This technical summary is based on the academic paper "STUDIES CONCERNING THE INFLUENCE OF THE HIGH PRESSURE DIE CASTING PROCESS PARAMETERS TO THE STRUCTURAL RESISTANCE OF PINION HOUSINGS" published by Ferencz Peti, et al. in a Conference Paper (December 2018). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: HPDC Shrinkage Porosity

- Secondary Keywords: High Pressure Die Casting, Pinion Housing, Solidification Simulation, Squeeze Pin, Structural Resistance, Aluminium Die Casting, Leakage Performance

Executive Summary

- The Challenge: Pinion housings for hydraulic power steering systems demand high structural integrity and must be free from leakage. However, their design often includes areas with large wall thickness, making them highly susceptible to shrinkage porosity during the HPDC process.

- The Method: Researchers used a two-step approach. First, they employed virtual solidification simulation to predict porosity in a critical, thick-walled area of a pinion housing. Second, they conducted laboratory analysis on physically cast samples to verify the simulation and test a novel solution.

- The Key Breakthrough: While simulations and initial tests confirmed the presence of significant shrinkage porosity, the implementation of an additional, synchronized squeeze pin system successfully eliminated the defect in the critical area.

- The Bottom Line: This study proves that local intensification via a squeeze pin is a highly effective method for overcoming shrinkage porosity in challenging HPDC components, ensuring good structural resistance and preventing leakage.

The Challenge: Why This Research Matters for HPDC Professionals

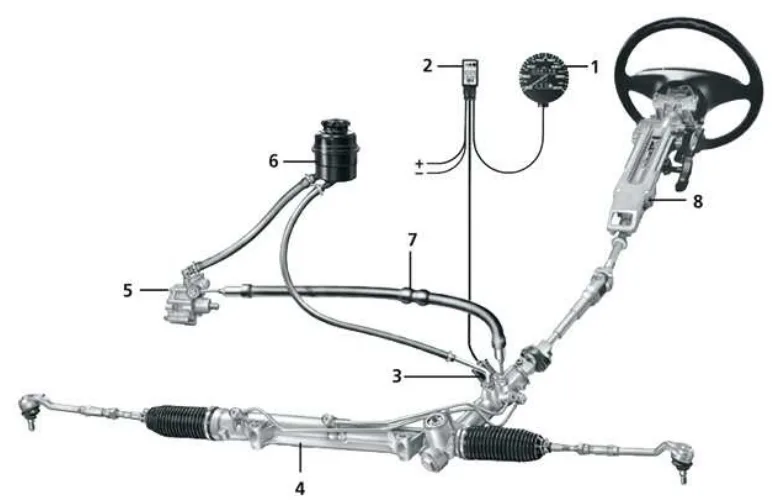

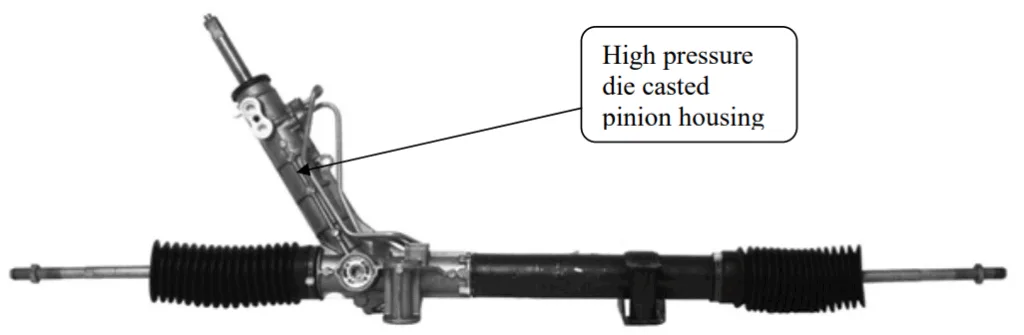

In the manufacturing of automotive components, consistency and reliability are paramount. For parts like the pinion housing in a hydraulic power steering system (Figure 1), structural integrity is not just a quality metric—it's a functional necessity. These components must have a compact material structure to withstand high pressures and prevent fluid leakage.

The most common manufacturing method, high-pressure die casting (HPDC), is excellent for producing complex geometries at high volumes. However, it presents a persistent challenge: shrinkage porosity. This defect is especially prevalent in areas with a large mass of aluminium and significant wall thickness. As the molten alloy cools and solidifies, these thick sections are the last to harden, and if they are not adequately fed with liquid metal, voids or pores will form. This porosity compromises the part's structural resistance and can lead to costly failures and high scrap rates. This study directly addresses this critical industry problem.

The Approach: Unpacking the Methodology

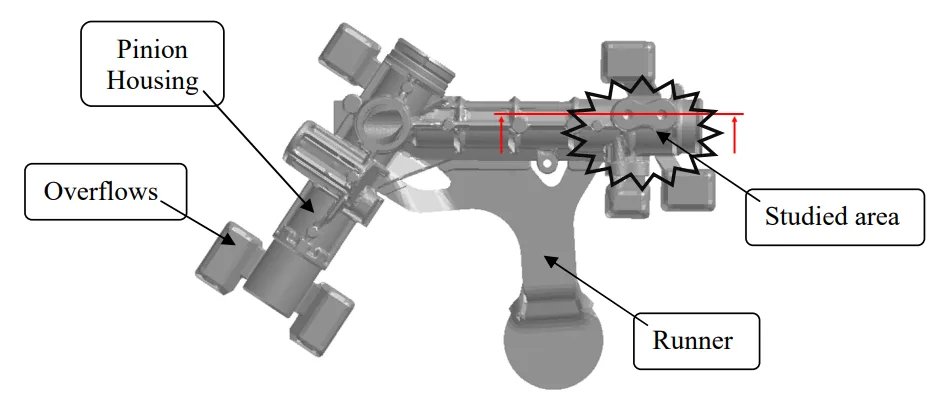

The research team organized their study into two main stages to find a definitive solution for porosity in a pinion housing's critical section (Figure 7).

- Virtual Simulation: The first stage involved using specialized software for mold flow and solidification analysis. The goal was to predict the formation of shrinkage porosities in a high-mass area of the part under two conditions: one without a pre-casted hole and one with a pre-casted hole. This allowed the team to visualize and quantify the problem before any metal was cast.

- Physical Testing and Validation: The second stage involved manufacturing physical samples based on the simulation scenarios. These samples were sectioned and analyzed in a laboratory to confirm the presence and extent of the porosity predicted by the software. Following this validation, the mold was modified to include a "squezze system"—an additional hydraulic pin designed to apply localized pressure (intensification) to the critical area during solidification. Samples were then cast using this new setup to evaluate its effectiveness.

The Breakthrough: Key Findings & Data

The study's step-by-step approach yielded clear and conclusive results, confirming the problem and validating the solution.

- Finding 1: Simulation Accurately Predicts Porosity: The solidification simulations for both the part without a pre-casted hole (Figure 8) and with a pre-casted hole (Figure 9) showed that a significant volume of liquid alloy remained in the studied area long after the rest of the part had solidified. The simulation results in Figure 10 clearly indicated that this would lead to the formation of shrinkage porosities.

- Finding 2: Laboratory Analysis Confirms Simulation: The physical samples confirmed the simulation's predictions. The sectioned parts from both "Case 1: Samples without precasted hole" (Figure 11) and "Case 2: Samples with precasted hole" (Figure 12) showed significant shrinkage porosities in the exact areas highlighted by the simulation. This confirmed that the thick wall section was the root cause of the defect.

- Finding 3: Squeeze Pin Solution Eliminates Porosity: The introduction of the squeeze pin system (detailed in Figure 13 and Figure 14) provided the final, decisive result. By applying complementary, localized pressure to the critical area during the intensification phase, the system was able to feed the section with molten metal and compact the material as it solidified. The resulting samples (Figure 15) showed a dramatic improvement in material health, with the shrinkage porosity being "practically eliminated."

Practical Implications for HPDC Products

The findings of this paper offer direct, actionable insights for improving the quality and reliability of complex die-cast components.

- For Process Engineers: The study demonstrates that for parts with unavoidable thick-walled sections, standard process intensification may not be enough. The research suggests that implementing a synchronized squeeze pin system can be a powerful tool to eliminate localized shrinkage porosity, leading to a reduction in scrap rates and an increase in parts that meet strict leakage performance requirements.

- For Quality Control: The strong correlation between the solidification simulation (Figure 10) and the actual laboratory analysis (Figures 11 & 12) reinforces the value of simulation as a predictive quality tool. It can be used in the early design stages to identify potential porosity hotspots, saving significant time and resources that would otherwise be spent on physical trials and troubleshooting.

- For Die Design: This study provides a clear blueprint for solving a common design challenge. When designing molds for parts with known critical areas, incorporating a squeeze pin system, as shown in Figure 13, can be a proactive solution. The pin can be mounted directly in the part area or on an overflow to apply the necessary local pressure to ensure a sound, compact material structure.

Paper Details

STUDIES CONCERNING THE INFLUENCE OF THE HIGH PRESSURE DIE CASTING PROCESS PARAMETERS TO THE STRUCTURAL RESISTANCE OF PINION HOUSINGS

1. Overview:

- Title: STUDIES CONCERNING THE INFLUENCE OF THE HIGH PRESSURE DIE CASTING PROCESS PARAMETERS TO THE STRUCTURAL RESISTANCE OF PINION HOUSINGS

- Author: Ferencz, Peti; Lucian, Grama; Iñigo, Loizaga; Attila, Püspöki, and 4 other authors.

- Year of publication: 2018

- Journal/academic society of publication: Conference Paper

- Keywords: High pressure die casting, aluminium, pinion housing, porosity, mold, squezze

2. Abstract:

This article describes the influence of the high pressure diecasting process parameters as the geometry of the ingate area, the alloy injection parameters to the structural resistance of pinion housings, which are part of the steering systems. The objective of this study is to ameliorate the health of the injected material in the mold, by reducing the shrinkage porosities which is part of the high pressure diecasting process. The research is organised in two main steps: a preliminar one concerning the virtual simulation, and a second one which is related directly to the mold, with the objective to correlate the virtual simulations with the results obtained with the mould. The virtual simulation has the objective to improve the design of the high pressure diecasting process especially the runner and overflow system, using special software for mold flow analysis and for solidification. The filling of the molds cavities and the solidification of the alloy in the cavities are the main factors for the health of the material of the diecasted parts from point of view of porosity. The filling simulation supports the design of the runner and venting systems and allows to improve the mold from early design stage, in order to minimize the antrenation of gas porosities. The solidification simulation supports the design of the part from technological point of view and indicates the critical areas which may contain shrinkage porosities after solidification.

3. Introduction:

The pinion housing is a part of the rack and pinion power steering gear system, and the most common actual technology for manufacturing the pinion housings is the high pressure diecasting process. Pinion housings can be part of electric power steering, hydraulic power steering or electrically powered hydraulic steering. The pinion housings part of hydraulic power steering has to have a high performance from leakage point of view in order to have a good structural resistance, which means a compact structure and good health of material from porosity point of view.

4. Summary of the study:

Background of the research topic:

The study focuses on pinion housings for hydraulic power steering systems, which are manufactured using the high-pressure die casting (HPDC) process. These parts require excellent structural resistance and material health (i.e., low porosity) to prevent leakage. A common problem in HPDC is shrinkage porosity, especially in areas with large wall thickness.

Status of previous research:

The paper does not explicitly detail the status of previous research but frames its work as an investigation into improving a known industrial process. It leverages established tools like mold flow and solidification simulation software and standard HPDC process steps. The innovation lies in applying and validating a specific solution (squeeze pin) for this particular component.

Purpose of the study:

The primary objective is to improve the material health of die-cast pinion housings by reducing or eliminating shrinkage porosity. The study aims to achieve this by first using virtual simulation to identify problem areas and then implementing and testing a physical modification to the mold—an additional squeeze pin system—to solve the problem.

Core study:

The core of the study is a three-part investigation into a critical, thick-walled area of a pinion housing.

- Case 1: Simulation and physical casting of the part without a pre-casted hole.

- Case 2: Simulation and physical casting of the part with a pre-casted hole.

- Case 3: Modifying the mold with a squeeze pin system and casting samples to evaluate its effect on eliminating the porosity identified in the first two cases.

5. Research Methodology

Research Design:

The research was designed in two main phases. The first was a preliminary phase using virtual simulation to analyze solidification and predict porosity. The second phase was a practical application phase involving the direct modification of the casting mold and laboratory analysis of the resulting parts. This comparative design allowed researchers to validate the simulation and then prove the effectiveness of their proposed solution.

Data Collection and Analysis Methods:

- Virtual Simulation: Special software was used for mold flow and solidification analysis to predict areas of liquid fraction and potential shrinkage porosity.

- Laboratory Analysis: Physical samples were manufactured, sectioned, and analyzed to observe the material health. Micrographs were taken to visualize and confirm the presence and size of porosities.

- Process Implementation: A squeeze pin system, including an additional hydraulic cylinder and external control equipment, was integrated with the die casting machine and mold.

Research Topics and Scope:

The research is focused specifically on the elimination of shrinkage porosity in a thick-walled section of an aluminum HPDC pinion housing. The scope includes the simulation of the solidification process, the physical validation of these simulations, and the implementation and testing of an additional squeeze pin (squeezing) system as a solution.

6. Key Results:

Key Results:

- Solidification simulations correctly predicted that the studied area, due to its large mass, would contain significant liquid fractions after the normal solidification time, leading to shrinkage porosity (Figures 8, 9, 10).

- Laboratory analysis of manufactured samples without the squeeze pin solution confirmed the presence of significant shrinkage porosities, validating the simulation's results (Figures 11, 12).

- The implementation of a squeeze pin system, which applies local intensification, was presented as the solution (Figure 13).

- Samples manufactured with the squeeze pin solution showed a significant improvement in material health, with the practical elimination of shrinkage porosity (Figure 15). This ensures good structural resistance and positive leakage performance.

Figure Name List:

- Fig. 1. Hydraulic power steering system

- Fig. 2. Subassembly of the Rack and pinion power steering gear system

- Fig. 3. Filling of the shotsleeve

- Fig. 4. Beginning of first phase

- Fig.5. Beginning of the second phase

- Fig.6. Third phase, pressure intensification

- Fig.7. Pinion Housing with runner and overflow system

- Fig.8. Simulation without precasted hole

- Fig.9. Simulation with precasted hole

- Fig.10. Result of the solidification simulation

- Fig.11. Samples material health without precasted holes

- Fig. 12. Samples material health with precasted holes

- Fig.13. Solution in the mold with squezze pin

- Fig.14. The external squezze equipment

- Fig.15. Samples material health with squezze pin solution

7. Conclusion:

The solidification simulation results have been confirmed by the laboratory analysis of the manufactured diecasted samples. In both cases the shrinkage porosity has been present due to the big wall thickness. The solution to eliminate succesfully the shrinkage porosity was the using of the squezze pin equipment which is synchronized with the Die Casting Machine control during the injection cycle. Even if this method requires aditional investments, the effort is justified due to the fact that it is giving the posibility to diecast good parts with strict porosity requirements and in this way to reduce the scrap rate and the waste.

8. References:

- [1] Ernst Brunhuber – Praxis der Druckgussfertigung, Ed. Schiele & Schön, Berlin, 1991

- [2] Herbert Rees – Mold Engineering, Ed. Carl Hanser Verlag, Munich, 2002

- [3] Montes Jose - Revision Tecnica del Producto, CIE C. Vilanova, 2008

- [4] Street, Arthur, The diecasting handbook, Portcullis Press LTD, 1977

- [5] Șeres I. – Matrițe de injectat, Ed. Imprimeriei de Vest, Oradea, 1999

- [6] Zirbo, Gh., Dan V. – Turnarea sub presiune. Elemente de proiectare a formelor metalice, Ed. U.T. Pres, Cluj-Napoca, 1997

- [7] *** - Company documentation Buhler

- [8] http:// www.buhlergroup.com

- [9] http:// www.diecastingengineer.org

- [10] http://eb-cat.ds-navi.co.jp/enu/jtekt/tech/ej/

- [11] http://www.flow3d.com/

- [12] http://www.springerlink.com

Expert Q&A: Your Top Questions Answered

Q1: What is the primary cause of defects in die-cast hydraulic pinion housings?

A1: According to the paper, the primary challenge is ensuring high performance from a leakage point of view. This requires good structural resistance, which is compromised by shrinkage porosity. This porosity often forms in areas with big wall thickness, which is a common feature in these components (Source: Introduction, page 2).

Q2: Can simulation software reliably predict where these porosity defects will occur?

A2: Yes. The study demonstrated a strong correlation between the virtual simulation and the physical results. The solidification simulation (Figure 10) accurately indicated the critical areas that would contain shrinkage porosities, and this was later confirmed by laboratory analysis of the actual cast parts (Figures 11 and 12).

Q3: What is a "squeeze pin" and how does it work?

A3: A squeeze pin is a component added to the die casting mold, typically a hydraulic pin, designed to apply complementary, localized pressure (intensification) to a specific critical area of the part during the solidification phase. As shown in Figure 13, it is synchronized with the die casting machine's cycle to compact the material in areas prone to shrinkage, ensuring a denser, healthier structure.

Q4: How effective was the squeeze pin solution in this study?

A4: It was highly effective. The paper's conclusion states that the squeeze pin solution was able to "eliminate succesfully the shrinkage porosity." The image of the final sample in Figure 15 shows a vastly improved material health, which the authors note assures good structural resistance and a positive leakage performance.

Q5: Is implementing a squeeze pin system a worthwhile investment?

A5: The paper argues that it is. While acknowledging that the method requires additional investment in equipment (Figure 14) and mold modification, the authors conclude the effort is justified. It provides the ability to cast good parts that meet strict porosity requirements, which in turn reduces the scrap rate and waste (Source: Conclusion, page 9).

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing part integrity in HPDC. For any engineer or manager struggling with defects originating from thick-walled sections, the findings offer a clear, data-driven path toward improving quality, reducing scrap, and optimizing production. The successful elimination of shrinkage porosity through a targeted squeeze pin system is a powerful testament to how innovative tooling solutions can overcome inherent process challenges.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Ferencz Peti, et al.". Based on "STUDIES CONCERNING THE INFLUENCE OF THE HIGH PRESSURE DIE CASTING PROCESS PARAMETERS TO THE STRUCTURAL RESISTANCE OF PINION HOUSINGS".

- Source of the paper: https://www.researchgate.net/publication/329542568

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.