Precision Reinforcement: A Breakthrough in Electromagnetic Casting for High-Wear Components

This technical summary is based on the academic paper "Model of Casting Process of Composites Reinforced Locally at Inner Wall of Bush in Electromagnetic Field" by Sławomir Golak, published in Composites Theory and Practice (2013).

Keywords

- Primary Keyword: Electromagnetic Casting

- Secondary Keywords: Metal Matrix Composites (MMCs), Functionally Graded Materials, Local Reinforcement, Centrifugal Casting Alternative, Magnetohydrodynamics

Executive Summary

- The Challenge: Conventional casting methods like centrifugal casting struggle to reinforce the inner surfaces of components like bushes and bearings, especially when the reinforcement material is denser than the matrix.

- The Method: The study models a novel process using an internal electromagnetic inductor to generate a force that pushes reinforcement particles toward the inner wall of a cylindrical casting.

- The Key Breakthrough: Adding conductive elements to the mold and matching the inductor height to the charge height eliminates disruptive melt flow, enabling the formation of a highly uniform reinforced layer, even with fine particles.

- The Bottom Line: This electromagnetic casting technique provides a viable and precise method for manufacturing metal matrix composites with superior inner-surface properties, opening new possibilities for high-performance engineering components.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive, aerospace, and engineering industries, there is a constant demand for components that are lighter, more durable, and offer superior performance. Metal matrix composites (MMCs), particularly those with strategically placed reinforcement, are a key solution. For components like engine cylinders, plain bearings, and tubes, the highest wear occurs on the inner surface. Therefore, concentrating reinforcement particles like Silicon Carbide (SiC) in this area is highly desirable.

However, established manufacturing methods face significant limitations. Centrifugal casting, a popular technique, uses rotational force to segregate materials. If the reinforcement particles are denser than the metal matrix (e.g., SiC in aluminum), they are forced to the outer wall, not the inner one. This makes it impossible to achieve the desired inner-surface reinforcement for most common material combinations. This research directly addresses this critical manufacturing gap by exploring an alternative physical force: electromagnetic buoyancy.

The Approach: Unpacking the Methodology

The study proposes and models a casting process that uses an internal inductor placed inside the channel of a cylindrical mold. This setup is designed to produce a bush from AK12 aluminum alloy reinforced with SiC particles.

Here’s how it works:

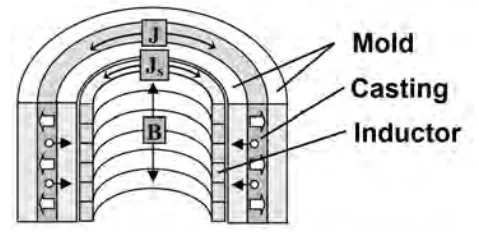

1. An alternating current is passed through the internal inductor, generating an alternating electromagnetic field.

2. This field induces eddy currents within the molten AK12 aluminum alloy.

3. The interaction between the eddy currents and the magnetic field creates a powerful Lorentz force, which pushes the molten metal matrix outward, toward the outer wall of the bush.

4. This action creates an opposite "electromagnetic buoyancy" force that acts on the non-conductive SiC particles, pushing them inward toward the inner wall.

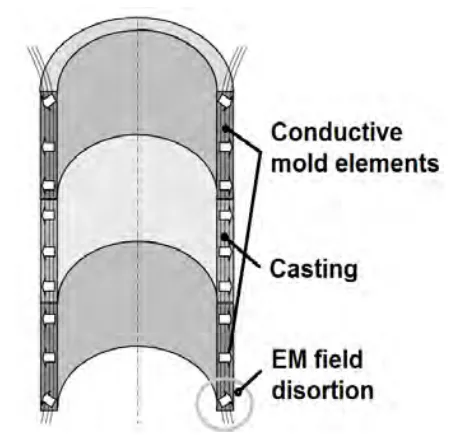

A key challenge identified was that in a real-world, finite-length casting, the electromagnetic field becomes distorted at the ends. This distortion creates strong, undesirable stirring in the molten metal, which prevents the particles from settling uniformly. To counteract this, the researchers modeled the addition of conductive elements to the mold, effectively extending the casting's length from an electromagnetic perspective and creating a more uniform force field. The entire process was simulated using Ansys Fluent software, coupling electromagnetic, fluid dynamics, and particle movement models.

The Breakthrough: Key Findings & Data

The simulations revealed critical parameters for successfully implementing this technique and demonstrated its superiority over a basic setup.

Finding 1: Conductive Elements are Essential for a Uniform Force Field

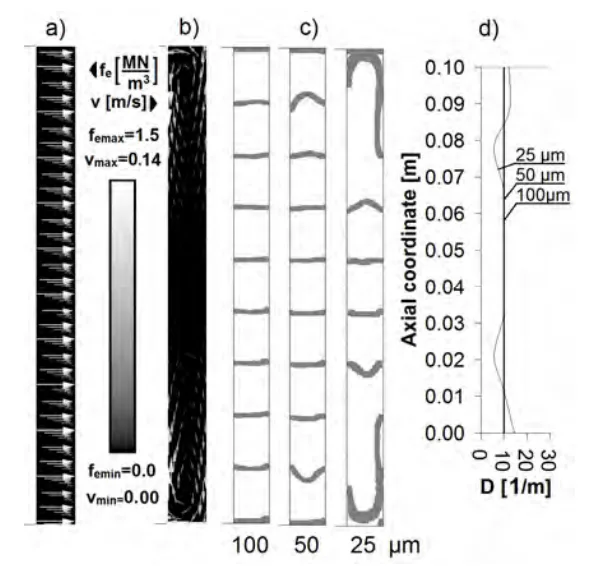

Without any modification, the electromagnetic field in the casting is highly non-uniform, causing intense stirring of the molten metal (Vmax=0.84 m/s). This flow is so strong that it prevents smaller particles from reaching their target. The study found that adding conductive elements to the mold and, crucially, making them the same height as the inductor, creates a nearly uniform force field. As shown in the comparison between Figure 5a and Figure 7a, this addition dramatically calms the melt flow (Vmax reduced to 0.02 m/s), creating ideal conditions for particle segregation.

Finding 2: Uniform Reinforcement is Achievable for All Particle Sizes

The effectiveness of the process is directly linked to the uniformity of the force field.

- Without Conductive Elements: The intense melt flow severely distorted the particle trajectories. As seen in Figure 5, only the largest particles (100 µm) managed to reach the inner wall, resulting in a highly non-uniform reinforced layer concentrated at the ends of the bush. Smaller particles (25 and 50 µm) were swept away by the flow.

- With Full-Height Conductive Elements: The stabilized melt flow allowed particles of all tested sizes (25, 50, and 100 µm) to travel almost undisturbed to the inner wall. Figure 7 shows that this configuration produces a consistent, uniform distribution of reinforcement along the entire length of the inner wall, a significant improvement that makes the process viable for a wider range of reinforcement materials.

Practical Implications for R&D and Operations

The findings from this paper provide actionable insights for teams working on advanced material manufacturing.

For Process Engineers: This study suggests that when implementing electromagnetic casting for internal reinforcement, the use of conductive elements is not optional—it is critical for success. Ensuring the inductor height matches the total charge (cast + elements) height is a key parameter for minimizing melt turbulence and achieving a predictable, uniform reinforced layer.

For Quality Control Teams: The data in Figures 5d, 6d, and 7d, which show the linear distribution of reinforcement, could inform new quality inspection criteria for functionally graded composites. The dramatic difference in particle trajectories highlights how sensitive the final microstructure is to the process setup, emphasizing the need for tight process control.

For Design Engineers: The findings indicate that it is now feasible to design components with selectively reinforced inner surfaces for extreme wear resistance, while the bulk of the component remains a standard, lighter alloy. This opens the door to creating more efficient, durable, and lightweight parts for demanding applications like bearings and cylinder liners.

Paper Details

MODEL OF CASTING PROCESS OF COMPOSITES REINFORCED LOCALLY AT INNER WALL OF BUSH IN ELECTROMAGNETIC FIELD

1. Overview:

- Title: MODEL OF CASTING PROCESS OF COMPOSITES REINFORCED LOCALLY AT INNER WALL OF BUSH IN ELECTROMAGNETIC FIELD

- Author: Sławomir Golak

- Year of publication: 2013

- Journal/academic society of publication: COMPOSITES THEORY AND PRACTICE / Polish Society of Composite Materials

- Keywords: electromagnetic buoyancy, magnetohydrodynamics, functionally graded materials, metal matrix composites

2. Abstract:

The methods of manufacturing composites with spatial variation in the reinforcement distribution which exploit reinforcement segregation in the liquid matrix are among the most effective ones. However, methods based on density differences such as gravitational casting and centrifugal casting have their limitations in the range of reinforcement configurations that are possible to obtain. An alternative is to exploit the phenomenon of electromagnetic buoyancy occurring in situations where the particles and the matrix have different electric conductivities. This paper presents some possibilities of exploiting this phenomenon to obtain the local reinforcement of a bush made of aluminum alloy AK12 with SiC particles at its inner wall. The paper discusses the model of such a process and the effect of its parameters on the trajectories of the particles moving in the molten matrix.

3. Introduction:

Metal matrix composites with non-uniform reinforcement distribution are utilized in automotive, aerospace, and engineering industries due to the ability to control spatial properties like hardness and thermal conductivity. Casting techniques that use physical forces to move reinforcement particles in a liquid matrix are among the most effective manufacturing methods. Techniques based on density differences, such as gravitational and centrifugal casting, are popular but limited. Specifically, for light metal matrix composites, achieving a higher concentration of reinforcement at the inner surfaces of cylindrical components is often impossible with centrifugal casting, as denser particles move outward. This study explores an alternative method to address this limitation.

4. Summary of the study:

Background of the research topic:

The research addresses the manufacturing of functionally graded materials (FGMs), specifically metal matrix composites (MMCs), where the spatial distribution of reinforcement is deliberately controlled to achieve tailored properties. The focus is on casting methods that induce reinforcement segregation in the liquid matrix.

Status of previous research:

Previous work has explored electromagnetic buoyancy for creating FGMs. Xu [7] used a forced current in a static magnetic field. Taniguchi et al. [14] used a high-frequency electromagnetic field from an external inductor to push particles inward, but the high frequency limited the reinforced layer to a few micrometers. A modification using a low-frequency field allowed for a thicker reinforced layer at the outer wall [15]. However, a method for achieving significant local reinforcement at the inner wall of a cast using a low-frequency field remained an area for investigation.

Purpose of the study:

The purpose of this paper is to present and analyze a model of a casting process that utilizes an internal inductor to generate an electromagnetic field, with the goal of obtaining local reinforcement with SiC particles at the inner wall of a bush made of aluminum alloy AK12. The study aims to investigate the process parameters and their effect on the trajectories of reinforcement particles within the molten matrix.

Core study:

The core of the study is a numerical model of the casting process. The model investigates the phenomenon of electromagnetic field distortion that occurs at the ends of a finite-length casting. This distortion generates a non-uniform Lorentz force field, which in turn induces vorticity (stirring) in the molten metal, disrupting the desired segregation of reinforcement particles. The paper proposes a solution involving the addition of conductive elements to the mold to homogenize the electromagnetic force field, thereby suppressing the undesirable fluid flow. The study simulates and compares the trajectories of SiC particles (25, 50, and 100 µm) in an AK12 aluminum alloy matrix under three conditions: without conductive elements, with conductive elements at half the cast height, and with conductive elements at the full cast height.

5. Research Methodology

Research Design:

The study employed a numerical simulation approach to model the casting process. The model was developed to analyze the coupled phenomena of electromagnetism, fluid dynamics, and particle mechanics.

Data Collection and Analysis Methods:

The analysis was based on solving Maxwell's equations for the electromagnetic field, the Navier-Stokes equations for the fluid flow of the molten matrix, and a force balance equation (including Stokes drag and electromagnetic forces) for the particle trajectories. The commercial software application Ansys Fluent was used to perform the calculations. An optimization criterion (Eq. 13), representing the ratio of the curl of the force field to the total desired force, was used to assess field uniformity without requiring full hydrodynamic simulations for every parameter set.

Research Topics and Scope:

The research was conducted on a specific case: a bush made of aluminum alloy AK12 with an outer diameter of 100 mm, length of 100 mm, and wall thickness of 8 mm, reinforced with SiC particles. The inductor had an outer diameter of 62 mm and was supplied with a frequency of 1000 Hz. The study investigated the influence of the height of the inductor and the height of conductive mold elements on the uniformity of the electromagnetic field and the resulting trajectories of reinforcement particles with diameters of 25, 50, and 100 µm.

6. Key Results:

Key Results:

- In a finite-length cast without modifications, the electromagnetic field is significantly distorted at the ends, creating a non-uniform force distribution that induces strong vorticity in the molten metal.

- The addition of conductive elements to the mold, which electromagnetically extend the length of the cast, is an effective method to homogenize the force field and suppress this unwanted melt flow.

- Analysis showed that optimal field uniformity is achieved when the height of the inductor is equal to the height of the charge (the cast plus the conductive elements).

- Without conductive elements, the melt flow is intense, and only the largest (100 µm) particles reach the inner wall, leading to a highly non-uniform reinforcement distribution.

- In the system with conductive elements equal in height to the cast, the melt flow is minimal. This allows particles of all tested sizes (25, 50, and 100 µm) to reach the inner wall with nearly straight trajectories, resulting in a uniform linear distribution of reinforcement.

- Achieving a homogenous electromagnetic field via conductive elements comes at the cost of significantly increased power consumption and power loss (Table 1).

Figure Name List:

- Fig. 1. Schematic diagram of process: B induction, Js - source current of inductor supply, J - eddy currents in casting, white arrows - Lorentz force, black arrows - electromagnetic buoyancy

- Rys. 1. Schemat procesu: B indukcja, Js prąd źródłowy wzbudnika, J - prądy wirowe w odlewie, białe strzałki - siła Lorentza, czarne strzałki - wypór elektromagnetyczny

- Fig. 2. Distortion of electromagnetic field in casting of finite length: thin lines - magnetic field lines, white arrows - Lorentz force, black arrows - flow of metal

- Rys. 2. Zburzenie pola elektromagnetycznego w odlewie skończonej długości: cienkie linie - linie pola magnetycznego, białe strzałki - siła Lorentza, czarne strzałki - przepływ metalu

- Fig. 3. Moving electromagnetic field distortion away from cast by conductive elements of mold. Non-conductive parts of mold are not shown

- Rys. 3. Wyprowadzenie zaburzenia pola elektromagnetycznego z odlewy przez przewodzące elementy formy. Nieprzewodzące elementy formy zostały pominięte

- Fig. 4. Dependence of field uniformity measure on height of inductor and the height of charge

- Rys. 4. Zależność miary jednorodności pola od wysokości wzbudnika i wsadu

- Fig. 5. Casting system without conductive elements: a) distribution of electromagnetic force field, b) structure of matrix flow, c) trajectories of representative particles, d) linear reinforcement distribution on inner wall

- Rys. 5. Układ odlewniczy bez elementów przewodzących: a) rozkład pola sił elektromagnetycznych, b) struktura przepływów osnowy, c) trajektorie reprezentatywnych cząstek, d) liniowy rozkład zbrojenia przy wewnętrznej ścianie

- Fig. 6. Casting system with conductive elements of height equal to half height of cast: a) distribution of electromagnetic force field, b) structure of matrix flow, c) trajectories of representative particles, d) linear reinforcement distribution on inner wall

- Rys. 6. Układ odlewniczy z elementami przewodzącymi o połowie wysokości odlewu: a) rozkład pola sił elektromagnetycznych, b) struktura przepływów osnowy, c) trajektorie reprezentatywnych cząstek, d) liniowy rozkład zbrojenia przy wewnętrznej ścianie

- Fig. 7. Casting system with conductive elements of height equal to height of cast: a) distribution of electromagnetic force field, b) structure of matrix flow, c) trajectories of representative particles, d) linear reinforcement distribution on inner wall

- Rys. 7. Układ odlewniczy z elementami przewodzącymi wysokości odlewu: a) rozkład pola sił elektromagnetycznych, b) struktura przepływów osnowy, c) trajektorie reprezentatywnych cząstek, d) liniowy rozkład zbrojenia przy wewnętrznej ścianie

7. Conclusion:

The presented model and simulations confirm that it is possible to obtain local reinforcement at the inner wall of a cylindrical bush by exposure to an alternating electromagnetic field generated by an internal inductor. The analysis proved that the size of the inductor and the conductive elements of the mold must be selected appropriately. The use of conductive elements to move the field distortion away from the liquid metal is a critical step in achieving a uniform reinforcement distribution, particularly for smaller particles. A regular inductor was found to be sufficient. The presented solution is an interesting alternative to other production methods for locally reinforced MMCs, but it is limited to castings whose geometry allows for their inner channels to be electromagnetically extended by such conductive elements.

8. References:

- [1] Dolata-Grosz A., Śleziona J., Wieczorek J., Dyzia M., Layered structure of AK12-Al2O3 and AK12-SiC composites formed by the centrifugal casting, Kompozyty (Composites) 2002, 5(2), 305-308.

- [2] Dolata-Grosz A, Śleziona J., Wieczorek J., Pietrzak K., Production and forming of structure aluminium composites with assumption a distribution of reinforcement, Kompozyty (Composites) 2003, 6(3), 125-130.

- [3] Drenchev L., Sobczak J., Malinov S. and Sha W., Numerical simulation of macrostructure formation in centrifugal casting of particle reinforced metal matrix composites. Part 1: model description, Modelling Simul. Mater. Sci. Eng. 2003, 11, 635-649.

- [4] Duleba A., Cholewa M., Morphology and segregation reinforced phase in AlSi-CrFe composite cast, Kompozyty (Composites) 2010, 10(3), 200-205.

- [5] Dolata-Grosz A., Wieczorek J., Śleziona J., Myalski J., Tribological properties of heterophase composite obtained by centrifugal casting, Kompozyty (Composites) 2007, 7 (1), 46-50.

- [6] Drenchev L., Sobczak J., Malinov S. and Sha W., Numerical simulation of macrostructure formation in centrifugal casting of particle reinforced metal matrix composites. Part 2: simulations and practical applications, Modelling Simul. Mater. Sci. Eng. 2003, 11, 651-674.

- [7] Xu Z., Li T., Zhou Y., An in situ surface composite produced by electromagnetic force, Materials Research Bulletin 2000, 35(14-15), 2331-2336.

- [8] Xu Z., Li T., Zhou Y., Application of electromagnetic separation of phases in alloy melt to produce in-situ surface and functionally gradient composites, Metallurgical and Materials Transactions A 2003, 34A, 1719-1725.

- [9] Song C., Xu Z., Li J., Fabrication of in situ Al/Mg2Si functionally gradient materials by electromagnetic separation method, Composites: Part A 2007, 38 (2), 427-433.

- [10] Song C., Xu Z., Li J., Structure of in situ Al/Si functionally graded materials by electromagnetic separation method, Materials and Design 2007, 28 (3), 1012-1015.

- [11] Drenchev L., Sobczak J., Formation of Graded Structures and Properties in Metal Matrix Composites by use of Electromagnetic Field, Foundry Research Institute 2010.

- [12] Cholewa M., Formanek B., Duleba A., Stawarz M., Aluminium composites casting in rotating magnetic field, Archives of Foundry Engineering 2008, 8(1), 155-162.

- [13] Duleba A., Cholewa M., Segregation reinforced phase in AlSi/CrxCy composite produced under electromagnetic field, Kompozyty (Composites) 2011, 11(3) 317-323.

- [14] Takahashi K., Taniguchi S., Fabrication of aluminium-matrix composites locally reinforced with SiC particles by using electromagnetic force, Journal of Japan Institute of Light Metals 2005, 55(10), 483-488.

- [15] Golak S., Przylucki R., Homogenization of electromagnetic force field during casting of functionally graded composites, IEEE Transactions on Magnetics 2011, 47 (12), 4701--4706.

- [16] Leenov D., Kolin A., Theory of electromagnetophoresis. I. Magnetohydrodynamic forces experienced by spherical and symmetrically oriented cylindrical particles, Journal of Chemical Physics 1954, 22(4), 684-688.

- [17] Golak S., The influence of the supply parameters on the reinforcement distribution in a composite cast in the electromagnetic field, Przegląd Elektrotechniczny 2013, 89(2b), 335-338.

Expert Q&A: Your Top Questions Answered

Q1: Why was an internal inductor used in this study instead of an external one, which has been used in other research?

A1: An internal inductor was chosen specifically to achieve reinforcement at the inner wall of the bush. An external inductor generates a Lorentz force that squeezes the molten metal inward, which in turn pushes non-conductive particles outward. An internal inductor does the opposite: it creates a Lorentz force that pushes the metal outward, causing the non-conductive particles to move inward via electromagnetic buoyancy. This is the key to solving the problem that centrifugal casting cannot address.

Q2: What is the primary cause of non-uniform reinforcement in this process, and what is the specific solution?

A2: The primary cause is the natural distortion of the electromagnetic field at the physical ends of the casting. This creates a non-uniform force field that causes the liquid metal to stir vigorously. The solution presented in the paper is to add conductive elements (e.g., rings made of the same material) to the mold, above and below the casting. These elements "extend" the electromagnetic field, pushing the distorted regions away from the molten composite and creating a calm, uniform force field within the casting itself.

Q3: The paper emphasizes that particle size is a critical factor. Why are smaller particles more challenging to control?

A3: According to the physics described (Dependence 14), the velocity of a particle under the electromagnetic force is quadratically dependent on its diameter (vₚ ~ d²). This means smaller particles move much more slowly. Because they take longer to travel to the inner wall, they are far more susceptible to being carried away by any unwanted flow in the molten metal. Therefore, achieving a very calm melt pool by homogenizing the electromagnetic field is absolutely essential for successfully segregating smaller reinforcement particles.

Q4: What is the main trade-off for achieving a more uniform electromagnetic field using conductive elements?

A4: The main trade-off is a significant increase in energy consumption. As shown in Table 1, to achieve the same average radial force on the casting, the required supply power increases dramatically as conductive elements are added and their height is increased. This is because a large portion of the energy is dissipated as heat (power loss) within the conductive elements themselves, not just in the casting.

Q5: Why did the study use AK12 aluminum alloy and SiC particles specifically?

A5: The paper states this popular combination was chosen because the two materials have similar densities. This was a deliberate choice to minimize the effects of gravitational segregation (sinking or floating). By neutralizing the impact of gravity, the researchers could more clearly isolate and analyze the effects of the electromagnetic forces on particle movement, leading to a more accurate and focused analysis of the process itself.

Q6: What is the main practical limitation of this proposed manufacturing technique?

A6: The conclusion explicitly states that the solution is best suited for castings whose geometry allows for the electromagnetic extension of their inner channels. This means the component must have a shape where it's physically possible to add the conductive elements above and below the casting area within the mold to create the uniform field. This may limit its application for more complex or irregularly shaped parts.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of reinforcing the inner surfaces of high-wear components has long been a hurdle for conventional manufacturing. This research on Electromagnetic Casting presents a powerful and elegant solution. By using an internal inductor and carefully engineering the electromagnetic field with conductive elements, it is now possible to create a uniform, dense layer of reinforcement precisely where it's needed most. This breakthrough paves the way for a new class of lighter, more durable, and higher-performing metal matrix composites.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Model of Casting Process of Composites Reinforced Locally at Inner Wall of Bush in Electromagnetic Field" by "Sławomir Golak".

Source: S. Golak, "Model of casting process of composites reinforced locally at inner wall of bush in electromagnetic field," Composites Theory and Practice, vol. 13, no. 1, pp. 65-71, 2013.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.