Rethinking Wear Resistance: Why Softer Aluminium MMCs Can Outperform Harder Ones in HPDC Applications

This technical summary is based on the academic paper "Comparison between high-pressure die-cast and rheo-cast aluminium-SiCp MMC; wear and friction behaviour" by A. E. W. Jarfors, R. Ghasemi, S. Awe, C. K. Jammula, published in La Metallurgia Italiana (2021). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Aluminium MMC Wear Performance

- Secondary Keywords: High-Pressure Die-Casting, Rheocasting, Silicon Carbide, Friction Behaviour, Tribolayer, Brake Discs

Executive Summary

- The Challenge: To create lightweight, wear-resistant aluminium metal matrix composites (MMCs) for demanding applications like brake discs, it is critical to understand how casting processes affect friction and wear.

- The Method: Researchers compared aluminium MMCs with 15% and 20% silicon carbide (SiCp), produced by both conventional high-pressure die-casting (HPDC) and rheocasting, analyzing their microstructure, hardness, and sliding wear characteristics.

- The Key Breakthrough: Counterintuitively, the study found that the softest material (a rheo-cast composite) exhibited the lowest wear rate, directly challenging the common engineering principle that higher hardness leads to better wear resistance.

- The Bottom Line: For Al-SiCp MMCs, the stability of the tribolayer (the thin layer formed on surfaces during sliding contact) is a more dominant factor in determining wear performance than the material's bulk hardness.

The Challenge: Why This Research Matters for HPDC Professionals

In the transportation industry, the drive for energy efficiency and a reduced carbon footprint is relentless. Lightweighting is a primary strategy, and components like brake disc rotors are prime targets for weight reduction. Aluminium metal matrix composites (MMCs) reinforced with silicon carbide (SiCp) are promising candidates due to their low weight and good mechanical properties.

However, the performance of these MMCs is highly dependent on their manufacturing process. While stir casting followed by high-pressure die-casting (HPDC) is a common fabrication route, variables like the casting method (conventional vs. rheocasting) and reinforcement levels can significantly alter the material's microstructure and, consequently, its friction and wear behavior. This research was undertaken to better understand how modifying the matrix and particle distribution through different casting processes impacts the real-world wear performance of these critical components.

The Approach: Unpacking the Methodology

The researchers investigated four distinct Al-MMC materials to provide a comprehensive comparison:

* Materials: Aluminium matrix composites reinforced with two levels of silicon carbide particles (SiCp): 15% and 20%.

* Casting Processes: Two casting methods were used:

1. Conventional High-Pressure Die-Casting (HPDC): Designated as L15 (15% SiCp) and L20 (20% SiCp).

2. Rheocasting: Using the RheoMetal™ process to create a semi-solid slurry before HPDC. Designated as S15 (15% SiCp) and S20 (20% SiCp).

* Analysis & Testing: A multi-faceted testing protocol was employed to characterize the materials:

* Microstructural Analysis: An Olympus GX microscope was used to study particle distribution and matrix structure.

* Hardness Testing: Both Rockwell C and Micro-Vickers hardness tests were conducted to measure bulk and micro-scale hardness.

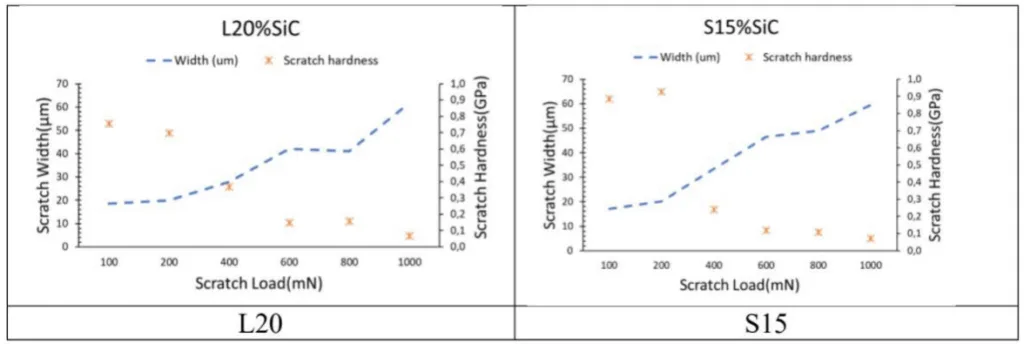

* Micro-Scratch Test: A progressive load scratch test (5 mN to 1000 mN) was performed to analyze the micro-mechanics of wear.

* Dry Sliding Wear Test: A reciprocating pin-on-plate test was run for 120 minutes under a 20N load to simulate conditions relevant to brake applications and measure mass loss and the coefficient of friction (CoF). The substrate for all tests was the L20 material.

The Breakthrough: Key Findings & Data

The study revealed a complex and non-intuitive relationship between material hardness, friction, and wear, upending conventional expectations based on Archard's law.

Finding 1: Hardness is Not a Reliable Predictor of Wear Resistance

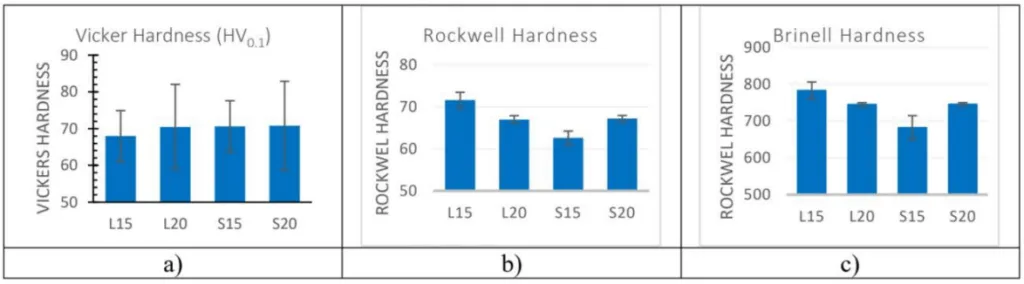

Standard engineering principles suggest that harder materials should resist wear more effectively. However, the data showed the opposite. The Rockwell C hardness test, which measures bulk properties, revealed that the conventionally cast L15 was the hardest material, while the rheo-cast S15 was the softest.

- As shown in Figure 3b, the L15 sample registered the highest Rockwell C hardness, followed by L20 and S20, with S15 being the softest.

- However, as shown in Figure 5a, the wear test results demonstrated that the softest material, S15, had the lowest mass loss (i.e., the best wear resistance). The hardest material, L15, experienced a higher rate of wear. This directly contradicts the expectation that wear loss should be inversely proportional to hardness.

Finding 2: The Tribolayer and Friction Dynamics Dictate Performance

Since hardness alone couldn't explain the results, the researchers looked closer at the friction behavior and the worn surfaces. The key differentiator was the formation and stability of a "tribolayer"—a protective layer formed from wear debris on the contact surfaces.

- The softest material, S15, which had the lowest wear, also exhibited the highest average coefficient of friction (CoF), as seen in Figure 5b.

- Analysis of the worn surfaces (Figure 7) showed significant differences. S15 and L15 showed signs of adhesive wear (smearing), while the S20 surface showed an unstable tribolayer with loose debris. The L20 surface showed a more stable tribolayer was necessary for wear resistance.

- The time-series data for CoF (Figure 6) further supported this, showing that materials like S20 experienced a high number of "adhesive events" where friction spiked, indicating an unstable contact. The study concludes that the nature of the contact and the ability to form a stable, protective tribolayer are more critical to wear performance than the material's initial hardness.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the casting method from conventional HPDC to rheocasting may contribute to superior wear resistance, even if it results in a softer material. The choice of process directly influences the matrix microstructure and the subsequent formation of a stable tribolayer.

- For Quality Control Teams: The data in Figure 3b and Figure 5a of the paper illustrates that relying solely on Rockwell hardness to predict wear performance for Al-SiCp MMCs can be misleading. Incorporating microstructural analysis or scratch testing could provide more accurate criteria for in-service performance.

- For Design Engineers: The findings indicate that for wear-critical components, designing for stable tribolayer formation could be a more effective strategy than simply specifying a high hardness value. Material selection should consider the entire tribological system, including how the material behaves under friction.

Paper Details

Comparison between high-pressure die-cast and rheo-cast aluminium-SiCp MMC; wear and friction behaviour

1. Overview:

- Title: Comparison between high-pressure die-cast and rheo-cast aluminium-SiCp MMC; wear and friction behaviour

- Author: A. E. W. Jarfors, R. Ghasemi, S. Awe, C. K. Jammula

- Year of publication: 2021

- Journal/academic society of publication: La Metallurgia Italiana - International Journal of the Italian Association for Metallurgy

- Keywords: ALUMINIUM, METAL MATRIX COMPOSITE, HIGH-PRESSURE DIE-CASTING, RHEOCASTING, WEAR

2. Abstract:

Aluminium is essential in automobile industry together with cast iron. Because of its lightweight property and good mechanical properties, aluminium reinforced with silicon carbide have found application as brake discs. Aluminium reinforced with 15% and 20% silicon carbide were high-pressure die-cast (HPDC) and Rheo-HPDC cast in the current paper. Micro-Vickers hardness and Rockwell C hardness showed different trends with the increasing amounts of SiCp-particles. Scratch resistance of the surface on micro-scale was analysed using a micro-scratch test to study the mechanics of the wear process. Reciprocating sliding wear of the composites was considered, using the HPDC cast aluminium with 20% silicon carbide of liquid casting as the sliding surface. The wear showed a combination of abrasive wear and adhesive wear. The metallography of the wear surfaces showed deep abrasive wear grooves. Wear debris from both the surfaces were forming a tribolayer. The formation of this layer decided the friction and wear performance as a result of the abrasive and adhesive wear mechanisms seen both in the micromechanics of the scratch test and in the friction behaviour.

3. Introduction:

The need for lightweight solutions in transport is increasing to meet demands for energy efficiency and reduced carbon footprints. Brake disc rotors are a critical component targeted for weight reduction. Aluminium MMC brake rotors are commonly fabricated using stir casting, with Al-SiCp MMCs being a frequent choice. These composites typically require Si as an alloying element to stabilize the SiCp particles, resulting in a nearly eutectic matrix. This study investigates the friction and wear performance of Al-MMCs with 15% and 20% SiCp additions, fabricated by stir casting and then cast using either conventional high-pressure die-casting or rheocasting. The aim is to better understand wear and friction performance by modifying the matrix and particle distributions through these different casting processes.

4. Summary of the study:

Background of the research topic:

The research addresses the need for lightweight, high-performance materials in the automotive industry, specifically focusing on aluminium-silicon carbide (Al-SiCp) metal matrix composites (MMCs) for applications like brake discs.

Status of previous research:

Previous work has established the use of stir casting for fabricating Al-SiCp MMCs and the necessity of silicon in the alloy to stabilize the SiCp particles. This often leads to a nearly eutectic matrix in the final component.

Purpose of the study:

The aim was to better understand the wear and friction performance of Al-SiCp MMCs by modifying the matrix and particle distributions. This was achieved by comparing two different casting processes—conventional high-pressure die-casting and rheocasting—at two different SiCp reinforcement levels (15% and 20%).

Core study:

The core of the study involved casting four different Al-SiCp MMC variants and subjecting them to a series of tests to characterize their microstructure, hardness (Micro-Vickers and Rockwell C), scratch resistance, and dry sliding wear behavior (mass loss and coefficient of friction). The results were then analyzed to understand the complex interplay between casting process, microstructure, hardness, and tribological performance.

5. Research Methodology

Research Design:

The study employed a comparative research design. Four material types were created by varying two factors: the casting process (conventional HPDC vs. Rheocasting) and the percentage of SiCp reinforcement (15% vs. 20%). These samples were then subjected to identical characterization and testing protocols to allow for direct comparison.

Data Collection and Analysis Methods:

- Material Preparation: Al-MMC material was cast using conventional HPDC and rheocasting (RheoMetal™ process).

- Compositional Analysis: Spectrometer and EDS analysis were used to determine the chemical composition (Table 1).

- Microstructural Analysis: An Olympus GX microscope and stream image analysis software were used for quantitative particle characterization.

- Hardness Testing: Rockwell C (50 kgf load) and Micro-Vickers (100gms load) tests were performed.

- Scratch Testing: A micro-scratch test was conducted with a progressive load from 5 mN to 1000 mN.

- Wear Testing: A reciprocating pin-on-plate dry sliding wear test was run with a 20N load for up to 120 minutes. Pin wear was measured by weight change, and friction force was recorded. Worn surfaces were examined using a Scanning Electron Microscope (SEM).

Research Topics and Scope:

The research focused on the wear and friction behaviour of Al-SiCp MMCs. The scope was limited to two SiCp concentrations (15% and 20%) and two casting processes (HPDC and Rheo-HPDC). The wear tests were conducted under dry, reciprocating sliding conditions against a single substrate material (L20).

6. Key Results:

Key Results:

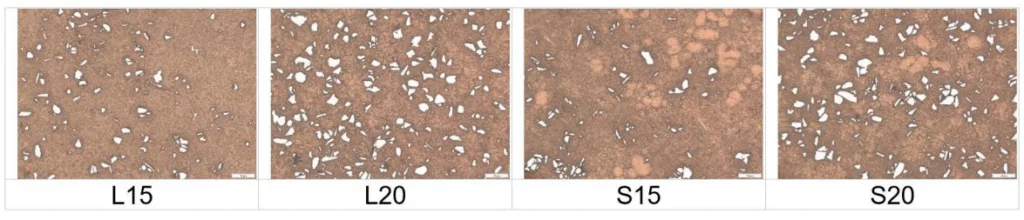

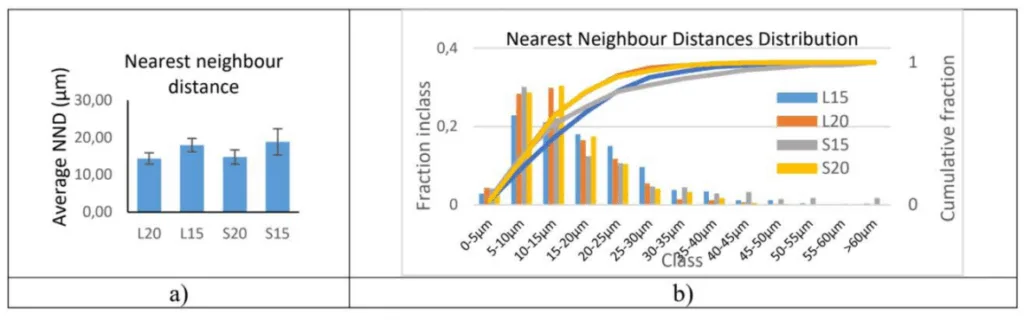

- The rheo-cast samples (S15, S20) exhibited coarser α-Al regions compared to the conventionally cast samples (L15, L20).

- Rockwell C hardness tests showed L15 to be the hardest material and S15 to be the softest. Micro-Vickers hardness did not show significant differences between samples.

- The wear rate did not correlate with hardness. The softest material (S15) showed the lowest wear mass loss, while the hardest (L15) had a higher mass loss.

- The material with the lowest wear rate (S15) had the highest coefficient of friction.

- Wear performance was determined by the formation and stability of a tribolayer, with different materials showing varying degrees of abrasive and adhesive wear mechanisms.

Figure Name List:

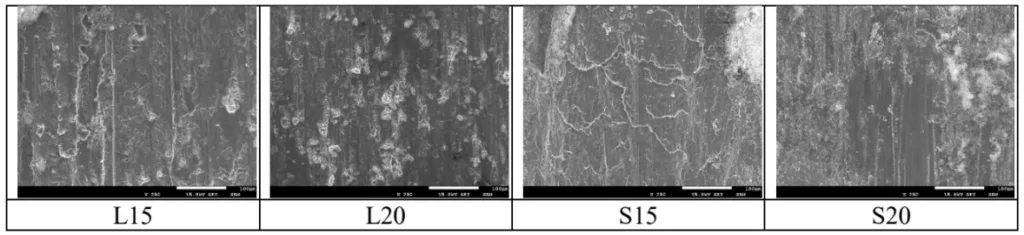

- Fig.1 - Illustration of the microstructures with L15 and L20 samples being cast using conventional high-pressure die casting and S15 and S20 being cast using rheocasting. Scale bar is 100μm.

- Fig.2 - Nearest neighbour distances a) averages and error, b) distribution of nearest neighbour distances.

- Fig.3 - Hardness of the composite, a) Micro-Vickers results, b) Rockwell C hardness results, c) Brinell hardness converted from Rockwell hardness.

- Fig.4 - Scratch test using progressive load.

- Fig.5 - a) Mass loss from the dry sliding wear test b) CoF during the sliding wear test.

- Fig.6 - CoF as a function over time for samples L15, L20, S15 and S20 illustrating the number of adhesive events where the friction force exceeds the normal force.

- Fig.7 - Wear surface samples L15, L20, S15 and S20 illustrating the adhesive and abrasive nature of the wear mechanisms as well as the stability of the tribo-layer. (Scale bar is 100µm).

7. Conclusion:

In the current study, the wear performance of conventionally cast and rheo-cast Al-SiCp MMCs was studied. It was shown that there is a highly complex interaction between the wear and friction properties of the material. The wear loss could not be established clearly as suggested by hardness according to Archard's law. Instead, the nature of the contact has a great influence on the wear, resulting in the softest material with the highest friction coefficient having the lowest wear.

8. References:

- [1] Serrenho AC, Norman JB, Allwood JM. The impact of reducing car weight on global emissions: the future fleet in Great Britain. Philos Trans R Soc A Math Phys Eng Sci [Internet]. 2017;375(2095):20160364. Available from: http://rsta.royalsocietypublishing.org/lookup/doi/10.1098/rsta.2016.0364

- [2] Sadagopan P, Natarajan HK, Praveen Kumar J. Study of silicon carbide-reinforced aluminum matrix composite brake rotor for motorcycle application. Int J Adv Manuf Technol. 2018;94(1–4):1461-75.

- [3] Sijo MT, Jayadevan KR. Analysis of Stir Cast Aluminium Silicon Carbide Metal Matrix Composite: A Comprehensive Review. Procedia Technol [Internet]. 2016;24:379–85. Available from: http://dx.doi.org/10.1016/j.protcy.2016.05.052

- [4] Ghasemi R, Johansson J, Ståhl JE, Jarfors AEW. Load effect on scratch micro-mechanisms of solution strengthened Compacted Graphite Irons. Tribol Int [Internet]. 2019;133(January):182–92. Available from: https://doi.org/10.1016/j.triboint.2019.01.010

- [5] Poulios K, Drago N, Klit P, De Chiffre L. A reciprocating pin-on-plate test-rig for studying friction materials for holding brakes. Wear. 2014;311(1-2):40-6.

- [6] Popov V. Generalized archard law of wear based on rabinowicz criterion of wear particle formation. Facta Univ Ser Mech Eng. 2019;17(1):39-45.

Expert Q&A: Your Top Questions Answered

Q1: Why was there a significant difference between the Micro-Vickers and Rockwell C hardness results?

A1: The paper explains this discrepancy is due to the fundamental differences in the test methods. The Micro-Vickers test is based on the size of the indent and is thus primarily dependent on the material's plastic deformation. In contrast, the Rockwell C test is based on the difference in displacement depths between two loads, meaning it is also affected by deformation hardening that occurs during indentation. This makes the Rockwell test more sensitive to the properties of the matrix material, which differed between the conventionally cast and rheo-cast samples.

Q2: The micro-scratch test showed a "breakthrough threshold" for the rheo-cast samples (S15 and S20). What does this signify?

A2: As shown in Figure 4 for sample S15, the scratch hardness drops significantly at loads above 200mN. The paper suggests this indicates a possible instability due to limited subsurface strength in the semisolid cast materials. This is a key mechanical difference compared to the conventionally cast materials (L15 and L20), which showed a more consistent, inversely proportional relationship between scratch hardness and load.

Q3: The paper concludes that Archard's law, which links wear to hardness, was not followed. What was the primary reason for this?

A3: The primary reason is that the nature of the contact surface was more influential than the bulk hardness. Archard's law (Δm = K * Fvt / H) implies that for a given system, wear (Δm) is inversely proportional to hardness (H). However, this study found that the "K" coefficient—a parameter that depends on the wear and contact mechanisms—was the dominant factor. The formation of a stable tribolayer on the surface of the softer S15 material provided better protection against wear than the higher intrinsic hardness of the L15 material.

Q4: How did the tribolayer and wear mechanisms differ between the various materials?

A4: The SEM images in Figure 7 and the discussion on page 5 reveal distinct differences. The S20 sample showed an unstable tribolayer with loose debris. The L20 sample showed open pores in its tribolayer but was more stable than S20. Both S15 and L15 showed more adhesive wear, characterized by material smearing. This suggests that the rheo-cast S15 material was able to form a more protective, smeared layer that resulted in lower overall mass loss, despite being the softest material.

Q5: What was the key microstructural difference between the HPDC and rheo-cast samples?

A5: The paper notes on page 2, referencing Figure 1, that the most visible difference was in the aluminium matrix. The semisolid rheo-cast samples (S15 and S20) displayed coarser, light α-Al regions. These distinct regions were not visible in the conventionally cast HPDC samples (L15 and L20), indicating that the rheocasting process fundamentally altered the solidification and final microstructure of the matrix.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a critical insight for engineers working with advanced materials: for Aluminium MMC Wear Performance, the story is more complex than just hardness. The study clearly demonstrates that the manufacturing process—specifically, the choice between conventional HPDC and rheocasting—has a profound impact on the microstructure and, more importantly, on the dynamic behaviour of the material's surface under friction. The key takeaway is that fostering the formation of a stable tribolayer can be a more effective path to superior wear resistance than simply maximizing bulk hardness.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Comparison between high-pressure die-cast and rheo-cast aluminium-SiCp MMC; wear and friction behaviour" by "A. E. W. Jarfors, R. Ghasemi, S. Awe, C. K. Jammula".

- Source: La Metallurgia Italiana - November/December 2021, pagina 13-18.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.