Beyond 2D X-Rays: Revolutionizing Aluminium Casting Quality with 3D Casting Inspection

This technical summary is based on the academic paper "Establishment of Acceptance Criteria for Tomography Inspection of Aluminium Alloy Castings" by Abdel Rahman DAKAK, Pr. Valérie KAFTANDJIAN, Dr. Philippe DUVAUCHELLE, and Mr. Patrick BOUVET, published in International Symposium on Digital Industrial Radiology and Computed Tomography – DIR2019 (2019).

Keywords

- Primary Keyword: 3D Casting Inspection

- Secondary Keywords: Tomography Inspection, Aluminium Alloy Castings, Acceptance Criteria, Non-Destructive Testing, Defect Detection, CT Scanning for Castings

Executive Summary

- The Challenge: Current 2D X-ray inspection for aluminium castings is subjective and unreliable, often leading to the costly rejection of good parts or the acceptance of flawed ones.

- The Method: Researchers developed an advanced, multi-step image segmentation algorithm to automatically detect and highlight potential defects within 3D tomographic slices.

- The Key Breakthrough: The proposed methodology successfully isolates defect indications from complex part geometry and image artefacts, creating a reliable foundation for automated 3D classification and standardized acceptance criteria.

- The Bottom Line: This research provides a clear pathway to replace outdated 2D inspection standards with objective, data-driven 3D criteria, significantly enhancing quality control, reducing waste, and preventing disputes.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, the standard for internal quality control of aluminium castings has been 2D X-ray radiography, with inspectors comparing images to ASTM reference standards. However, this method is fraught with problems that directly impact your bottom line and product reliability.

As the paper highlights, 2D projections are inherently ambiguous. They make it difficult to locate discontinuities precisely, especially in complex parts with varying thicknesses. This can lead to two costly errors:

1. False Rejections: A part with a harmless shrinkage cavity located in a non-critical area (like the neutral axis) might be scrapped, wasting resources and money.

2. False Acceptances: A small but critical defect near a high-stress surface—one that could reduce fatigue strength by over 30%—might be missed, posing a significant risk.

Furthermore, the manual comparison process is subjective, leading to inconsistent decisions between operators and frequent disputes between foundries and their customers. The industry has lacked a reliable, objective, and approved 3D reference standard for computed tomography (CT) inspection—until now.

The Approach: Unpacking the Methodology

To solve this challenge, the researchers focused on the first critical step: developing a robust algorithm to automatically and accurately detect potential defects from raw tomographic data. Their proposed methodology processes each 2D slice of the 3D CT scan through a sequence of advanced image processing steps.

Method 1: A Multi-Step Image Segmentation Process

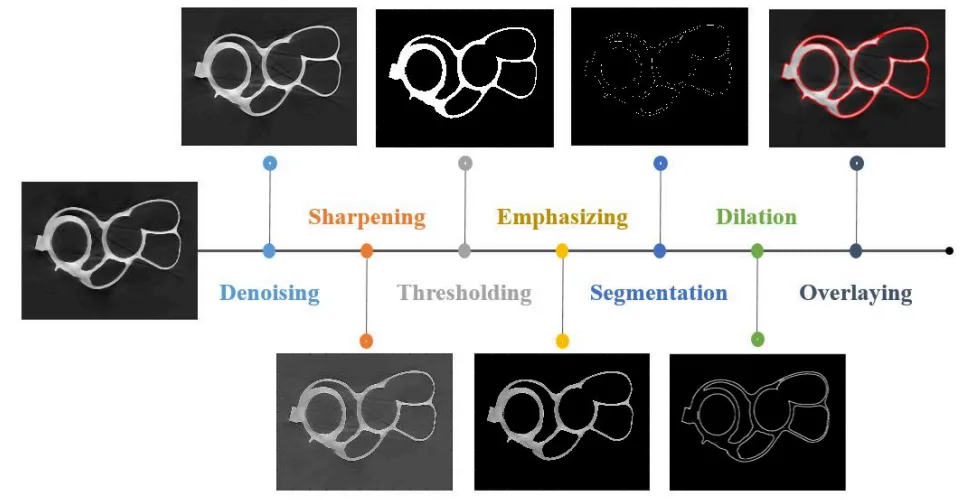

The core of the research is an edge-based segmentation technique designed to isolate defects from the casting's geometry and background noise. As illustrated in Figure 1 of the paper, the process involves several key operations:

* Denoising: A wavelet transformation is used to reduce image noise without blurring or affecting the features of real defects.

* Sharpening: This step accentuates the edges of both the casting's geometry and any internal defects, making them easier for the algorithm to detect.

* Thresholding & Segmentation: The image is converted to a binary format to create an initial separation of features.

* Emphasizing & Edge Detection: The algorithm compares the processed images to highlight the casting and uses an edge operator to precisely trace the contours of all indications.

* Dilation: The detected contours are slightly thickened so they can be clearly overlaid on the original image for verification.

This systematic approach transforms a noisy, complex tomographic slice into a clean image where potential defects are clearly highlighted.

The Breakthrough: Key Findings & Data

The paper's primary contribution is the successful establishment of this segmentation technique, which lays the groundwork for a fully automated 3D inspection system.

Finding 1: Effective and Precise Defect Indication

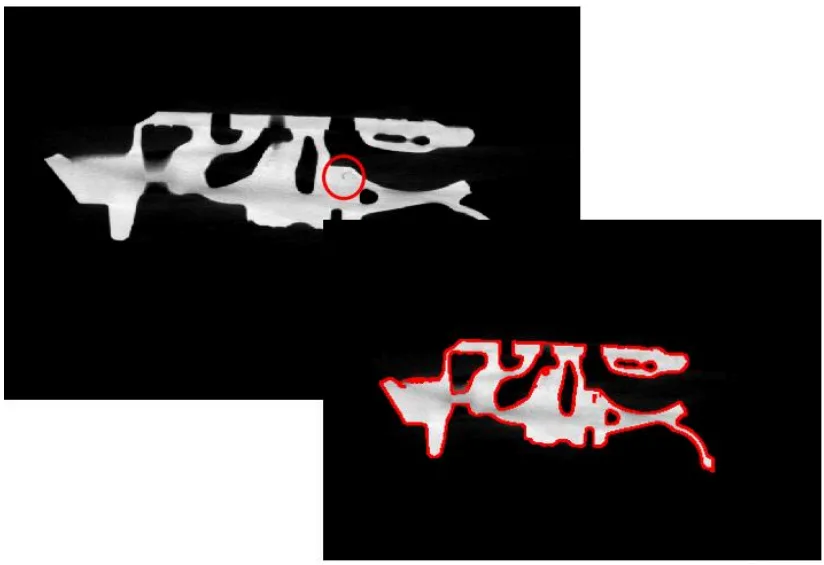

The research demonstrates that the proposed algorithm can successfully process a tomographic slice and highlight defect contours with high precision. As shown in Figure 2 of the paper, the final output clearly overlays the detected defect boundaries on the original image. This proves the method's capability to distinguish potential flaws from the main body of the aluminium casting, even in areas with complex geometry.

Finding 2: A Foundation for Machine Learning Classification

This segmentation process is not the end goal but a crucial enabler for the next phase. The paper explains that the detected "indications" can be one of two types: real defects or "false alarms" (tomographic artefacts). By successfully isolating these indications, the researchers have created the clean input data needed to train a machine-learning classifier. This future step will allow the system to automatically determine if a highlighted region is a true defect, paving the way for a fully automated and objective quality control process.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that the ability to precisely locate, measure, and classify 3D defects will enable a more direct correlation between casting flaws and specific process parameters, accelerating root cause analysis and process optimization.

- For Quality Control Teams: The data in Figure 2 of the paper illustrates the potential for automated sanctioning systems. This approach can eliminate operator subjectivity, increase throughput, and create a digital, objective quality reference that can be shared between suppliers and customers.

- For Design Engineers: The findings indicate that having precise 3D data on defect morphology and location (e.g., proximity to a machined surface) allows for more accurate fatigue life predictions and informs design modifications to mitigate defect formation in critical zones.

Paper Details

Establishment of Acceptance Criteria for Tomography Inspection of Aluminium Alloy Castings

1. Overview:

- Title: Establishment of Acceptance Criteria for Tomography Inspection of Aluminium Alloy Castings

- Author: Abdel Rahman DAKAK, Pr. Valérie KAFTANDJIAN, Dr. Philippe DUVAUCHELLE, Mr. Patrick BOUVET

- Year of publication: 2019

- Journal/academic society of publication: International Symposium on Digital Industrial Radiology and Computed Tomography – DIR2019

- Keywords: X-ray tomography, automatic analysis, defects detection, defects classification, extraction of characteristics.

2. Abstract:

In October 2018, the French company CTIF, in collaboration with the laboratory LVA of INSA Lyon, has launched a PhD thesis. The aim of this thesis is to establish a set of acceptance criteria for tomography inspection of aluminium alloy castings.

Currently, the agreement on conformity of aluminium castings inspected by 2D X-ray radiography is based on the ASTM reference images. However, when it comes to tomography inspection, such images have not yet been established in 3D. Consequently, tomography inspectors and their casting customers do not have an approved reference on which they could rely to create their own scope statement and evaluate the 3D casting defects and their criticality.

Based on the aforementioned motivation, the objective of our thesis is the establishment of such quality standards that will be applicable to the characterization of aluminium castings defects and their types by 3D tomography. The methodological approach proposed to reach our endeavour is as follows: (1) development of image-processing algorithms to establish automatic detection of casting defects in the tomographic slices, (2) a 3D reconstruction of the defects, and finally (3) automatic processing and measurement of features from the 3D volume of the defects to classify them and finally determine a 3D quality reference.

For the first step, which is currently in making, two classes of regions can be detected on a digital tomographic slice of an aluminium casting after segmentation: regions belonging to the geometric structures of the specimen or tomographic artefacts (false alarms), and those relating to real defects. The distinction between these two classes can be done by using pattern recognition techniques for object detection and classification. By using a defects library, a classifier can be trained to determine whether a segmented indication is a false alarm, or whether it belongs to a real defect.

3. Introduction:

The use of aluminium alloy casting parts in automotive and aeronautics industries is increasing. These components are often subjected to high mechanical strain, necessitating rigorous non-destructive testing. Internal conformity is typically inspected by 2D radiography, which projects the part's volume onto a plane. This method presents difficulties in visualizing complex geometries and accurately locating discontinuities. Such ambiguities can lead to incorrect rejection of serviceable parts or acceptance of parts with critical defects. Tomography offers superior detection and localization of discontinuities in 3D, providing critical information about their size, shape, and position relative to functional surfaces. Despite the advantages and increasing adoption of CT scanners, the industry lacks a set of established 3D acceptance criteria, forcing reliance on outdated and subjective 2D ASTM reference images.

4. Summary of the study:

Background of the research topic:

The research addresses the need for standardized quality control in the inspection of aluminium alloy castings used in high-performance applications. It focuses on the transition from traditional 2D X-ray radiography to more advanced 3D computed tomography (CT).

Status of previous research:

Current industry practice for radiographic inspection relies on 2D reference images specified by standards such as ASTM E155, E505, E2422, and E2973. These standards are recognized to have significant disadvantages, including subjectivity, the potential for incorrect part disposition (scrapping good parts or accepting bad ones), and a lack of logical progression between defect levels. For 3D tomography, no such approved reference standards exist.

Purpose of the study:

The primary objective of the thesis is to establish a set of quality standards and acceptance criteria applicable to the inspection of aluminium alloy castings using 3D tomography. The goal is to create an objective, reliable, and automatable alternative to the current 2D-based methods.

Core study:

The paper details the first phase of a larger project: the development of an image-processing algorithm for the automatic detection of defects in individual 2D tomographic slices. This serves as the foundational step for subsequent 3D defect reconstruction and classification. The proposed methodological approach aims to segment indications, which will then be classified as either true defects or false alarms (artefacts) using pattern recognition techniques.

5. Research Methodology

Research Design:

The overall research is designed as a three-part process: (1) development of image-processing algorithms for automatic detection of casting defects in tomographic slices, (2) 3D reconstruction of the detected defects, and (3) automatic processing and measurement of features from the 3D defect volume to classify them and establish a 3D quality reference. This paper focuses specifically on the first part.

Data Collection and Analysis Methods:

The study employs a slice-by-slice image processing approach. The algorithm is based on edge-based segmentation and involves a sequence of operations:

1. Denoising: Using wavelet transformation to reduce noise.

2. Image Sharpening: To accentuate the edges of defects and geometric structures.

3. Segmentation (Thresholding): To create a binary image.

4. Emphasizing: Comparing the segmented and sharpened images to highlight the casting.

5. Segmentation (Edge Operator): Using a first-order derivative to find the contours of the casting and defects.

6. Dilation: To thicken the detected contours for clear visualization.

Research Topics and Scope:

The research is focused on the non-destructive testing of aluminium alloy castings. The scope of the work presented in this paper is the establishment of an edge-based segmentation technique for 2D tomographic slices as a precursor to full 3D analysis and criteria development.

6. Key Results:

Key Results:

- An edge-based segmentation technique was successfully established to highlight indications within a tomographic slice of an aluminium casting.

- The multi-step algorithm effectively processes the image to isolate defect contours from the part's main structure and background.

- The output of the algorithm provides segmented indications suitable for subsequent classification by a machine-learning algorithm to distinguish true defects from false alarms.

Figure Name List:

- Fig. 1. Proposed 2D Segmentation Approach.

- Fig. 2. Tomographic slice Segmentation using the proposed algorithm.

7. Conclusion:

An edge-based segmentation technique has been established to highlight indications in a tomographic slice of an aluminium casting. These indications will subsequently be tested by a machine-learning algorithm to determine their types (false or true alarms). Finally, the true alarms (defects) will be characterized in 2D and 3D to establish the acceptance criteria for tomography inspection of aluminium alloy castings.

8. References:

- [1] ASTM E155, Standard Reference Radiographs for Inspection of Aluminium and Magnesium Castings.

- [2] ASTM E505, Standard Reference Radiographs for Inspection of Aluminum and Magnesium Die Castings.

- [3] ASTM E2422, Standard Digital Reference Images for Inspection of Aluminium Castings.

- [4] ASTM E2973, Standard Digital Reference Images for Inspection of Aluminium and Magnesium Die Castings.

- [5] Cristina Stolojescu-Crisan, Holban StefanA Comparison of X-Ray Image Segmentation Techniques, 2013.

- [6] Survey of Image Denoising Techniques Mukesh C. MotwaniMukesh C. GadiyaRakhi C. Motwani.

- [7] C.A. Glasbey. An analysis of histogram-based thresholding algorithms. GMIP, 55(6), 199.

- [8] Edge Detection Techniques for Image Segmentation: A Survey of Soft Computing Approaches N. Senthilkumaran and R. Rajesh.

Expert Q&A: Your Top Questions Answered

Q1: What are the main technological obstacles that make CT inspection for production challenging?

A1: The paper identifies several key obstacles. First is the trade-off between resolution, speed, and cost; achieving the very fine resolution needed to detect small discontinuities over a large volume is often prohibitively slow and expensive for production lines. Second is the difficulty of penetrating dense or thick parts. Third, tomographic images often contain artefacts (like beam hardening or concentric rings) that must be corrected. Finally, the process of thresholding to create binary images for analysis is a delicate operation that can lead to incorrect results if not validated properly.

Q2: Why is a new set of 3D acceptance criteria needed? Why not just adapt the existing 2D ASTM standards?

A2: The existing 2D standards are based on projected images, which lack critical depth and location information. A defect's criticality is highly dependent on its 3D position—for example, whether it is in a low-stress core or near a high-stress surface. Tomography provides this precise 3D data, which cannot be evaluated against a 2D reference. Therefore, a completely new set of 3D criteria is required to leverage the superior information provided by CT scanning.

Q3: The paper describes a "slice-by-slice" processing approach. Why was this chosen over processing the entire 3D volume at once?

A3: The paper mentions that there are two ways to achieve the goal: processing the whole volume directly or taking a slower approach by processing each slice separately. The authors detail the slice-by-slice method, which breaks a complex 3D problem into a series of more manageable 2D problems. This is often done to simplify algorithm development and manage computational resources before scaling to a full 3D analysis.

Q4: What is the role of machine learning in this proposed methodology?

A4: The image segmentation algorithm described in the paper is the first step; it identifies all potential "indications." The next critical step, as mentioned in the abstract and conclusion, is to use a pre-trained machine-learning classifier. This classifier will analyze the features of each indication to automatically determine whether it is a real defect or a false alarm (an artefact from the scanning process), bringing automation and objectivity to the analysis.

Q5: What are the specific industrial objectives of this research project?

A5: The paper outlines three main industrial objectives. First, to help manufacturers transition from 2D radiographic criteria to 3D tomographic criteria. Second, to define a relevant and applicable quality reference for the production-line characterization of foundry parts by tomography. Third, to enhance non-destructive testing by reducing the rejection of safe parts and preventing the acceptance of parts with critical, undetected defects.

Conclusion: Paving the Way for Higher Quality and Productivity

The limitations of subjective, 2D-based inspection have long been a source of cost, risk, and inefficiency in the casting industry. This research represents a significant step toward a new paradigm of quality control based on objective, data-rich 3D Casting Inspection. By developing a robust algorithm to automatically detect defects, the authors are building the foundation for a system that can eliminate guesswork, enhance product integrity, and foster better collaboration between foundries and their customers.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Establishment of Acceptance Criteria for Tomography Inspection of Aluminium Alloy Castings" by "Abdel Rahman DAKAK, Pr. Valérie KAFTANDJIAN, Dr. Philippe DUVAUCHELLE, Mr. Patrick BOUVET".

Source: http://www.ndt.net/?id=24768

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.