How High Thermal Conductivity Steel Revolutionizes Die Casting Molds for Faster Cycles and Higher Quality

This technical summary is based on the academic paper "High Thermal Conductivity Steel and its Application to Die Casting Tools" by K. Namiki, Masamichi. Kawano, and Thomas Schade, published in NADCA DIE CASTING CONGRESS & EXPOSITION (2012). It has been analyzed and summarized for technical experts by CASTMAN.

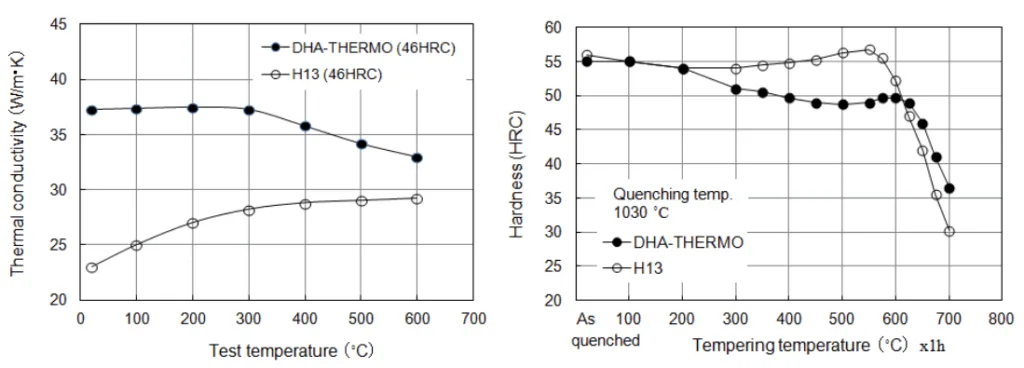

Figure 2 Hardness vs. tempering temperature.

Keywords

- Primary Keyword: High Thermal Conductivity Steel

- Secondary Keywords: Die Casting Mold, Cycle Time Reduction, H13 Steel, DHA-THERMO, Heat Checking, Mold Steel, HPDC

Executive Summary

- The Challenge: The die casting industry requires shorter cycle times and higher quality parts, but conventional mold steels like H13 have limited thermal conductivity, and alternatives are either too soft or too expensive.

- The Method: A new high thermal conductivity steel, DHA-THERMO, was developed and tested against H13 steel in both laboratory analysis and a live die casting trial focusing on a sprue core.

- The Key Breakthrough: DHA-THERMO demonstrates 1.6 times the thermal conductivity of H13, resulting in significantly lower mold surface temperatures, finer cast microstructures, and superior resistance to heat checking.

- The Bottom Line: Applying high thermal conductivity steel like DHA-THERMO to die casting tools can directly lead to improved product quality, reduced cycle times, and cost savings by serving as a viable alternative to expensive W alloys.

The Challenge: Why This Research Matters for HPDC Professionals

In modern die casting, the pressure is on to produce high-quality, lightweight components—especially for the automotive industry—while simultaneously shortening cycle times for cost reduction. The die casting mold is not just a shaping tool; it's a critical heat exchanger responsible for solidifying molten alloy. Inefficient heat removal leads to longer cycles, internal defects, and coarse grain structures in the final product.

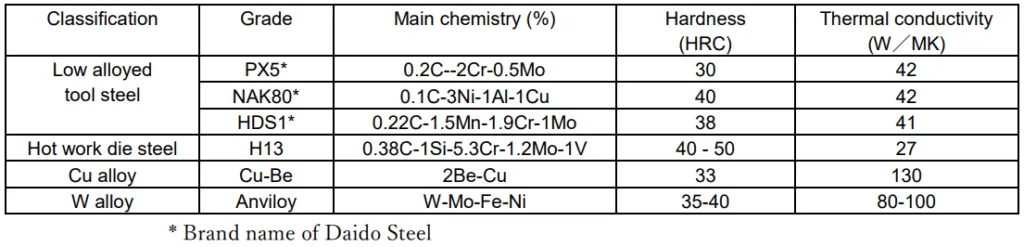

While the industry standard, 5%Cr-1%Mo steel (H13), is a reliable workhorse, its thermal conductivity is a limiting factor. Engineers have tried to compensate with more complex internal cooling channels, but this can introduce new failure points, such as cracking from water lines. Alternative materials with high thermal conductivity exist, like Copper (Cu) and Tungsten (W) alloys, but their high cost and poorer mechanical properties limit their widespread application. Similarly, low-alloy steels offer better conductivity than H13 but typically lack the required hardness, topping out at around 40 HRC. This creates a clear technological gap: the need for a mold material that combines high thermal conductivity with the high hardness required for die casting durability.

The Approach: Unpacking the Methodology

To address this challenge, researchers developed and tested a new hardened and tempered hot work die steel named DHA-THERMO. The evaluation was comprehensive, covering both fundamental material properties and real-world performance.

First, the fundamental properties of DHA-THERMO were characterized and compared to H13. This included:

- Thermal Conductivity: Measured at both room and elevated temperatures up to 500°C.

- Tempering Hardness: Assessed how hardness changes with tempering temperature to determine the achievable working hardness.

- Hardenability: Evaluated using a Continuous Cooling Transformation (CCT) diagram and by measuring hardness distribution across large-diameter round bars.

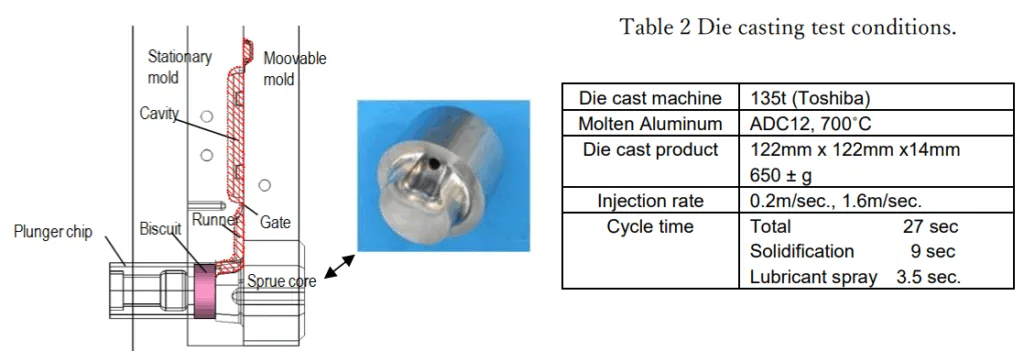

Next, a practical die casting test was performed using a 135t machine with ADC12 aluminum. The researchers focused on the sprue core—a critical component for cooling the biscuit—by making one core from DHA-THERMO and another from H13. During the test, they measured the surface temperature of the sprue core using a radiant thermograph, observed the microstructure of the resulting aluminum biscuit, and evaluated the mold's resistance to heat checking after 10,000 shots.

The Breakthrough: Key Findings & Data

The study yielded compelling data that highlights the significant advantages of using a high thermal conductivity steel for die casting tools.

Finding 1: Superior Heat Dissipation and Thermal Performance

DHA-THERMO demonstrated a significant advantage in its ability to remove heat from the casting. As shown in Figure 1, at room temperature, the thermal conductivity of DHA-THERMO (46 HRC) is approximately 1.6 times greater than that of H13 (46 HRC). This superior conductivity translated directly into lower operating temperatures during the die casting test. The sprue core made of DHA-THERMO showed a surface temperature of 220°C after unclamping, which was 120°C lower than the 340°C measured on the H13 sprue core under the same conditions (Figure 6).

Finding 2: Enhanced Product Quality and Mold Durability

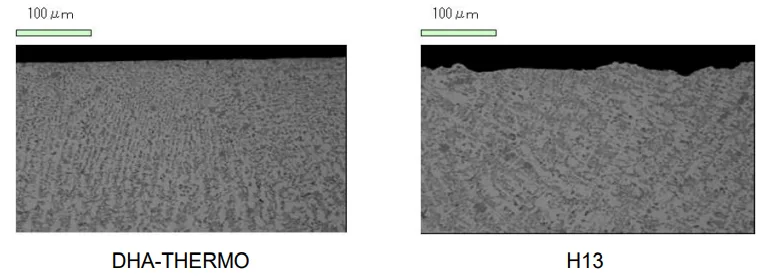

The faster heat extraction provided by DHA-THERMO had a direct impact on both the quality of the cast part and the longevity of the mold. The optical micrographs in Figure 7 show that the center surface of the aluminum biscuit that solidified against the DHA-THERMO core was much finer than the one from the H13 core. This indicates faster, more controlled solidification. Furthermore, after 10,000 shots, the mold's durability was assessed. As seen in Figure 8, the H13 mold surface exhibited remarkable heat checking, especially at the gate side and center. In contrast, the DHA-THERMO mold showed only mild cracks at the gate and almost none at the center, a superiority attributed to lower thermal stress from the reduced peak surface temperature.

Practical Implications for R&D and Operations

The findings of this paper offer actionable insights for engineering and operations teams in the HPDC industry.

- For Process Engineers: This study suggests that substituting conventional H13 with high thermal conductivity steel in critical areas like sprue cores, core pins, and distributors can directly reduce cycle time. One case study noted a cycle time reduction of 18% (Table 3) by preventing un-solidified biscuit issues. The lower operating temperature also reduces the thermal load on the mold, potentially extending its service life.

- For Quality Control Teams: The data in Figure 7 illustrates the effect of faster cooling on the cast microstructure. The finer grain structure achieved with DHA-THERMO can lead to improved mechanical properties and reduced internal defects like shrinkage porosity. Several case studies in Table 3 reported an improved yield rate due to reduced shrinkage when using DHA-THERMO for center pins and core pins.

- For Design Engineers: The findings indicate that for components where rapid cooling is essential but internal water lines are difficult to machine, high thermal conductivity steel offers a powerful alternative. Furthermore, DHA-THERMO proved to be a capable and inexpensive substitute for W alloy pins, lasting a comparable 20,000 shots in one trial. This provides a cost-effective material selection option for high-wear, high-heat applications.

Paper Details

High Thermal Conductivity Steel and its Application to Die Casting Tools

1. Overview:

- Title: High Thermal Conductivity Steel and its Application to Die Casting Tools

- Author: K. Namiki, Masamichi. Kawano (Daido Steel Co., Ltd.), Thomas Schade (International Mold Steel Inc. Hebron, Kentucky)

- Year of publication: 2012

- Journal/academic society of publication: NADCA DIE CASTING CONGRESS & EXPOSITION, Transaction No. T12-071

- Keywords: High thermal conductivity, die casting, mold steel, H13, cycle time, heat checking

2. Abstract:

It is required in die casting operations not only to produce high enough quality products but also to shorten cycle time. Increased usage of light weight components produced by die casting, have made reduced cycle time a critical issue for die casters. To reduce cycle time, the application of high thermal conductivity materials to die casting tools is effective as well as reinforced internal cooling of molds. Although W alloys are high thermal conductivity metals, the price is too high to increase their applications. On the other hand, it has been widely known that low alloy type steels have higher thermal conductivity than the most popular 5%Cr-1%Mo type die casting mold steel H13. But, they are generally supplied as pre- hardened steel: the highest hardness is usually 40 HRC. DHATM-THRMO is a high thermal conductivity steel and high hardness of 48HRC is available by quenching and tempering. In this paper, examples of the application to die casting tools are introduced as well as the fundamental features of this grade.

3. Introduction:

The roles of die casting molds are two folds. One is to inject and cast molten alloys in the cavity of molds to make required geometries. Another is to solidify molten alloys by removing the heat as heat exchanger. Needless to say, the latter is more important to produce good quality products with fine grain structure without internal defects in short cycle time. When automotive industries are considered, aluminum die casts are increasingly used for various components such as engine block and transmission case to produce light weight vehicles for improved fuel economy. Therefore, shorter cycle time is one of the key issues in automotive industries for cost reduction. Furthermore, fine cast microstructure with less defects in shorter time solidification contributes to further cost reduction and application of die cast products to wider variety automobile components. To reduce cycle time by faster solidification of molten alloys various efforts have been strived to improve cooling efficiency. Among them are increased internal cooling by the increase in water lines and their proper layout. The distance between the top of water line and the mold surface is becoming shorter, for example. These efforts, however, have accompanied with early stage gross cracking from water lines, especially from the crossing of water lines and oxidized internal surface. Another solution is to apply high thermal conductivity materials such as Cu alloys and W alloys. Although thermal conductivity of these metals are much larger than tool steels, they have difficulties in actual applications as die casting molds mainly due to their high price and poorer mechanical properties than tool steels, resulting in limited applications.

4. Summary of the study:

Background of the research topic:

The die casting industry, particularly in the automotive sector, faces increasing pressure to reduce cycle times and improve the quality of lightweight components. Effective heat removal during solidification is paramount to achieving fine grain structures and minimizing defects.

Status of previous research:

The industry standard steel, H13, has limited thermal conductivity. Attempts to improve cooling with complex water lines can lead to premature mold failure. High-conductivity materials like Cu and W alloys are often prohibitively expensive or lack the necessary mechanical properties for widespread use. Low-alloy steels, while having better thermal conductivity than H13, are typically too soft (max 40 HRC) for demanding die casting applications.

Purpose of the study:

The study aimed to introduce and validate a new hot work die steel, DHA-THERMO, designed to bridge this gap by offering both high thermal conductivity and high hardness (up to 48 HRC) suitable for die casting tools.

Core study:

The study involved a comprehensive evaluation of DHA-THERMO. This included laboratory testing of its fundamental properties (thermal conductivity, hardness, hardenability) in comparison to H13. It also included a practical die casting test where DHA-THERMO and H13 were used as sprue cores to measure real-world performance in terms of surface temperature, effect on cast microstructure, and resistance to heat checking. Finally, several successful industrial case studies were presented.

5. Research Methodology

Research Design:

The research employed a comparative study design. The newly developed DHA-THERMO steel was benchmarked against the industry-standard H13 steel and other relevant materials. The evaluation included both fundamental material property analysis and an applied performance test in a simulated production environment.

Data Collection and Analysis Methods:

- Material Property Testing: Standard laboratory methods were used to measure thermal conductivity at various temperatures, hardness after different tempering treatments, and to create a CCT diagram for hardenability. Hardness distribution was measured across quenched and tempered round bars.

- Die Casting Test: A 135t die casting machine was used. A radiant thermograph measured the surface temperature of the sprue cores. Optical microscopy was used to analyze the microstructure of the solidified aluminum biscuit. Visual inspection and photography were used to document heat checking on the mold surfaces after 10,000 cycles.

Research Topics and Scope:

The research focused on the properties and application of high thermal conductivity steel for die casting tools. The scope included:

1. Characterization of DHA-THERMO's thermal and mechanical properties.

2. Direct comparison of DHA-THERMO's performance against H13 in a die casting test.

3. Evaluation of its effect on cast product quality (microstructure) and mold durability (heat checking).

4. Documentation of industrial applications to demonstrate benefits in quality, cycle time, and cost.

6. Key Results:

Key Results:

- At room temperature, the thermal conductivity of DHA-THERMO is 1.6 times greater than that of H13 (Figure 1).

- DHA-THERMO can achieve a target hardness of 40 to 47 HRC by selecting a tempering temperature between 610°C and 680°C (Figure 2).

- In a die casting test, the sprue core made of DHA-THERMO ran 120°C cooler on the surface than the H13 core (340°C vs. 220°C) (Figure 6).

- The aluminum biscuit solidified against the DHA-THERMO core exhibited a much finer microstructure compared to the one solidified against H13 (Figure 7).

- After 10,000 shots, the DHA-THERMO mold showed significantly less heat checking than the H13 mold (Figure 8).

- In industrial applications, DHA-THERMO led to improved yield rates (shrinkage reduction), a cycle time reduction of 18% in one case, and successfully substituted for expensive W alloy pins with a comparable service life (Table 3).

Figure Name List:

- Figure 1 Thermal conductivity vs. test temperature.

- Figure 2 Hardness vs. tempering temperature.

- Figure 3 CCT diagram.

- Figure 4 Examples of hardness in round bars 4Bar gas Quenched and tempered.

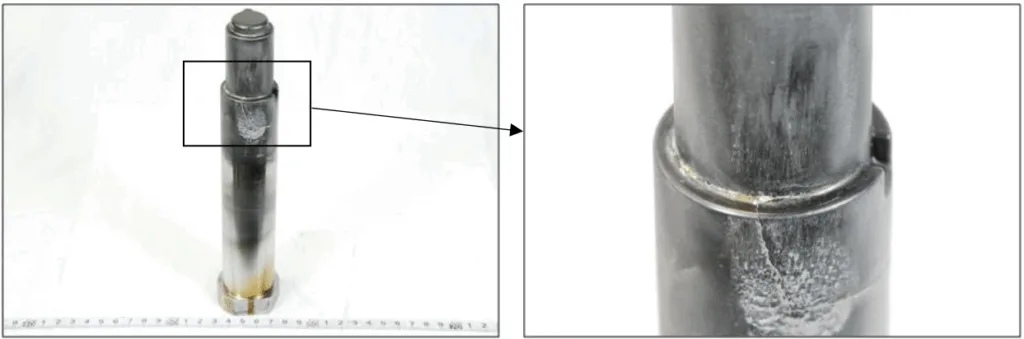

- Figure 5 Application of DHA-THERMO in die casting test.

- Figure 6 Surface temperature of sprue core.

- Figure 7 Optical micrographs taken from biscuit surface.

- Figure 8 Heat checking observed on the surface of movable molds as of 10,000 shots.

- Figure 9 A part of Al die cast product where internal soundness was improved by the application of DHA-THERMO core pins.

- Figure 10 An example of core pin and failed area.

7. Conclusion:

The application of the newly developed high thermal conductivity steel, DHA-THERMO, to die casting tools has been shown to be highly effective. The material's combination of high thermal conductivity and high hardness (up to 48 HRC) provides a superior alternative to conventional H13 steel in applications where rapid cooling is critical. The benefits are threefold:

1. Quality Improvement: Faster solidification leads to finer microstructures and reduced defects like shrinkage, improving yield rates.

2. Cycle Time Reduction: More efficient heat removal shortens the required solidification time, directly reducing the overall cycle time.

3. Cost Reduction: DHA-THERMO can serve as a durable, cost-effective substitute for expensive high-conductivity materials like W alloys.

8. References:

- 1) K. Bungardt, W. Spyra: Archiv fur das Eisenhuttenswesen, vol. 36, p 257 (1965)

- 2) M. Ayabe, K. Shibata, H. Koyama, K. Ozaki, M. Kawano and T. Yanagisawa: SAE Technical Paper Series, 07M-113 (2007)

- 3) M. Kawano and K. Inoue: Materia Japan, vol.48, p32, (2009)

Expert Q&A: Your Top Questions Answered

Q1: Why develop a new steel instead of using existing high-conductivity materials like Copper or Tungsten alloys?

A1: While Cu and W alloys have excellent thermal conductivity, the paper notes they have "difficulties in actual applications as die casting molds mainly due to their high price and poorer mechanical properties than tool steels." DHA-THERMO was developed to provide a solution that balances high thermal conductivity with the necessary hardness, toughness, and cost-effectiveness required for industrial die casting operations.

Q2: The paper mentions DHA-THERMO has "slightly inferior hardenability" to H13. How does this impact its use in large molds?

A2: Figure 4 provides data on this. It shows the hardness distribution across a 200 mm diameter round bar after quenching and tempering. While the surface hardness is consistent, the hardness in the center of the 100 mm and 150 mm long bars is slightly lower than that of the 60 mm long bar. This suggests that for very large mold blocks, there might be a slight drop in core hardness, which engineers should consider during the design and heat treatment process.

Q3: What is the optimal hardness range for DHA-THERMO and how is it achieved?

A3: According to the paper, an aimed hardness of 40 to 47 HRC is available. As shown in Figure 2, this hardness is achieved by quenching from 1030°C and then selecting a tempering temperature between 610°C and 680°C. This range allows it to maintain higher hardness than H13 at these high tempering temperatures.

Q4: The die casting test focused on a sprue core. Why was this component chosen for the comparison?

A4: The paper states this choice was made because "the cooling of the biscuit that finally solidify is the key issue in operation." The sprue and biscuit are the last parts of the shot to solidify, and inefficient cooling here can extend cycle times or cause defects. By testing the sprue core, the researchers could directly measure the impact of thermal conductivity on this critical phase of the casting cycle.

Q5: How does DHA-THERMO's performance compare to expensive W alloys like Anviloy in a real-world application?

A5: The "Cost Reduction" section on page 7 details a trial where DHA-THERMO was used for core pins, an application where Anviloy (a W alloy) was typically used. A DHA-THERMO pin heat-treated to 50 HRC endured its planned life of 20,000 shots without trouble, which is directly comparable to the average life of Anviloy pins (15,000 to 20,000 shots). This demonstrates that DHA-THERMO can be an inexpensive substitute for W alloy in certain applications, offering similar performance at a lower cost.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of balancing speed, quality, and cost in die casting is perpetual. This research demonstrates that significant progress can be made by innovating the tool material itself. The development of High Thermal Conductivity Steel like DHA-THERMO provides a powerful solution to the limitations of conventional H13, enabling faster heat extraction without compromising the hardness required for mold durability. The resulting benefits—improved product quality through finer microstructures, shorter cycle times, and reduced tooling costs—are critical for maintaining a competitive edge in today's manufacturing landscape.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "High Thermal Conductivity Steel and its Application to Die Casting Tools" by "K. Namiki, Masamichi. Kawano, and Thomas Schade".

- Source: NADCA DIE CASTING CONGRESS & EXPOSITION, (2012), Transaction No. T12-071

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.