Unlocking Superior Performance in Zinc Die Casting: A Deep Dive into Zn-Al-Cu Alloy Modification

This technical summary is based on the academic paper "Characteristic of Cast Zn-Al-Cu Alloy Microstructure after Modification" by B. Krupińska, M. Krupiński, Z. Rdzawski, K. Labisz, and M. Król, published in ARCHIVES of FOUNDRY ENGINEERING (2014).

Keywords

- Primary Keyword: Zn-Al-Cu Alloy Modification

- Secondary Keywords: zinc alloy microstructure, die casting, grain refinement, hardness improvement, Ti-B modifier, Sr modifier

Executive Summary

- The Challenge: Standard Zn-Al-Cu alloys often suffer from coarse-grained dendritic structures, gassing, and oxidation, leading to inconsistent mechanical properties in final castings.

- The Method: Researchers introduced metallic modifiers (Titanium-Boron and Strontium) into a liquid Zn-Al-Cu alloy and analyzed the resulting changes in microstructure and hardness.

- The Key Breakthrough: The addition of both Ti-B and Sr successfully refined the alloy's grain structure, homogenized the microstructure, and led to a significant and measurable increase in material hardness.

- The Bottom Line: Chemical modification is a proven and effective strategy for enhancing the mechanical properties of Zn-Al-Cu alloys, offering a direct path to producing more durable and reliable high-precision components.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-precision die casting, consistency is king. However, zinc alloys, despite their excellent properties for thin-walled components, present persistent manufacturing challenges. The primary issues are a natural tendency for gassing and oxidation during the melting process and, critically, the formation of a coarse-grained dendritic structure during slow solidification.

This coarse structure leads to dendritic microsegregation, where alloying elements are unevenly distributed. The result is a casting with heterogeneous properties—inconsistent strength, hardness, and durability—which is unacceptable for high-performance applications in the automotive, electronics, and construction industries. To overcome these limitations and ensure the production of castings with a desirable, stable microstructure and superior mechanical properties, a reliable method of metallurgical modification is essential.

The Approach: Unpacking the Methodology

To investigate a solution, the researchers conducted a controlled study focused on the chemical modification of a standard Zn-Al-Cu alloy.

- Base Material: A zinc-aluminium-copper alloy with an aluminium concentration of 8.04-11.27% and a copper concentration of 0.68-1.09%.

- Modifiers: Two different modifiers were added to the molten alloy:

- A master alloy of Titanium and Boron (Ti-B) in concentrations up to 0.58%.

- Strontium (Sr).

- Casting Process: The modified alloys were prepared in a resistance furnace and cast into metal moulds.

- Analysis Techniques: A comprehensive suite of analytical tools was used to characterize the alloys before and after modification:

- Microstructure Analysis: Light microscopy (MEF4A) and scanning electron microscopy (SEM - Zeiss Supra 25) with EDS X-ray microanalysis were used to visualize the structure and confirm the presence of modifying elements.

- Phase Identification: High-resolution transmission electron microscopy (TEM - Titan 80-300) was employed to identify the specific crystalline phases formed by the modifiers.

- Mechanical Property Testing: Hardness was measured using a Rockwell hardness tester (Zwick ZHR 4150) to quantify the improvement in mechanical properties.

The Breakthrough: Key Findings & Data

The study yielded clear evidence that chemical modification dramatically improves the quality of the cast Zn-Al-Cu alloy.

Finding 1: Significant Microstructural Refinement and Homogenization

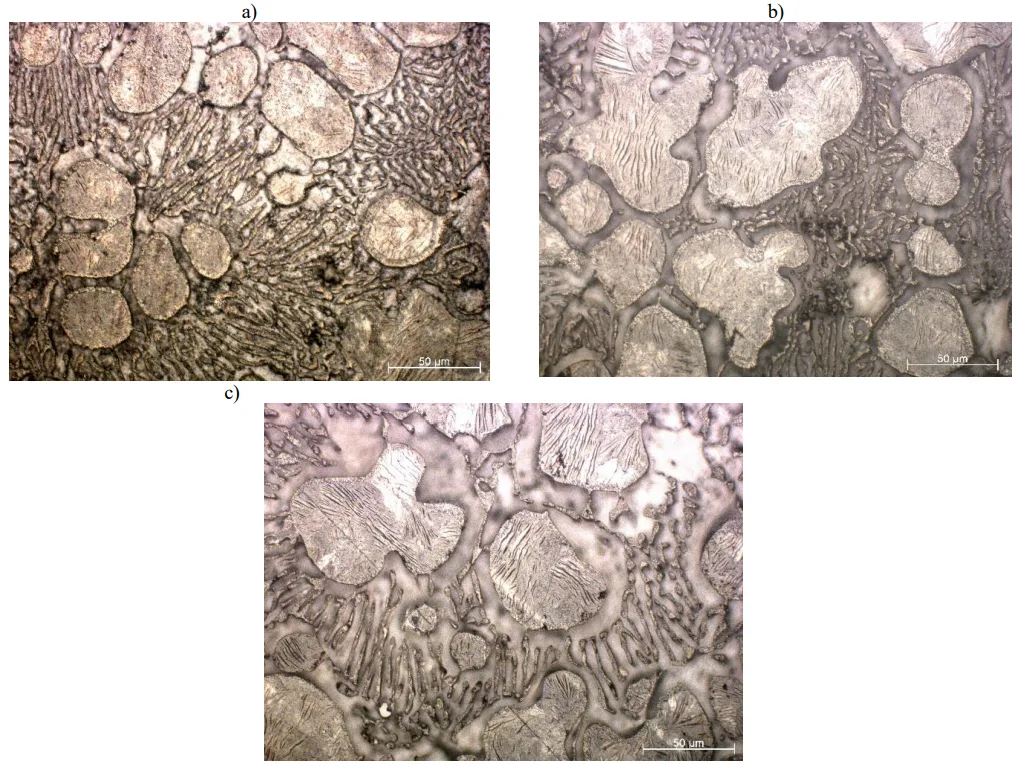

The addition of modifiers fundamentally changed the alloy's structure. The coarse, dendritic structure of the unmodified alloy was replaced by a more refined and homogenous grain structure.

- Visual Evidence: As shown in Figure 2, the unmodified alloy (Fig. 2a) exhibits a coarse dendritic structure. In contrast, the alloys modified with Ti-B (Fig. 2b) and Sr (Fig. 2c) show a significantly refined and more uniform microstructure.

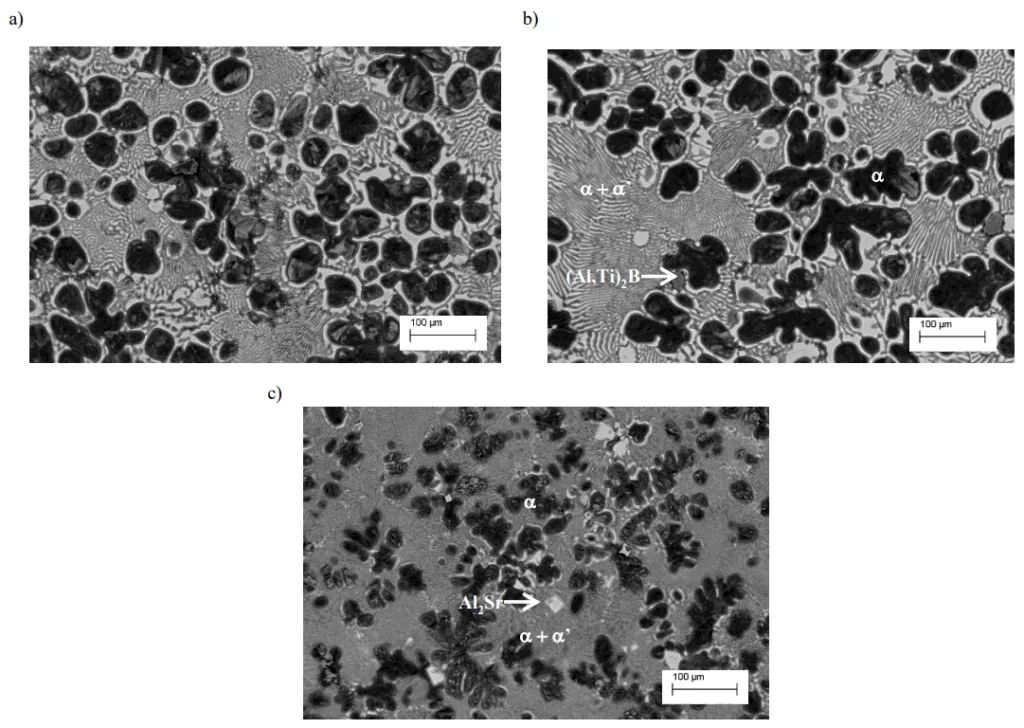

- Phase Confirmation: High-resolution TEM analysis confirmed the mechanism behind this refinement. In the Ti-B modified alloy, the presence of the (AlTi)₂B phase was identified (Figures 4-7). In the Sr-modified alloy, the Al₂Sr phase was confirmed (Figures 8-11). These newly formed particles act as nucleation sites, promoting the formation of finer, more numerous grains during solidification.

Finding 2: Measurable Increase in Material Hardness

The refined microstructure directly translated into improved mechanical properties, specifically a notable increase in hardness.

- Hardness Data: As shown in the graph in Figure 12, the base Zn-Al-Cu alloy had an average Rockwell hardness (HRA) of approximately 32.5. The addition of Ti-B increased the hardness to around 33.5 HRA. Most impressively, the modification with Sr resulted in the highest hardness, reaching approximately 37.5 HRA. This demonstrates that modification not only refines the structure but also makes the material stronger and more wear-resistant. The modified alloys also showed a lower standard deviation in hardness values, indicating greater property consistency.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that incorporating master alloys containing Ti-B or Sr into the melt can be a powerful tool for grain refinement. This may contribute to reducing defects associated with coarse structures and improving the overall castability and integrity of components.

- For Quality Control Teams: The data in Figure 12 of the paper illustrates the direct correlation between modification and increased hardness. Hardness testing could therefore serve as an effective and efficient proxy for verifying the success of the modification process and ensuring material consistency batch-to-batch.

- For Design Engineers: The findings indicate that the formation of a fine, equiaxed grain structure through modification can lead to more isotropic (uniform in all directions) mechanical properties. This allows for greater confidence when designing complex, thin-walled components where stress distribution is critical.

Paper Details

Characteristic of Cast Zn-Al-Cu Alloy Microstructure after Modification

1. Overview:

- Title: Characteristic of Cast Zn-Al-Cu Alloy Microstructure after Modification

- Author: B. Krupińska, M. Krupiński, Z. Rdzawski, K. Labisz, M. Król

- Year of publication: 2014

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 14, Special Issue 4/2014

- Keywords: Innovative cast materials and technologies, metallography, modification, cast zinc alloys, microstructure

2. Abstract:

Cast zinc alloys have similar properties to aluminium alloys but differ due to a lower melting point and higher density. They are used for producing thin-walled, high-precision casts for various industries. Properly performed chemical modification can improve the properties of castings. This work studied the effect of chemical modification of a cast zinc alloy with Ti-Sr and B modifiers on its properties and microstructure. The investigation involved thermo-derivative analysis, light and scanning electron microscopy with EDS, and hardness measurements of the modified Zn-Al-Cu alloys.

3. Introduction:

The main problems in zinc alloy production include their tendency for gassing, oxidation, and the formation of a coarse-grained dendritic structure in slowly solidifying castings. This leads to dendritic microsegregation and heterogeneous properties. To improve the quality of the liquid metal and ensure a desired cast structure with high and stable mechanical properties, special modification is applied. Zinc alloys are primarily used for thin-walled, high-precision castings in various industries and are suitable for small-volume production.

4. Summary of the study:

Background of the research topic:

Zinc alloys are crucial for precision casting but suffer from microstructural issues like coarse dendritic grains, which lead to inconsistent properties. Chemical modification is a known method to refine the structure and improve performance.

Status of previous research:

Copper is a main alloying element in zinc alloys, affecting strength and hardness. Modifiers like strontium and antimony are used for their long-term acting effects. Rare earth metals are also increasingly used. This paper investigates the effects of Ti-B and Sr.

Purpose of the study:

To study the effect of chemical modification of a cast Zn-Al-Cu alloy on its properties and microstructure. The goal was to understand how adding metallic modifiers (Ti-B and Sr) changes the cast structure and, consequently, its mechanical properties like hardness.

Core study:

The study involved preparing Zn-Al-Cu alloys with and without Ti-B and Sr modifiers. These alloys were then subjected to a series of analyses, including thermo-derivative analysis, detailed microstructure investigation using optical, scanning, and transmission electron microscopy, and mechanical testing via hardness measurements.

5. Research Methodology

Research Design:

An experimental study was conducted comparing a base Zn-Al-Cu alloy with two modified versions: one with a Ti-B master alloy and another with Sr.

Data Collection and Analysis Methods:

- Chemical Analysis: ICP OES was used to determine the mass concentrations of alloying elements.

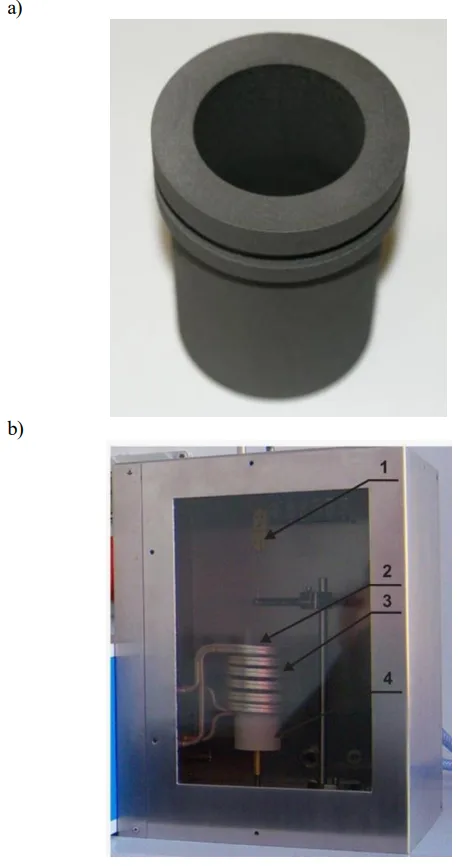

- Thermo-derivative Analysis: A UMSA (Universal Metallurgical Simulator and Analyzer) was used to study crystallization kinetics.

- Microstructure Investigation: Performed using a MEF4A optical microscope, a Zeiss Supra 25 scanning electron microscope (SEM) with EDS, and a Titan 80-300 high-resolution transmission electron microscope (TEM).

- Hardness Measurement: A Zwick ZHR 4150 Rockwell hardness tester was used.

Research Topics and Scope:

The research focused on Zn-Al-Cu alloys with aluminium content from 8.04% to 11.27% and copper from 0.68% to 1.09%. Modifiers were added in the range of 0.1% to 1%. The scope included preparation of the alloys, casting into metal moulds, and detailed characterization of their microstructure and hardness.

6. Key Results:

Key Results:

- The addition of Ti-B and Sr modifiers causes a modification of the Zn-Al-Cu alloy structure, characterized by grain and subgrain refinement.

- The morphology of Al dendrites is altered, with precipitations appearing in their neighbourhood.

- Transmission electron microscopy (TEM) confirmed the presence of the (AlTi)₂B phase in the Ti-B modified alloy and the Al₂Sr phase in the Sr modified alloy.

- Modification of the Zn-Al-Cu alloy leads to an increase in hardness. The Sr-modified alloy showed the highest hardness value.

- The modified alloys exhibited a lower standard deviation in hardness values, indicating more consistent properties.

Figure Name List:

- Fig. 1. a) Graphite crucible, b) Working chamber of the UMSA device: 1 -thermocouple, 2- tested sample, 3 – induction coli, 4 – ceramic isolation

- Fig. 2. Microstructure of the Zn-Al-Cu alloy;a) alloy without modification, b) modified alloy with Ti-B,c) modified alloy with Sr

- Fig. 3. Microstructure of the Zn-Al-Cu alloy; a) alloy without modification, b) modified alloy with Ti-B, c) modified alloy with Sr

- Fig. 4. Structure of the cast alloy Zn-Al-Cu-Ti-B, bright field image, TEM

- Fig. 5. Structure of the cast alloy Zn-Al-Cu-Ti-B, dark field image, TEM

- Fig. 6. Diffraction pattern from Fig. 4

- Fig. 7. Solution of the diffraction pattern from Fig. 6

- Fig. 8. ZnAlCuSr alloy, bright field, TEM

- Fig. 9. ZnAlCuSr alloy, dark field, TEM

- Fig. 10. Diffraction pattern of Fig 8

- Fig. 11. Solution of the diffraction pattern of Fig.10

- Fig. 12. Results of the hardness measurement of the base alloy Zn-Al-Cu, modified with Zn-Al-Cu-Ti-B and Zn-Al-Cu-Sr

7. Conclusion:

The addition of Ti-B and Sr to the Zn-Al-Cu alloy effectively modifies the microstructure through grain and subgrain refinement. This was confirmed by TEM investigations, which identified (AlTi)₂B and Al₂Sr phases acting as refinement agents. As a direct result of this structural modification, the hardness of the alloy increases significantly. The modified alloys also demonstrate more uniform properties, as indicated by a lower standard deviation in hardness measurements.

8. References:

- [1] Skrzypek, S.J., Przybyłowich, K. (2012). Engineering metals and their alloys, Publisher AGH, Cracow

- [2] Górny, Z., Sobczak J. (2005). Non-ferrous metals based novel materials in foundry practice, ZA-PIS, Cracow

- [3] Krupińska, B., Labisz, K., Rdzawski, Z. (2012). Light and electron microscope investigations of cast Zn-Al alloys. Arch. Mater. Sci. Eng. vol. 55, nr 1, s. 29-36

- [4] Krupińska, B., Labisz, K., Rdzawski, Z. (2011). Crystallisation kinetics of the Zn-Al alloys modified with lanthanum and cerium. -J. Achiev. Mater. Manuf. Eng. vol. 46 iss. 2, s. 154-160

- [5] Krajewski, W. (2001). Shaping the structure of Zn-Al alloys by doping with Zn-Ti master alloy, St. Staszic University of Mining and Metallurgy, Faculty of Foundry Engineering, Cracow

Expert Q&A: Your Top Questions Answered

Q1: Why were Ti-B and Sr specifically chosen as modifiers for this study?

A1: The paper mentions that modifiers like strontium are known to be "long-term acting," meaning their effect is maintained even after multiple remelting processes, which is highly valuable in a foundry environment. Ti-B master alloys are a well-established and highly effective grain refiner for aluminium alloys, and since cast zinc alloys share similarities with aluminium alloys, it was a logical candidate to test for achieving similar structural refinement.

Q2: What is the practical significance of identifying the (AlTi)₂B and Al₂Sr phases using TEM?

A2: Identifying these specific phases is crucial because it confirms the mechanism of modification. These microscopic particles, introduced by the modifiers, do not dissolve into the alloy. Instead, they remain as solid particles in the melt and act as nucleation sites for new grains to form during solidification. This leads to a much finer, more uniform grain structure instead of a few large, coarse dendrites, which directly results in improved mechanical properties.

Q3: Figure 12 shows that Strontium (Sr) modification resulted in a significantly higher hardness increase than Ti-B. Does the paper explain why?

A3: The paper does not explicitly state the reason for the superior performance of Sr. However, the conclusion notes that modification changes the morphology of the aluminum dendrites and causes "precipitations" to appear in their neighborhood. The formation of the Al₂Sr phase, confirmed in Figures 8-11, likely contributes more effectively to strengthening the alloy matrix compared to the (AlTi)₂B phase, leading to the greater observed hardness.

Q4: The study cast samples into metal moulds. How might these results translate to a high-pressure die casting (HPDC) process?

A4: The paper doesn't test HPDC directly, but the fundamental principles of metallurgical modification remain highly relevant. In HPDC, cooling rates are much faster, which naturally promotes a finer grain structure. The introduction of these modifiers would likely enhance this effect, potentially leading to an even finer, more robust microstructure. The modifiers could provide the nucleation sites needed to take full advantage of the rapid solidification, resulting in superior properties compared to an unmodified alloy under the same HPDC conditions.

Q5: What was the purpose of the thermo-derivative analysis mentioned in the methodology?

A5: Although the specific results from the thermo-derivative analysis are not detailed in the "Results" section, its purpose is to study the crystallization kinetics of the alloy. This technique precisely measures temperature changes during cooling and solidification, allowing researchers to identify the exact temperatures at which different phases begin to form. This information is critical for understanding how the modifiers alter the solidification sequence of the alloy.

Conclusion: Paving the Way for Higher Quality and Productivity

The persistent challenge of inconsistent properties in zinc alloy castings, caused by coarse and heterogeneous microstructures, can be effectively overcome. This research demonstrates that strategic Zn-Al-Cu Alloy Modification with agents like Titanium-Boron and Strontium is a powerful tool for achieving significant grain refinement and homogenization. The direct result is a casting with measurably higher hardness and greater property consistency, paving the way for more reliable and durable high-performance components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Characteristic of Cast Zn-Al-Cu Alloy Microstructure after Modification" by "B. Krupińska, M. Krupiński, Z. Rdzawski, K. Labisz, M. Król".

- Source: ARCHIVES of FOUNDRY ENGINEERING, Volume 14, Special Issue 4/2014, pp. 77-82.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.