Slash Tooling Costs by 95%: A Deep Dive into Rapid Tooling for Metal Prototypes

This technical summary is based on the academic paper "Advanced Sheet Metal Manufacturing Using Rapid Tooling" by Du Zhao Hui, Chua Chee Kai, Chua Yew Sen, Loh-Lee Leow Gek, and Lim Ser Tiak. It was analyzed and summarized for manufacturing experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Rapid Tooling for Sheet Metal

- Secondary Keywords: Rapid Prototyping, Sheet Metal Prototyping, SLS (Selective Laser Sintering), SLA (Stereolithography), High-Speed CNC Milling, Tooling Cost Comparison, RapidSteel

Executive Summary

- The Challenge: Creating tooling for sheet metal prototypes and short-run production using conventional methods is extremely slow and expensive, often involving a high-risk, trial-and-error process.

- The Method: The research team systematically compared four distinct rapid tooling (RT) approaches—three indirect methods using SLS, SLA, and high-speed CNC milling as master patterns, and one direct method using RapidSteel—to produce an embossed sheet metal part.

- The Key Breakthrough: The study demonstrated that rapid tooling techniques can produce functional prototype tools in just 1-2 days for approximately 5% of the cost of conventional tooling. The indirect method using high-speed CNC milling provided the best balance of speed, cost, and quality.

- The Bottom Line: For engineers and managers needing to validate designs, test formability, or produce small batches, rapid tooling offers a proven, data-backed alternative that dramatically reduces lead times and financial risk compared to traditional methods.

The Challenge: Why This Research Matters for HPDC Professionals

While our core expertise at CASTMAN lies in High-Pressure Die Casting, we believe in staying at the forefront of all advanced manufacturing technologies. The challenges of tooling—long lead times, high costs, and the risk of design flaws discovered late in the process—are universal. This paper on sheet metal tooling addresses a problem that every engineer, R&D manager, and procurement professional can relate to.

Conventional methods for creating forming tools are often a bottleneck. They rely on a "trial and error-prone approach" to account for material spring-back and non-linearities, which can lead to multiple iterations and rebuilt dies (Ref. [7]). This process is not only time-consuming but also drives up costs, making it prohibitive for prototypes or small-batch production. The paper highlights a "strong demand in industries for rapid tooling of sheet metal forming with a shorter time and lower cost" to overcome these critical hurdles. This research provides a valuable roadmap, and its principles on rapid iteration and cost reduction hold important lessons for the entire metal forming industry, including die casting.

The Approach: Unpacking the Methodology

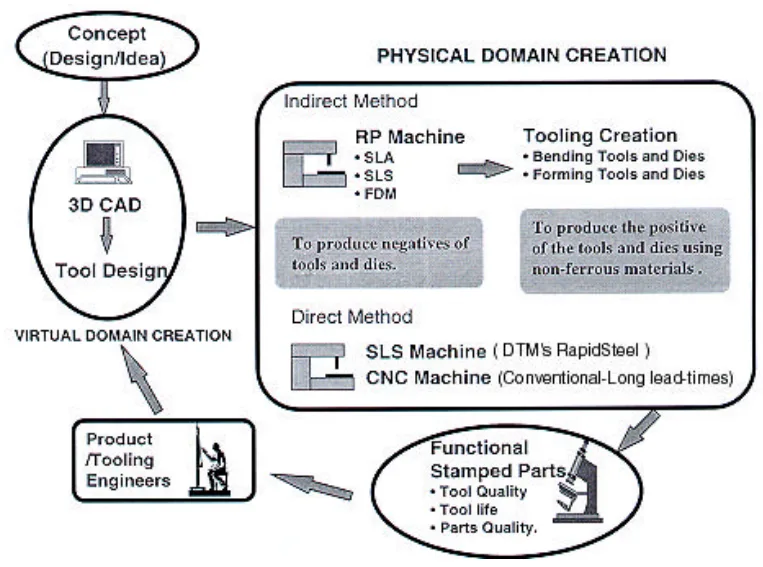

To find a practical solution, the researchers developed a closed-loop system for Rapid Sheet Metal Prototyping (RSMP), as shown in Figure 1. The core of the study involved a head-to-head comparison of four different manufacturing paths to create a die insert for an embossing process.

The four approaches investigated were (as detailed in Figure 2):

- Approach A (SLS): An indirect method starting with a master pattern created via Selective Laser Sintering (SLS).

- Approach B (SLA): An indirect method using a master pattern from Stereolithography (SLA).

- Approach C (High-Speed CNC): An indirect method using a master pattern machined via high-speed CNC milling.

- Approach D (RapidSteel): A direct method where the tool is built directly using DTM's RapidSteel process.

For the three indirect methods, the master patterns were used to create a silicone rubber mold, which was then used to cast the final tool from aluminum epoxy. The study meticulously tracked time, cost, surface quality, and dimensional accuracy for each path, providing a clear, data-driven comparison.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable data on the performance of each rapid tooling method, culminating in the successful production of embossed aluminum sheet metal samples (Figure 11).

Finding 1: High-Speed CNC Delivers Superior Quality. Among the rapid tooling methods, the approach using a high-speed CNC-milled master produced the best results. It yielded an emboss tool with a surface roughness (Ra) of 6.8µm and the lowest dimensional deviation. In contrast, the SLS-based tool was the roughest at 16µm. (See Table 1).

Finding 2: Drastic Time Reduction is Achievable. The high-speed CNC approach was the fastest, requiring only 23.5 hours from start to finish. The SLS and SLA methods were also quick, at 27 and 29 hours, respectively. The direct RapidSteel method was the slowest at approximately 57 hours, largely due to the 24-hour debinding and 24-hour infiltration steps. All these are a fraction of the time required for conventional tooling. (See Table 2).

Finding 3: Massive Cost Savings Confirmed. This is perhaps the most compelling finding. The total cost for the SLS, High-Speed CNC, and SLA approaches were $136.8, $150, and $151.2, respectively. The direct RapidSteel method cost $139. This stands in stark contrast to the estimated $3000 for a conventionally machined die insert. This represents a cost reduction of approximately 95%. (See Table 3).

Finding 4: Functional Prototypes are a Reality. The tools produced by all four methods were successfully used to emboss 0.4mm thick aluminum sheet metal. While some spring back was observed, the experiment proved that these low-cost, rapidly produced tools are robust enough for prototype stamping operations. No significant tool wear was observed after 10 stamping operations.

Practical Implications for HPDC Products

While this study focuses on sheet metal, the principles of rapid, cost-effective tooling have direct parallels and offer valuable insights for the HPDC industry.

For Process Engineers: The paper's "closed loop" concept (Figure 1), where physical parts are measured and fed back into the virtual CAD model for rapid iteration, is a powerful paradigm. This suggests that for prototype HPDC runs, creating lower-cost, "soft" tooling could allow for faster design validation and optimization before committing to expensive, hardened steel dies. The study shows that a functional tool can be made in about a day.

For Quality Control: The detailed comparison of surface roughness and dimensional accuracy in Table 1 underscores the importance of selecting the right rapid prototyping method for the application. The finding that high-speed CNC milling provides superior surface finish is a key takeaway for anyone creating master patterns, whether for sheet metal tools or investment casting patterns used in die development.

For Die Design: The research demonstrates that complex features, like the embossed Merlion logo, can be successfully translated from a CAD model to a physical tool at a fraction of the typical cost and time. This implies that HPDC die designers could use similar techniques to test complex die features, such as lifters or slides, in a low-cost epoxy or soft metal tool before finalizing the design for a production H13 steel die. The cost comparison in Table 3 provides a compelling business case for this approach.

Paper Details

Advanced Sheet Metal Manufacturing Using Rapid Tooling

1. Overview:

- Title: Advanced Sheet Metal Manufacturing Using Rapid Tooling

- Author: Du Zhao Hui¹, Chua Chee Kai¹, Chua Yew Sen¹, Loh-Lee Leow Gek², Lim Ser Tiak²

- Year of publication: The paper does not specify a publication year, but references are from 1993-1997.

- Journal/academic society of publication: The paper does not explicitly name the journal or conference proceedings.

- Keywords: Sheet metal manufacturing; Rapid prototyping; Rapid tooling; RapidSteel

2. Abstract:

A closed loop process is proposed for making sheet metal prototyping parts by using advanced computer aided techniques and computer controlled machines. The key aspect of this process is the method used to fabricate and modify the sheet metal forming tools, which are not necessarily for mass production but should be suitable for short run production or design evaluation of sheet metal products where the prototyping cost and lead-time are greatly reduced. Various approaches are investigated in the preparation of the tooling for onward embossing on a sheet metal. The three indirect approaches use Selective Laser Sintering (SLS), Stereolithography(SLA), and high speed Computer Numerical Controlled (CNC) milling to build the masters from computer data models. And the masters are then served in the vacuum casting process to generate the non-ferrous tooling. The direct approach uses DTM’s RapidSteel to produce the metal tooling without going through any secondary process. Comparisons on quality, leading time and cost are presented.

3. Introduction:

Parts from rapid prototyping (RP) / rapid tooling (RT) could be produced not only for engineering prototyping, but also for marketing purposes by distributors and dealers. However, only a few developmental results have been reported on sheet metal products by using RP and RT. Berger, et al. [6] discussed that the process of sheet metal forming can be improved with the integration of concurrent engineering methods and RP technology. This paper presents a case study using easily castable amorphous material and integrating Stereolithography in the fabrication of the casting shell. However, more result and information desired are still unavailable.

4. Summary of the study:

Background of the research topic:

Conventional tooling preparation for sheet metal manufacturing is a crucial but difficult stage. It is often a trial-and-error process due to material spring back and non-linearities, making it slow and costly, especially for small-batch series and prototypes. This creates a strong industry demand for faster, lower-cost rapid tooling methods for sheet metal forming.

Status of previous research:

Previous work by researchers like Berger et al. [6] had discussed improving sheet metal forming by integrating RP technology, but detailed information and results were still limited. Present RP techniques were not intended for directly forming sheet metal but could be used with additional steps to transform a CAD model into a final product.

Purpose of the study:

The study aims to investigate and compare various rapid tooling approaches to establish a viable, closed-loop process for Rapid Sheet Metal Prototyping (RSMP). The goal is to create functional tooling for short-run production or design evaluation, significantly reducing cost and lead-time compared to conventional methods.

Core study:

The core of the study is a comparative analysis of four different methods for producing a die insert to emboss a Merlion logo onto a sheet metal part. Three indirect methods (using masters from SLS, SLA, and high-speed CNC milling, followed by vacuum casting) and one direct method (using DTM's RapidSteel) are evaluated based on the quality (surface finish, dimensional accuracy), lead time, and cost of the resulting tooling.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. Four distinct approaches (A, B, C, D as per Figure 2) were used to fabricate a tool for an embossing process. The design to be embossed was a Merlion logo. All four resulting tools were then used in a Turret Punch Press to emboss a 0.4mm thick aluminum sheet.

Data Collection and Analysis Methods:

Data was collected at various stages. The machine occupying time for each step was recorded to calculate total lead time (Table 2). The cost of materials for each process was calculated to determine the total tooling cost (Table 3). The surface finish of the masters and final tools was measured using a profilometer (Mitutoyo Surftest 301). Dimensional accuracy was measured and compared against the original CAD design values (Table 1). The final embossed parts were visually inspected.

Research Topics and Scope:

The research focuses on the fabrication of "soft tooling" for sheet metal prototyping. The scope covers:

- Three indirect rapid tooling methods (SLS, SLA, CNC) involving master pattern creation, silicone rubber molding, and epoxy casting.

- One direct rapid tooling method (RapidSteel).

- A quantitative comparison of these methods based on time, cost, and quality.

- A functional test of the produced tooling via an embossing operation.

The study does not investigate long-term tool wear or the optimization of the stamping process itself.

6. Key Results:

Key Results:

- The high-speed CNC milling/vacuum casting approach produced the best surface finishing and dimensional accuracy among the tested RT methods (Table 1).

- The high-speed CNC milling approach was the fastest, taking 23.5 hours, while the direct RapidSteel method was the slowest at approximately 57 hours (Table 2).

- All rapid tooling approaches offered a dramatic cost saving of ~95% compared to conventional tooling, with costs ranging from $136.8 to $151.2 versus $3000 for a conventional die insert (Table 3).

- All tools were functional and successfully produced embossed samples, proving the viability of RT for creating prototype sheet metal parts.

Figure Name List:

- Figure 1. The closed loop of the RSMP system

- Figure 2. The flow diagram of the four approaches

- Figure 3. The embossed design

- Figure 4. The design of the die insert

- Figure 5. The design of the master

- Figure 6. Masters made by SLS, CNC, and SLA

- Figure 7. Silicon rubber mold assembled

- Figure 8. The three sets of aluminum/epoxy tooling

- Figure 9. The RapidSteel die and punch insert (left) and the partially polished insert (right)

- Figure 10. The assembled tooling

- Figure 11. Embossed sheet metal samples

7. Conclusion:

The various approaches have been carried out to implement the concept of rapid sheet metal prototyping. The flexibility of CAD systems enables the optimization of the tooling needed for sheet metal manufacturing. With the further introduction of SLA, SLS, High speed CNC milling, and RapidSteel in the tool making stages, a short-run production of sheet metal product is possible with the lower cost and shorter leading time. The paper concludes that it will be possible in the future to optimize tooling design based on feedback from scanning actual parts, bringing more benefits from the close loop concept of the RSMP system.

8. References:

- [1] Jacobs, Paul F, “ Stereolithography and other RP&M technologies: from Rapid Prototyping to Rapid Tooling”, ASME Press 1996.

- [2] C.K. Chua and K. F. Leong, “Rapid Prototyping: Principles and Applications in Manufacturing”, John Wiley, 1997.

- [3] Atkinson, David,”Rapid Prototyping and Tooling: A Practical Guide”, Welwyn Garden City, Herts: Strategy Publications, 1997.

- [4] Daniel F. Walczyk and David E. Hardt, “A New Rapid Tooling Method for Sheet Metal Forming Dies”, Paper presented at the 5th International Conference on Rapid Prototyping, June 12-15 1994

- [5] Wiliam Miller, “Rapid Prototyping for Stamped and Stretch-Formed Metal Parts ”, Paper presented at the Society of Manufacturing Engineers Conference, April 23-25, 1996.

- [6] Ulrich Berger, Klaus Dieter Thoben, Hans Muller, “Rapid Prototyping Technologies for Advanced Sheet Metal Forming”, Paper presented at the Society of Manufacturing Engineers Conference, May 11-13, 1993, pp55-65

- [7] Jurag Gupta and Jerry Lee, “Rapid Prototyping in Die Manufacturing”, Paper presented at the Society of Manufacturing Engineers Conference, May 11-13, 1993.

- [8] Sinterstation 2500 operation manual, DTM Corp., 1993.

- [9] Peter J. Sayki, “Rapid Prototyping & Vacuum Cast Moulding Technologies”, Paper presented at the Society of Manufacturing Engineers Conference, May 11-13, 1993.

Expert Q&A: Your Top Questions Answered

Q1: What is the single biggest advantage of using these rapid tooling methods?

A1: The most significant advantage is the dramatic reduction in cost and lead time. The study shows that functional prototype tooling can be produced for about 5% of the cost of conventional tooling ($150 vs. $3000) and in just 1-2 days instead of weeks. [Source: Table 3, Table 2]

Q2: Which rapid tooling method produced the highest quality tool?

A2: The indirect method using a high-speed CNC milled master pattern resulted in the highest quality tool. It had the best surface finish (6.8µm Ra) and the lowest dimensional deviation from the CAD model. [Source: Table 1, Section 5]

Q3: Are these "soft tools" durable enough for actual use?

A3: Yes, for prototyping and short runs. The paper confirms that the aluminum epoxy tools and the RapidSteel tool were all successfully used to emboss 0.4mm aluminum sheet. No significant tool wear was observed after 10 stamping operations, indicating they are suitable for their intended purpose of design validation and short-run production. [Source: Section 4.5]

Q4: What is the difference between the "indirect" and "direct" methods discussed?

A4: The indirect methods (Approaches A, B, C) first create a master pattern using a technology like SLS, SLA, or CNC. This pattern is then used in a secondary process (silicone molding and vacuum casting) to create the final tool. The direct method (Approach D, RapidSteel) builds the final metal tool directly from the CAD file in one primary process, without needing a master pattern. [Source: Abstract, Figure 1]

Q5: Why was the RapidSteel (direct metal) method so much slower than the others?

A5: The RapidSteel process itself is not excessively long, but it requires significant post-processing. The study notes a 24-hour cycle for debinding (burning out the polymer binder) and another 24-hour cycle for bronze infiltration to create a fully dense part. These two steps account for 48 hours of the total 57-hour lead time. [Source: Section 4.4, Table 2]

Conclusion & Next Steps

This research provides a valuable roadmap for any organization looking to accelerate its product development cycle and de-risk the tooling process. The findings offer a clear, data-driven path toward improving the speed and cost-efficiency of producing prototype and short-run metal parts. By embracing the principles of rapid tooling, companies can iterate on designs faster, test functionality sooner, and get products to market quicker.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. While our focus is on high-volume HPDC, the principles of front-loading the design and validation process using rapid, cost-effective methods are universal. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement advanced principles in your component development.

Copyright

- This material is a paper by "Du Zhao Hui, Chua Chee Kai, Chua Yew Sen, Loh-Lee Leow Gek, and Lim Ser Tiak". Based on "Advanced Sheet Metal Manufacturing Using Rapid Tooling".

- Source of the paper: The paper appears to be a conference proceeding, but a specific DOI or URL is not provided in the document.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.