Enhanced Copper Heat Sink Design: A Modeling Approach to Optimize Cooling Performance

This technical summary is based on the academic paper "Copper Heat Sink Design A Practical Application of Mathematical Modelling" published by Jafar Mahmoudi and Jussi Vaarno in Proceedings of SIMS (2003). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Heat Sink Design

- Secondary Keywords: conjugate boundary condition, mathematical modelling, fluid flow, heat transfer, thermal performance, electronic cooling

Executive Summary

- The Challenge: Efficiently cooling electronic components is crucial due to increasing heat density, yet conventional cooling methods often fall short.

- The Method: This research uses a three-dimensional model, validated with experimental data, to analyze and optimize copper-based heat sink designs.

- The Key Breakthrough: The study demonstrates the reliability and effectiveness of modeling to predict heat spreading and optimize heat sink geometry for improved thermal performance.

- The Bottom Line: Modeling methodologies can optimize copper-based heat sink designs, improving reliability and effectiveness in heat spreading.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have struggled with the increasing heat load from electronic components, requiring more effective thermal management solutions. As electronic devices become more powerful and compact, the need for efficient cooling systems becomes paramount. Conventional cooling techniques are often inadequate for dissipating the concentrated heat generated by modern microelectronics, leading to performance degradation and potential failure. This is a critical issue for HPDC professionals involved in manufacturing components for electronics.

The Approach: Unpacking the Methodology

To investigate heat sink design, the researchers developed a three-dimensional model using FLUENT software to simulate flow and conjugate heat transfer in copper-based heat sinks [Abstract]. The model was validated by comparing its predictions with available experimental data [Abstract]. The study analyzed various cooling methods and manufacturing processes to demonstrate the reliability and effectiveness of heat spreading [Abstract]. The model was produced with the commercial program FLUENT [Abstract].

The Breakthrough: Key Findings & Data

- Finding 1: The study proposes a new concept for cooling electronic components using a copper-base heat sink [Abstract].

- Finding 2: Thermal performance and temperature distribution for the heat sink were analyzed, and a procedure for optimizing geometrical design parameters was presented [Abstract].

- Finding 3: Several examples with different types of cooling methods and manufacturing processes are analyzed to show the reliability and effectiveness in heat spreading of those [Abstract].

- Finding 4: Replacing aluminum with copper in a rectangular heat sink resulted in a maximum temperature around 22 degrees Kelvin less than with aluminum [Fig. 9, Fig. 13].

- Finding 5: The heat spreads out faster in all x, y, and z directions for the copper heat sink [Fig. 9, Fig. 13].

- Finding 6: A rectangular heat sink based on straight fins has a superior potential for thermal management of electronic packages [Section 5.4].

- Finding 7: A high average heat transfer coefficient (in order of 120-170 W/M² K) can be achieved in the straight fin base copper heat sink [Section 5.4].

Practical Implications for HPDC Products

This research suggests that by using modeling methodologies, copper-based heat sink designs can be optimized, improving reliability and effectiveness in heat spreading.

- For Process Engineers: Replacing aluminum with copper can improve the heat spread.

- For Quality Control: The thermal performance and temperature distribution for the heat sink can be analyzed and a procedure for optimizing the geometrical design parameter can be presented [Abstract].

- For Die Design: The presented modeling methodology can be used to predict performance, with comparison to experimental data [Abstract].

Paper Details

Copper Heat Sink Design A Practical Application of Mathematical Modelling

1. Overview:

- Title: Copper Heat Sink Design A Practical Application of Mathematical Modelling

- Author: Jafar Mahmoudi and Jussi Vaarno

- Year of publication: 2003

- Journal/academic society of publication: Proceedings of SIMS

- Keywords: Heat sink designn conjugate boundary condition, mathematical modelling, fluid flow, heat transfer

2. Abstract:

In this work, a new concept for cooling the electronic components using the copper-base

heat sink is proposed. The thermal performance and temperature distribution for the heat

sink were analysed and a procedure for optimising the geometrical design parameter is

presented. A three-dimensional model is developed to investigate flow and conjugate heat

transfer in the copper-based heat sink. The model was produced with the commercial

program FLUENT. The theoretical model developed is validated by comparing the

predictions of the model with available experimental data.

Several examples with different types of cooling methods and manufacturing processes

are analysed to show the reliability and effectiveness in heat spreading of those. This

report will also describe a modelling methodology that can be used to predict

performance, with comparison to experimental data. The reliability of the presented

model in optimising the copper-base heat sink design will be discussed.

3. Introduction:

The heat removal problem has become an important factor in the advancement of

microelectronics due to both drastically increased integration density of chips in digital devices as

well as an increased current density capability of power electronic devices. The task of removing

a large amount of dispersed heat from a constrained, small space is often beyond the capability of

conventional cooling techniques, therefore, new methods with removal capabilities at least one

order larger than that of conventional ones are required [1-5].

Increasing the power dissipation and mounting density of electronic equipment are requiring

more effective thermal systems to cool the chip and device. One the commonly used method for

the effective thermal enhancement is to use heat sinks [6-9].

The undesirable temperature gradient is an important consideration in the design of an electronic

cooling scheme. A large temperature rise produces thermal stresses in chips and packages due to

the coefficient of thermal expansion (CTE) mismatch among different materials; thus

undermining device reliability [10-17]

Sabry [18] proposed a mechanism for heat transfer improvement based on the increased

importance of surface roughness for small channels. The relation deduced for fluid flow perfectly

matched friction data. As for heat transfer, the proposed relation was closer to measured h than

standard correlations, but still predicting higher values. It was concluded that another mechanism

might have contributed to heat transfer reduction.

In this work, a thermal design and evaluation method for heat sink is presented. The thermal

performance of the proposed Al-base heat sink is examined numerically using a finite volume

method. The optimisation issues for design parameters for a new copper base heat sink are

addressed as well.

4. Summary of the study:

Background of the research topic:

The heat removal problem has become an important factor in the advancement of

microelectronics due to both drastically increased integration density of chips in digital devices as

well as an increased current density capability of power electronic devices [Section 1].

Status of previous research:

Increasing the power dissipation and mounting density of electronic equipment are requiring

more effective thermal systems to cool the chip and device [Section 1].

Purpose of the study:

In this work, a thermal design and evaluation method for heat sink is presented [Section 1].

Core study:

In this work, a new concept for cooling the electronic components using the copper-base

heat sink is proposed. The thermal performance and temperature distribution for the heat

sink were analysed and a procedure for optimising the geometrical design parameter is

presented [Abstract].

5. Research Methodology

Research Design:

A three-dimensional model is developed to investigate flow and conjugate heat transfer in the copper-based heat sink [Abstract].

Data Collection and Analysis Methods:

The theoretical model developed is validated by comparing the

predictions of the model with available experimental data [Abstract].

Research Topics and Scope:

Several examples with different types of cooling methods and manufacturing processes

are analysed to show the reliability and effectiveness in heat spreading of those [Abstract].

6. Key Results:

Key Results:

- Replacing aluminum with copper in a rectangular heat sink resulted in a maximum temperature around 22 degree Kelvin less than with aluminum [Section 4.2.1].

- The heat spreads out faster in all x, y, and z directions for the copper heat sink [Section 4.2.1].

- A rectangular heat sink based on straight fins has a superior potential for thermal management of the electronic packages [Section 5.4].

- A high average heat transfer coefficient (in order of 120-170 W/M² K) can be achieved in the straight fin base copper heat sink [Section 5.4].

Figure Name List:

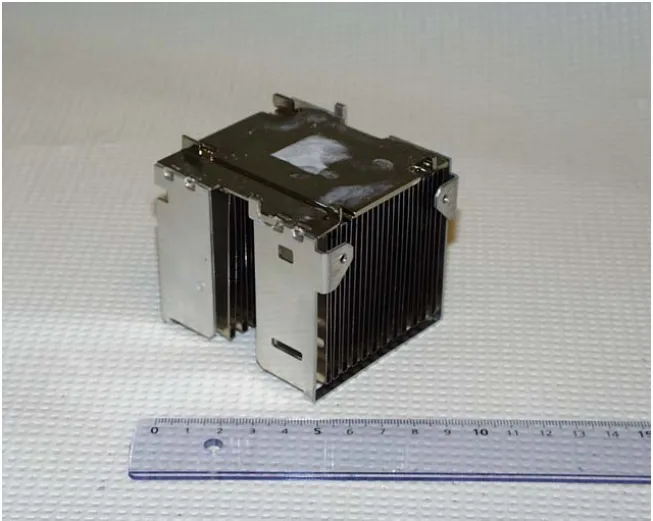

- Fig.1) Al-base heat sink

- Fig.2a) Computational domain

- Fig.2b) Computational domain for case No. 1

- Fig. 3a) Unit cell for case No. 1

- Fig. 3b) Unit cell for case No. 2

- Fig. 3c) Unit cell for case No. 3

- Fig. 4a) Computational domain for case No.1

- Fig. 4b) Computational domain for case No.2

- Fig. 4c) Computational domain for case No.3

- Fig. 4d) Computational domain for case No.4

- Fig. 5) Fan specificarion (Flow rate vs pressure drop)

- Fig. 6a) Temperature distribution in the fins

- Fig. 6b) Temperature distribution in the bottom plate

- Fig. 7a) Velocity distribution in the domain

- Fig. 7b) Pressure distribution in the domain

- Fig. 8) Overall heat transfer coefficient

- Fig. 9) Temperature distribution in the domain

- Fig.10) Velocity distribution in the domain

- Fig.11) Pressure distribution in the domain.

- Fig.12) Overall heat transfer coefficient

- Fig.13) Temperature distribution in the bottom plate of the domain

- Fig.14) Velocity magnitude in the longitude direction

- Fig. 15a) Velocity distribution in the unit cell

- Fig. 15b) Temperature field in the unit cell

- Fig. 16a) Velocity pattern in the unit cell with top mounted fan

- Fig. 16b) Temperature distribution in the unit cell with top mounted fan

- Fig. 17a) Velocity pattern in the unit cell with side-mounted fan

- Fig. 17b) Temperature distribution in the unit cell with side-mounted fan

- Fig. 18a) Velocity pattern in the cylindrical unit cell

- Fig. 18b) temperature in the cylindrical unit cell

- Fig. 19a) Velocity pattern in the domain

- Fig. 19b) Pressure pattern in the domain

- Fig. 19c) Temperature distribution in the domain

- Fig. 19d) Temperature distribution in the bottom plate

- Fig. 19d) Velocity distribution in the longitudinal direction

- Fig. 20a) Velocity pattern in the top mounted fan

- Fig. 20b) Pressure pattern in the top mounted fan

- Fig. 20c) Temperature distribution in the top mounted fan

- Fig. 20d) Heat transfer coefficient pattern in the top mounted fan

- Fig. 21a) Velocity pattern in a top mounted suction mode fan

- Fig. 21b) Temperature distribution in a top mounted suction mode fan

- Fig. 21c) Heat transfer coefficient in a top mounted suction mode fan

- Fig. 22a) Velocity pattern in the domain

- Fig. 22b) Temperature distribution in the domain

- Fig. 22c) Heat transfer pattern in the domain

- Fig. 23a) Velocity pattern in the domain

- Fig. 23b) Pressure distribution in the domain

- Fig. 23c) Temperature distribution in the domain

- Fig. 23d) Temperature distribution in the domain

- Fig. 23E) Temperature distribution in the domain

7. Conclusion:

The theoretical analysis performed, provides a fundamental understanding of the combined flow

and conjugate convection-conduction heat transfer in the copper-base heat sink. The developed

three-dimensional mathematical model, using incompressible turbulent Navier-Stokes equations

of motion, is capable of predicting correctly the flow, temperature and heat distribution in the

domin. It has been validated using available data-reported earlier.

This work, however, represents a critical first step toward a systematic approach to the design of

Cu-base heat sink, for improvement of the productivity and quality of the cooling process in

electronic device. The thermal performance of different proposed constructions are modelled and

studied numerically. In particular, this study is focused on the temperature distribution, the

thermal resistance and the optimization of geometrical design parameters. The present work

establishes the process for a tailored design and optimization of a Cu-base heat sink. Our result

demonstrates that a rectangular heat sink based on the straight fins can be considered as a

substantial improvement over a conventional Al-base heat sink. Further, it was found that the

rectangular Cu-base heat sink with triangle fins could also be considered as an alternative.

8. References:

- Vafai, K and Zhu, L.; Heat and Mass Trans.; 42 (1999) 2287-2297.

- T.Y.Chang, et al., J. of Electronic Packaging Vol. 123 (2001) 225-230. 3. S. Gu, T.J.Lu and A.G. Evans, Int. J. heat mass transfer, V. 44 (2001) 2163-75. 4. Zhang, H.Y and X.Y. huang, Int. J. heat mass transfer, V. 44 (2001) 1593-1603.

- Vladimir V et al, Int. J. heat mass transfer, V. 43 (2000) 3481-3496.

- Maveety J.G and H.H Jung, Int. Comm. Heat transfer, V. 27 (2000), 229-240.

- Mustafizur Rahman, M, Int. Comm. Heat Mass Trans., V. 27 No. 4 (2000), 495-506.

- Kim, S.J. et al, Int. J. heat mass transfer, V. 43 (2000) 1735-48.

- Morega, A. et al, Int. J. heat mass transfer, V. 38, No. 3 (1995) 519-531.

- Lu, T.J, Int. J. heat mass transfer, V. 42 (1999) 2031-40.

- Lage, J.L et al, Int. J. heat mass transfer, V. 39, No. 17 (1996) 3633-47.

- Ledezam, G and A. Bejan, Int. J. heat mass transfer, V. 39, No. 9 (1996) 1773-83.

- Bhavani, S, IEE Trans; 24 (2001) 166-175.

- Shin, Donglyoul; Tech. Report; Samsung Electronic Co; Flowtherm Web side

- Fedorov, A.G. and Viskanta, R; Heat and Mass Trans.; 43 (2000) 399-415

- Sabri, M. N; Tech. Rrans. Of the ASME; 123 (2001) 344-350.

- Kevin, G; Tech. Report; Thermacore, Inc; Flowtherm Web side

- Sabry, M.N; IEE Trans; 23(2000 562-567

- Biber, C; Tech. Report; Wakefield Eng.; Flowtherm Web side

- Behm, J; and Huttunen, J; Int. Flowther user Con.,2001

- Grubb, K..; Tech. Report, Thermacore, Inc, www. Thermacore.com.

- Fluent user guides, Fluent6, 2001.

Expert Q&A: Your Top Questions Answered

Q1: How can modeling help optimize heat sink design for electronic components?

A1: Three-dimensional modeling, validated with experimental data, allows engineers to analyze thermal performance, temperature distribution, and flow characteristics, leading to optimized geometrical designs [Abstract].

Q2: What materials offer better thermal performance in heat sinks?

A2: Replacing aluminum with copper can improve heat spreading, with a maximum temperature around 22 degrees Kelvin less than aluminum in a rectangular heat sink [Section 4.2.1].

Q3: What type of heat sink design is most effective for thermal management?

A3: A rectangular heat sink based on straight fins has a superior potential for thermal management of electronic packages [Section 5.4].

Q4: What level of heat transfer can be achieved with an optimized heat sink?

A4: A high average heat transfer coefficient (in order of 120-170 W/M² K) can be achieved in the straight fin base copper heat sink [Section 5.4].

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing heat sink design in HPDC. The findings offer a clear, data-driven path toward improving quality, reducing defects, and optimizing production.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Jafar Mahmoudi and Jussi Vaarno". Based on "Copper Heat Sink Design A Practical Application of Mathematical Modelling".

- Source of the paper: [No DOI URL in the Paper]

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.