Beyond Human Vision: A New Gradient-Based Method for Automatic Casting Defect Detection

This technical summary is based on the academic paper "Automatic Detection Method for Casting Defects based on Gradient Features" by S. Arita, H. Takimoto, H. Yamauchi, and A. Kanagawa, published in ADCON P (2014).

Keywords

- Primary Keyword: Automatic Casting Defect Detection

- Secondary Keywords: Casting Defects, Visual Inspection, Machine Learning, Gradient Features, Contour Discontinuity, Surface Texture Analysis

Executive Summary

- The Challenge: Manual visual inspection of casting defects is subjective, slow, and ill-suited for the high-volume, high-stakes environment of modern manufacturing, particularly in the automotive industry.

- The Method: Researchers developed a novel automated system that mimics the human visual mechanism, using a dual approach that analyzes both product contour discontinuities (for cracks/chips) and surface texture variations (for pores/hollows) via machine learning.

- The Key Breakthrough: The combined method proved highly effective and robust, successfully identifying a wide range of defects—including cracks, hollows, and chips—with high precision across a standardized set of test images.

- The Bottom Line: This research presents a powerful, non-model-based automated inspection system that offers a practical and reliable alternative to manual inspection, paving the way for significantly improved quality control and production rates.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-pressure die casting industry, especially for safety-critical automotive components, ensuring every part is free from defects is non-negotiable. However, the industry has long relied on manual visual inspection, a process fundamentally limited by human factors like experience, intuition, and fatigue. This subjectivity can lead to inconsistent quality and slower production cycles.

While some automated systems exist, they often come with their own set of challenges. Methods like radioscopic imaging are expensive and time-consuming, making them unsuitable for mass production. Other computer-vision techniques struggle to differentiate subtle defects from the complex background textures inherent to casting surfaces. The industry needs a robust, accurate, and cost-effective automated solution that can perform reliably in a demanding production environment. This paper addresses that exact need.

The Approach: Unpacking the Methodology

The researchers proposed a novel method that combines two complementary detection techniques, drawing inspiration from the human visual system's ability to quickly spot anomalies.

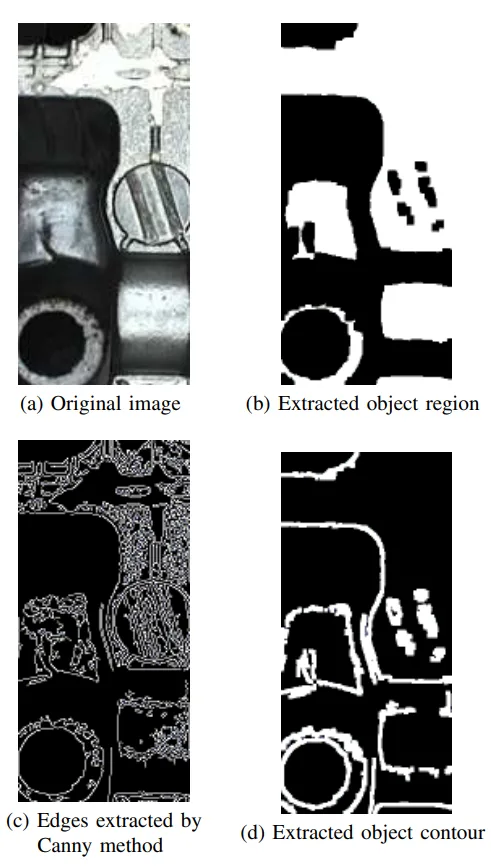

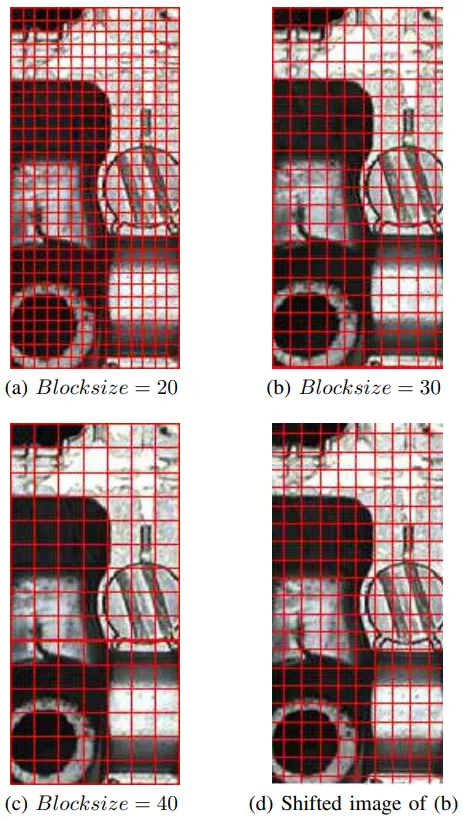

Method 1: Defect Detection via Contour Discontinuity

This approach is designed to find defects like cracks and chips that disrupt the product's outline. The system first uses standard image processing techniques (thresholding, Canny edge detection) to precisely extract the object's contour. It then analyzes this contour in small, overlapping blocks. By calculating an "orientation histogram" within each block, the algorithm can quantify any sudden breaks or irregularities—a "contour discontinuity"—which signals a likely defect. This process mimics human peripheral vision by using various block sizes and simulates involuntary eye microvibrations by shifting the blocks, making the detection more robust.Method 2: Defect Detection via Surface Texture and Machine Learning

This approach targets defects like gas pores, blurred textures, and hollows that appear on the casting's surface. The system analyzes the image in blocks and calculates a "weighted orientation histogram" for the texture within each block. Unlike the contour method, this histogram is weighted by the gradient magnitude, effectively capturing the unique texture signature of the surface. This feature data is then fed into a Support Vector Machine (SVM), a powerful machine learning classifier, which is trained to distinguish between normal and defective surface textures.

By combining the outputs of both methods, the system creates a final "likelihood map" that robustly identifies a wide variety of casting defects.

The Breakthrough: Key Findings & Data

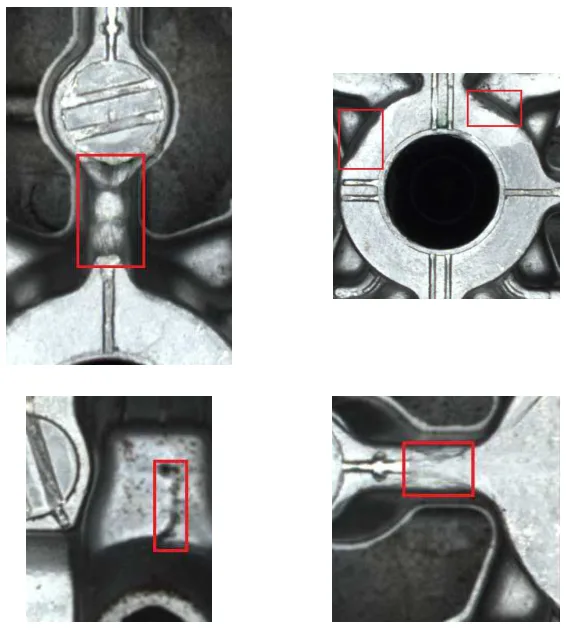

The proposed system was tested on a standardized dataset of 52 images of a car engine casting, which included 22 images containing a total of 27 defects. The results demonstrated the effectiveness of the dual-method approach.

Finding 1: Complementary Methods Lead to Comprehensive Detection

The two methods proved highly effective at identifying their target defect types. The contour discontinuity method excelled at finding linear defects, as shown in the successful detection of a crack in Figure 4. In contrast, the surface texture method was superior at identifying a hollow and chip defect, which the contour method missed (Figure 5). The combined result (Imix) successfully captured both types of flaws with a clear and localized signal.

Finding 2: High Accuracy and Reliability

The authors conclude that the system demonstrated exceptional performance, stating, "It was found that all defects were correctly detected without overdetection." Table I in the paper provides a detailed performance breakdown at various confidence thresholds. For instance, using the combined method (Imix) with a threshold (Th) of 50, the system correctly identified 24 defects with zero false positives (over-detections). At a threshold of 40, it identified 25 defects with only one false positive. This performance highlights the system's ability to be tuned for either maximum precision or maximum recall, depending on the application's needs.

Practical Implications for R&D and Operations

For Process Engineers: This system's sensitivity to subtle surface texture changes could serve as an early warning system for process drift. Variations in texture might indicate issues like mold degradation, inconsistent lubrication, or fluctuating cooling rates, allowing for proactive process adjustments.

For Quality Control Teams: The data in Figure 4, Figure 5, and Table I illustrates the system's potential to establish an objective, repeatable, and automated quality standard. This replaces the subjectivity of manual inspection, ensuring consistent quality assessment across all shifts and operators. The generated likelihood maps could also be used to classify defect severity automatically.

For Design Engineers: The findings from the contour discontinuity method underscore the impact of part geometry on defect formation. Its high sensitivity to cracks and chips suggests that designers should pay close attention to features that create stress concentrations, as this automated system can reliably flag defects that arise in those areas.

Paper Details

Automatic Detection Method for Casting Defects based on Gradient Features

1. Overview:

- Title: Automatic Detection Method for Casting Defects based on Gradient Features

- Author: S. Arita¹, H. Takimoto², H. Yamauchi², and A. Kanagawa²

- Year of publication: 2014

- Journal/academic society of publication: ADCON P 2014 Hiroshima

- Keywords: Automatic Casting Defect Detection, Visual Inspection, Gradient Features, Machine Learning, Contour Discontinuity, Surface Texture

2. Abstract:

In this paper, we propose an automated visual inspection method for casting defects. Automatic inspection systems have the potential to significantly improve quality and increase production rates. In our method, the contour discontinuity of casting product and machine-learning-based defect detection are utilized to detect defects on the surface of products. The peripheral vision and involuntary eye microvibration theories of the human visual mechanism in the field of the physiology of vision are modeled and applied in our feature extraction. By using several gradient features and different types of detector, we achieved robust casting defect detection.

3. Introduction:

Recently, aluminium and steel castings are widely used, particularly in the automotive industry to make cars lighter and more energy-efficient. The inspection of all safety-critical parts is standard, but the visual inspection of casting defects is typically performed manually, relying on human experience and intuition. Automated systems can significantly improve quality and production rates. While several automated methods have been proposed, such as those based on radioscopic images, they often suffer from high cost and long processing times, making them unsuitable for mass production. The automotive industry requires robust and accurate classifiers that can operate under changing conditions. Existing methods are often designed for periodic textures and are difficult to apply to the complex, non-uniform surfaces of castings. This paper proposes an automated detection method based on visual physiology and machine learning to address these challenges.

4. Summary of the study:

Background of the research topic:

The research addresses the critical need for reliable, automated inspection of casting products in industries like automotive manufacturing. Manual inspection is a bottleneck and a source of inconsistency, while existing automated solutions have practical limitations for mass production.

Status of previous research:

Previous research includes automated inspection using stationary radioscopic images, which is costly and slow. Other computer-vision approaches like ANFIS-based classifiers require long processing times. Methods designed to detect salient regions or defects on surfaces with periodic textures are not easily applicable to casting surfaces, which have complex and irregular backgrounds.

Purpose of the study:

The purpose is to propose and validate a novel, non-model-based automated detection method for casting defects. The method aims to achieve robust detection by modeling mechanisms of human visual physiology—specifically peripheral vision and involuntary eye movement—and applying them to feature extraction for machine learning.

Core study:

The study develops a dual-approach method for detecting casting defects.

1. Contour Discontinuity Method: This method focuses on identifying defects like cracks or chips that interrupt the product's outline. It involves extracting the object's contour and analyzing its orientation continuity within local blocks of varying sizes and positions.

2. Surface Texture Method: This method is designed to detect surface irregularities like pores or hollows. It uses a weighted orientation histogram, where gradient magnitude acts as a weight, to capture texture features. A Support Vector Machine (SVM) is then used to classify these features as either defective or non-defective.

The outputs of these two methods are combined to produce a final, more robust detection result.

5. Research Methodology

Research Design:

The study was designed to develop and evaluate a new automated inspection algorithm. Two distinct feature extraction and classification methods were created and then combined. The performance of the individual methods and the combined method was experimentally evaluated on a standard image dataset. The results were also qualitatively compared with two conventional saliency detection methods.

Data Collection and Analysis Methods:

The test dataset was provided by the Visual Inspection Algorithm Contest Committee [14] and consisted of 52 images of a car engine casting, with 22 images containing a total of 27 defects. The machine-learning component was evaluated using the leave-one-out cross-validation method. The block size for analysis was varied from 30 to 50 pixels, and the block shift was set to 5 pixels. Performance was quantified by counting the number of correctly detected defects (Corr) and the number of over-detections (Over) at various detection thresholds (Th).

Research Topics and Scope:

The research is focused on the automatic detection of visual defects on the surface of casting products from 2D images. Defects are defined as hollows, cracks, chips, or blurred textures. The scope includes image preprocessing, gradient-based feature extraction inspired by human vision, and classification using both a threshold-based method (for contour) and a machine learning model (SVM for texture).

6. Key Results:

Key Results:

- The proposed dual-method approach was effective for different defect types. The contour discontinuity method successfully detected cracks, while the surface texture method was effective for hollows and chips.

- The combined method (

Imix) provided robust detection, leveraging the strengths of both individual approaches. - The authors state in the text that "all defects were correctly detected without overdetection," confirming the method's overall effectiveness.

- Quantitative results in Table I show that the combined method (

Imix) correctly detected 24 of 27 defects with 0 over-detections at a threshold of 50, and 26 of 27 defects with 8 over-detections at a threshold of 10.

Figure Name List:

- Fig. 1. Contour extraction of casting product

- Fig. 2. Examples of block division

- Fig. 3. Examples of casting images with casting defects

- Fig. 4. Results of defect detection for a crack

- Fig. 5. Results of defect detection for a hollow and a chip

- TABLE I RESULTS OF TESTS

7. Conclusion:

In this paper, different automated detection methods for casting defects based on the visual physiology mechanism and machine learning were proposed. Experimental results showed the effectiveness of the proposed method. By using several gradient features and different types of detector, robust casting defect detection was achieved.

8. References:

- [1] A. Yamamoto, T. Fujiwara, M. Hashimoto, T. Funahashi, and H. Koshimizu, A Proposal of the Rareness Measure of Pixel Blocks and Its Application to Region Extraction, Proc. of the 17th Korea-Japan Joint Workshop on Frontiers of Computer Vision, PID-1059, 2011.

- [2] S. Arita, H. Takimoto, H. Yamauchi, and A. Kanagawa, Non-model based Defect Detection using Gradient Feature, Proc. of the RISP 2014 International Workshop on Nonlinear Circuits, Communication and Signal Processing, pp. 57-60, 2014.

- [3] M. R. Reynolds, C. Campana, and D. Shetty,, Design of Machine Vision Systems for Improving Solder Paste Inspection, ASME International Mechanical Engineering Congress and Exposition, ASME Paper IMECE2004-62133, pp. 13-20, 2004.

- [4] F. Gayubo, J. L. Gonzalez, E. Fuente, F. Miguel, and J. R. Peran, Online Machine Vision Systems to Detect Split Defects in Sheet-metal Forming Processes, Proc. of the International Conference of Pattern Recognition (ICPR2006), pp. 20-24, Hong Kong, 2006.

- [5] D. Mery and D. Filbert, Automated Flaw Detection in Aluminum Castings based on the Tracking of Potential Defects in a Radioscopic Image Sequence, IEEE Transactions on Robotics and Automation, Vol. 18, Issue 6, pp. 890-901, 2002.

- [6] H. C. Garcia, J. R. Villalobos, R. Pan, and G. C. Runger, A Novel Feature Selection Methodology for Automated Inspection Systems, IEEE Transactions on Pattern Analysis and Machine Intelligence, Vol. 31, Issue 7, pp. 1338-1344, 2009.

- [7] J. Sun, amd Q. Sun, A Support Vector Machine Based Online Learning Approach for Automated Visual Inspection, Proc. of Canadian Conference on Computer and Robot Vision (CRV2009), pp. 192-199, 2009.

- [8] S. Chun, Y. Hayakawa, and K. Nakajima, Hardware Neural Network for a Visual Inspection System, IEICE Transactions on Fundamentals of Electronics, Communications and Computer Sciences, Vol. E91-A, Issue 4, pp. 935-942, 2008.

- [9] B. C. Miles and B. W. Surgenor, Industrial Experience with a Machine Vision System for the Detection of Missing Clip,h Changeable, Agile, Reconfigurable and Virtual Production (CARV 2009), pp. 5-7. 2009.

- [10] J. Killing, B. W. Surgenor, and C. K. Mechefske, A Machine Vision System for the Detection of Missing Fasteners on Steel Stampingsh, International Journal of Advanced Manufacturing Technology, Vol. 41, No. 7-8, pp. 808-819, 2009.

- [11] L. Itti, C. Koch, and E. Niebur, A model of saliency-based visual attention for rapid scene analysis, IEEE Trans. on PAMI, Vol. 20, Issue 11, pp. 1254-1259, 1998.

- [12] C. J. C. Burges, A Tutorial on Support Vector Machines for Pattern Recognition, Data Mining and Knowledge Discovery, Vol. 2, No. 2, pp. 121-167, 1998.

- [13] K. Aoki, T. Funahashi, H. Koshimizu, and Y. Miwata, "KIZUKI" Algorithm inspired by Peripheral Vision and Involuntary Eye Movement, Journal of the Japan Society for Precision Engineering, Vol. 79, Issue 11, pp. 1045-1049, 2013 (in Japanese).

- [14] http://alcon.itlab.org/

- [15] http://www.tc-iaip.org/

Expert Q&A: Your Top Questions Answered

Q1: Why was it necessary to use two different detection methods (contour and texture) instead of relying on a single, more complex one?

A1: The paper demonstrates that the two methods are complementary. The contour discontinuity method is highly effective for linear defects that break the object's edge, such as cracks (Fig. 4). The machine learning-based texture method excels at identifying surface-level flaws like hollows and chips (Fig. 5). By combining them, the system achieves greater robustness and can reliably detect a wider variety of defects than either method could alone.

Q2: What is the practical significance of modeling "peripheral vision" and "involuntary eye microvibration" in the algorithm?

A2: Modeling these human visual mechanisms is key to the system's robustness. Simulating peripheral vision by using different block sizes allows the algorithm to detect defects at multiple scales without being overly sensitive to a defect's specific size. Simulating eye microvibration by shifting the block division points ensures that a defect is detected regardless of its precise location relative to the analysis grid, preventing flaws from being missed.

Q3: Why was a Support Vector Machine (SVM) chosen as the classifier for the surface texture method?

A3: The paper specifies the use of an SVM with a radial basis function (RBF) kernel, which is a standard and powerful tool for two-class classification problems like identifying a region as either "defective" or "non-defective." The SVM's ability to find an optimal separating hyperplane in a high-dimensional feature space makes it well-suited for discriminating between the subtle texture differences of a normal casting surface and a defective one.

Q4: How were the SVM parameters (γ and cost) determined?

A4: The paper states that the parameters were determined experimentally. The RBF kernel parameter was set to γ = 0.1, and the cost parameter was set to 0.25. This suggests the authors performed tuning trials to find the optimal values that yielded the best classification performance on their training data.

Q5: The paper mentions the dataset came from a contest committee. What is the advantage of using this specific dataset?

A5: The dataset was provided by the Visual Inspection Algorithm Contest Committee, organized by the Technical Committee on the Industrial Application of Image Processing in Japan. Using a standardized dataset from a recognized body ensures that the results are comparable, repeatable, and evaluated against a common, industry-relevant benchmark. This adds credibility to the findings, as the system is tested on a pre-vetted set of real-world images rather than a custom-curated one.

Conclusion: Paving the Way for Higher Quality and Productivity

This research tackles a fundamental challenge in casting quality control by developing a robust system for Automatic Casting Defect Detection. By cleverly mimicking the human eye's ability to spot anomalies and combining it with the analytical power of machine learning, the proposed method offers a reliable and practical path to automating visual inspection. The system's proven ability to detect a wide range of defects with high accuracy can help manufacturers move beyond the limitations of manual inspection, leading to higher quality, increased throughput, and greater process control.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Automatic Detection Method for Casting Defects based on Gradient Features" by "S. Arita, H. Takimoto, H. Yamauchi, and A. Kanagawa".

Source: Published in ADCON P 2014 Hiroshima. A direct link is not available in the source document.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.