Predicting Perfection: How Casting Simulation Solves Stress and Distortion in Hybrid Lightweight Components

This technical summary is based on the academic paper "Material combinations in light-weight casting components" by Dr.-Ing. Götz Hartmann, published in Casting Plant & Technology (4/2013).

Keywords

- Primary Keyword: Casting Simulation for Hybrid Components

- Secondary Keywords: Lightweight Casting, Residual Stress in Castings, Die Casting Simulation, Aluminum-Steel Hybrid Casting, Distortion Control, Material Combination Casting

Executive Summary

- The Challenge: Combining different materials in lightweight castings to enhance local properties creates critical issues like residual stress, distortion, and cracks that are difficult to manage with traditional methods.

- The Method: Advanced casting process simulation is used to predict complex thermo-mechanical phenomena, including melt flow, solidification, and stress formation, before the first part is ever produced.

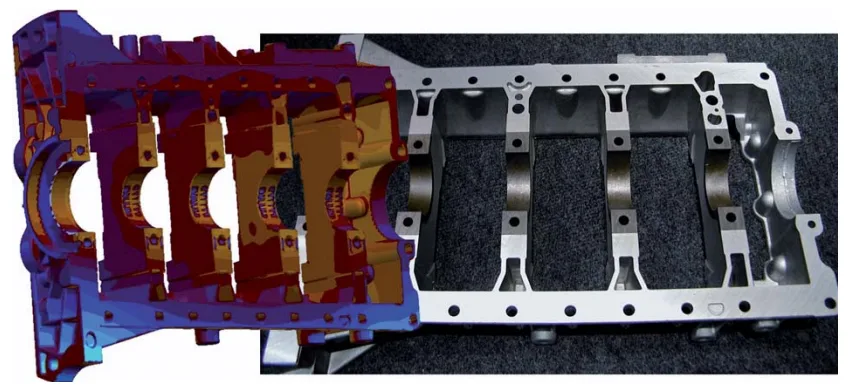

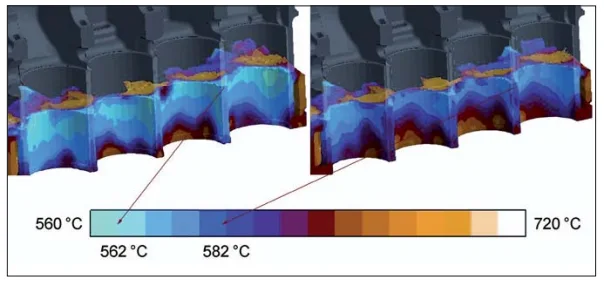

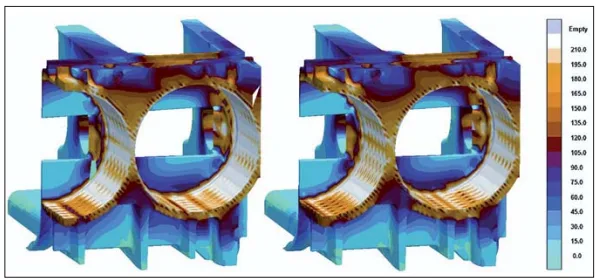

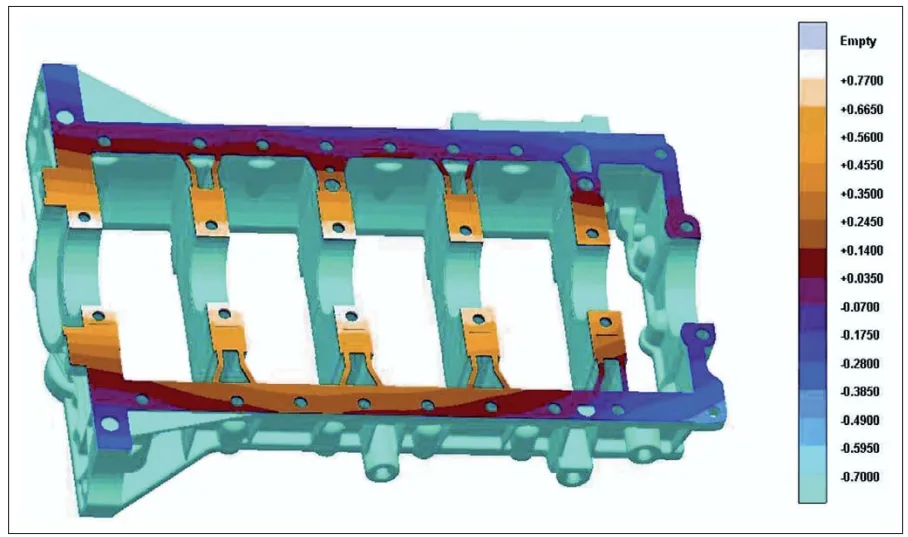

- The Key Breakthrough: Simulation can accurately calculate and visualize specific defects, such as incomplete mold filling (Figure 1), high residual stress concentrations (Figure 2), and final component distortion (Figure 3), enabling preventative design and process adjustments.

- The Bottom Line: Integrating casting simulation early in the design phase is essential for successfully manufacturing reliable, high-performance hybrid cast components and avoiding costly production failures.

The Challenge: Why This Research Matters for HPDC Professionals

In the quest for lighter, more efficient components, engineers are increasingly turning to hybrid castings—combining aluminum or magnesium with robust inserts made of steel or cast iron. While this approach allows for tailoring local properties to meet specific mechanical or tribological demands, it introduces significant manufacturing challenges.

As the paper highlights, the interaction between the molten light metal and the solid insert is not always straightforward. The insert can chill the melt locally, blocking flow paths and causing incomplete fills. More critically, the different rates of thermal expansion and heat conductivity between the paired materials lead to non-uniform cooling. This process generates significant residual stress, distortion, and, in some cases, catastrophic cracks and fractures. These phenomena are complex and often ignored during the initial component design, leading to expensive trial-and-error cycles and production delays. This research demonstrates a path to proactively manage these risks.

The Approach: Unpacking the Methodology

The solution presented in the paper lies in leveraging comprehensive casting process simulation. This is not merely a flow analysis; it is a multi-faceted computational approach that models the entire casting process from start to finish. The methodology relies on a combination of sophisticated models:

- 3-D Geometry Models: The process starts with 3-D CAD models of the casting, inserts, gating systems, and the die itself, which are automatically cross-linked for analysis.

- Rheology Models: These models describe the flow behavior of the molten metal, accounting for factors like viscosity and surface tension, especially as solidification begins during mold filling.

- Solidification Models: These simulate the transition from liquid to solid, predicting the formation of microstructures like grain size and dendrite arm spacing, which directly influence the final mechanical properties.

- Elasto-Plastic Models: Crucially for hybrid components, these state-of-the-art models calculate the buildup of residual stresses and the resulting distortion as the casting cools and the different materials contract and interact.

By integrating these models, engineers can run virtual casting trials to predict and assess the outcomes of specific design choices and process parameters before committing to expensive tooling.

The Breakthrough: Key Findings & Data

The paper illustrates the power of this simulation-driven approach with several practical examples.

Finding 1: Optimizing Melt Flow by Controlling Insert Temperature

In aluminum engine blocks with gray-iron cylinder liners, the gap between the liners is a critical area. Simulation shows that the pre-heating temperature of the liners is a decisive factor for a successful fill.

- As shown in Figure 1, when the pre-heating temperature of the liners is sufficiently high (left image), the aluminum melt flows freely and fills the seam. However, when the liners are cooler (right image), the liquid metal chills prematurely and cannot fill the gap completely, resulting in a critical defect. This allows engineers to define a precise and optimal pre-heating window.

Finding 2: Quantifying and Managing Residual Stress

As the aluminum solidifies and shrinks around the stiffer cast iron liners, it develops tensile residual stress. The magnitude of this stress is directly related to the component's geometry.

- The simulation in Figure 2 reveals that closer liner distances result in significantly higher maximum principal stress (206 MPa, left) compared to larger distances (187 MPa, right). This data enables designers to understand the trade-offs between weight reduction (thinner walls) and mechanical integrity, ensuring stress remains within acceptable limits.

Finding 3: Predicting and Compensating for Component Distortion

For components like a ladder-type aluminum frame with cast-in bearing shells, distortion is a major concern. The non-uniform cooling caused by the partially immersed shells causes the part to warp.

- As shown in Figure 3, the simulation predicts the dimensional variation across the frame, revealing a difference of up to 1.0mm between the corner points and the bearing seats. Quantifying this distortion is invaluable, as it allows for the precise determination of machining allowances at the design stage, ensuring the final part meets its required tolerances without costly rework.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the pre-heating temperature of inserts (as shown in Figure 1) is a critical process parameter to control for preventing mold filling defects in hybrid components.

- For Quality Control Teams: The data in Figure 2 illustrates the direct relationship between liner distance and residual tensile stress, which could inform new non-destructive testing (NDT) criteria focused on these predicted high-stress areas.

- For Design Engineers: The findings in Figure 3, showing significant predictable distortion, indicate that running a simulation is crucial for defining appropriate machining allowances and ensuring final part geometry in the early design phase.

Paper Details

Material combinations in light-weight casting components

1. Overview:

- Title: Material combinations in light-weight casting components

- Author: Dr.-Ing. Götz Hartmann, Engineering Services, Business Development, MAGMA GmbH, Aachen

- Year of publication: 2013

- Journal/academic society of publication: Casting Plant & Technology 4/2013

- Keywords: Lightweight casting, material combinations, hybrid components, casting simulation, residual stress, distortion, aluminum casting, magnesium casting, cast-in inserts

2. Abstract:

Aluminum and magnesium castings play a major role in light-weight casting, with continually expanding applications and increasing demands on materials. Often, the properties of the base casting material are insufficient, necessitating the use of cast-in inserts (steel or cast iron) to tailor local component properties. These inserts introduce critical phenomena during casting, such as localized chilling of the molten metal, which can block flow paths. Non-uniform cooling and differences in thermal properties between the materials cause residual stress, distortion, and sometimes cracks. This article shows how casting simulation can be used to calculate, predict, and ultimately reduce these issues before the first parts are cast.

3. Introduction:

The demand for lightweight components is driving the use of aluminum and magnesium castings. To meet specific local performance requirements that the base alloy cannot provide (e.g., mechanical strength, tribological properties), designers incorporate inserts made of steel or cast iron. This combination creates a "hybrid" component but introduces significant manufacturing complexities. During pouring, the inserts can cause various uncritical phenomena, including chilling the melt, blocking flow, and causing non-uniform cooling. This leads to residual stress, distortion, and fractures. This article demonstrates how simulation can predict and mitigate these risks.

4. Summary of the study:

Background of the research topic:

The increasing use of hybrid castings (light metal alloys with cast-in inserts) to achieve weight reduction and tailored local performance in demanding applications.

Status of previous research:

Conventional design and calculation of castings are often based on standardized, uniform material properties. This approach disregards the locally different conditions that occur during solidification and cooling, which lead to variations in microstructure and mechanical properties. Furthermore, the development of residual stress in hybrid castings is an inevitable process that is often ignored in component design.

Purpose of the study:

To demonstrate that modern casting process simulation can predict and assess complex phenomena in hybrid castings, such as mold filling issues, microstructure formation, residual stress, distortion, and crack formation, providing a methodical basis for design and production improvements.

Core study:

The article presents and analyzes several industrial case studies to show the practical application of casting simulation for hybrid components. These include:

1. An aluminum sand-cast engine block with induction pre-heated gray-iron liners, focusing on melt flow and residual stress.

2. A die-cast aluminum ladder-type frame with grey-iron bearing shells, focusing on distortion.

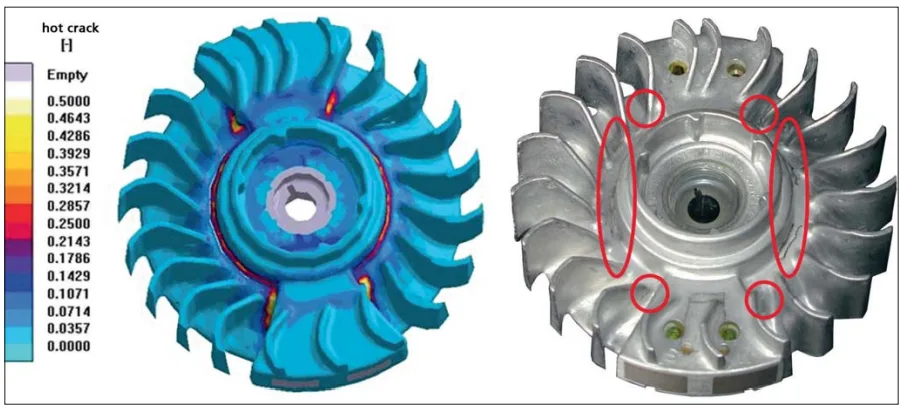

3. A magnesium flywheel with cast-in magnets, focusing on hot crack formation.

5. Research Methodology

Research Design:

The study is based on the application of casting process simulation software to model and analyze the thermo-mechanical behavior of hybrid lightweight components during manufacturing.

Data Collection and Analysis Methods:

The methodology is computational. It uses 3-D CAD models of the component, inserts, and tooling as geometric inputs. It then applies a series of physics-based material models to simulate the casting process:

- Rheology models for melt flow.

- Solidification models for the liquid-to-solid phase transformation and microstructure development.

- Elasto-plastic and viscoplastic models for the formation of residual stresses and distortion during cooling and heat treatment.

Research Topics and Scope:

The scope covers the prediction of manufacturing outcomes for hybrid castings, specifically:

- Mold filling behavior around inserts.

- Development of as-cast residual stresses.

- Final component distortion after cooling.

- Susceptibility to defects like hot cracking.

6. Key Results:

Key Results:

- Simulation can predict incomplete mold filling between inserts and identify the required insert pre-heating temperature to prevent it (Figure 1).

- The magnitude of tensile residual stress in the aluminum surrounding an insert is quantifiable and directly dependent on geometric factors like the distance between inserts (Figure 2).

- Final component distortion is predictable, allowing for the calculation of necessary machining allowances at the design stage (Figure 3).

- The risk of hot cracking around inserts can be assessed by simulating whether a critical shrinkage rate is exceeded during solidification (Figure 4).

- The simulation of these effects provides a basis for design and process optimization before production begins.

Figure Name List:

7. Conclusion:

The weight of a cast component can be optimized through material-adapted design or by using combinations of materials in a single casting. These hybrid components with cast-in inserts offer special opportunities to create specific local mechanical, tribological, or magnetic properties. However, this potential is counterbalanced by more complex, high-risk, and expensive casting processes. To minimize these engineering risks, reliable and rapid simulation is a critical element. As the examples show, effects like residual stress distribution and distortion are computable and can be exploited in computerized casting construction, moving problem-solving from production to the early design stage.

8. References:

- This article is based on a lecture held at the VDI conference “Simulation im automobilen Leichtbau” in November 2011 in Baden-Baden, Germany.

Expert Q&A: Your Top Questions Answered

Q1: Why is pre-heating the inserts so critical in hybrid aluminum castings?

A1: The inserts, typically made of steel or cast iron, have a high capacity to absorb heat. As shown in the case of the engine block (Figure 1), if the liners are not sufficiently pre-heated, they rapidly chill the incoming molten aluminum. This localized cooling can cause the melt to solidify prematurely before it has completely filled the cavity, especially in thin sections between inserts, leading to a critical misrun defect.

Q2: The paper states that tensile stress in the aluminum between liners is high. Why is this considered "probably uncritical" in the cylinder block example?

A2: While the tensile residual stress is high, its location is key. The paper notes that for the cylinder block, these stresses are concentrated in the seam between the liners. Any potential cracks developing in this specific area would have a low effect on the overall rigidity of the cylinder block at its operating temperature. The simulation allows engineers to make this informed judgment about whether a high-stress area is truly critical to the part's function.

Q3: How does simulation account for the complex behavior of a partly solidified melt during mold filling?

A3: The simulation employs advanced rheology models. The paper explains that when solidification starts before the end of mold filling, the partly solidified melt displays a shear-rate-dependent and temperature-dependent viscosity. The simulation models account for this complex behavior, which is crucial for accurately predicting flow in processes where a "mushy" metal state exists during filling.

Q4: What is the fundamental cause of residual stress in hybrid castings with steel or cast iron inserts?

A4: The primary cause is the difference in thermal properties and stiffness between the materials. The paper explains that the matrix material (aluminum or magnesium) shrinks onto the stiffer, colder insert during cooling and solidification. Because the aluminum is constrained by the insert, it develops tensile residual stress, which is balanced by compressive stress within the insert. This process is an inevitable consequence of combining these materials.

Q5: The article mentions "hot cracking" in the magnesium flywheel example (Figure 4). What specific conditions, according to the simulation, lead to this defect?

A5: According to the paper, hot cracking occurs in the areas around the inserts while these areas are solidifying. The simulation in Figure 4 identifies this risk by calculating if a "critical solidification rate—and, consequently, shrinkage rate" is exceeded. When this happens, the almost-solidified, brittle metal is pulled apart by shrinkage forces, and liquid metal cannot feed into the location fast enough to "cure the crack," resulting in the defect.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of managing residual stress, distortion, and defects in hybrid components is a major hurdle in lightweight manufacturing. This paper demonstrates conclusively that Casting Simulation for Hybrid Components is no longer a theoretical exercise but a powerful, predictive tool for modern engineering. By moving the identification and resolution of complex thermo-mechanical problems from the foundry floor to the designer's desktop, simulation enables the full potential of material combinations to be realized reliably and cost-effectively.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Material combinations in light-weight casting components" by "Dr.-Ing. Götz Hartmann".

- Source: Casting Plant & Technology 4/2013

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.