This technical summary is based on the academic paper "Are the Mechanical Properties of High Pressure Die-Castings Directional?" published by Roger Lumley in the 51st AFI & 16th ADCA Conference (2016). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: HPDC mechanical properties directionality

- Secondary Keywords: high pressure die-casting, Al-Si-Cu alloy, anisotropic properties, metal flow direction, fracture resistance, microstructural defects, heat treatment

Executive Summary

- The Challenge: Variability in mechanical properties due to metal flow direction in high pressure die-casting (HPDC) can affect part performance.

- The Method: Tensile and fracture properties of thin-wall Al-Si-Cu alloy castings were tested in different orientations relative to metal flow.

- The Key Breakthrough: Mechanical properties, especially ductility and fracture resistance, show anisotropy due to defect alignment with metal flow.

- The Bottom Line: Gating design and metal flow orientation are critical for optimizing HPDC part performance.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, HPDC engineers have faced challenges in achieving consistent mechanical properties in thin-wall castings. Variations in tensile strength, ductility, and fracture resistance can compromise part reliability, particularly in demanding applications like automotive and aerospace components. The paper "Are the Mechanical Properties of High Pressure Die-Castings Directional?" by Roger Lumley investigates whether the direction of metal flow during casting influences these properties, revealing that anisotropy—direction-dependent behavior—may be a critical factor. This is especially relevant for professionals aiming to enhance part quality and durability without sacrificing production efficiency.

The Approach: Unpacking the Methodology

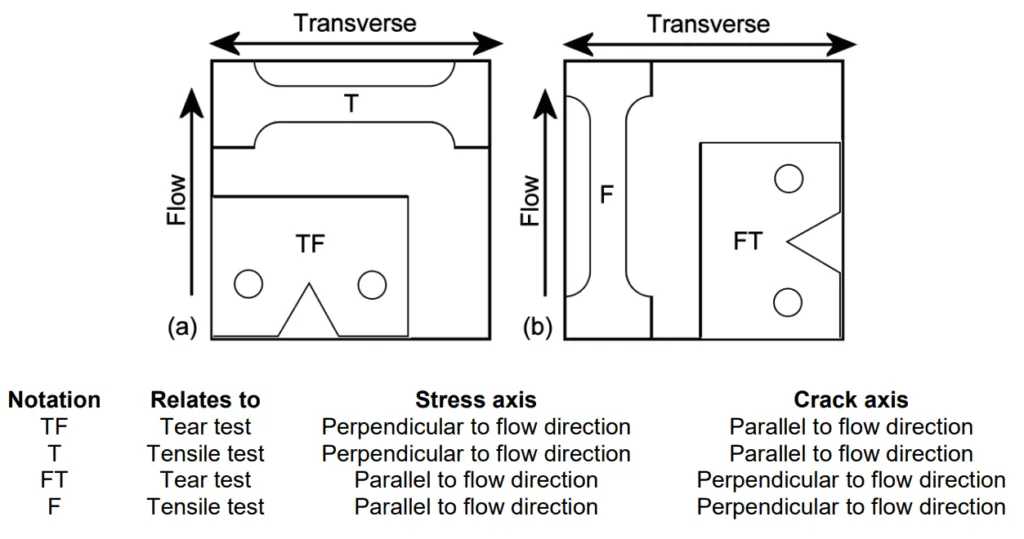

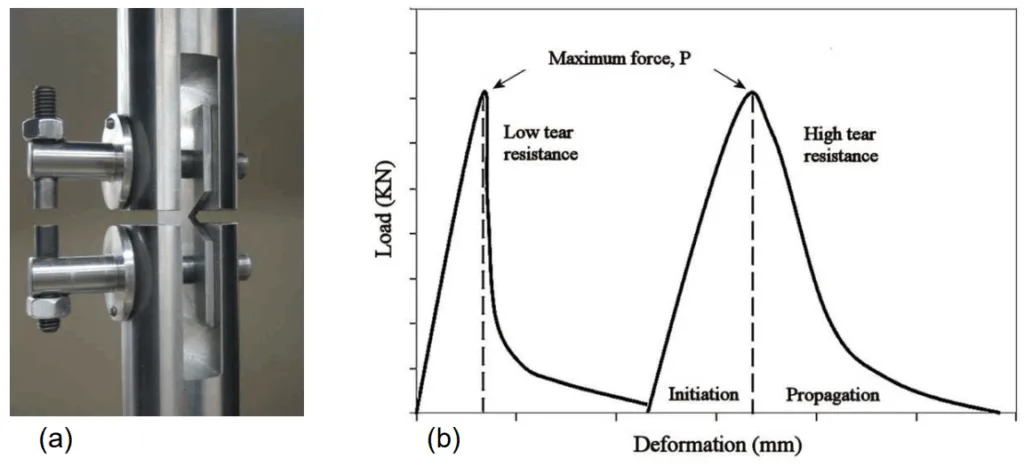

To explore anisotropy, the researchers cast plate-shaped thin-wall Al-Si-Cu alloy parts using HPDC. They conducted tensile and fracture tests on samples cut in different orientations relative to the metal flow direction, specifically comparing properties parallel and perpendicular to the flow. The study tested castings in three conditions: as-cast, T4 (solution-treated and quenched), and T6 (solution-treated, quenched, and aged). The methodology focused on identifying how microstructural defects, influenced by metal flow, affect mechanical behavior, with results documented in Tables 1 and 2 of the paper.

The Breakthrough: Key Findings & Data

The study revealed significant anisotropic behavior in HPDC parts, driven by the alignment of microstructural defects with the metal flow direction:

- Finding 1: Tensile ductility varies depending on the orientation of the stress axis relative to metal flow, with lower ductility observed when stress is applied perpendicular to the flow direction (Tables 1 and 2).

- Finding 2: Fracture resistance is also anisotropic, with samples in the FT (flow-transverse) orientation showing higher average tear strengths in the T6 temper compared to other orientations (Page 4).

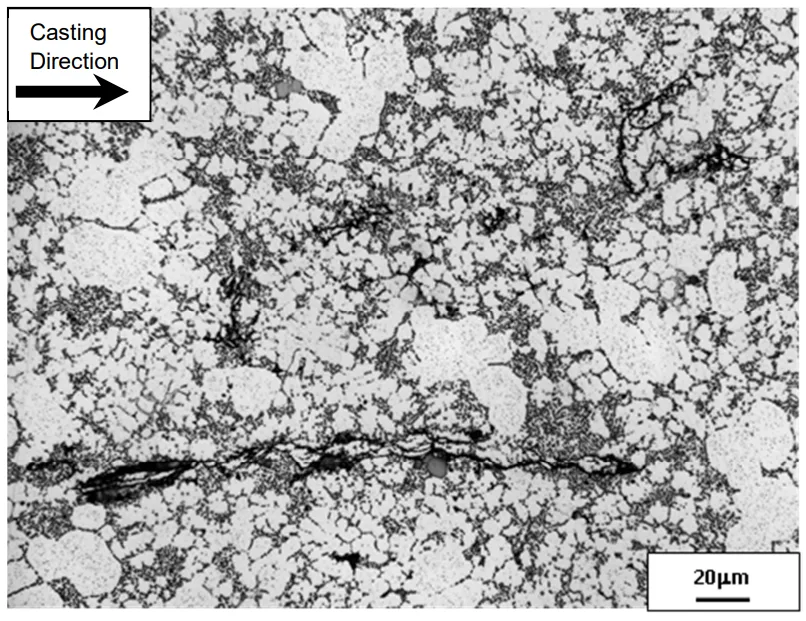

- Finding 3: Microstructural evidence, shown in Figure 4, indicates that continuous and discontinuous defects align with the metal flow, contributing to direction-dependent mechanical properties.

- Finding 4: The anisotropy persists across as-cast, T4, and T6 conditions, suggesting that heat treatment does not fully mitigate the effect of defect alignment.

Practical Implications for HPDC Products

The findings in this paper offer actionable insights for optimizing HPDC operations:

- For Process Engineers: The alignment of defects with metal flow, as shown in Figure 4, suggests that optimizing gating systems to control flow direction could reduce anisotropy and improve ductility and fracture resistance.

- For Quality Control: Monitoring defect orientation during inspection, particularly in critical stress zones, can help identify potential weak points, as the study links defect alignment to reduced mechanical performance (Conclusion).

- For Die Design: Gating and runner designs should consider metal flow orientation to minimize defect alignment perpendicular to expected stress directions, potentially enhancing part reliability (Conclusion).

Paper Details

Are the Mechanical Properties of High Pressure Die-Castings Directional?

1. Overview:

- Title: Are the Mechanical Properties of High Pressure Die-Castings Directional?

- Author: Roger Lumley

- Year of Publication: 2016

- Journal/Academic Society: 51st AFI & 16th ADCA Conference

- Keywords: HPDC, Al-Si-Cu alloy, anisotropic properties, metal flow, fracture resistance, microstructural defects, heat treatment

2. Abstract:

The study examines the tensile and fracture properties of thin-wall HPDC Al-Si-Cu alloy castings to determine if mechanical behavior is influenced by metal flow direction. Results indicate anisotropy in tensile ductility and fracture resistance, attributed to microstructural defect alignment, with implications for gating design in structural die-cast parts.

3. Introduction:

The introduction highlights that Al-Si-Cu/Mg alloys dominate HPDC, accounting for ~50% of aluminium castings. It notes that heat treatment can enhance tensile properties but may reduce fracture toughness. The study focuses on whether metal flow direction causes anisotropic mechanical properties, potentially impacting part performance (Page 1).

4. Summary of the Study:

Background of the Research Topic:

HPDC parts are critical in industries like automotive and aerospace, where consistent mechanical properties are essential. Anisotropy due to metal flow could affect part reliability.

Status of Previous Research:

Prior studies (e.g., Ref. [1], [2]) established that heat-treated HPDC parts can achieve high strength without blistering, but fracture toughness may be compromised. Tailored alloys for fracture resistance were explored (Ref. [3]).

Purpose of the Study:

To investigate whether the direction of metal flow in HPDC influences tensile and fracture properties, and to understand the role of microstructural defects.

Core Study:

The study tested thin-wall Al-Si-Cu alloy castings in as-cast, T4, and T6 conditions, comparing mechanical properties in different orientations relative to metal flow (Page 1).

5. Research Methodology

Research Design:

Plate-shaped castings were produced using HPDC, with samples cut in orientations parallel and perpendicular to metal flow (FT orientation). Tensile and fracture tests were conducted.

Data Collection and Analysis Methods:

Tensile and fracture properties were measured, with results summarized in Tables 1 and 2. Microstructural analysis (Figure 4) examined defect alignment.

Research Topics and Scope:

The study focused on anisotropy in Al-Si-Cu alloy HPDC parts, specifically tensile ductility and fracture resistance, across different heat treatment conditions (Page 1, 5).

6. Key Results:

Key Results:

- Tensile ductility and fracture resistance vary with orientation relative to metal flow (Tables 1 and 2).

- FT orientation in T6 temper showed higher tear strengths (Page 4).

- Microstructural defects align with metal flow, influencing mechanical properties (Figure 4).

- Anisotropy persists in as-cast, T4, and T6 conditions (Page 5).

Figure Name List:

- Figure 4: Examples of continuous and discontinuous defects present in high pressure diecast plates, where the defects orientation align with the direction of metal flow.

7. Conclusion:

The mechanical properties of HPDC parts are directional due to defect alignment with metal flow. To minimize anisotropy, gating designs should consider the relationship between metal flow and stress directions, as this impacts failure mechanisms (Page 5).

8. References:

- [1] R. Lumley, R. G. O’Donnell, D.R. Gunasegaram, M. Givord, Met. and Mat. Trans. A, 2007, 3A, 2544-2547,4

- [2] F.N. Lumley and J.R. Griffiths, Cont. Proc. 1122" Metalcasting Congress, NADCA, 2008, paper T08-042.

- [3] R.N. Lumley, M. Gershenzon, D.R. Gunasegaram, A.C. Yob. International Patent Application PCTAL2000/005/52, 2009.

- [4] E.J. Vinarek, High Integrity Die Casting Processes, John Wiley and Sons, USA, p 13-20.

- [5] C.M. Gourlay, H.I. Laukli, A.K. Dahle. Metallurgical Transactions A. 35, #9, pp. 2811. 2811(11), 2004.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving fracture resistance?

A1: The study concluded that the alignment of microstructural defects with metal flow direction was the most critical factor, as detailed in the Conclusion and supported by Figure 4.

Q2: How does this research compare to traditional methods for addressing HPDC part performance?

A2: The paper’s Introduction notes that traditional methods focus on heat treatment to improve tensile properties (Ref. [1]), but this study highlights that controlling metal flow direction can further optimize fracture resistance and ductility by addressing defect alignment.

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research, as described in the Methodology section, was conducted using an Al-Si-Cu alloy. Applicability to other alloys would require further investigation (Page 1).

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers used tensile and fracture testing, with microstructural analysis via optical microscopy (Figure 4), to quantify defect alignment and its impact on properties, as explained in the Methodology section (Page 5).

Q5: According to the paper, what is the main limitation or area for future research?

A5: The paper does not explicitly state limitations but implies in the Conclusion that further research is needed to optimize gating designs to mitigate anisotropy caused by metal flow (Page 5).

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that optimizing gating to control metal flow direction can reduce anisotropic mechanical properties, improving part reliability, as strongly supported by the overall results of the paper (Page 5).

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the reliability of HPDC parts by addressing directionality in mechanical properties. By understanding how metal flow influences defect alignment, manufacturers can optimize gating designs to improve tensile ductility and fracture resistance.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers’ most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Roger Lumley". Based on "Are the Mechanical Properties of High Pressure Die-Castings Directional?".

- Source of the paper: 51st AFI & 16th ADCA Conference (No DOI provided).

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.