This article introduces the paper "Computer Aided Manufacturability Analysis of Die-cast Parts".

1. Overview:

- Title: Computer Aided Manufacturability Analysis of Die-cast Parts

- Author: J. Madan, P. V. M. Rao, and T. K. Kundra

- Publication Year: 2007

- Publishing Journal/Academic Society: Computer-Aided Design & Applications

- Keywords: Design for manufacturability (DFM), Geometric reasoning, Die-casting, Process knowledge, Feature recognition.

2. Research Background:

- Social/Academic Context of the Research Topic:

- Industries are continuously striving to reduce product development time and enhance productivity and efficiency.

- The concept of Design for Manufacture (DFM) has emerged, especially in large enterprises with geographically dispersed design and manufacturing teams.

- DFM is defined as the "optimization of the product and process concepts during the design phase of a product to ensure ease of manufacture" [30].

- It is reported that a significant portion, "70% of the cost of a part is decided at the design stage itself" [1], highlighting the importance of incorporating DFM principles early in the design process.

- DFM tools are crucial for a seamless transition from design to manufacturing, requiring designers to possess up-to-date knowledge of manufacturing processes or DFM support systems.

- Implementing DFM leads to benefits such as improved product manufacturability, reduced time-to-market, and lower costs.

- DFM applications can be categorized into Verification, Quantification, and Optimization [30].

- DFM approaches are broadly classified as rule-based or plan-based [11]. Rule-based approaches use rules to identify design attributes exceeding process capabilities, while plan-based approaches involve generating feasible process plans to minimize time and cost.

- DFM metrics include qualitative aspects (good practice rules) and quantitative aspects (cost and time estimates) [27].

- Limitations of Existing Research:

- Existing DFM research has predominantly focused on machining [11, 32] and sheet metal working [25, 31], with limited attention given to die casting.

- Comprehensive automated manufacturability studies for die-cast parts are largely non-existent.

- Implementing DFM in die casting is particularly important due to longer production lead times, attributed to multiple iterations between design and manufacturing teams, die design and manufacturing, and process simulation and testing.

- While some research has addressed reducing production lead times in mold design [33, 34], automated DFM analysis for die-cast parts remains a critical gap.

- Previous DFM systems exhibit limitations, including:

- Reliance on interactive part information input.

- Consideration of only overall part attributes from CAD models.

- Unaddressed DFM issues such as inaccessible features, wall thickness variations, and process limitation violations.

- Lack of comprehensive suggestions for design improvement based on good practice rules.

- Limited capability in recognizing manufacturing features and evaluating geometric aspects for manufacturability.

- Partial automation and dependence on design history or mid-surface quality.

- Missing manufacturability advice for design improvement in shape modification systems.

- Necessity of the Research:

- The need for automated DFM analysis for die-cast parts is evident to overcome the limitations of existing approaches and address the specific challenges of die-casting manufacturing.

- There is a necessity for a system that can provide automated manufacturability advice from part CAD models, serving as feedback for designers to improve designs.

- Incorporating automated cost and time estimation is crucial to enable designers to understand the impact of design changes on manufacturing cost and time.

- A comprehensive system addressing both design verification and quantification phases of manufacturability analysis is required to enhance the efficiency and effectiveness of die-cast part design.

3. Research Purpose and Research Questions:

- Research Purpose:

- The primary purpose of this research is to develop a system for automated manufacturability analysis specifically for die-cast parts.

- The system aims to assist designers in creating manufacturable die-cast parts.

- It intends to economize cost and time in the design and manufacturing process.

- The system is designed to achieve these objectives without compromising the quality and functional requirements of the die-cast parts.

- Key Research Questions:

- How can a system be developed to automatically analyze the manufacturability of die-cast parts based on CAD models?

- What geometric reasoning techniques and process knowledge can be effectively utilized to identify manufacturability issues in die-cast part designs?

- How can manufacturability advice be presented to designers in a clear and actionable manner to facilitate design improvements?

- How can automated cost and time estimation be integrated into the manufacturability analysis system to quantify the impact of design changes?

- How can the system address both design verification (identifying violations) and quantification (cost and time estimation) aspects of manufacturability analysis for die-cast parts?

- Research Hypotheses: (Implicitly stated and inferred from the paper's objectives and results)

- It is hypothesized that a computer-aided system employing geometric reasoning and die-casting process knowledge can effectively automate manufacturability analysis for die-cast parts.

- It is hypothesized that providing designers with automated manufacturability advice and cost/time estimations will lead to improved die-cast part designs, reduced design iterations, and enhanced manufacturing efficiency.

- It is hypothesized that the proposed system will be more comprehensive and effective than existing DFM approaches for die-casting by addressing previously unaddressed manufacturability issues and integrating design verification and quantification.

4. Research Methodology:

- Research Design:

- The research employs a system development approach to create a computer-aided tool for manufacturability analysis of die-cast parts.

- The system is designed to be automated, requiring minimal user intervention in the analysis process.

- The design focuses on integrating geometric reasoning, process knowledge, and cost/time estimation modules into a cohesive system.

- Data Collection Method:

- The system utilizes CAD models of die-cast parts as input, specifically in STEP file format, which is a neutral and standardized format (ISO 10303).

- Process knowledge and design rules for die-casting are compiled and incorporated into a knowledge base. This knowledge base includes material-specific process limitations and capabilities.

- Material and energy data, along with manufacturing resource and tooling data, are collected to support cost and time estimation.

- Analysis Method:

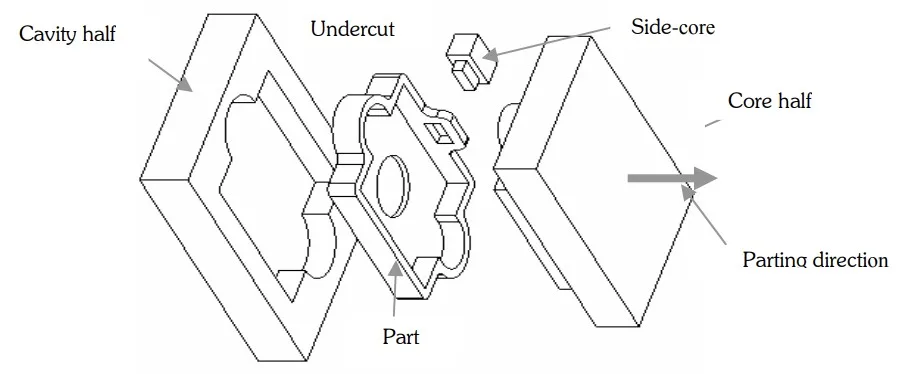

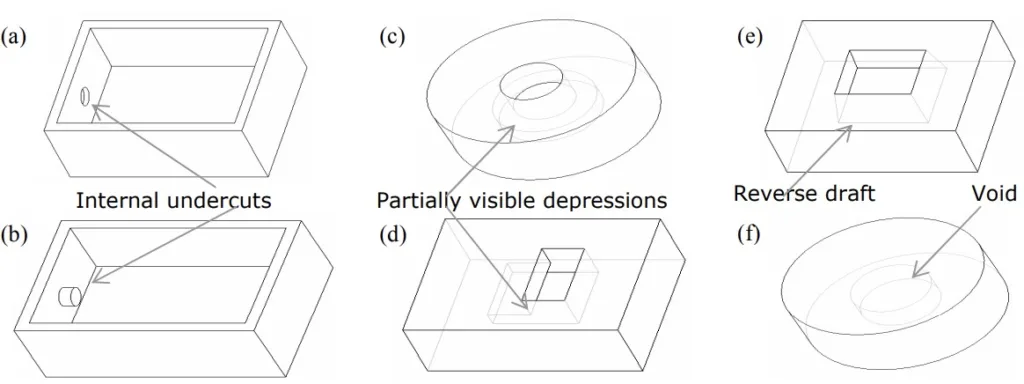

- Geometric Reasoning: Geometric reasoning is applied to extract manufacturing features and part attributes from the STEP file data. This involves parsing STEP files to obtain face-edge and edge-vertex relationships and applying rules to recognize die-casting features.

- Feature Recognition: A feature recognition module is developed to identify die-casting specific features, including non-manufacturability features, features requiring side-cores, and part attributes. This module uses geometric reasoning and builds upon previously developed methods [20].

- Process Knowledge Application: The extracted features and attributes are evaluated against the knowledge base of die-casting process constraints and design guidelines. This includes checking for part geometry limitations, overall part attribute limitations, and adherence to good practice rules.

- Thickness Analysis: Proprietary software GeomCaliper® [10] is used to analyze thickness variations and identify thickness violations, employing a rolling spherical ball algorithm.

- Cost and Time Estimation: A module for automated cost and time estimation is integrated, utilizing feature mapping knowledge, manufacturing resources, tooling data, and knowledge. The methodology for cost and time estimation is detailed in earlier work [21].

- Manufacturability Advice Generation: Based on the analysis, the system generates manufacturability advice, suggesting design changes to address identified issues and improve manufacturability.

- Research Subjects and Scope:

- The research focuses on die-cast parts and the die-casting manufacturing process.

- The scope is limited to geometric manufacturability analysis, addressing geometric aspects of part design that affect manufacturability.

- The system considers various die-casting materials (Zinc, Aluminum, Magnesium, Copper) and their specific process constraints.

- Tolerance and surface finish evaluation are addressed interactively due to data unavailability in machine-readable format, indicating a partial scope in these areas.

5. Main Research Results:

- Key Research Results:

- A computer-aided system for automated manufacturability analysis of die-cast parts was successfully developed and implemented using MATLAB 7 on Windows 2000.

- The system effectively identifies non-manufacturable design features and provides feedback to designers in the form of manufacturability advice.

- Designers can incorporate the suggested changes by redesigning the part, leading to improved manufacturability.

- The system quantifies manufacturability improvement by displaying time and cost estimations for both the original and redesigned parts.

- The system was demonstrated and validated using two typical die-casting parts (Example part 1 and Example part 2).

- Statistical/Qualitative Analysis Results:

- Example Part 1:

- Initial design cost: $30.0

- Initial design manufacturing time: 137 seconds

- Redesigned part cost (after implementing manufacturability advice): $18.9

- Redesigned part manufacturing time: 85 seconds

- Improvement: Cost reduction of 37%, Time reduction of 38%.

- Example Part 2:

- Initial design cost: $128.0

- Initial design manufacturing time: 138 seconds

- Redesigned part cost (after implementing manufacturability advice): $61.0

- Redesigned part manufacturing time: 80 seconds

- Improvement: Cost reduction of 52%, Time reduction of 42%.

- The results demonstrate a significant improvement in manufacturability, indicated by substantial reductions in both manufacturing cost and time after applying the system's advice and redesigning the parts.

- Example Part 1:

- Data Interpretation:

- The manufacturability advice generated by the system effectively guided design modifications that addressed manufacturability issues.

- Implementing the suggested design changes resulted in parts that are easier and more economical to manufacture, as evidenced by the reduced manufacturing time and cost.

- The system's ability to quantify the improvements in cost and time provides designers with concrete metrics to evaluate the impact of design changes and the effectiveness of the manufacturability analysis system.

- The reduction in manufacturing time and cost also suggests a potential reduction in design iterations, contributing to faster product development cycles.

- Figure Name List:

- Fig. 1: Die-casting process terminology.

- Fig. 2: Part geometrical limitations.

- Fig. 3: Good practice rules in die-casting (Source: [2, 3, 22]).

- Fig. 4: Design rules related with rib feature.

- Fig. 5: Automated manufacturability analysis system architecture.

- Fig. 6 (a) Example part 1

- Fig. 6(b) Redesigned example part 1

- Fig. 7 (a): Example part 2

- Fig. 7(b): Redesigned example part 2

6. Conclusion and Discussion:

- Summary of Main Results:

- The research successfully presented a system for computer-aided design for manufacturability analysis of die-cast parts.

- The developed system is described as more comprehensive than previous systems, effectively combining rule-based and plan-based design evaluation methods.

- The system provides designers with quick feedback on improving manufacturing productivity, even without detailed process knowledge.

- Manufacturability feedback suggestions are generated and presented to the designer for consideration and potential implementation.

- Academic Significance of the Research:

- The research addresses a significant gap in the field of automated DFM by focusing on die-casting, an area that has received less attention compared to machining and sheet metal forming.

- The system contributes to the body of knowledge in DFM by integrating geometric reasoning, die-casting process knowledge, and cost/time estimation within a single automated framework.

- The research demonstrates the feasibility and effectiveness of using geometric reasoning and process knowledge to automate manufacturability analysis for complex manufacturing processes like die-casting.

- Practical Implications:

- The developed system offers a valuable tool for designers of die-cast parts to proactively address manufacturability issues early in the design stage.

- By using the system, designers can improve the manufacturability of their designs, leading to reduced manufacturing costs and production time.

- The system can help reduce the number of design iterations required to finalize a manufacturable design, shortening product development cycles and time-to-market.

- The improved productivity and efficiency of designers using this system can contribute to more economical and competitive manufacturing operations.

- Limitations of the Research:

- The system, in its current form, does not explicitly account for functional requirements of the part. The designer is responsible for evaluating the manufacturability advice in the context of functional needs and deciding whether to implement the suggestions.

- Automation of the redesigned part generation is not implemented; the designer must manually redesign the part based on the system's advice.

- The system's capability to handle interacting features and parts with free-form surfaces is identified as an area for future improvement.

- Tolerance and surface finish evaluation are only partially addressed through interactive input, indicating a limitation in full automation in these aspects.

7. Future Follow-up Research:

- Directions for Follow-up Research:

- Automation of Redesign: Future work should focus on automating the process of generating redesigned parts based on the manufacturability advice provided by the system. This could involve integrating shape modification algorithms or generative design techniques.

- Handling Interacting Features: Research is needed to enhance the system's ability to analyze and address manufacturability issues arising from interacting features. This could involve developing more sophisticated feature recognition and analysis methods.

- Free-Form Surfaces: Extending the system to handle parts with free-form surfaces is crucial for broader applicability. This would require advancements in geometric reasoning and feature recognition for non-planar geometries.

- Integration of Functional Requirements: Future research should aim to integrate functional requirements into the manufacturability analysis process. This could involve incorporating functional simulation and analysis tools to evaluate the impact of design changes on part performance.

- Areas Requiring Further Exploration:

- Further exploration is needed in developing more comprehensive knowledge bases that capture a wider range of die-casting process variations, materials, and design guidelines.

- Investigating the use of advanced AI and machine learning techniques to improve feature recognition, manufacturability prediction, and advice generation could be beneficial.

- User interface enhancements to improve the clarity and usability of the manufacturability advice and system feedback are also areas for further exploration.

8. References:

- [1] Barton, J. A; Love, D. M; Taylor, G. D.: Design determines 70% of cost: A review of implications for design evaluation, J. Engineering Manufacture, 12 (1), 2001, 41-58.

- [2] Boothroyd, G.; Dewhurst; P.; Knight, W.: Product Design for Manufacture and Assembly, Marcel Dekker Inc., New York, 1994.

- [3] Bralla, J.G.: Design for Manufacturability Handbook, McGraw Hill, New York, 1999.

- [4] Chen, Y.-M.; Miller, R. A; Sevellar, K.: Knowledge-based manufacturability assessment: an object-oriented approach, Journal of Intelligent Manufacturing, 6, 1995, 321-337

- [5] Chen, Y.-M.: Development of a computer-aided concurrent net shape product and process development environment, Robotics and Computer Integrated Manufacturing, 13 (4), 1997, 337-360.

- [6] Chen, Y. -M.; Wen, C. C.; Ho, C. T.: Extraction of geometric characteristics for manufacturability assessment, Robotics and Computer Integrated Manufacturing, 19, 2003, 371-385.

- [7] Deng, Y. M.; Britton, G. A; Lam, Y. C: Towards automatic shape modification in injection-moulded-plastic-part design, 2005. (Available online: DOI 10.1007/s00170-004-2388-9)

- [8] Dixon, J. R.; Poli, C.: Engineering Design and Design for Manufacture, Field Stone Publishers, Massachusetts, USA, 1995.

- [9] Driscoll, M. O.: Design for manufacture, Journal of Materials Processing Technology, 22, 2002, 318-321.

- [10] GeomCaliper® Software, Geometric Software Solutions Limited, USA.

- [11] Gupta, S. K.;, Das, D.; Regli, W. C; Nau, D. S.: Automated manufacturability analysis: A survey, Research in Engineering Design, 9(3), 1997, 168-190.

- [12] Grosse, I. R.; Sahu, K.: Preliminary design of injection moulded parts based on manufacturing and functional simulations. In Advances in Feature Based Manufacturing. (Shah, J. J.; Mantyla M.; Nau, D. S.: Elsevier Science Limited, 1994.)

- [13] Hanada, H.; Leifer, L. J.: Intelligent design system for injection moulded parts based on the process function analysis method, Proc. NSF Engineering Design Research Conf., Amherts, MA, 1989, 599-612.

- [14] Herrmann, J. A; Cooper, J.; Gupta, S. K; Hayes, C. C.; Ishii, K.; Kazmer, D.; Sandborn, P. A.; Wood, W. A.: New Directions In Design For Manufacturing, Proceedings of ASME, DETC 2004-57770, September 28-October 2, 2004, Salt Lake City, Utah USA.

- [15] Hui, K. C.: Geometric aspects of the mouldability of parts, Computer aided design, 29 (3), 1997, 197-208.

- [16] Ishii, K.; Miller, R. A.; Design Representation for Manufacturability Evaluation in CAD: Beyond Feature-based Design, ASME/ CIE '92 AI stream, 1992.

- [17] Kuo, T. C.; Huang, S. M.; Zhang, H. C.: Design for manufacture and design for, X': Concepts, applications and perspectives, Computers & Industrial Engineering, 41, 2001, 241-260.

- [18] Lockett, H. L.; Guenov, M. D.: An Intelligent Manufacturing Advisor for Casting and Injection-Moulding Based On A Mid-Surface Approach, Proceedings of ASME, DETC2002/CIE-34497, Montreal, Canada, September 29-October 2, 2002.

- [19] Lenau, T.; Nielsen, L.H.; Alting, L.: Design for Pressure Die Casting--a DFM Example, International Journal of Advanced Manufacturing Technology, Vol. 6 (2), 1991, 141-154.

- [20] Madan, J.; P. V. M. Rao; Kundra, T. K.: An automated cost estimation system for die-cast parts, Transactions of ASME Journal of Computing and Information Science in Engineering, 2006. (Article submitted)

- [21] Madan, J.; P. V. M Rao.; Kundra, T. K.: System for early cost estimation of die-cast parts, International Journal of Production Research, 2006. (Available online)

- [22] Product Design for Die Casting, North American Die Casting Association (NADCA), Rosemont, USA, 1998.

- [23] Poli, C.; Dastidar, P.; Fernandez, R.: Design Knowledge Acquisition for DFM Methodologies, Research in Engineering Design, 4, 1992, 131-145.

- [24] Pratt, M. J.; Wilson, P. R.: Requirements for support of form features in a solid modeling system', CAM-I, R-85-ASPP-01, 1985.

- [25] Ramana, K. V.; Rao, P. V. M.: Automated manufacturability evaluation system for sheet metal components in mass production, International Journal of Production Research, 43 (18), 2005, 3889–3913.

- [26] Shah, J.; Rogers, M.: Functional Requirements and Conceptual Design of Feature Based Modeling System, Journal of Computer Aided Engineering, 5(1), 1988, 9-15.

- [27] Shah, J. J.; Wright, P. K.: Developing theoretical foundations of DfM, DETC2000/ DFM 14015, September 10-14, Baltimore, MD, 2000.

- [28] Stauffer, L.; Rule, R.: A template for design for manufacture guidelines, Proceedings of ASME, DETC2003/DFM-48135, Chicago, Illinois, USA, September 2-6, 2003.

- [29] Venkatchalam, A. R.; Mellichamp, J. A.; Miller, D. M.: A knowledge-based approach to design for manufacturability, Journal of Intelligent Manufacturing, 4, 1993, 355-366.

- [30] Van Vliet, J. W.; Van Luttervelt, C. A.; Kals, H. J. J.: State of the art report on design for manufacturing, Proceedings of ASME DETC, Las Vegas, Navada, September 12-15, 1999.

- [31] Zhao, Z.; Shah, J. J.: Domain independent shell for DfM and its application to sheet metal forming and injection molding, Computer-Aided Design, 37, 2005, 881–898.

- [32] Srikumaran, S.; Sivaloganathan, S.: Proving manufacturability at the design stage using commercial modeling software, Computer-Aided Design and Applications, 2 (1-4), 2005, 507-516.

- [33] Song, I. -H.; Park, J. –M; Chung, S. -C: web based interference verification system for injection mold design, Computer-Aided Design and Applications, 3 (1-4), 2005, 129-138.

- [34] Ni, Q.; Lu, W. F.; Yarlagadda, P. K. D. V.: A PDM-based framework for Design to Manufacturing in mold making industry, 3 (1-4), 211-220.

9. Copyright:

- This material is J. Madan, P. V. M. Rao, and T. K. Kundra's paper: Based on Computer Aided Manufacturability Analysis of Die-cast Parts.

- Paper Source: [https://doi.org/](DOI URL is not provided in the text)

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.