This introduction paper is based on the paper "DEFORMATION BEHAVIOR OF LOW PRESSURE CAST Mg-3Al-1Zn ALLOY DURING HOT COMPRESSION TEST: A STUDY WITH PROCESSING MAPS" published by "Conference Paper".

1. Overview:

- Title: DEFORMATION BEHAVIOR OF LOW PRESSURE CAST Mg-3Al-1Zn ALLOY DURING HOT COMPRESSION TEST: A STUDY WITH PROCESSING MAPS

- Author: Lalu G Robin, G.Ganesan, K.Raghukandan, U.T.S.Pillai, B.C.Pai

- Year of publication: January 2005

- Journal/academic society of publication: Conference Paper

- Keywords: Not specified in the paper.

2. Abstract:

Low pressure cast Mg-3Al-1Zn (AZ31) alloy was hot compression tested in the temperature and strain rate range of 300 °C to 500 °C and 0.001 S⁻¹ to 1.0 S⁻¹ respectively. Discs of 30 mm diameter and height 10 mm were tested in Universal Testing Machine (FIE) using a specially fabricated furnace. The temperature was varied in the intervals of 50 °C and the strain rates were 0.001 S⁻¹, 0.01 S⁻¹, 0.1 S⁻¹ and 1.0 S⁻¹. The hot deformation characteristics of the alloy were studied using processing maps. Which were developed on the basis of dynamic material model. The domain of dynamic recrystallization (DRX) of this alloy is identified, and which is the optimum for hot working of the alloy. The areas of grain boundary cracking, flow localization and wedge cracking, if any, are established from the processing maps. At higher strain rates the material undergoes flow localization which has to be avoided in mechanical processing for obtaining consistent properties. Flow stress data will help in optimizing the microstructure during the secondary processing of the materials. The influence of processing variables on the final recrystallized texture and microstructure is discussed.

3. Introduction:

Magnesium, with a density of 1.738 g cm⁻³, is the lightest of all structural metals and has seen increased demand in recent years. It possesses outstanding properties such as high strength, good castability, appreciable machining properties, encouraging weldability, excellent dimensional stability, and favorable hot forming properties. These attributes allow magnesium to replace zinc and aluminum die castings, cast iron, steel components, and assemblies in aerospace and automobile industries, as well as in materials handling equipment, portable tools, and sporting goods, primarily due to weight savings.

However, magnesium production is largely limited to die casting due to its high productivity and dimensional accuracy. This creates a scope for examining the hot workability of commercial Mg alloys to establish a database for process optimization and guide the introduction of new alloys.

The concept of processing maps originated in 1984 at the Processing and High Temperature Materials Branch of Wright-Patterson Air Force Base (WPAFB), Ohio, USA. It was developed to integrate materials behavior into Finite Element Model (FEM) simulations like ALPID (Analysis of Large Plastic Incremental Deformation), making solutions more material-specific and realistic. Subsequent research integrated this concept into FEM codes like ANTARES and pursued metallurgical interpretation of processing maps for the science of mechanical processing.

4. Summary of the study:

Background of the research topic:

Magnesium alloys offer significant advantages due to their low density and favorable mechanical properties. However, their application is predominantly in die casting. To expand their use into other wrought products, a thorough understanding of their hot workability is essential.

Status of previous research:

Previous research laid the foundation for processing maps, which graphically represent a material's response to processing parameters. This involved developing Finite Element Models (e.g., ALPID, ANTARES) for simulating metal working processes and establishing criteria for flow stability. Metallurgical interpretations of these maps were also pursued to understand microstructural evolution during processing.

Purpose of the study:

The primary purpose of this study was to investigate the hot working characteristics of a low pressure cast Mg-3Al-1Zn (AZ31) alloy. The aim was to develop a database that could be used for optimizing hot working processes and to guide the introduction of new magnesium alloys by understanding their deformation behavior under various conditions of temperature and strain rate.

Core study:

The core of the study involved conducting hot compression tests on the Mg-3Al-1Zn (AZ31) alloy over a temperature range of 300 °C to 500 °C and strain rates from 0.001 S⁻¹ to 1.0 S⁻¹. Based on the flow stress data obtained, processing maps were developed using the dynamic material model. These maps were then used to identify optimal conditions for hot working, particularly the domain of dynamic recrystallization (DRX), and to delineate regions prone to flow instabilities such as grain boundary cracking, flow localization, and wedge cracking. Microstructural analysis was performed to correlate with the processing map predictions.

5. Research Methodology

Research Design:

The study employed hot compression testing to evaluate the deformation behavior of low pressure cast Mg-3Al-1Zn (AZ31) alloy. Cylindrical specimens, 30 mm in diameter and 10 mm in height, were machined for the tests. These tests were performed using a Universal Testing Machine (FIE) integrated with a specially fabricated furnace to maintain the desired test temperatures. In each test, specimens were compressed to half their original height. The low pressure cast Mg alloy was supplied by Regional Research Laboratory, Thiruvananthapuram, Kerala.

Data Collection and Analysis Methods:

Load-displacement data obtained from the hot compression tests were converted into true stress-true plastic strain curves using standard equations. Flow stress values were corrected for adiabatic temperature rise during testing. The core of the analysis involved the development of processing maps based on the principles of the dynamic material model. The log flow stress versus log strain rate data were fitted using a cubic spline to calculate the strain rate sensitivity (m) as a function of strain rate at different temperatures.

The efficiency of power dissipation through microstructural changes (η) was calculated using the equation:

η = 2m/ (m+1) (Eq. 1)

An instability parameter (ξ) was evaluated using the criterion:

ξ(έ) = (∂ln(m/(m+1))/ ∂ln έ) + m ≤ 0 (Eq. 2)

where a negative value indicates flow instability.

The power dissipation map (plotting η against temperature and strain rate) and the instability map (plotting ξ against temperature and strain rate) were superimposed to generate the final processing map. Deformed specimens were air cooled and subjected to standard metallographic techniques for microstructural examination.

Research Topics and Scope:

The research focused on the hot deformation behavior of low pressure cast Mg-3Al-1Zn (AZ31) alloy. The experimental scope included:

- Temperatures ranging from 300 °C to 500 °C, with intervals of 50 °C.

- Strain rates of 0.001 S⁻¹, 0.01 S⁻¹, 0.1 S⁻¹, and 1.0 S⁻¹.

The study involved generating processing maps at different strains, interpreting these maps to identify safe (e.g., dynamic recrystallization - DRX) and unsafe (flow instability) processing regimes, and correlating these regimes with observed microstructures.

6. Key Results:

Key Results:

- Flow stress data for the AZ31 alloy were determined across the tested range of temperatures and strain rates, and compiled (Table 1).

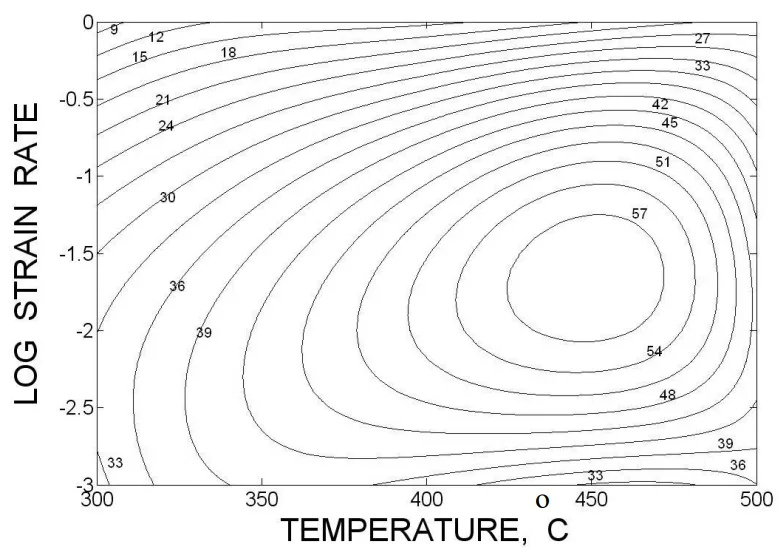

- Processing maps, consisting of superimposed power dissipation maps and instability maps, were developed. For instance, Fig. 1 shows the Power Dissipation Map for AZ31 alloy at a strain of 0.4, and Fig. 2 presents the Instability map for the same strain.

- The instability map (Fig. 2) for a strain of 0.4 indicated that the material exhibits flow instability at strain rates higher than approximately 0.1 S⁻¹.

- The processing map for AZ31 alloy at a strain of 0.4 (Fig. 3) revealed a domain of dynamic recrystallization (DRX) with peak efficiency of about 57% occurring around 450 °C and a strain rate of 0.01 S⁻¹. This domain is considered optimum for hot working. The map also delineated shaded regions corresponding to flow instability.

- A comparison between the processing map at a strain of 0.1 (Fig. 4) and that at a strain of 0.4 (Fig. 3) showed an increase in the size of the unstable zone with increasing strain.

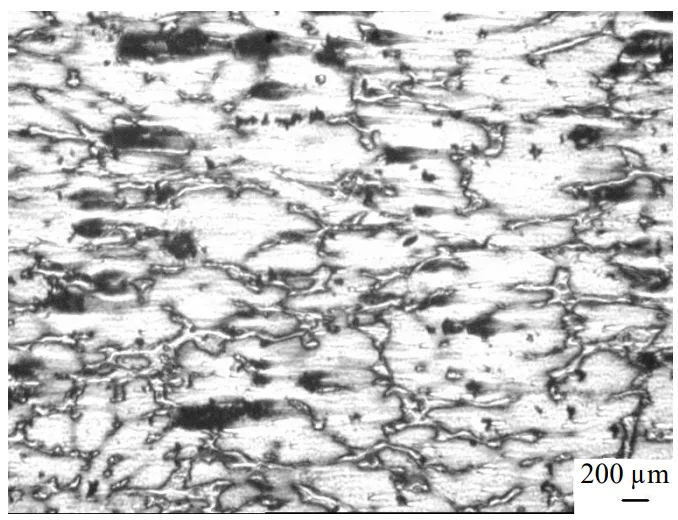

- Microstructural observations supported the processing map predictions:

- The as-cast microstructure is shown in Fig. 5.

- Dynamic recrystallization (DRX) was observed at 400 °C and 0.01 S⁻¹ (Fig. 6) and more extensively at 450 °C and 0.01 S⁻¹ (Fig. 7).

- Dynamic recovery features were observed at 350 °C and 0.01 S⁻¹ (Fig. 8), a condition away from DRX and cracking domains.

- At strain rates higher than 0.1 S⁻¹, the material undergoes flow instability, often manifesting as bands of flow localization. These strain rates are recommended to be avoided during mechanical processing to ensure consistent properties.

- Flow instability observed in the strain rate range of 0.1 S⁻¹ to 1.0 S⁻¹ and temperature range of 300 °C to 400 °C was attributed to the cracking of grain boundaries.

Figure Name List:

- Fig.1. Power Dissipation Map for AZ31 alloy obtained at a strain of 0.4

- Fig. 2. Instability map for AZ31 alloy obtained at a strain of 0.4

- Fig. 3. Processing Map for AZ31 alloy obtained at a strain of 0.4. The contours represent iso-efficiency expressed in percent.

- Fig. 4. Processing Map for AZ31 alloy obtained at a strain of 0.1. The contours represent iso-efficiency expressed in percent.

- Fig. 5. Microstructure of as cast AZ31 alloy

- Fig. 6. Dynamic recrystallization (DRX) of AZ31 alloy observed at 400 °C and at a strain rate of 0.01 S⁻¹

- Fig. 7. Dynamic recrystallization (DRX) of AZ31 alloy observed at 450 °C and at a strain rate of 0.01 S⁻¹

- Fig. 8. Dynamic recovery of AZ31 alloy observed at 350 °C and at a strain rate of 0.01 S⁻¹

Table Name List:

- Table 1. Flow stress values for AZ31 alloy at various strain rates and temperatures

7. Conclusion:

The hot deformation characteristics of low pressure cast Mg-3Al-1Zn alloy were investigated in the temperature range of 300 °C to 500 °C and strain rate range of 0.001 S⁻¹ to 1.0 S⁻¹ using processing maps. The following conclusions were drawn from this investigation:

- The alloy exhibits Dynamic Recrystallization (DRX) at 450 °C at a strain rate of 0.01 S⁻¹, which are identified as the optimum conditions for hot working of this material.

- At temperatures higher than 450 °C and at lower strain rates (specifically 0.001 S⁻¹), the material exhibits lower ductility, which is attributed to grain boundary cracking.

- At strain rates higher than 0.1 S⁻¹, the material exhibits flow instability, manifesting as bands of flow localizations. These strain rates should be avoided in the processing of the material to ensure desirable and consistent properties.

8. References:

- [1] E.F. Emley: Principles of Magnesium Technology, Pergamon Press Ltd., 1966.

- [2] Michael M. Avedesian and Hugh Baker: Magnesium and magnesium Alloys, ASM International, 1999.

- [3] B.L. Mordike and T. Ebert: Materials Science and Engineering, 2001, Vol. A (302), pp. 37-45.

- [4] B.L.Mordike and F. Hehmann: Magnesium Alloys and their Applications, DGM Informationsgesellsch-aft M.B.H, 1992.

- [5] H. Friedrich and S. Schumann: Journal of Materials Processing Technology, 2001, Vol. (117), pp. 276-281.

- [6] H. Furuya, N. Kogiso, S. Mutunaga and K. Senda: Materials Science Forum, 2000, Vol. (350-351), pp. 341-348.

- [7] Y.V.R.K.Prasad and S.Sasidhara: Hot Working Guide: A Compendium of Processing Maps, ASM International, Materials Park, OH, 1997, pp.1-24.

- [8] M.M. Myshlyaev, H.J. McQueen, A. Mwembela and E. Konopleva: Materials Science and Engineering, 2002, Vol. A (337), pp. 121-133.

- [9] O. Sivakesavan and Y.V.R.K. Prasad: Materials Science and Engineering, 2003, Vol. A (362), pp. 118-124.

- [10] G. Ganesan, K. Raghukandan, R. Karthekeyan and B. C. Pai: Materials Science and Engineering, 2004, Vol. A (369), pp. 230-235.

- [11] J.C.Tan and M.J.Tan: Materials Science and Engineering, 2003, Vol. A (339), pp. 124-132.

- [12] Hirohiko Takuda, Shiomi Kikuchi and Natsuo Hatta: Journal of Materials Science, 1992, Vol. (27), pp. 937-940.

- [13] Bussiba, A. Ben Artzy, A. Shtechman S.Ifergan and M. Kupiec: Materials Science and Engineering, 2001, Vol. A (302), pp. 56-62.

- [14] H. Watanabe, H. Tsutsui, T. Mukai, K. Ushikawa, Y.Okanda, M. Kozhu and K.Higashi: Materials Science Forum, 2000, Vol. (350-351), pp. 171-176.

- [15] J.C. Tan and M.J. Tan: Materials Science and Engineering, 2003, Vol. A (339), pp. 81-89.

- [16] A.Mwembela, E.B.Konopleva and H.J.McQueen: Scripta Materialia, 1997, Vol. (37), No.11, pp. 1789-1795.

9. Copyright:

- This material is a paper by "Lalu G Robin, G.Ganesan, K.Raghukandan, U.T.S.Pillai, B.C.Pai". Based on "DEFORMATION BEHAVIOR OF LOW PRESSURE CAST Mg-3Al-1Zn ALLOY DURING HOT COMPRESSION TEST: A STUDY WITH PROCESSING MAPS".

- Source of the paper: https://www.researchgate.net/publication/268512154

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.