This introduction paper is based on the paper "Enhancing the Cooling Efficiency of Aluminum-Filled Epoxy Resin Rapid Tool by Changing Inner Surface Roughness of Cooling Channels" published by "Polymers".

1. Overview:

- Title: Enhancing the Cooling Efficiency of Aluminum-Filled Epoxy Resin Rapid Tool by Changing Inner Surface Roughness of Cooling Channels

- Author: Chil-Chyuan Kuo, Hong-Wei Chen, Geng-Feng Lin, Song-Hua Huang and Shih-Feng Tseng

- Year of publication: 2024

- Journal/academic society of publication: Polymers

- Keywords: surface roughness; cooling efficiency; aluminum-filled epoxy resin; rapid tool; cooling time; low-pressure wax injection molding

2. Abstract:

In low-pressure wax injection molding, cooling time refers to the period during which the molten plastic inside the mold solidifies and cools down to a temperature where it can be safely ejected without deformation. However, cooling efficiency for the mass production of injection-molded wax patterns is crucial. This work aims to investigate the impact of varying surface roughness on the inner walls of the cooling channel on the cooling efficiency of an aluminum-filled epoxy resin rapid tool. It was found that the cooling time for the injection-molded products can be determined by the surface roughness according to the proposed prediction equation. Employing fiber laser processing on high-speed steel rods allows for the creation of microstructures with different surface roughness levels. Results demonstrate a clear link between the surface roughness of cooling channel walls and cooling time for molded wax patterns. Employing an aluminum-filled epoxy resin rapid tool with a surface roughness of 4.9 µm for low-pressure wax injection molding can save time, with a cooling efficiency improvement of approximately 34%. Utilizing an aluminum-filled epoxy resin rapid tool with a surface roughness of 4.9 µm on the inner walls of the cooling channel can save the cooling time by up to approximately 60%. These findings underscore the significant role of cooling channel surface roughness in optimizing injection molding processes for enhanced efficiency.

3. Introduction:

The cooling phase constitutes a significant portion of processing time in injection molding operations. Conformal cooling channels (CCs) have become a recommended standard for enhancing mold capabilities in various manufacturing processes, including plastic injection molding and die casting, due to their ability to improve heat dissipation. While CCs are extensively used, their cooling efficiency can be limited. This study focuses on enhancing the cooling efficiency of aluminum-filled epoxy resin rapid tools, particularly for mass production in low-pressure wax injection molding. The approach involves modifying the inner surface roughness of the cooling channels. By creating characteristic microstructures on the cooling channel surfaces using fiber laser patterning, the contact area for the coolant can be increased, potentially improving heat transfer and thus cooling efficiency. This research investigates the relationship between different surface roughness levels on the inner walls of cooling channels and the cooling performance of an aluminum-filled epoxy resin rapid tool.

4. Summary of the study:

Background of the research topic:

The cooling stage is a critical determinant of cycle time and efficiency in injection molding. Conformal cooling channels (CCs) are designed to follow the shape of the molded product, offering improved heat dissipation compared to conventional straight cooling channels. Aluminum-filled epoxy resin is utilized for rapid tooling. Enhancing the cooling efficiency of such tools is vital for applications like mass production of wax patterns in low-pressure wax injection molding.

Status of previous research:

Previous research has explored various aspects of CCs, including plasticity loss of steel cores with CC [6], temperature distribution enhancement [7], cooling efficiency assessment via simulation [8], optimization using Taguchi-integrated principal component analysis [9], biomimetic engineering approaches for CC design [10], innovative CC systems for reduced cycle time and warping [11, 14], hybrid cooling models [15], CC system selection methods [12], and metal additive manufacturing of molds with CCs [13]. While CCs are widely adopted [16-21], there remains a need to further improve their cooling efficiency, especially for specific tool materials and manufacturing processes. The concept of modifying surface structures to increase contact area [22, 23] and using fiber laser patterning [24] for surface modification has been explored.

Purpose of the study:

This study aimed to investigate the impact of varying the surface roughness on the inner walls of cooling channels on the cooling efficiency of an aluminum-filled epoxy resin rapid tool used in low-pressure wax injection molding. A key objective was to establish a relationship, potentially a predictive equation, between surface roughness and the cooling time of injection-molded products. The ultimate goal was to demonstrate a method for significantly improving cooling efficiency and reducing cooling time.

Core study:

The core of the study involved:

- Creating microstructures with different surface roughness levels (Sz values of approximately 2.4 µm, 3.2 µm, 4.1 µm, and 4.9 µm) on high-speed steel rods using a fiber laser patterning system.

- Fabricating silicone rubber molds from these textured rods.

- Using these silicone molds to produce wax cooling channels (CCs) with the transferred surface roughness.

- Manufacturing an aluminum-filled epoxy resin rapid tool incorporating these wax CCs.

- Conducting low-pressure wax injection molding experiments using the fabricated rapid tool to assess its cooling performance by measuring the cooling time of the wax patterns for each surface roughness configuration.

- Analyzing the relationship between the cooling channel's inner surface roughness and the cooling time, and quantifying the improvement in cooling efficiency.

5. Research Methodology

Research Design:

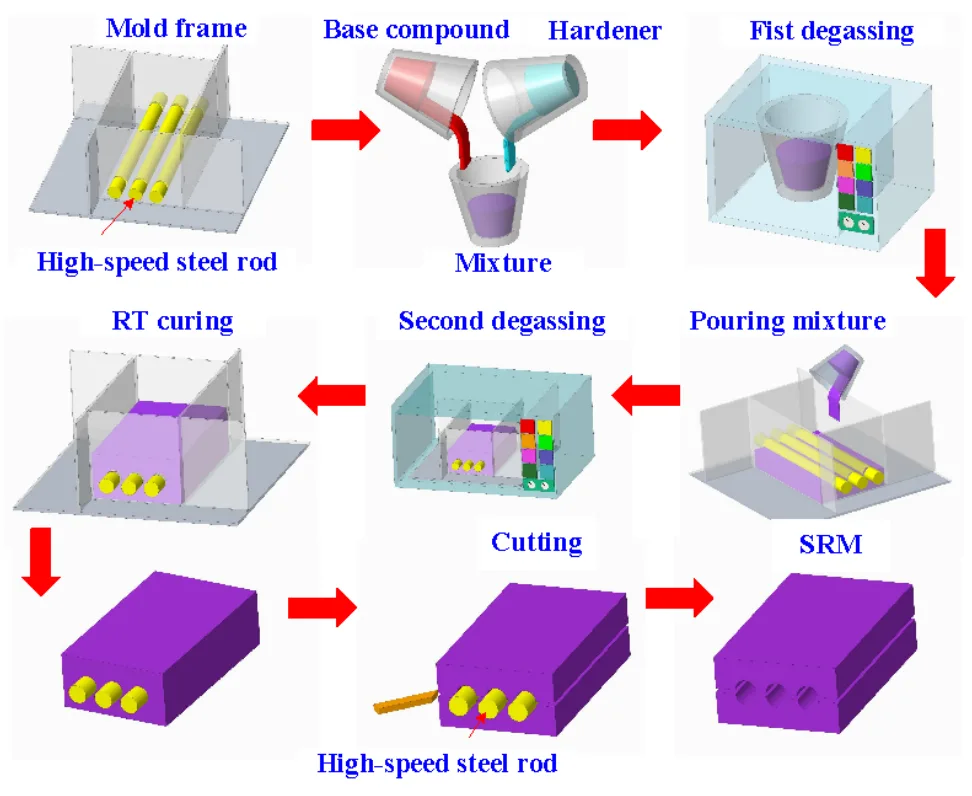

The experimental methodology followed a sequential process (Figure 1):

- Surface Texturing: High-speed steel rods were processed using a fiber laser system to create distinct microstructures, resulting in varying surface roughness levels. Laser processing parameters (laser power, scan speed, hatch distance, number of laser processing passes) were controlled to achieve these different roughness values.

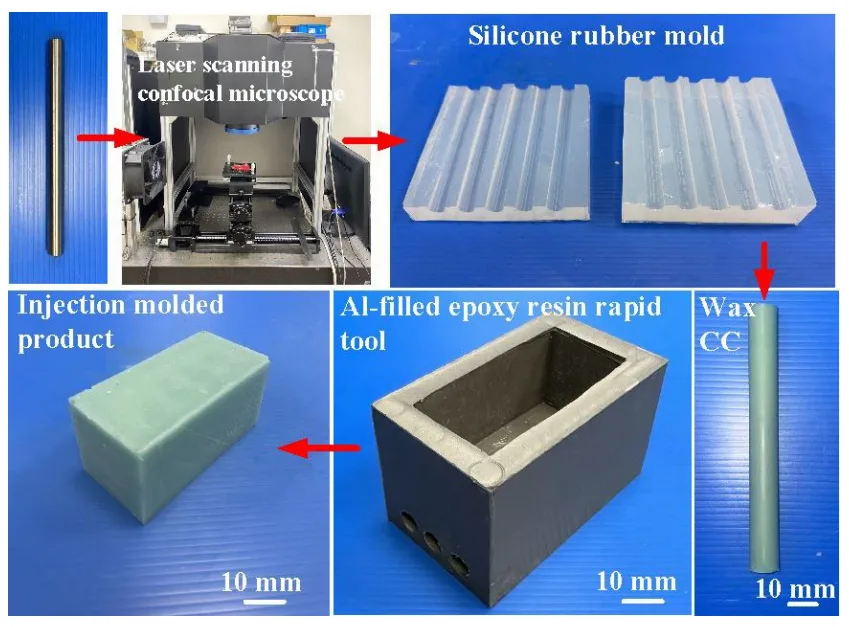

- Mold Replication: Silicone rubber molds (SRM) were fabricated using the textured high-speed steel rods as master models. This process transferred the surface roughness from the rods to the silicone molds.

- Wax CC Fabrication: The silicone rubber molds were then used to cast wax cooling channels, thereby imparting the desired surface roughness to the wax CCs.

- Rapid Tool Manufacturing: An aluminum-filled epoxy resin rapid tool was manufactured, incorporating the wax CCs. After the epoxy resin cured, the wax CCs were removed, leaving cooling channels with the specific inner surface roughness.

- Cooling Performance Evaluation: Low-pressure wax injection molding was performed using the fabricated rapid tool. The cooling time of the molded wax patterns was measured for tools with different cooling channel surface roughness values and for a tool without cooling channels.

Data Collection and Analysis Methods:

- Surface Roughness Creation: A fiber laser patterning system (YLPN-1-4×200-30-M, IPG photonics Co., Ltd.) was used. Key parameters included: wavelength 1064 nm, maximum average power 30 W, pulse duration 4 ns, processing laser power 28 W, scan speed 30 mm/s, hatch distance 0.05 mm. The number of laser processing cycles (1, 3, 5, and 7 times) was varied to achieve different roughness levels. (Table 1)

- Surface Roughness Measurement: A laser scanning confocal microscope (VK-X3000, Keyence Co., Ltd.) was employed to measure the surface roughness (Sz - maximum height) of the specimens and cooling channels.

- Morphology Investigation: Optical microscope (Quick Vision 404, Mitutoyo Inc.) and FE-SEM (JEC3000-FC, JEOL Inc.) were used.

- Silicone Rubber Mold (SRM) Fabrication: Silicone rubber (KE-1310ST, Shin Etsu Inc.) and curing agent (CAT-1310S, Shin Etsu Inc.) were mixed in a 10:1 weight ratio. Air bubbles were removed using a vacuum machine (F-600, Feiling, Inc.).

- Rapid Tool Fabrication: Aluminum-filled epoxy resin (approx. 70% aluminum powder by weight, average particle size 48 µm, purity 96–99%). Curing agent (EP-2N-B, Ruixin Inc.) and base compound of epoxy resin (EP-2N-A, Ruixin Inc.) were mixed in a 1:2 weight ratio.

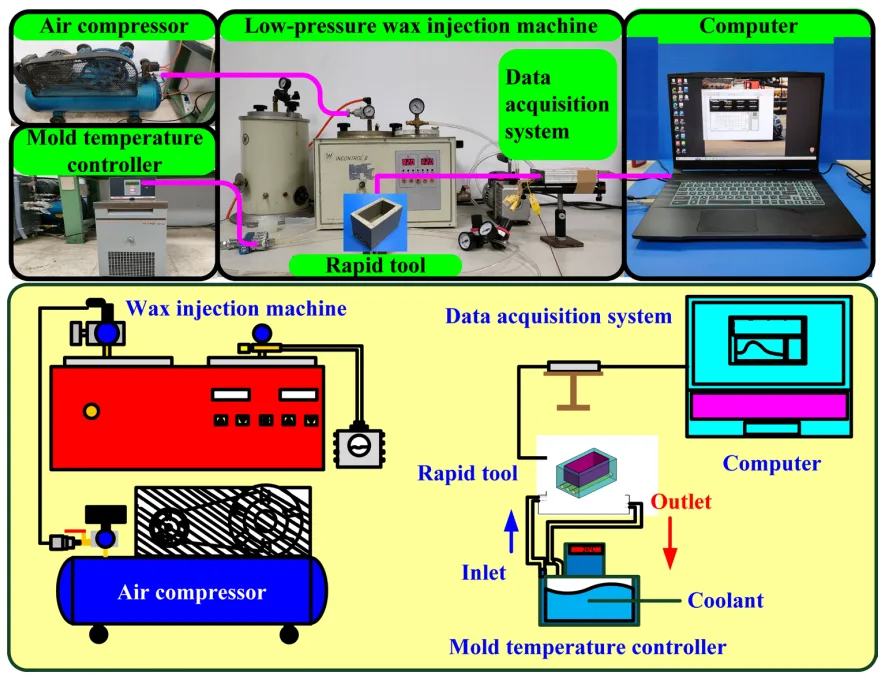

- Low-Pressure Wax Injection Molding: A low-pressure wax injection molding machine (0660, W&W Inc.) was used. Molten wax (K512, Kato Inc.) was injected at 82 °C into the mold cavity (set at 27 °C).

- Cooling Time Measurement: A homemade system (Figure 7) including a mold temperature controller (JCM-33A, Shinko Inc.), K-type thermocouple (C071009-079, Cheng Tay Inc., sensitivity ±1 °C), a coolant reservoir with a thermo-electric cooler (TEC12706AJ, Caijia Inc.), and a data acquisition system (MRD-8002L, IDEA System Inc.) was used. Coolant flow rate was ~4 L/min. Wax injection pressure was ~0.06 MPa. Ejection temperature for the molded wax pattern was 30 °C. Inlet coolant temperature was 27 °C, and ambient temperature was 27 °C.

- Data Analysis: Cooling times were compared, and a prediction equation relating surface roughness (Sz) to cooling time (y) was developed. Cooling rates were also calculated and compared.

Research Topics and Scope:

- Investigation of the effect of different inner surface roughness values (Sz ≈ 2.4 µm, 3.2 µm, 4.1 µm, and 4.9 µm) of cooling channels on the cooling time of wax patterns.

- Quantification of cooling efficiency improvement in an aluminum-filled epoxy resin rapid tool due to changes in cooling channel surface roughness.

- Comparison of cooling times for tools with cooling channels of varying roughness versus a tool without cooling channels.

- Development of a predictive model for cooling time based on the Sz surface roughness of the cooling channel.

- Analysis of first and second cooling rates during the cooling stage.

6. Key Results:

Key Results:

- Fiber laser processing successfully created microstructures on high-speed steel rods, resulting in different Sz surface roughness values: approximately 2.4 µm, 3.2 µm, 4.1 µm, and 4.9 µm corresponding to 1, 3, 5, and 7 laser processing cycles, respectively (Figure 8).

- The presence of cooling channels in the aluminum-filled epoxy resin rapid tool significantly reduced the cooling time for injection-molded products by approximately 40%, from 120 min (without CCs) to 72 min (with CCs of Sz = 2.4 µm) (Figure 9).

- The cooling time of injection-molded wax patterns decreased as the Sz surface roughness of the inner wall of the cooling channel increased. Cooling times were approximately 72 min (Sz 2.4 µm), 64 min (Sz 3.2 µm), 60 min (Sz 4.1 µm), and 48 min (Sz 4.9 µm) (Figure 10).

- Utilizing an aluminum-filled epoxy resin rapid tool with an inner cooling channel surface roughness of Sz = 4.9 µm resulted in a cooling time saving of about 34% compared to a tool with Sz = 2.4 µm.

- Compared to a tool without cooling channels, a tool with an inner cooling channel surface roughness of Sz = 4.9 µm achieved a cooling time saving of up to 60%.

- The cooling time for injection-molded products was found to be repeatable, as demonstrated by five trials with an average cooling time of about 64 min for Sz = 3.2 µm (Figure 11).

- The average cooling time (y) for injection-molded products can be determined by the Sz surface roughness (x) according to the prediction equation: y = -x² - 2.6x + 75, with a correlation coefficient of 0.976 (Figure 12).

- The first cooling rate (eight minutes before the cooling time) increased with increasing surface roughness: 2.13 °C/s (Sz 2.4 µm), 2.396 °C/s (Sz 3.2 µm), 3.462 °C/s (Sz 4.1 µm), and 3.966 °C/s (Sz 4.9 µm) (Figure 14).

- The second cooling rate (eight minutes after the cooling time) also increased with increasing surface roughness: 0.232 °C/s (Sz 2.4 µm), 0.272 °C/s (Sz 3.2 µm), 0.302 °C/s (Sz 4.1 µm), and 0.328 °C/s (Sz 4.9 µm) (Figure 15).

- The enhanced cooling efficiency is attributed to the increased contact area for heat transfer within the cooling channel due to the feature structures, promoting more effective cooling (Figure 16).

Figure Name List:

- Figure 1. Flowchart of experimental methodology.

- Figure 2. Processing paths for machining microstructures on the high-speed steel rod.

- Figure 3. Manufacturing process of a silicone rubber mold for making wax cooling channel with microstructures.

- Figure 4. 3D CAD model and dimensions of an aluminum-filled epoxy resin rapid tool with parallel CC.

- Figure 5. Manufacturing process of a rapid tool using an aluminum-filled epoxy resin.

- Figure 6. Research process of this study.

- Figure 7. A homemade system for investigating the cooling time of the wax pattern after low-pressure wax injection molding.

- Figure 8. Surface roughness of the high-speed steel rods after fiber laser processing.

- Figure 9. Cooling time of the molded wax pattern using aluminum-filled epoxy resin rapid tool with and without cooling channels.

- Figure 10. Cooling time of the molded wax pattern using different surface roughness of the inner wall of the cooling channel inside the aluminum-filled epoxy resin rapid tool.

- Figure 11. Results of injection-molded product cooling time reproducibility test.

- Figure 12. Experimental results of cooling time reproducibility of injection-molded products.

- Figure 13. Two cooling rates in the cooling stage after low-pressure wax injection molding using an aluminum-filled epoxy resin rapid tool.

- Figure 14. First cooling rate in the cooling stage after low-pressure wax injection molding using an aluminum-filled epoxy resin rapid tool.

- Figure 15. Second cooling rate in the cooling stage after low-pressure wax injection molding using an aluminum-filled epoxy resin rapid tool.

- Figure 16. Cooling mechanisms for aluminum-filled epoxy resin rapid tool proposed by this work compared with conventional method.

7. Conclusion:

The main objective of this study was to investigate the effects of the surface roughness of the inner wall of the cooling channel on the cooling efficiency of an aluminum-filled epoxy resin rapid tool in low-pressure wax injection molding. The key conclusions are:

- The findings highlight substantial potential applications in the investment casting industry, primarily due to the significant impact of reduced cooling times on production costs during the mass manufacturing of wax patterns.

- Fiber laser processing on high-speed steel rods enables the creation of microstructures with diverse surface roughness. The average cooling time (y) for injection-molded products can be predicted from the Sz surface roughness (x) using the equation y = -x² - 2.6x + 75, which has a correlation coefficient of 0.976.

- The surface roughness of the inner walls of the cooling channel significantly influences the cooling duration of injection-molded items. Employing an aluminum-filled epoxy resin rapid tool with a surface roughness of 4.9 µm on the cooling channel's inner walls, compared to one with 2.4 µm, can result in time savings and an improvement in cooling efficiency of approximately 34%.

- Utilizing an aluminum-filled epoxy resin rapid tool with a surface roughness of 4.9 µm on the inner walls of the cooling channel can reduce cooling time by up to approximately 60% compared to a similar tool without a cooling channel.

These results underscore the significant role of cooling channel surface roughness in optimizing injection molding processes for enhanced efficiency.

8. References:

- [1] Arman, S.; Lazoglu, I. A comprehensive review of injection mold cooling by using conformal cooling channels and thermally enhanced molds. Int. J. Adv. Manuf. Technol. 2023, 127, 2035–2106. [CrossRef]

- [2] Marl, S.; Giesen, R.-U.; Heim, H.-P. Liquid Silicone Rubber Foamed with Thermoplastic Expandable Microspheres. Materials 2022, 15, 3779. [CrossRef]

- [3] Nabavi, S.F.; Farshidianfar, A.; Dalir, H. An applicable review on recent laser beam cutting process characteristics modeling: Geometrical, metallurgical, mechanical, and defect. Int. J. Adv. Manuf. Technol. 2023, 130, 2159–2217. [CrossRef]

- [4] Rodríguez, N.B.; Moroni, F.; Lutey, A.H.A.; Favi, C. Sustainable design and life cycle engineering of adhesive joints for polymeric products: Assessment of surface activation technologies. Int. J. Adv. Manuf. Technol. 2023, 130, 1279–1306. [CrossRef]

- [5] Bian, Y.; Dong, B.; Chen, B.; Guo, J.; Li, S.; Tian, C.; Xu, S.; He, X.; Yu, G. Dynamic evolution behavior of cracks for single-track and multi-track clads in laser cladding. Int. J. Adv. Manuf. Technol. 2023, 130, 2313–2328. [CrossRef]

- [6] Piekło, J.; Garbacz-Klempka, A. Analysis of Phenomenon of Plasticity Loss of Steel Core Made by Selective Laser Melting Method in Zone of Pressure Mould Conformal Cooling Channel. Materials 2023, 16, 4205. [CrossRef]

- [7] Nguyen, V.-T.; Minh, P.S.; Uyen, T.M.T.; Do, T.T.; Ha, N.C.; Nguyen, V.T.T. Conformal Cooling Channel Design for Improving Temperature Distribution on the Cavity Surface in the Injection Molding Process. Polymers 2023, 15, 2793. [CrossRef] [PubMed]

- [8] Vargas-Isaza, C.; Benitez-Lozano, A.; Rodriguez, J. Evaluating the Cooling Efficiency of Polymer Injection Molds by Computer Simulation Using Conformal Channels. Polymers 2023, 15, 4044. [CrossRef]

- [9] Minh, P.S.; Dang, H.-S.; Ha, N.C. Optimization of 3D Cooling Channels in Plastic Injection Molds by Taguchi-Integrated Principal Component Analysis (PCA). Polymers 2023, 15, 1080. [CrossRef]

- [10] Choi, J.H.; Gim, J.; Rhee, B. A Novel Design Method of an Evolutionary Mold Cooling Channel Using Biomimetic Engineering. Polymers 2023, 15, 798. [CrossRef] [PubMed]

- [11] Torres-Alba, A.; Mercado-Colmenero, J.M.; Caballero-Garcia, J.d.D.; Martin-Doñate, C. Application of New Conformal Cooling Layouts to the Green Injection Molding of Complex Slender Polymeric Parts with High Dimensional Specifications. Polymers 2023, 15, 558. [CrossRef]

- [12] Gotlih, J.; Brezocnik, M.; Pal, S.; Drstvensek, I.; Karner, T.; Brajlih, T. A Holistic Approach to Cooling System Selection and Injection Molding Process Optimization Based on Non-Dominated Sorting. Polymers 2022, 14, 4842. [CrossRef]

- [13] Kanbur, B.B.; Zhou, Y.; Shen, S.; Wong, K.H.; Chen, C.; Shocket, A.; Duan, F. Metal Additive Manufacturing of Plastic Injection Molds with Conformal Cooling Channels. Polymers 2022, 14, 424. [CrossRef]

- [14] Torres-Alba, A.; Mercado-Colmenero, J.M.; Caballero-Garcia, J.d.D.; Martin-Doñate, C. Application of New Triple Hook-Shaped Conformal Cooling Channels for Cores and Sliders in Injection Molding to Reduce Residual Stress and Warping in Complex Plastic Optical Parts. Polymers 2021, 13, 2944. [CrossRef]

- [15] Torres-Alba, A.; Mercado-Colmenero, J.M.; Caballero-Garcia, J.D.D.; Martin-Doñate, C. A Hybrid Cooling Model Based on the Use of Newly Designed Fluted Conformal Cooling Channels and Fastcool Inserts for Green Molds. Polymers 2021, 13, 3115. [CrossRef]

- [16] Abbès, B.; Abbès, F.; Abdessalam, H.; Upganlawar, A. Finite element cooling simulations of conformal cooling hybrid injection molding tools manufactured by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 103, 2515–2522. [CrossRef]

- [17] Hunter, L.W.; Brackett, D.; Brierley, N.; Yang, J.; Attallah, M.M. Assessment of trapped powder removal and inspection strategies for powder bed fusion techniques. Int. J. Adv. Manuf. Technol. 2020, 106, 4521–4532. [CrossRef]

- [18] Mercado-Colmenero, J.M.; Martin-Doñate, C.; Rodriguez-Santiago, M.; Moral-Pulido, F.; Rubio-Paramio, M.A. A new conformal cooling lattice design procedure for injection molding applications based on expert algorithms. Int. J. Adv. Manuf. Technol. 2019, 102, 1719–1746. [CrossRef]

- [19] Li, Z.; Wang, X.; Gu, J.; Ruan, S.; Shen, C.; Lyu, Y.; Zhao, Y. Topology Optimization for the Design of Conformal Cooling System in Thin-wall Injection Molding Based on BEM. Int. J. Adv. Manuf. Technol. 2018, 94, 1041–1059. [CrossRef]

- [20] Shin, K.-H. A method for representation and analysis of conformal cooling channels in molds made of functionally graded tool steel/Cu materials. J. Mech. Sci. Technol. 2019, 33, 1743–1750. [CrossRef]

- [21] Park, H.-S.; Dang, X.-P. Optimization of conformal cooling channels with array of baffles for plastic injection mold. Int. J. Precis. Eng. Manuf. 2010, 11, 879–890. [CrossRef]

- [22] Yuan, X.; Tao, Z.; Li, H.; Tian, Y. Experimental investigation of surface roughness effects on flow behavior and heat transfer characteristics for circular microchannels. Chin. J. Aeronaut. 2016, 29, 1575–1581. [CrossRef]

- [23] Peng, M.; Chen, L.; Ji, W.; Tao, W. Numerical study on flow and heat transfer in a multi-jet microchannel heat sink. Int. J. Heat Mass Transf. 2020, 157, 119982. [CrossRef]

- [24] Kuo, C.-C.; Jiang, Z.-F.; Lee, J.-H. Effects of cooling time of molded parts on rapid injection molds with different layouts and surface roughness of conformal cooling channels. Int. J. Adv. Manuf. Technol. 2019, 103, 2169–2182. [CrossRef]

- [25] Kuntoğlu, M.; Salur, E.; Canli, E.; Aslan, A.; Gupta, M.K.; Waqar, S.; Krolczyk, G.M.; Xu, J. A state of the art on surface morphology of selective laser-melted metallic alloys. Int. J. Adv. Manuf. Technol. 2023, 127, 1103–1142. [CrossRef]

- [26] Kuo, C.-C.; Tasi, Q.-Z.; Huang, S.-H.; Tseng, S.-F. Enhancing Surface Temperature Uniformity in a Liquid Silicone Rubber Injection Mold with Conformal Heating Channels. Materials 2023, 16, 5739. [CrossRef]

- [27] Jia, J.; Ma, L.; Sun, Y.; Li, D.; Liu, W.; Han, Z.; Li, M. Study on the surface formation mechanism and theoretical model of brittle surface roughness in turning machinable ceramics. Int. J. Adv. Manuf. Technol. 2024, 130, 3877–3889. [CrossRef]

- [28] Zeng, S.; Pi, D.; Xu, T. Milling surface roughness prediction method based on spatiotemporal ensemble learning. Int. J. Adv. Manuf. Technol. 2023, 128, 91–119. [CrossRef]

- [29] Ouazzani, K.; El Jai, M.; Akhrif, I.; Radouani, M.; El Fahime, B. An experimental study of FDM parameter effects on ABS surface quality: Roughness analysis. Int. J. Adv. Manuf. Technol. 2023, 127, 151–178. [CrossRef]

- [30] Koç, E.; Zeybek, S.; Kısasöz, B.; Çalışkan, C.I.; Bulduk, M.E. Estimation of surface roughness in selective laser sintering using computational models. Int. J. Adv. Manuf. Technol. 2022, 123, 3033–3045. [CrossRef]

- [31] Yang, J.S.; Jeong, M.; Park, Y.G.; Ha, M.Y. Numerical study on the flow and heat transfer characteristics in a dimple cooling channel with a wedge-shaped vortex generator. Int. J. Heat Mass Transf. 2019, 136, 1064–1078. [CrossRef]

- [32] Burlaga, B.; Kroma, A.; Poszwa, P.; Kłosowiak, R.; Popielarski, P.; Stręk, T. Heat Transfer Analysis of 3D Printed Wax Injection Mold Used in Investment Casting. Materials 2022, 15, 6545. [CrossRef] [PubMed]

- [33] Addugala, H.; Venugopal, V.N.; Rengasamy, S.; Yadalam, P.K.; Albar, N.H.; Alamoudi, A.; Bahammam, S.A.; Zidane, B.; Bahammam, H.A.; Bhandi, S.; et al. Marginal and Internal Gap of Metal Copings Fabricated Using Three Types of Resin Patterns with Subtractive and Additive Technology: An In Vitro Comparison. Materials 2022, 15, 6397. [CrossRef] [PubMed]

- [34] Narwani, S.; Yadav, N.S.; Hazari, P.; Saxena, V.; Alzahrani, A.H.; Alamoudi, A.; Zidane, B.; Albar, N.H.M.; Robaian, A.; Kishnani, S.; et al. Comparison of Tensile Bond Strength of Fixed-Fixed Versus Cantilever Single- and Double-Abutted Resin-Bonded Bridges Dental Prosthesis. Materials 2022, 15, 5744. [CrossRef] [PubMed]

- [35] Alshehri, H.A.; Altaweel, S.M.; Alshaibani, R.; Alahmari, E.A.; Alotaibi, H.N.; Alfouzan, A.F.; Labban, N. Effect of Different Wax Pattern Manufacturing Techniques on the Marginal Fit of Lithium Disilicate Crowns. Materials 2022, 15, 4774. [CrossRef] [PubMed]

- [36] Zamani, P.; Zabihi, O.; Ahmadi, M.; Zamani, M.R.; Zohuriaan-Mehr, M.J.; Kannangara, T.; Joseph, P.; Naebe, M. Assessing sustainability and green chemistry in synthesis of a vanillin-based vitrimer at scale: Enabling sustainable manufacturing of recyclable carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108016. [CrossRef]

- [37] Dasari, S.S.; Wright, A.J.; Carroll, J.M.; Sarmah, A.; Carey, D.G.; Nagabandi, N.; Tran, T.Q.; Green, M.J. Freeform additive manufacturing of carbon fiber reinforced composites using dielectric barrier discharge-assisted Joule heating. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108047. [CrossRef]

- [38] Alexander Air, B. Gangadhara Prusty, Manufacturing feasibility of a bend free ellipsoidal composite pressure vessel using automated fibre placement. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107968.

- [39] Mao, M.; Liu, S.; Jiang, J.; Sun, S.; Wang, D. Study on flow field and convective heat transfer characteristics in grinding zone of large spiral angle flow disturbance grooved wheel. Int. J. Adv. Manuf. Technol. 2023, 129, 39–63. [CrossRef]

- [40] Tian, S.; Xie, X.; Xu, W.; Liu, J.; Zhang, X. Dynamic assessment of sustainable manufacturing capability based on correlation relationship for industrial cloud robotics. Int. J. Adv. Manuf. Technol. 2023, 124, 3113–3135. [CrossRef]

- [41] Chai, M.; Li, Z.; Yan, H.; Huang, Z. Flow field characteristics analysis of interelectrode gap in electrochemical machining of film cooling holes. Int. J. Adv. Manuf. Technol. 2021, 112, 525–536. [CrossRef]

- [42] Da Silva, L.J.; Souza, D.M.; de Araújo, D.B.; Reis, R.P.; Scotti, A. Concept and validation of an active cooling technique to mitigate heat accumulation in WAAM. Int. J. Adv. Manuf. Technol. 2020, 107, 2513–2523. [CrossRef]

- [43] Abdelrazek, A.H.; Choudhury, I.A.; Nukman, Y.; Kazi, S.N. Metal cutting lubricants and cutting tools: A review on the performance improvement and sustainability assessment. Int. J. Adv. Manuf. Technol. 2020, 106, 4221–4245. [CrossRef]

- [44] Ricciardi, M.R.; Papa, I.; Coppola, G.; Lopresto, V.; Sansone, L.; Antonucci, V. Effect of Plasma Treatment on the Impact Behavior of Epoxy/Basalt Fiber-Reinforced Composites: A Preliminary Study. Polymers 2021, 13, 1293. [CrossRef]

- [45] Khettabi, I.; Benyoucef, L.; Boutiche, M.A. Sustainable reconfigurable manufacturing system design using adapted multi-objective evolutionary-based approaches. Int. J. Adv. Manuf. Technol. 2021, 115, 3741–3759. [CrossRef]

9. Copyright:

- This material is a paper by "Chil-Chyuan Kuo, Hong-Wei Chen, Geng-Feng Lin, Song-Hua Huang and Shih-Feng Tseng". Based on "Enhancing the Cooling Efficiency of Aluminum-Filled Epoxy Resin Rapid Tool by Changing Inner Surface Roughness of Cooling Channels".

- Source of the paper: https://doi.org/10.3390/polym16070874

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.