Beyond Standard Simulation: A New Porosity Damage Model for Predicting Failure in Aluminum Die Castings

This technical summary is based on the academic paper "Modeling of Damage Behavior of Cast Aluminum Components Taking into Account Porosity Effects" by Dong-Zhi Sun, Andrea Ockewitz, Florence Andrieux, and Herbert Klamser, published in Proceedings of the 12th International Conference on Aluminium Alloys (2010).

Keywords

- Primary Keyword: Porosity Damage Model

- Secondary Keywords: Characterization, damage model, porosity, simulation, component tests, aluminum die casting, stress triaxiality, fracture strain

Executive Summary

- The Challenge: Standard simulation models often fail to accurately predict fracture in complex aluminum die-cast components because they neglect the critical, combined effects of inherent porosity and varying stress states.

- The Method: Researchers developed a novel "Bi-Failure" damage model that explicitly incorporates both stress triaxiality and initial porosity, validating it with extensive material tests and full-scale component simulations.

- The Key Breakthrough: The Bi-Failure model, when fed with porosity data mapped from casting simulations, successfully predicted component damage and load drop, showing vastly superior accuracy over the conventional Johnson-Cook model.

- The Bottom Line: For reliable performance prediction of aluminum die castings, it is essential to use an advanced porosity damage model that integrates manufacturing defects (porosity) with complex mechanical stress states.

The Challenge: Why This Research Matters for HPDC Professionals

Aluminum pressure die-cast components are essential for lightweighting in the automotive industry. However, their complex geometries, combined with an inhomogeneous microstructure and inherent porosity, create a high risk of fracture. Stress concentrations at notches and reduced fracture strain in porous regions make predicting component failure a significant engineering challenge.

A reliable analysis requires considering both the influence of the stress state (e.g., tension, shear, compression) on damage development and the large scatter of local material properties caused by the casting process. While coupling casting simulation with crash simulation is a promising approach, few investigations have successfully modeled the combined influences of porosity and loading type on the fracture behavior of these components. This gap leads to either over-engineered, heavy parts or an unacceptable risk of field failure.

The Approach: Unpacking the Methodology

To build a more predictive model, the researchers executed a multi-stage experimental and numerical investigation.

Method 1: Comprehensive Material Characterization

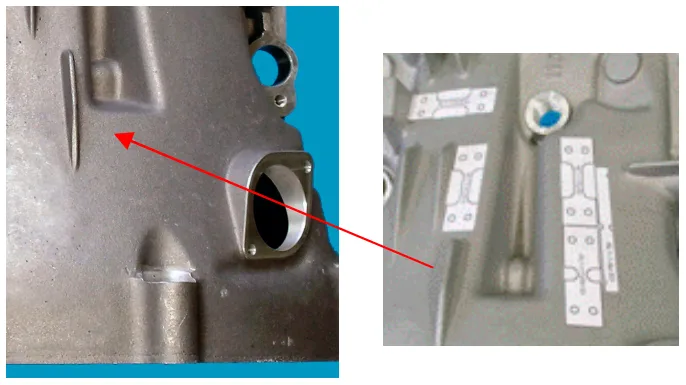

Small specimens were meticulously cut from various positions within an actual aluminum die-cast component (Fig. 1). These specimens were subjected to a range of tests—including tension, compression, and shear—to fully characterize the material's behavior under different loading conditions. This process determined the fundamental relationship between fracture strain and stress triaxiality (a measure of the stress state).

Method 2: Development of the "Bi-Failure" Porosity Damage Model

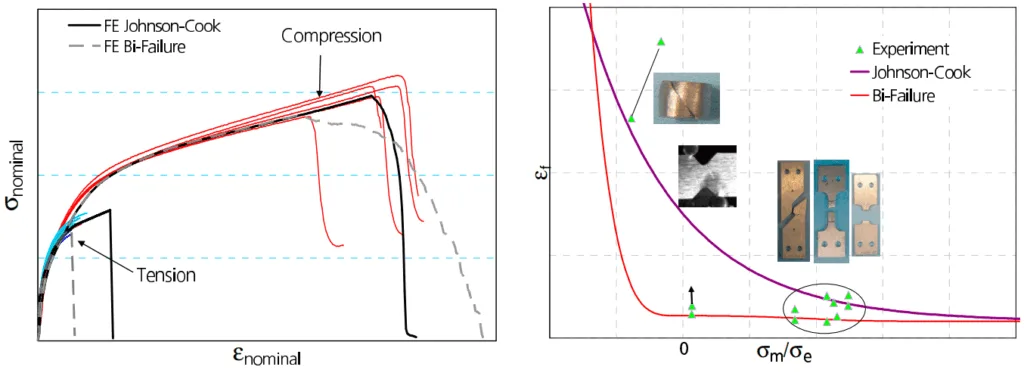

The core of the research was the development of a new damage model. Unlike the standard Johnson-Cook model, which assumes fracture strain decreases monotonically, the new "Bi-Failure" model divides the stress state into two distinct regions:

1. High Triaxiality (Tension-Dominated): Governed by dimple rupture, modeled using a Johnson-Cook type equation.

2. Low Triaxiality (Shear-Dominated): Governed by shear failure, modeled using an empirical polynomial that accounts for different failure strains in tension and compression.

Crucially, the model also incorporates the effect of initial porosity on both the material's yield stress (Eq. 4) and its fracture strain (Eq. 5), linking the manufacturing process directly to mechanical performance.

Method 3: Simulation and Component-Level Validation

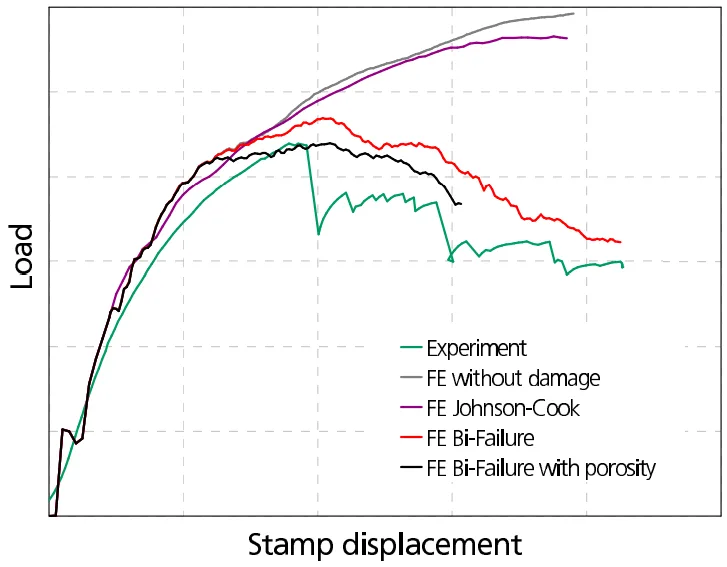

The new model was validated by performing static compression tests on the full aluminum component. The experimental load vs. displacement curves were then compared against several finite element simulations:

- A simulation with no damage model.

- A simulation using the standard Johnson-Cook damage model.

- A simulation using the new Bi-Failure model.

- A simulation using the Bi-Failure model with porosity distribution data mapped directly from a casting simulation.

The Breakthrough: Key Findings & Data

The component-level validation revealed critical differences between the simulation models, highlighting the superiority of the new approach.

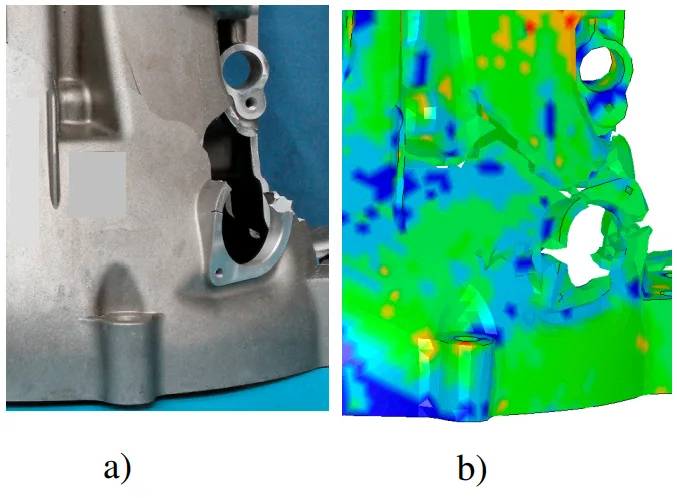

Finding 1: The Bi-Failure Model Accurately Predicts Damage Initiation

The component tests showed a distinct drop in load at a stamp displacement of 4 mm, indicating the onset of fracture. As shown in Figure 10, the simulation using the standard Johnson-Cook model (red line) completely failed to predict this load drop, behaving similarly to a simulation with no damage model at all. In contrast, the simulation with the Bi-Failure model (purple line) successfully captured the course of the load curve and predicted the damage-induced failure in a satisfactory way.

Finding 2: Integrating Porosity Data from Casting Simulation is Essential for Precision

While the Bi-Failure model alone was a significant improvement, the highest level of accuracy was achieved by integrating manufacturing data. As seen in Figure 10, the simulation that used the Bi-Failure model combined with porosity data mapped from a casting simulation (blue line) delivered the best agreement with the experimental results (green line). This confirms that linking the predicted porosity from the casting process to the structural simulation is a necessary step for a truly reliable component analysis. This is further supported by Figure 5, which shows experimentally and analytically that as porosity increases, both the flow stress and, more significantly, the fracture strain decrease.

Practical Implications for R&D and Operations

- For Process Engineers: This study demonstrates a quantifiable link between casting-induced porosity and final part failure. It suggests that adjusting casting parameters to minimize porosity in high-stress regions can directly improve component durability and reliability.

- For Quality Control Teams: The data in Figure 5 illustrates the significant effect of porosity on mechanical properties and their scatter. This supports the use of non-destructive methods like CT scanning, as mentioned in the paper, to map porosity and inform quality inspection criteria for critical components.

- For Design Engineers: The findings are a clear warning that relying on standard damage models like Johnson-Cook for aluminum die castings can lead to non-conservative and unsafe designs. The paper shows that adopting an advanced porosity damage model that accounts for both triaxiality and manufacturing defects is critical for accurate virtual prototyping and performance prediction.

Paper Details

Modeling of Damage Behavior of Cast Aluminum Components Taking into Account Porosity Effects

1. Overview:

- Title: Modeling of Damage Behavior of Cast Aluminum Components Taking into Account Porosity Effects

- Author: Dong-Zhi Sun¹, Andrea Ockewitz¹, Florence Andrieux¹, Herbert Klamser²

- Year of publication: 2010

- Journal/academic society of publication: Proceedings of the 12th International Conference on Aluminium Alloys, ©2010 The Japan Institute of Light Metals

- Keywords: Characterization, damage model, porosity, simulation, component tests.

2. Abstract:

The analysis of the damage behavior of cast components is very complex, since local mechanical properties in the components are inhomogeneous as a consequence of spatial distribution of microstructure e.g. pore and grain sizes, arm spacing of secondary dendrites. In this work the flow stress and fracture strain were determined for different positions in a die cast component. Tension, shear and compression tests on different specimens cut from the component were performed to determine the dependence of the fracture strain on stress triaxiality. A damage model was developed to take into account the influence of triaxiality and initial porosity on damage. Component tests and simulations were conducted to validate the numerical method. The distribution of porosity in the component calculated by casting simulation was transferred to the component simulation. It was found that material characterization under different loading types and damage modeling with consideration of the influence of triaxiality and porosity are necessary for a reliable component simulation.

3. Introduction:

Aluminum pressure die cast components are widely utilized in vehicle construction for their lightweight properties and economic benefits. However, their complex geometries, combined with inhomogeneous microstructure and porosity, lead to a higher risk of fracture. High stress and strain concentrations occur at notches, and areas with higher porosity exhibit significantly lower fracture strain. This inhomogeneity complicates the analysis of damage behavior. A meaningful approach is to couple casting simulation with crash simulation to consider the influence of the die-cast process on local properties. Previous work has shown that porosity distribution can be calculated and that it significantly reduces fracture strain in tension. While some models have been proposed to describe the influence of porosity and triaxiality, few comprehensive investigations exist. This work aims to characterize and model these effects for an aluminum die-cast component under various load types.

4. Summary of the study:

Background of the research topic:

The use of aluminum pressure die-cast components in vehicles is driven by lightweighting requirements. However, predicting their structural integrity is challenging due to process-induced inhomogeneities, such as porosity, which can act as fracture initiation sites and degrade local mechanical properties.

Status of previous research:

Previous studies have explored coupling casting and crash simulations [1], calculating the spatial distribution of microstructure and residual stresses [2], and modeling the influence of porosity and triaxiality. Some approaches have extended the Gurson-Model for shear regions [3] or used the Gologanu model with fracture criteria [4]. However, the paper notes a limited number of investigations that comprehensively characterize and model these combined effects for aluminum die-cast components.

Purpose of the study:

The study's purpose was to characterize the effects of stress triaxiality and porosity on the fracture behavior of an aluminum die-cast component. A further goal was to develop and validate a damage model that incorporates these effects to enable more reliable component simulations.

Core study:

The core of the study involved three main activities: 1) Experimental characterization of an aluminum die-cast alloy using specimens extracted from a component, tested under tension, compression, and shear to determine the fracture strain's dependence on stress triaxiality. 2) Development of a new "Bi-Failure" damage model that accounts for both triaxiality and the influence of initial porosity on yield stress and fracture strain. 3) Validation of the model through full-scale component tests and finite element simulations, comparing its predictive capability against the standard Johnson-Cook model and a simulation without a damage model.

5. Research Methodology

Research Design:

The research employed a combined experimental and numerical approach. Material properties were first determined experimentally from a real-world component. This data was then used to develop and parameterize a new phenomenological damage model. Finally, the model's validity was assessed by comparing numerical simulations of a component test with corresponding experimental results.

Data Collection and Analysis Methods:

Small specimens were cut from an aluminum die-cast component for mechanical testing under tension (smooth and notched), compression, and shear (modified Iosipescu and double-notched). Load-displacement data was recorded to derive true stress-strain curves. Fracture strains and corresponding triaxialities were determined by modeling the specimen tests. Porosity distribution was calculated via casting simulation and verified with CT scans. This porosity data was then mapped to the component's finite element model. Component-level compression tests provided load-displacement curves for final validation.

Research Topics and Scope:

The study focused on a single aluminum die-cast alloy and component. The research scope included the characterization of plastic flow and fracture behavior under quasi-static loading conditions with varying stress triaxialities (from compression to biaxial tension). The investigation modeled the influence of initial shrinkage porosity on mechanical properties and validated a new damage model ("Bi-Failure") for use in component-level finite element analysis.

6. Key Results:

Key Results:

- The aluminum die-cast alloy fails under both tension and compression, with fracture strains being significantly smaller in tension (Fig. 3).

- A new "Bi-Failure" damage model was developed, which defines fracture strain as a function of stress triaxiality (T). It uses separate functions for T > T_trans (Johnson-Cook type) and T < T_trans (polynomial for shear-dominated failure), allowing for asymmetry between tension and compression.

- The influence of porosity (f₀) on yield stress and uniaxial tensile fracture strain was successfully described by a Gurson-type relation (Eq. 4) and an empirical power-law relation (Eq. 5), respectively.

- Metallographic examination confirmed that specimens with lower fracture strains exhibited more pores and shrinkage cavities (Fig. 6).

- Component simulations demonstrated that the standard Johnson-Cook model significantly underestimates damage and cannot predict the load drop caused by fracture (Fig. 10).

- The Bi-Failure model provided a satisfactory prediction of the component's load-displacement curve, including the load drop.

- The highest accuracy in simulation was achieved when the Bi-Failure model was coupled with porosity data mapped from the casting simulation, showing the best agreement with experimental results (Fig. 10).

Figure Name List:

- Fig. 1: Aluminum die cast component and example for specimen extraction

- Fig. 2: Different specimens after tests

- Fig. 3: True stress vs. true strain curves of tension and compression specimens

- Fig. 4: Fracture strain vs. triaxiality from experiments and two damage models

- Fig. 5: Influence of porosity on flow stress and fracture strain

- Fig. 6: Fracture surface of a smooth flat specimen with different sizes of pores

- Fig. 7: Measured and calculated nominal stress vs. nominal strain curves under tension and compression

- Fig. 8: Calculated damage pattern of tension and compression specimens

- Fig. 9: Damage pattern in experiment a) and in simulation with Bi-Failure model b)

- Fig. 10: Measured and calculated load vs. stamp displacement curves of component tests

Fig. 4: Fracture strain vs. triaxiality from experiments and two damage models

7. Conclusion:

The deformation and damage behavior of an aluminum die-cast component was characterized, revealing a strong dependence of fracture strain on triaxiality and a large scatter in properties. A damage model was developed to account for the influence of both triaxiality and porosity. Component tests and simulations validated the approach, showing that a suitable damage model and the determination of its corresponding damage curve are essential for reliable prediction. The simulation that mapped porosity distribution from a casting simulation and used the Bi-Failure model provided the best agreement with experiments. The study concludes that further investigations are needed to improve the model, particularly concerning porosity's influence under shear, and to enhance the predictive capability of casting simulations for both shrinkage and gas porosity.

8. References:

- [1] C. Leppin, H. Hooputra, H. Werner, S. Weyer, R.V. Büchi, VIII International Conference on Computational Plasticity, COMPLAS VIII, E. Oñate and D. R. J. Owen (Eds), Ó CIMNE, Barcelona, 2005.

- [2] E. Flender, G. Hartmann, GIESSEREI 92 03/2005, 38-49.

- [3] K. Nahshon, J.W. Hutchinson, Euro. J. Mech. A/Solids, 2008, 27, 1-17.

- [4] F. Andrieux, D.-Z. Sun, to be published in International Journal of Materials Research.

- [5] G.R. Johnson, W.H. Cook, Engineering Fracture Mechanics, vol.21, No.1, 1985, pp.31-48.

- [6] A. Needleman, V. Tvergaard, J. Mech. Phys. Solids 35, 1987, S. 151-183.

- [7] M. Gologanu, J.B. Leblond, J. Devaux, J. Mech. Phys. Solids 41, 1993, S. 1723-1754.

Expert Q&A: Your Top Questions Answered

Q1: Why was a new "Bi-Failure" model necessary instead of simply adjusting the parameters of the existing Johnson-Cook model?

A1: The standard Johnson-Cook fracture criterion assumes that fracture strain decreases monotonically as stress triaxiality increases. However, the experimental characterization in this study showed that aluminum die-cast alloys also fail under shear and compression (low and negative triaxiality), where the fracture behavior is different. The "Bi-Failure" model was created to address this by dividing the triaxiality domain into two regions, allowing it to accurately model both dimple rupture at high triaxialities and shear-dominated failure at low triaxialities, which the Johnson-Cook model cannot do.

Q2: How was the porosity distribution determined and applied in the final, most accurate simulation?

A2: The spatial distribution of shrinkage porosity in the component was first predicted using a casting simulation performed by Fraunhofer IFAM. This numerical prediction was then verified by conducting CT scans on samples cut from several positions in the actual component. Because the finite element meshes for the casting and component simulations were different, the calculated porosity values were "mapped" from the casting model onto the component model, assigning a local porosity value to the elements for the structural simulation.

Q3: The paper mentions that the material fractures even under compression. How does the Bi-Failure model account for this?

A3: The fracture under compression is shown experimentally in Figure 3. The Bi-Failure model accounts for this through the third term in Equation (2), which is designed to create an asymmetry in the failure strain curve. This term, dshear3<−T>m3, is only active for negative triaxiality values (like compression, where T = -1/3). The parameter dshear3 is specifically calculated using the fracture strain measured under uniaxial compression, allowing the model to differentiate between failure in tension and compression.

Q4: What is "stress triaxiality" and why is it so critical for this type of damage modeling?

A4: Stress triaxiality is a dimensionless parameter defined as the ratio of the mean stress (hydrostatic pressure) to the von Mises effective stress. It describes the stress state of the material: a triaxiality of 1/3 corresponds to uniaxial tension, 0 corresponds to pure shear, and -1/3 corresponds to uniaxial compression. It is critical because the mechanism of material failure (e.g., void growth in tension vs. shear band formation) and the resulting fracture strain are highly dependent on this stress state. Any accurate damage model for ductile metals must account for triaxiality.

Q5: What were the main limitations or areas for future improvement identified in the study?

A5: The authors noted two key areas for improvement. First, there was no experimental data for fracture strain under pure shear (triaxiality = 0), so the model's behavior in that region was an interpolation that could only be checked via component simulations. Further investigation is needed to refine the model's prediction under different load conditions, especially shear. Second, the casting simulation could be improved to predict not only shrinkage pores but also gas pores for a more complete picture of total porosity.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of accurately predicting failure in aluminum die-castings stems from their inherent complexity and process-induced defects. This research demonstrates that conventional simulation methods are inadequate and can lead to unreliable designs. The key breakthrough is the development of a sophisticated Porosity Damage Model (the Bi-Failure model) that successfully integrates the effects of both complex stress states and manufacturing-induced porosity. By mapping porosity data from casting simulation to structural analysis, engineers can achieve a new level of predictive accuracy.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Modeling of Damage Behavior of Cast Aluminum Components Taking into Account Porosity Effects" by "Dong-Zhi Sun, Andrea Ockewitz, Florence Andrieux, Herbert Klamser".

Source: Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan, pp. 1302-1307

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.