum shear stress is 48.195 MPa, and the minimum is -48.241 MPa at the hub.

- The maximum equivalent stress is 163.97 MPa.

- The maximum fatigue life of the wheel is 1.7667e6 cycles.

- The area with the highest predicted damage is the cross-sectional area of the wheel spokes.

- The S-N curve approach for predicting fatigue life via FEA was found to converge with experimental results.

Figure Name List:

- Figure 1. 2D Diagram of aluminum wheel

- Figure 2. 3D Model of Aluminum alloy wheel

- Figure 3. Meshing of alloy wheel

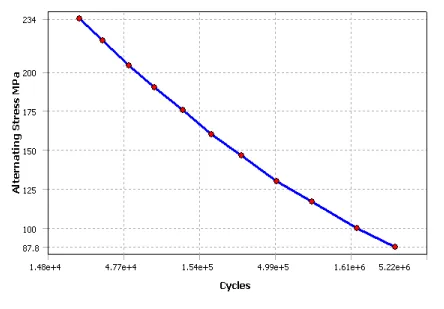

- Figure 5. Alternating Stress vs Cycle

- Figure 6. Constant amplitude fully reversed

- Figure 7. Life & Load

7. Conclusion:

The study successfully used finite element analysis to simulate test conditions and analyze the stress distribution, fatigue life, safety, and damage of an alloy wheel. The S-N curve approach for predicting fatigue life by simulating static analysis with cyclic loads was found to converge with experimental results. The paper proposes that the safety factors derived from such parametric studies can be useful for manufacturers and designers to reliably predict fatigue life for similar components subjected to radial fatigue loads.

8. References:

- [1] S.K. Biswas, W.A. Knight, Perform design for closed die forging: experimental basis for computer aided design, Int. J. Mach. Tool Des. Res. 15 (1975) 179–193.

- [2] Akgerman, T. Altan, Recent developments in computer-aided design of forging process, SME Technical Paper, 1972, pp. 72-110.

- [3] P. Perzyna, Fundamental problems in viscoplasticity, Adv. Appl.Mech. 9 (1966) 243.

- [4] N. Cristescu, Dynamic Plasticity, North-Holland, Amsterdam, 1967, pp. 577–579.

- [5] N. Rebelo, S. Kobayashi, A coupled analysis of viscoplastic deformation and heat transfer-I: theoretical considerations, Int. J.Mech. Sci. 22 (1980) 699-705.

- [6] N. Rebelo, S. Kobayashi, A coupled analysis of viscoplastic deformation and heat transfer-II: applications, Int. J. Mech. Sci. 22 (1980) 707–718.

- [7] S.I. Oh, G.D. Lahoti, T. Altan, ALPID-a general purpose FEM program for metal forming, in: Proceedings of NAMRC IX, State College, Pennsylvania, 1981.

- [8] Y.C. Yu, Hot workability of aluminum alloy, KOSEF Report, 1985, pp. 20–32.

- [9] T. Lyman, Metals Handbook, Vol. 1, Properties and Selection of Metals, American Society for Metals, Ohio, 1961, pp. 54–55.

Expert Q&A: Your Top Questions Answered

Q1: What were the specific boundary conditions used to simulate the radial load test in ANSYS?

A1: The simulation was set up to mimic a standard radial load test. According to the paper, the model was "constrained in all degree of freedom at the PCD and hub portion." This effectively fixes the wheel as it would be mounted on a vehicle. The load was simulated by applying a pressure of 2.8653 MPa directly onto the rim surface.

Q2: How does the predicted fatigue life of 1.7667e6 cycles correspond to a specific stress level in the S-N curve?

A2: Looking at Table 2, "Alternating Stress Vs Cycles," a life of 1.7667e+006 cycles (1,766,700 cycles) corresponds directly to an alternating stress level of 100 MPa. This demonstrates the inverse relationship between stress and life: as the alternating stress on the component decreases, its expected number of cycles to failure increases significantly.

Q3: The paper identifies the spokes as the area of highest damage. Does the data show where the highest stress occurs?

A3: Yes, the paper provides details on both. While the highest damage accumulates in the spokes under cyclic loading, the initial static analysis shows the highest deformation (0.2833mm) and load concentration is on the rim where the pressure is applied. The maximum shear stress is located at the hub. This distinction is critical; fatigue damage is not always in the same location as the absolute maximum static stress, which is why comprehensive FEA is so valuable.

Q4: Why was the A356.2 aluminum alloy chosen for this study?

A4: The paper does not explicitly state the reason for the selection, but it does note that low-pressure die casting is the "state of the art technology for manufacture of alloy wheels." A356.2 is a very common aluminum-silicon-magnesium casting alloy used for automotive wheels manufactured by processes like low-pressure die casting due to its excellent castability, corrosion resistance, and good mechanical properties.

Q5: The paper mentions the S-N curve approach "is found to converge with experimental results." Does it provide the experimental data for comparison?

A5: The paper states this convergence as a conclusion but does not include the specific experimental data sets within the document. It asserts that the simulation methodology is a reliable predictor that aligns with the outcomes of physical tests, which are the industry standard for validation. This suggests the FEA model is well-calibrated to real-world performance.

Conclusion: Paving the Way for Higher Quality and Productivity

This study effectively demonstrates how modern simulation tools can solve the long-standing challenge of predicting component durability. By integrating detailed 3D modeling with robust FEA, this Aluminum Alloy Wheel Fatigue Analysis provides a clear and reliable pathway to understanding stress distribution and fatigue life. The validation of the S-N curve approach within a simulation environment empowers engineers to innovate faster, reduce reliance on costly physical prototypes, and ultimately design lighter, stronger, and more reliable components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Fatigue Analysis of Aluminum Alloy Wheel Under Radial Load" by "N. Satyanarayana & Ch.Sambaiah".

- Source: International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No. 2231-6477, Vol-2, Issue-1, 2012.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.