This technical summary is based on the academic paper "Influence of continuous casting conditions on grey cast iron structure" by J. Szajnar, M. Stawarz, T. Wróbel, W. Sebzda, B. Grzesik, M. Stępień, published in Archives of Materials Science and Engineering (2010).

![Fig. 1. The scheme of an electromagnetic stirrer enforcing (a) rotary reversion, and (b) oscillatory motion of liquid metal along the axis originating ingot [5]](https://castman.co.kr/wp-content/uploads/image-3424.webp)

![Fig. 2. Macrostructure of pure aluminium of type EN AWAl99,5 ingot in initial state (a), and after casting with influence of rotate electromagnetic field (b) [11]](https://castman.co.kr/wp-content/uploads/image-3425.webp)

Keywords

- Primary Keyword: Continuous Casting Grey Cast Iron

- Secondary Keywords: Electromagnetic Stirring, Flake Graphite Morphology, Machinability, Hard Spots, EN GJL-200

Executive Summary

- The Challenge: Conventional continuous casting of grey cast iron often produces a non-uniform structure with hard spots (cementite), leading to inconsistent mechanical properties and poor machinability.

- The Method: Researchers implemented a rotating electromagnetic field within the continuous casting mould to induce forced convection in the solidifying liquid metal.

- The Key Breakthrough: Applying a 50 Hz electromagnetic field completely eliminated hard spots, unified the flake graphite morphology across the entire ingot, and significantly improved machinability.

- The Bottom Line: Electromagnetic stirring is a highly effective method for improving the quality, structural uniformity, and performance of continuously cast grey cast iron products.

The Challenge: Why This Research Matters for HPDC Professionals

In high-volume manufacturing, particularly for the automotive industry, the consistency and machinability of cast components are critical. For grey cast iron produced via continuous casting, a common and costly problem is the formation of a non-uniform microstructure.

This non-uniformity often manifests as:

* Hard Spots: Pockets of cementite that are extremely hard and brittle, causing rapid tool wear during machining operations and increasing production costs.

* Irregular Graphite Morphology: Inconsistent shape and distribution of graphite flakes across the casting's cross-section, leading to unpredictable mechanical properties.

* Hardness Gradients: A significant difference in hardness between the surface and the core of the ingot, which complicates machining and can affect the final component's performance.

These issues create significant challenges for engineers striving for process efficiency and product quality. This research was initiated to find a practical method to unify the structure of grey cast iron during the casting process itself, thereby solving these downstream problems.

The Approach: Unpacking the Methodology

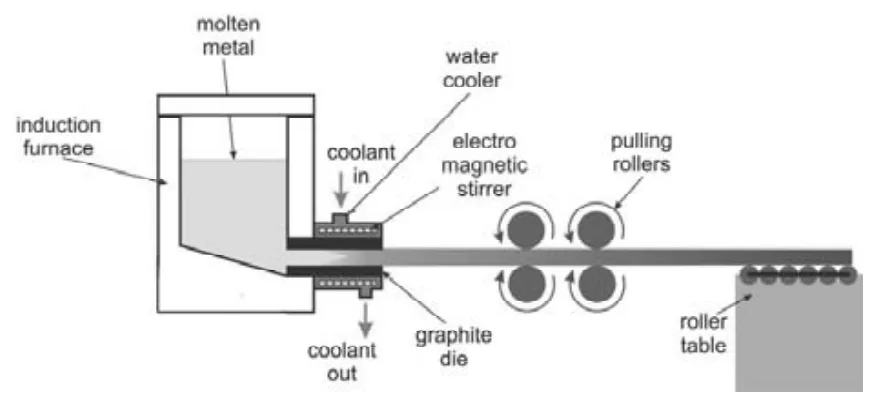

The research team conducted a series of controlled experiments on a laboratory-scale continuous casting stand specifically designed to investigate the effects of electromagnetic fields.

Method 1: Optimizing Casting Speed

* Material: Grey cast iron of type EN GJL-200.

* Equipment: A laboratory continuous casting line producing 20 mm diameter ingots.

* Key Variables: The velocity of the ingot pulling was varied from 200 to 700 mm/min. The temperature of the ingot after leaving the mould was measured to correlate with the resulting structure. The quantity of hard spots was quantified for each speed.

Method 2: Applying Electromagnetic Stirring

* Equipment: The continuous casting mould was equipped with an inductor to generate a rotating electromagnetic field, forcing the liquid metal to move in a circular motion during solidification.

* Key Variables: While maintaining a constant magnetic induction of 60 mT, the frequency of the supply voltage was varied (25 Hz, 50 Hz, 75 Hz, and 100 Hz). The optimal pulling speed of 700 mm/min, identified in Method 1, was used for these tests.

* Analysis: The resulting ingots were analyzed for microstructure (using a scanning electron microscope), hardness distribution across the cross-section, and machinability (measured as the time required to bore a standardized hole).

The Breakthrough: Key Findings & Data

The study yielded clear, data-driven evidence demonstrating the profound impact of combining optimized casting parameters with electromagnetic stirring.

Finding 1: High Pulling Speed Drastically Reduces Hard Spots

By increasing the ingot pulling speed, the researchers found a direct correlation with a reduction in hard spots. As shown in Figure 7, increasing the pulling velocity from 200 mm/min to 700 mm/min reduced the percentage of hard spots from 51% down to just 1%. This is because the faster speed reduces the ingot's dwell time in the water-cooled mould, causing it to exit at a higher temperature (approx. 1000°C) where the final, more uniform structure forms during air cooling.

Finding 2: 50 Hz Electromagnetic Field Perfects the Structure and Boosts Machinability

While high pulling speed nearly eliminated hard spots, the application of a rotating electromagnetic field delivered a complete solution.

* Structural Unification: The electromagnetic field, particularly at a frequency of 50 Hz, forced the convection of the liquid metal, resulting in a completely uniform flake graphite morphology across the entire cross-section of the ingot, from the periphery to the axis (Table 2). This process also completely eliminated the remaining 1% of hard spots.

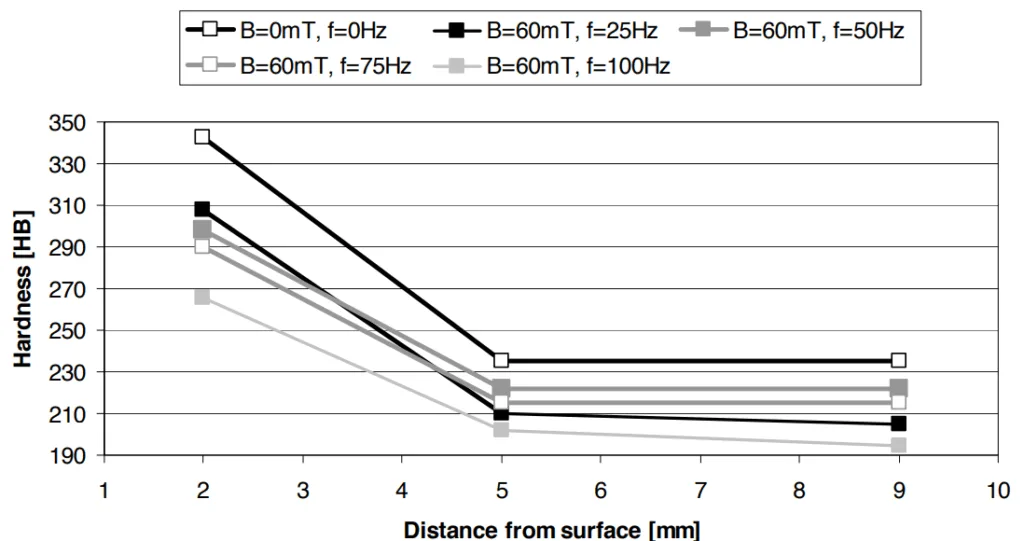

* Homogenized Hardness: Without an electromagnetic field, there was a steep hardness gradient from the surface to the core. As illustrated in Figure 9, the 50 Hz field significantly flattened this hardness profile, indicating a much more uniform material.

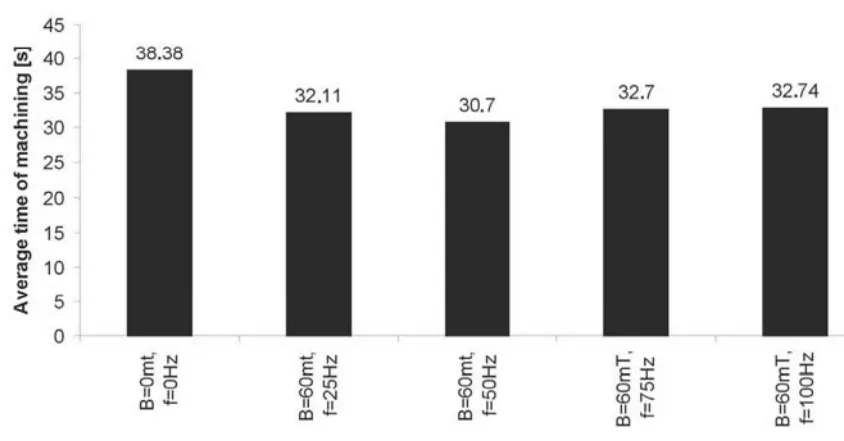

* Improved Machinability: The structural improvements translated directly to better performance. As shown in Figure 10, the time required for a standardized machining (boring) operation dropped from 38.38 seconds for the standard ingot to 30.7 seconds for the ingot cast with a 50 Hz field—a significant improvement.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing electromagnetic stirring in continuous casting lines for grey cast iron can contribute to eliminating hard spots and improving overall structural quality, leading to higher yields and less scrap. The 50 Hz frequency appears to be a highly effective starting point for process optimization.

- For Quality Control Teams: The data in Figure 9 illustrates that a cross-sectional hardness profile is an excellent indicator of microstructural uniformity. This could inform new, more comprehensive quality inspection criteria beyond simple surface hardness checks.

- For Design Engineers: The findings indicate that the solidification conditions fundamentally define the final material properties. This reinforces the importance of collaboration between design and manufacturing teams to ensure that casting processes are capable of delivering the microstructures required for demanding applications.

Paper Details

Influence of continuous casting conditions on grey cast iron structure

1. Overview:

- Title: Influence of continuous casting conditions on grey cast iron structure

- Author: J. Szajnar, M. Stawarz, T. Wróbel, W. Sebzda, B. Grzesik, M. Stępień

- Year of publication: 2010

- Journal/academic society of publication: Archives of Materials Science and Engineering

- Keywords: Casting; Cast iron; Graphite; Electromagnetic field

2. Abstract:

Purpose: The main aim of investigations was the unification of flake graphite morphology in cast iron ingots in conditions of forced convection of liquid metal in the continuous casting mould, which contains electromagnetic stirrer.

Design/methodology/approach: To investigations of grey cast iron ingots were used laboratory stand of continuous casting, which contains continuous casting mould with inductor of rotate electromagnetic field. To investigations were made metallographic researches on scanning electron microscope and investigations of usable properties i.e. measurements of hardness and machinability.

Findings: The results of investigations and their analysis show possibility of unification of flake graphite morphology in cast iron structure, and distribution of hardness on cross-section of ingot and its machinability.

Research limitations/implications: In further research, authors of this paper are going to application of introduced method of continuous casting with use of electromagnetic field in industrial tests.

Practical implications: The work presents method of unification of structure and properties, which are particularly important in continuous casting. Uniform morphology of flake graphite in structure of cast iron ingots for automobile industry is very important in viewpoint of machinability.

Originality/value: Contributes to improvement in quality of grey cast iron continuous casted ingots.

3. Introduction:

Forced convection of liquid metal in traditional or continuous casting moulds significantly influences the crystallization process. For many years, devices like mechanical or electromagnetic stirrers have been used to generate liquid metal movement, initially for purposes such as unifying metal in holding furnaces or accelerating the melting of additives. The development of refractory materials and electrical engineering, combined with a recognized positive effect of forced convection on casting structure, led to wider use of magnetohydrodynamic (MHD) devices in the 1970s.

4. Summary of the study:

Background of the research topic:

The study addresses the challenge of achieving uniform structure and properties in grey cast iron ingots produced by continuous casting. Non-uniformity in graphite morphology and the presence of hard spots (cementite) negatively impact mechanical properties, particularly machinability, which is critical for industries like automotive manufacturing.

Status of previous research:

The influence of electromagnetic fields to unify structure has been successfully applied in the casting of steel and non-ferrous metals. Previous work has demonstrated the ability of electromagnetic stirring to refine grain size in pure aluminum ingots. Papers also exist suggesting the potential for applying electromagnetic fields to influence the solidification of grey cast iron. This study builds upon that foundation to systematically investigate its effects on graphite morphology.

Purpose of the study:

The primary aim was to determine the influence of a rotating electromagnetic field on the graphite morphology in the structure of continuously cast EN GJL-200 grey cast iron, with the goal of achieving a more uniform microstructure.

Core study:

The investigation utilized a laboratory continuous casting stand equipped with a water-cooled mould and an inductor for generating a rotating electromagnetic field. Ingots of EN GJL-200 grey cast iron (ø20 mm) were cast under varying conditions. The study focused on two main parameters: the ingot pulling velocity (V) and the frequency (f) of the supply voltage to the inductor. The resulting ingots were subjected to metallographic analysis, hardness measurements across their cross-section, and machinability testing to evaluate the effects of these parameters on the final structure and properties.

5. Research Methodology

Research Design:

The study was an experimental investigation conducted on a laboratory stand for continuous casting. The core of the design was to systematically vary key process parameters—ingot pulling velocity and electromagnetic field frequency—and measure their impact on the microstructure and mechanical properties of the resulting grey cast iron ingots.

Data Collection and Analysis Methods:

- Microstructure Analysis: Morphology of flake graphite was evaluated using a scanning electron microscope (InspectF with EDS) on non-etch microsections taken from the periphery, half-radius, and axis of the ingots.

- Hardness Measurement: Hardness was measured on the cross-section of the ingots using the Brinell method.

- Machinability Testing: Machinability was designated using the Keep-Bauer method, where the time to bore a 3 test-holes in each 20 mm high sample was measured under a constant force (350 N) and rotational speed (360 rpm).

- Process Simulation: The solidification process was simulated using ANSYS software to model the effects of the process parameters.

Research Topics and Scope:

The research was focused on EN GJL-200 grey cast iron cast into 20 mm diameter ingots. The investigated parameters included:

- Ingot pulling velocity (V): 200 to 700 mm/min.

- Magnetic induction (B): 60 mT.

- Supply voltage frequency (f): 25 Hz, 50 Hz, 75 Hz, and 100 Hz.

- Other constant parameters: liquid metal temperature (1450°C), cooling water temperature (70°C).

6. Key Results:

Key Results:

- Increasing the ingot pulling velocity to 700 mm/min reduces the quantity of hard spots in the structure to approximately 1% (Fig. 7). This is attributed to the higher ingot exit temperature (~1000°C), which allows the final structure to form during air cooling.

- The application of a rotating electromagnetic field during solidification promotes the unification of flake graphite morphology (Table 2). The effect is most pronounced at a supply frequency of 50 Hz, which results in a uniform structure across the entire ingot cross-section.

- The use of electromagnetic field forced convection completely eliminates the presence of hard spots in the structure of grey cast iron.

- The unification of the microstructure leads to a significant reduction in the hardness gradient across the ingot's cross-section (Fig. 9).

- The structural improvements, particularly the unification of graphite morphology and elimination of hard spots, result in a marked improvement in machinability, as evidenced by a shorter boring time (Fig. 10).

Figure Name List:

- Fig. 1. The scheme of an electromagnetic stirrer enforcing (a) rotary reversion, and (b) oscillatory motion of liquid metal along the axis originating ingot [5]

- Fig. 2. Macrostructure of pure aluminium of type EN AW-A199,5 ingot in initial state (a), and after casting with influence of rotate electromagnetic field (b) [11]

- Fig. 3. Scheme of stand to continuous casting of grey cast iron ingots with circular section

- Fig. 4. Influence of current intensity I on magnetic induction B

- Fig. 5. Influence of frequency of supply voltage f on force F, which generates liquid metal movement at radius of ingot 10 mm

- Fig. 6. Influence of frequency f of supply voltage on distribution of velocity Vcm of liquid metal movement at radius of ingot 10 mm: a) 25 Hz, b) 50 Hz, c) 75 Hz and d) 100 Hz

- Fig. 7. Influence of the velocity of ingot pulling V on percentage quantity of hard spots in structure of grey cast iron (at definite value of the temperature of ingot after leaving the continuous casting mould To)

- Fig. 8. Influence of the velocity of ingot pulling V on position of crystallization front in continuous casting mould

- Fig. 9. Influence of the electromagnetic field on hardness distribution on cross-section of grey cast iron continuous ingot

- Fig. 10. Influence of the electromagnetic field on machinability of grey cast iron continuous ingot

7. Conclusion:

- Selection of continuous casting parameters that ensure temperature of ingot after leaving the continuous casting mould about 1000°C, allows to reduce defects in the form of fields of hard spots in structure of grey cast iron to about 1%.

- The change of thermal conditions on the crystallization front obtained as a result of the influence of electromagnetic field forced convection of the solidifying metal in continuous casting mould, ensures complete elimination of the presence of fields of hard spots and leads to unification of flake graphite morphology from consideration of its shape and distribution.

- Increasing the unification of flake graphite morphology is favored by the influence of the electromagnetic field created in the inductor powered with a frequency of supply voltage 50Hz.

- The unification of flake graphite morphology result from the influence of the electromagnetic field provides a reduction in gradient of hardness on cross-section hardness of ingots, which leads to an improvement in their machinability.

8. References:

- [1] R. Sikora, Theory of electromagnetic field, WNT, Warsaw, 1998, (in Polish).

- [2] P. Gillon, Uses of intense d.c. magnetic fields in materials processing, Materials Science and Engineering 287 (2000) 146-151.

- [3] J. Szajnar, The influence of selected physical factors on the crystallization process and castings structure, Archives of Foundry Engineering – Monograph, Gliwice, 2009, (in Polish).

- [4] J. Adamczyk, Development of the microalloyed constructional steels, Journal of Achievements in Materials and Manufacturing Engineering 14/1-2 (2006) 9-20.

- [5] J. Adamczyk, Engineering of metallic materials - part 1, Scientific book of Silesian University of Technology, Gliwice, 2004, (in Polish).

- [6] I. Nowak, J. Smołka, A. Nowak, A reproduction of boundary conditions in three-dimensional continuous casting problem, International Journal of Mathematical, Physical and Engineering Sciences 3 (2009) 193-198.

- [7] K. Miyazawa, Continuous casting of steels in Japan, Science and Technology of Advanced Materials 2 (2001) 59-64.

- [8] S. Asai, Recent development and prospect of electromagnetic processing of materials, Science and Technology of Advanced Materials 1 (2000) 191-196.

- [9] H. Harada, E. Takeuchi, M. Zeze, H. Tanaka, MHD analysis in hydromagnetic casting process of clad steel slabs, Applied Mathematical Modeling 23 (1998) 873-880.

- [10] C. Sajdak, S. Golak, A. Kurek, Electromagnetic stirring of ingot liquid core in continuous casting of steel, Electrotechnics Review 3 (2007) 67-70, (in Polish).

- [11] J. Szajnar, T. Wróbel, Methods of inoculation of pure aluminium structure, Journal of Achievements in Materials and Manufacturing Engineering 27 (2008) 95-98.

- [12] J. Szajnar, T. Wróbel: Influence of magnetic field and inoculation on size reduction in pure aluminium structrure, International Journal of Materials and Product Technology 3 (2008) 322-334.

- [13] C. Vives, R. Ricou, Experimental study of continuous electromagnetic casting of aluminium alloys, Metallurgical Transactions B 16B (1985) 377-384.

- [14] J. Szajnar, M. Stawarz, T. Wróbel, W. Sebzda, Influence of electromagnetic field on pure metals and alloys structure, Journal of Achievements in Materials and Manufacturing Engineering 34 (2009) 95-102.

- [15] L. Qiushu, L. Liqiang, L. Renxing, H. Xu, Z. Qijie, Effect of pulse magnetic field on graphite morphology and solidification of grey cast iron, Proceedings of the 66th World Foundry Congress, Istanbul, 2004, 147-156.

Expert Q&A: Your Top Questions Answered

Q1: Why was a pulling speed of 700 mm/min identified as the most advantageous?

A1: The study found that increasing the pulling speed reduces the amount of time the ingot spends in the direct water-cooled section of the mould. At 700 mm/min, the ingot exits the mould at approximately 1000°C. This high exit temperature means that a large part of the final microstructure forms during the slower, more uniform process of cooling in air, which significantly reduces the formation of hard spots (cementite) down to just 1%, as shown in Figure 7.

Q2: The study highlights 50 Hz as the optimal frequency. Why was it more effective than 25, 75, or 100 Hz?

A2: The results presented in Table 2 show a clear difference in the resulting microstructure. While frequencies of 25, 75, and 100 Hz promoted partial unification of the graphite morphology, this effect was mainly observed from the half-radius of the ingot to its center. Only the 50 Hz frequency was able to achieve a complete and uniform flake graphite morphology across the entire cross-section, from the periphery to the core, which is essential for consistent material properties.

Q3: What is the underlying mechanism by which the electromagnetic field unifies the graphite structure?

A3: The paper explains that the unification of the flake graphite morphology results from the change of thermal conditions on the crystallization front. The rotating electromagnetic field induces forced convection (movement) in the liquid metal. This stirring action homogenizes the temperature within the liquid, preventing localized undercooling at the solidification front, which in turn promotes a more uniform and controlled growth of graphite flakes.

Q4: How does the electromagnetic field achieve the complete elimination of hard spots, when high pulling speed alone could not?

A4: While high pulling speed minimizes hard spots by altering the bulk cooling conditions, the electromagnetic field acts directly on the solidification front. The forced convection created by the field ensures a more uniform temperature distribution in the liquid metal as it solidifies. This prevents the formation of localized regions that could favor the eutectic reaction that forms cementite (hard spots), thus ensuring the structure is composed entirely of the desired graphite and metal matrix.

Q5: What is the practical benefit of reducing the hardness gradient shown in Figure 9?

A5: A steep hardness gradient, with a very hard outer surface and a softer core, creates major challenges for machining. It requires frequent changes in cutting speeds and feeds, leads to inconsistent tool wear, and can make it difficult to maintain tight dimensional tolerances. By creating a flat hardness profile, the electromagnetic stirring process produces a material that is much more predictable and consistent to machine, reducing tool wear, simplifying machining processes, and improving the quality of the final component.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demonstrates that the chronic issues of hard spots, structural non-uniformity, and poor machinability in Continuous Casting Grey Cast Iron can be overcome. By combining an optimized, high-speed pulling process with the application of a 50 Hz rotating electromagnetic field, it is possible to produce ingots with a remarkably uniform microstructure, consistent hardness, and superior machinability. These findings provide a clear pathway for producers to enhance product quality and reduce downstream manufacturing costs.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Influence of continuous casting conditions on grey cast iron structure" by "J. Szajnar, M. Stawarz, T. Wróbel, W. Sebzda, B. Grzesik, M. Stępień".

Source: The paper was published in Archives of Materials Science and Engineering, Volume 42, Issue 1, March 2010, Pages 45-52.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.