Predicting Failure Before it Happens: A Breakthrough in Through-Process Modelling for HPDC Aluminum

This technical summary is based on the academic paper "Recent Developments in Through-Process Modelling of Aluminium Die-Castings" by Cato Dørum, Hans Ivar Laukli, Odd Sture Hopperstad, and Torodd Berstad, published in Proceedings of the 12th International Conference on Aluminium Alloys (2010).

Keywords

- Primary Keyword: Through-Process Modelling

- Secondary Keywords: HPDC, aluminium die-casting, fracture propagation, FE-analysis, mechanical properties, AlSi9MgMn alloy, Charpy test

Executive Summary

- The Challenge: High-Pressure Die-Casting (HPDC) components used in demanding automotive applications contain inherent defects that make predicting their structural performance under dynamic loads difficult and unreliable.

- The Method: Researchers developed a "through-process" model that links casting process simulations (which predict defect locations) to advanced finite element (FE) structural simulations to forecast fracture behavior.

- The Key Breakthrough: The study proved that for the common AlSi9MgMn alloy, complex dynamic behavior can be accurately predicted using simpler, quasi-static material data, validating a key assumption that significantly simplifies the modelling process.

- The Bottom Line: This validated modelling approach allows engineers to more accurately predict the real-world performance and failure points of HPDC components, leading to safer, more reliable, and better-optimized designs.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, every gram counts. HPDC aluminum alloys are essential for creating lightweight, complex components at a high production rate. However, these components must withstand dynamic loads, from road vibrations to crash impacts. The challenge is that the HPDC process itself introduces defects like porosity, oxide bifilms, and micro-segregations.

These defects act as potential failure points, creating uncertainty about the final component's strength and ductility. For engineers, this uncertainty is a major roadblock. How can you design a safety-critical part with confidence when its mechanical performance can vary significantly based on invisible, process-induced flaws? This research tackles that exact problem by creating a more robust and realistic way to simulate component behavior from manufacturing to failure.

The Approach: Unpacking the Methodology

To build and validate their predictive model, the researchers used a two-pronged approach combining rigorous physical testing with advanced numerical simulation.

Method 1: Experimental Characterization

The team first established a baseline for the material's real-world behavior. They used AlSi9MgMn, a workhorse alloy in the automotive sector, in both as-cast (T1) and heat-treated (T6) conditions.

- Uniaxial Tensile Tests: To understand the material's basic strength and hardening, 32 specimens were tested at various speeds (strain rates from 0.001 to 1 s⁻¹). This was done to check if the material behaved differently when pulled apart slowly versus quickly.

- Instrumented Charpy Tests: To understand fracture behavior under high-speed impact, specimens with a V-notch were struck by a heavy pendulum striker moving at 5.52 m/s. This test provides critical data on how much energy a material can absorb before and during fracture, mimicking a dynamic impact scenario.

Method 2: Through-Process FE Modelling

The physical test data was used to build and validate a sophisticated simulation framework.

- Virtual Casting: The process begins by simulating the mould filling and solidification of the component. This allows the model to predict where defects are most likely to form.

- Data Mapping: The predicted defect data is then mapped onto a 3D finite element (FE) mesh of the component. This creates a "digital twin" that isn't just a perfect shape but one that includes the material's internal flaws.

- Fracture Simulation: This enhanced model was then used to simulate the Charpy impact test. The simulation incorporated the Cockcroft-Latham fracture criterion, which predicts when and where the material will crack based on stress and strain, using a probabilistic approach to account for the random nature of defects.

The Breakthrough: Key Findings & Data

The research yielded two pivotal findings that have significant implications for the future of HPDC component design and analysis.

Finding 1: Strain-Rate Sensitivity is Negligible for AlSi9MgMn

A major question for any dynamic simulation is whether the material's properties change at high speeds. The tensile test results provided a clear answer.

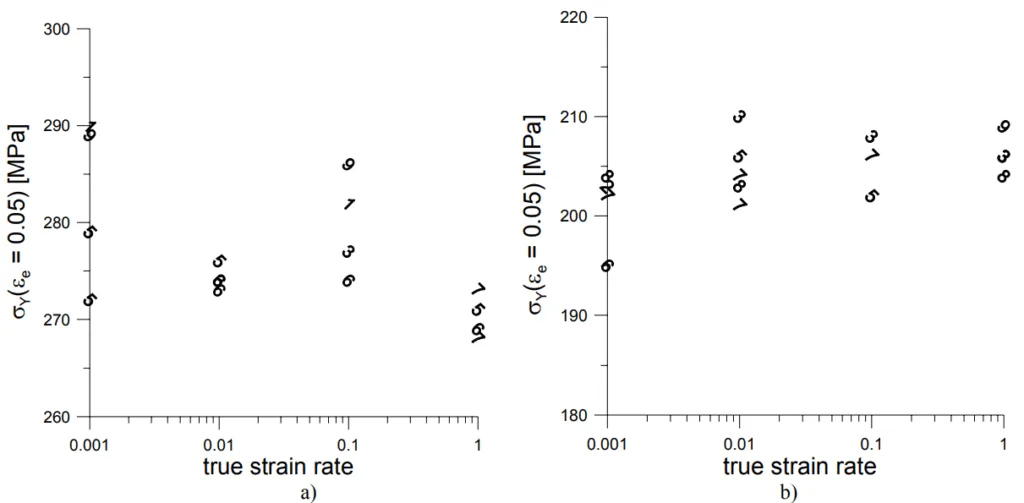

As shown in Figure 1, the stress required to deform the material at a plastic strain of 0.05 remained nearly constant across a wide range of strain rates (from 0.001 to 1 s⁻¹). This was true for both the T1 and T6 tempers. This finding is a crucial breakthrough because it confirms that engineers can use material data from simpler, slower, quasi-static tests to accurately model high-speed, dynamic events, saving significant time and resources in material characterization.

Finding 2: The Simulation Accurately Predicts Real-World Dynamic Fracture

The ultimate test of the model was whether it could replicate the results of the physical Charpy impact test. The comparison was a resounding success.

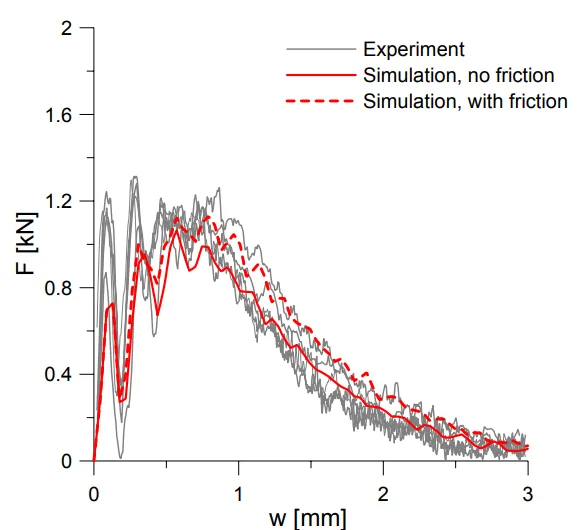

Figure 5 shows the force-displacement curves from the four experimental Charpy tests (the grey and blue lines) overlaid with the numerical simulation results. The simulation performed with a friction coefficient of 0.4 (the solid red line) closely tracks the experimental data, accurately capturing the peak force, the subsequent softening as the crack propagates, and the total energy absorbed. This validates the entire through-process modelling approach, proving its capability to predict fracture propagation under dynamic conditions.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting casting parameters to minimize the defects predicted by the initial simulation can directly improve the final part's structural performance and fracture resistance.

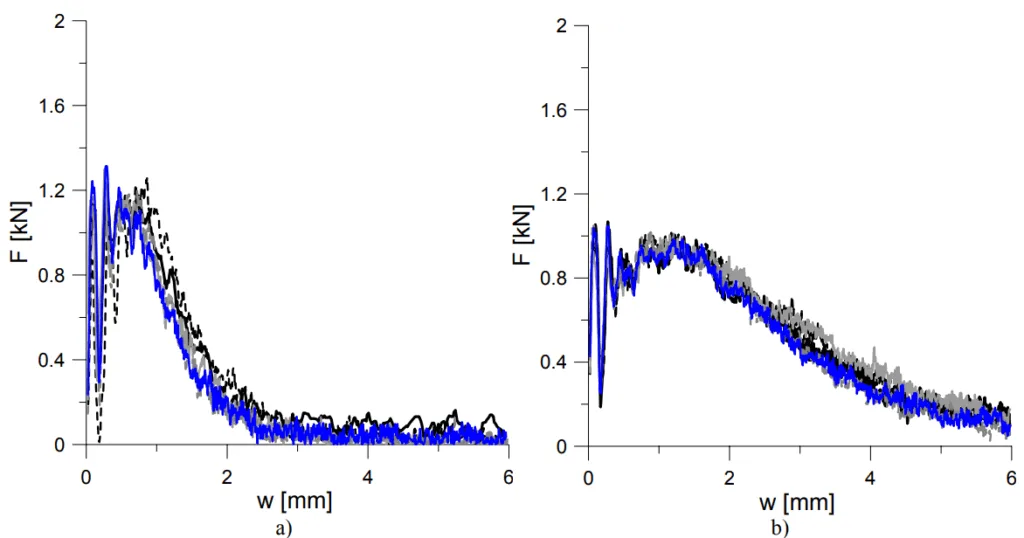

- For Quality Control Teams: The data in Figure 3 of the paper clearly illustrates the superior ductility and energy dissipation of the T6 temper compared to the T1. This quantitative data can inform new quality inspection criteria for components where impact resistance is a critical requirement.

- For Design Engineers: The findings indicate that designers can use this validated modelling approach in the early design phase. By simulating both the casting and subsequent loading, they can predict how component geometry might influence defect formation and use this insight to design more robust and reliable parts from the start.

Paper Details

Recent Developments in Through-Process Modelling of Aluminium Die-Castings

1. Overview:

- Title: Recent Developments in Through-Process Modelling of Aluminium Die-Castings

- Author: Cato Dørum, Hans Ivar Laukli, Odd Sture Hopperstad, Torodd Berstad

- Year of publication: 2010

- Journal/academic society of publication: Proceedings of the 12th International Conference on Aluminium Alloys, ©2010 The Japan Institute of Light Metals

- Keywords: mechanical properties, fracture, FE-analysis, through-process modelling, die-castings.

2. Abstract:

In the previous ICAA event held in Aachen in 2008, a novel through-process modelling approach for prediction of the structural behaviour of high-pressure die-cast (HPDC) aluminium alloys was outlined. The approach included identification of critical defects in the castings, virtual reproduction of the defects in numerical casting simulations of mould filling and solidification, and mapping of these data onto a shell-based finite element (FE) mesh for subsequent structural simulations of generic HPDC components. The recent developments have been focused on dynamic effects and fracture propagation. The strain-rate sensitivity of Al die-cast materials has been investigated. Further, instrumented Charpy tests have been carried out to provide a database for the fracture and crack propagation behaviour under dynamic conditions. The experimental results are here compared to numerical predictions using brick elements.

3. Introduction:

High-pressure die-casting (HPDC) aluminium alloys are of significant importance to the automotive industry for producing lightweight, near-net-shape components at a high production rate. There is a market demand for HPDC alloys with excellent castability and mechanical properties, suitable for joining with other components. HPDC components in vehicles must withstand dynamic loading, which necessitates a fundamental understanding of the factors controlling their deformation behaviour. Inherent defects from the HPDC process, such as macrosegregation, porosity, oxide bifilms, and confluence welds, can adversely affect mechanical performance. This work focuses on the AlSi9MgMn alloy in both T1 (as-cast) and T6 (heat-treated) conditions to address these challenges.

4. Summary of the study:

Background of the research topic:

The mechanical performance of HPDC aluminium components is often limited by process-inherent defects. Predicting the structural response, particularly under dynamic loading conditions relevant to the automotive sector, requires advanced modelling techniques that can account for these localized imperfections.

Status of previous research:

A prior study presented at ICAA in 2008 introduced a through-process modelling concept. This concept linked numerical simulations of casting (mould filling and solidification) to structural simulations by mapping predicted defect data onto an FE mesh. The present work represents a further development of this approach.

Purpose of the study:

The objective of this study was to extend the through-process modelling framework to incorporate dynamic effects and fracture propagation. This involved experimentally investigating the strain-rate sensitivity of the AlSi9MgMn alloy and using instrumented Charpy impact tests to create a validation database for fracture and crack propagation under dynamic loading.

Core study:

The study comprised two main parts: experimental work and numerical simulation. The experimental phase involved uniaxial tensile tests at strain rates from 0.001 to 1 s⁻¹ and instrumented Charpy V-notch impact tests on AlSi9MgMn alloy in T1 and T6 conditions. The numerical phase involved developing and validating a 3D FE model of the Charpy test using LS-DYNA. This model utilized a rate-independent plasticity law, calibrated from the tensile tests, and the Cockcroft-Latham fracture criterion with a Weibull distribution to simulate crack initiation and propagation.

5. Research Methodology

Research Design:

The research was designed as a combined experimental and numerical investigation. Experimental tests were conducted to characterize the material's mechanical and fracture properties under quasi-static and dynamic conditions. These experimental results were then used to calibrate material parameters for and validate the predictive capability of a finite element model.

Data Collection and Analysis Methods:

- Uniaxial Tensile Tests: Specimens (2.5 mm thickness) were machined from cast plates and tested at various strain rates. The resulting stress-strain data was used to determine work hardening parameters using a least squares method to fit a parametric equation (Eq. 1).

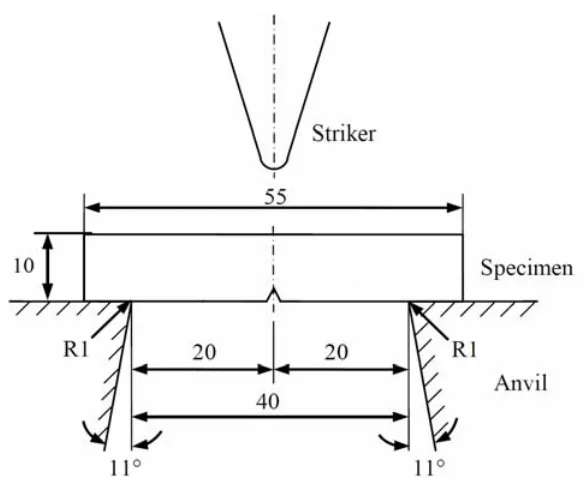

- Charpy Tests: An instrumented Charpy test set-up was used, with a 21.1 kg striker impacting V-notched specimens at 5.52 m/s. Force, time, displacement, and energy were measured and calculated.

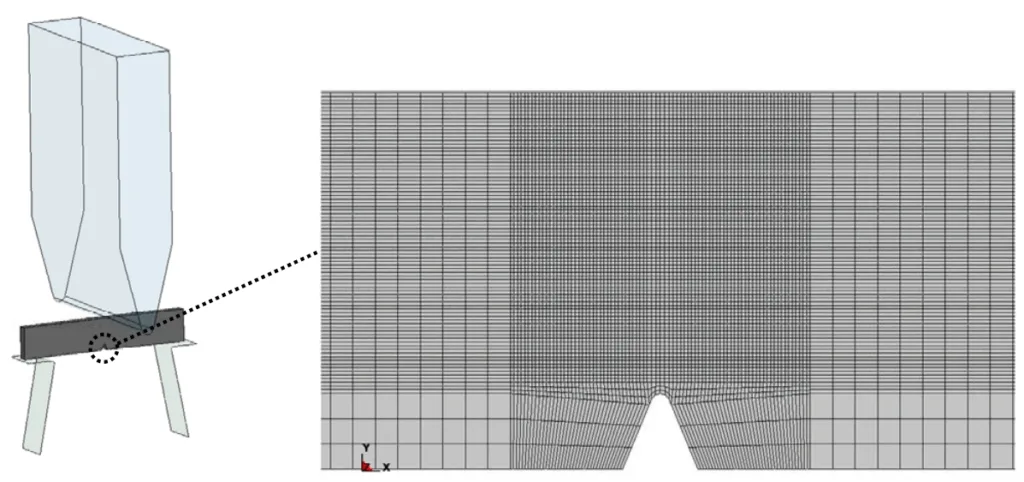

- Numerical Simulation: Simulations were performed using the explicit FE code LS-DYNA with a user-defined material model. The model employed J2-flow theory for plasticity and the Cockcroft-Latham criterion for fracture, implemented with a modified weakest-link Weibull distribution for stochastic fracture parameters. The model was meshed with 3D brick elements with characteristic lengths of approximately 0.1 mm.

Research Topics and Scope:

The research focused on the AlSi9MgMn high-pressure die-casting alloy in both T1 and T6 tempers. The scope included the investigation of strain-rate sensitivity, characterization of dynamic fracture behavior, and the development and validation of a through-process FE model for predicting fracture propagation.

6. Key Results:

Key Results:

- The strain-rate sensitivity of AlSi9MgMn in both T1 and T6 conditions was found to be negligible over the tested strain-rate range of 0.001 to 1 s⁻¹.

- The T6 heat-treated material exhibited significantly higher ductility and dissipated more energy during Charpy impact tests compared to the T1 as-cast material, which showed a higher peak force level.

- Numerical simulations of the Charpy test for the T1 material, using material parameters calibrated from quasi-static tests, showed good correlation with the experimental force-displacement curves.

- The accuracy of the numerical predictions was found to be highly dependent on the FE mesh size and the assumed friction coefficient between the specimen and the test rig anvils. A friction coefficient of 0.4 provided the best match to experimental data.

- The maximum strain rate observed during the simulated fracture propagation was approximately 400 s⁻¹.

Figure Name List:

- Fig. 1. Plots of the Cauchy stress at 0.05 equivalent plastic strain from uniaxial tests at different strain rates for a) AlSi9MgMn – T1 and b) AlSi9MgMn – T6.

- Fig. 2. Schematic drawing of the instrumented Charpy V-notch impact test set-up.

- Fig. 3. Plots of the force-displacement measurements from Charpy tests of a) AlSi9MgMn–T1 and b) AlSi9MgMn-T6.

- Fig. 4. FE model – 3D brick element mesh.

- Fig. 5. Comparison between experimental and numerical simulations of the Charpy test for AlSi9MgMn-T1 using a mesh with element lengths of approximately 0.1 mm.

7. Conclusion:

Strain-rate sensitivity studies on HPDC AlSi9MgMn alloy in T1 and T6 conditions demonstrated that this effect is negligible. Instrumented Charpy tests showed that the increased ductility of the T6 temper resulted in a significant increase in dissipated energy. Numerical simulations of the Charpy test for the T1 material, with parameters calibrated from quasi-static tests, provided good correlation with experimental results. This supports the assumption that strain-rate sensitivity can be neglected for modelling the dynamic behavior of this alloy. It is noted, however, that the numerical results are very dependent on mesh size and the friction model used.

8. References:

- [1] C.M. Gourlay, H.I. Laukli, A.K. Dahle, Met.& Mat. Trans.A, 2007, 38A, 1833-1844.

- [2] H.I. Laukli, C.M. Gourlay, A.K. Dahle, Met.& Mat. Trans.A, 2005, 36A, 805-818.

- [3] J. Campbell, Materials Science & Technology, 1988, 4, 194-204.

- [4] C. Dørum, H.I. Laukli, O.S Hopperstad. Through-process numerical simulations of the structural behaviour of Al–Si die-castings. Computational Materials Science 46 (2009) 100-111. ISSN: 0927-0256.

- [5] LS-DYNA Keyword User's Manual, Version 971, Livermore Software Technology Corporation, May 2007.

- [6] M.G. Cockcroft, D.J. Latham. Ductility and the workability of metals, J. Inst. Metals 96, (1968) pp. 33-39.

- [7] W. Weibull. A statistical distribution function of wide applicability, J. Appl. Mech. 18 (1951), pp. 293-297.

- [8] C. Dørum, O.S. Hopperstad, T. Berstad, D. Dispinar. Numerical modelling of magnesium die-castings using stochastic fracture parameters. Engineering Fracture Mechanics 76 (2009) 2232-2248.

- [9] Y. Chen, O.S. Hopperstad, A.H. Clausen, T. Børvik, T. Berstad. Finite element analysis of Charpy tests on extruded aluminium alloys. 9th Int. DYMAT conference Sept. 2009, Belgium.

Expert Q&A: Your Top Questions Answered

Q1: Why was it important to investigate strain-rate sensitivity?

A1: Many HPDC components, especially in automotive applications, are subjected to dynamic loads like impacts or crashes. Material properties can change dramatically at high deformation speeds (high strain rates). The study investigated this to determine if a complex, rate-dependent material model was necessary. Finding the sensitivity to be negligible was a key result, as it allows for the use of simpler, more efficient rate-independent models for simulating dynamic events.

Q2: What is the "through-process modelling" concept in simple terms?

A2: It is a holistic simulation strategy that connects the manufacturing process to the final product's performance. Instead of simulating a component as a perfect, homogenous material, this approach first simulates the casting process to predict the location and severity of defects. This "as-manufactured" information is then fed into the structural simulation, providing a much more realistic prediction of how the component will actually behave under stress.

Q3: The paper mentions the simulation is sensitive to mesh size and friction. What does this mean for engineers using this method?

A3: It means that careful model setup and calibration are critical for achieving accurate results. The "mesh size" refers to the level of detail in the FE model; a finer mesh (like the 0.1 mm used) is needed to accurately capture crack propagation. The "friction" between the component and its supports (the anvils in the Charpy test) significantly affects how load is transferred. As seen in Figure 5, the simulation with a realistic friction coefficient (0.4) was far more accurate than the frictionless one, highlighting the need to validate these modelling parameters against physical test data.

Q4: Why was the Cockcroft-Latham criterion chosen for modelling fracture?

A4: The Cockcroft-Latham criterion is a well-established model that links fracture to an accumulation of "damage" based on the history of tensile stress and plastic strain. It is effective for predicting ductile fracture in metals. A key advantage noted in the paper is that it is based on a single parameter (Wc), which can be calibrated from a single type of material test, simplifying the characterization process compared to more complex multi-parameter fracture models.

Q5: What is the practical difference between the T1 and T6 conditions highlighted by the Charpy tests?

A5: The Charpy tests (Figure 3) show that the T6 heat-treated material has significantly better ductility and absorbs more energy before failing. While the T1 (as-cast) material can withstand a slightly higher peak force, it fractures with much less deformation. For a safety-critical component that needs to deform and absorb energy during an impact rather than shattering, the T6 condition is far superior. This data provides engineers with quantitative evidence to justify the additional cost and time of heat treatment for demanding applications.

Conclusion: Paving the Way for Higher Quality and Productivity

Predicting the failure of HPDC components has long been a challenge due to the inherent, process-induced defects that define their microstructure. This research demonstrates a powerful solution through a validated Through-Process Modelling approach. By linking the virtual world of casting simulation with the physical reality of structural performance, this method provides a far more accurate way to forecast fracture and failure under dynamic loads.

The key takeaway is that by using this sophisticated, validated simulation technique, engineers can design better, safer, and more reliable components. This approach moves beyond assuming a perfect material and instead embraces the reality of the as-manufactured part, enabling optimization that was previously impossible.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Recent Developments in Through-Process Modelling of Aluminium Die-Castings" by "Cato Dørum, Hans Ivar Laukli, Odd Sture Hopperstad, Torodd Berstad".

Source: The paper was published in the Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan, pp. 681-686.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.