A Practical Guide to Boosting Productivity and Quality in Die Casting Using Proven Lean Principles

This technical brief is based on the academic paper "Case study of lean manufacturing application in a die casting manufacturing company" by Ng Tan Ching, Clarence Chan Kok Hoe, Tang Sai Hong, Morteza Ghobakhloo, and Chen Kah Pin, published in AIP Conference Proceedings (2015). It is summarized and analyzed for die casting professionals by the experts at CASTMAN.

Keywords

- Primary Keyword: Lean Manufacturing in Die Casting

- Secondary Keywords: 5S Housekeeping, Takt Time Calculation, House of Quality (HoQ), Die Casting Process Improvement, Manufacturing Waste Reduction, Continuous Improvement (Kaizen)

Executive Summary

- The Challenge: A die casting manufacturer faced common but critical production issues, including long operator idle times, high defect rates, time wasted searching for tools, and unexpected machine downtime.

- The Method: Researchers conducted a case study applying core lean manufacturing tools: time studies to measure workflow, Takt time to set production pace, House of Quality (HoQ) to align product design with customer needs, and 5S housekeeping to organize the workspace.

- The Key Breakthrough: The study demonstrated that a systematic, data-driven approach can precisely identify bottlenecks and sources of waste. Calculating the Takt time revealed process imbalances, while the HoQ provided a clear framework for prioritizing design improvements based on customer feedback.

- The Bottom Line: Implementing structured lean methodologies like 5S and cross-training operators offers a direct path to reducing defects, improving efficiency, and increasing profitability in a die casting environment.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive world of die casting, efficiency is paramount. The subject of this case study, a company referred to as "ABC," faced a familiar set of challenges that erode profitability and customer satisfaction. As detailed in the paper's background, operators experienced significant idle time, particularly at the EDM station, while waiting for machines to complete cycles. Despite this available time, the number of defective products remained high, and these defects were often discovered too late for rework.

Furthermore, operators spent an average of 2 to 3 minutes per task simply locating the necessary tools, a clear sign of workplace disorganization. Compounding these issues, critical machinery would break down without warning, disrupting production schedules despite a biannual maintenance program. These problems—wasted time, poor quality, and unreliability—are common pain points that directly impact the bottom line of any manufacturing operation. This study provides a practical framework for tackling them head-on.

The Approach: Unpacking the Methodology

To diagnose and solve these issues, the researchers applied a multi-faceted lean manufacturing approach. The goal was to move from anecdotal observations to a data-driven improvement plan. The methodology included:

- Time Study: The operations of a single assembly line—including grinding, milling, turning, and EDM stations—were timed to understand the actual performance and workload of each station.

- Takt Time Analysis: By calculating the effective working hours and the required daily output, the researchers established the "Takt time"—the rhythm or pace at which a completed product needs to be produced to meet customer demand.

- House of Quality (HoQ): This quality tool was used to translate customer complaints and requirements (e.g., "high precision," "cools quickly") into specific, measurable technical design characteristics for the die cast mould.

- 5S Housekeeping: The study analyzed the existing state of workplace organization and proposed a systematic implementation of the 5S principles (Sort, Set in order, Shine, Standardize, Sustain) to create a cleaner, safer, and more efficient environment.

The Breakthrough: Key Findings & Data

The application of these lean tools yielded clear, actionable insights into the company's operational inefficiencies.

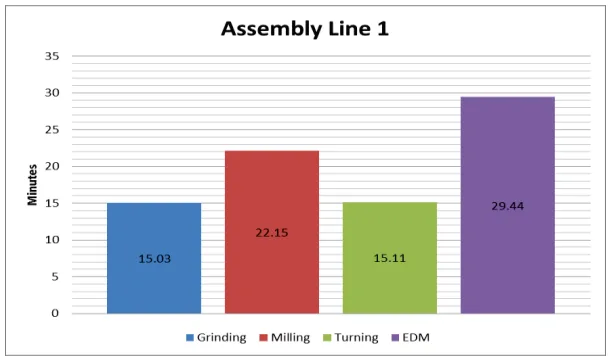

- Finding 1: Establishing the Production Pace with Takt Time: The study first calculated the total effective working time per day to be 430 minutes (Table 1). Based on production forecasts, the assembly line needed to produce 11 units per day (Table 3). This led to a calculated Takt time of 39.09 minutes per unit. The researchers then applied a more realistic 85% efficiency rule, resulting in an adjusted Takt time of 33.23 minutes. This new target encourages stations to complete their work well within the maximum allowable time, creating a smoother production flow (Figure 1).

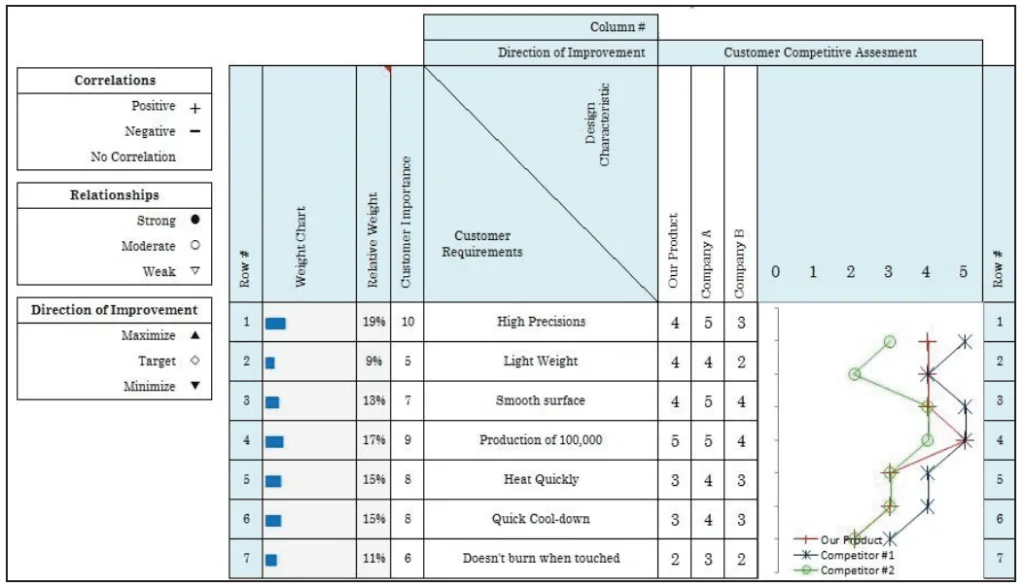

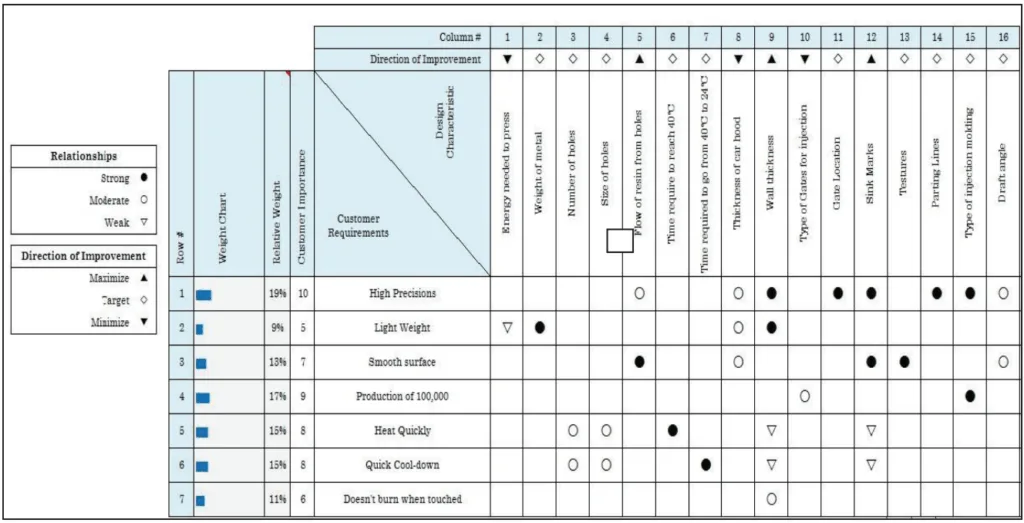

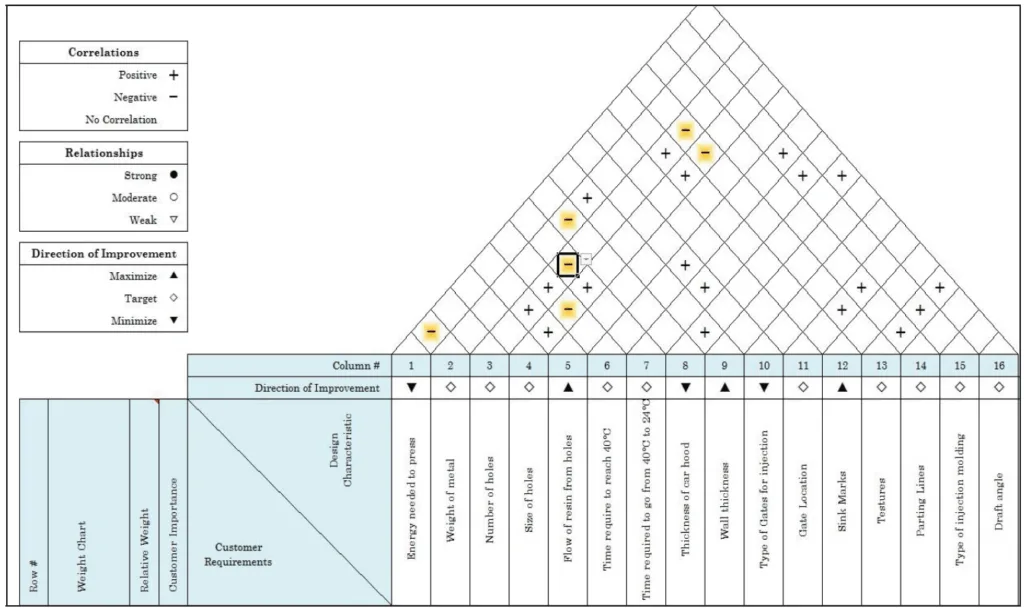

- Finding 2: Translating Customer Needs into Technical Solutions with HoQ: The House of Quality analysis provided a structured way to address customer requirements. The study identified that "High Precision" and "Production of 100,000 [units]" were the top customer priorities. The HoQ matrix (Figure 3) linked these needs to specific engineering characteristics like "Wall thickness" and "Type of Gates for injection." This process allows the design team to focus its efforts on the technical features that have the greatest impact on customer satisfaction.

- Finding 3: Reducing Waste and Defects with 5S Housekeeping: The paper highlights that a disorganized workspace was a major contributor to wasted time and quality defects. Photos of the workplace (Figure 7) showed tools left unorganized on tables. The research strongly advocates for a formal 5S program, where unnecessary items are removed (Sort), necessary tools are given a designated, labeled home (Set in order), and the area is kept clean (Shine). The study provides a sample 5S Tracking Sheet (Table 8) to help standardize these practices and sustain the improvements.

Practical Implications for Your HPDC Operations

The findings from this case study offer valuable, real-world lessons that can be applied to nearly any die casting facility.

- For Process Engineers: The Takt time calculation method detailed in the "RESULTS AND DISCUSSIONS" section is a powerful tool for balancing your assembly lines. By comparing each station's cycle time (Figure 1) to the Takt time, you can immediately identify bottlenecks (stations that are too slow) and opportunities to reallocate work or cross-train operators from underutilized stations.

- For Quality Control: This research reinforces the link between workplace organization and product quality, citing that 25-30% of quality defects can be related to this issue (Ref. [1]). Implementing a structured 5S program with a tracking sheet, as shown in Table 8, can be a low-cost, high-impact initiative to reduce defects and improve process consistency.

- For Die Design: The House of Quality (HoQ) framework (Figure 2 through Figure 6) provides an excellent model for your design and engineering teams. It ensures that design decisions are not made in a vacuum but are directly tied to what your customers value most, leading to more competitive and successful products.

Paper Details

Case study of lean manufacturing application in a die casting manufacturing company

1. Overview:

- Title: Case study of lean manufacturing application in a die casting manufacturing company

- Author: Ng Tan Ching, Clarence Chan Kok Hoe, Tang Sai Hong, Morteza Ghobakhloo, and Chen Kah Pin

- Year of publication: 2015

- Journal/academic society of publication: AIP Conference Proceedings 1660, 090007

- Keywords: Lean manufacturing; 5S; Takt Time; House of Quality.

2. Abstract:

The case study of lean manufacturing aims to study the application of lean manufacturing in a die casting manufacturing company located in Pulau Penang, Malaysia. This case study describes mainly about the important concepts and applications of lean manufacturing which could gradually help the company in increasing the profit by studying and analyzing their current manufacturing process and company culture. Many approaches of lean manufacturing are studied in this project which includes: 5S housekeeping, Kaizen, and Takt Time. Besides, the lean tools mentioned, quality tool such as the House of Quality is being used as an analysis tool to continuously improve the product quality. In short, the existing lean culture in the company is studied and analyzed, with recommendations written at the end of this paper.

3. Introduction:

The paper introduces the concept of Lean Manufacturing, tracing its origins to the Toyota Production System (TPS) developed by Taiichi Ohno and earlier principles from Henry Ford. It then presents the case study of "ABC," a die casting company founded in 2005 in Penang, Malaysia. The company specializes in precision machining, metal stamping, and die casting for various industries. Despite its success and ISO certification, ABC faces several persistent problems on its production floor, which form the basis for this investigation.

4. Summary of the study:

Background of the research topic:

The research is set within a die casting manufacturing company named ABC, which is experiencing four primary issues:

- Long idle time for operators at the EDM station.

- A large number of defective products.

- Excessive time spent by operators searching for tools.

- Unexpected machine breakdowns. These issues represent common forms of "muda" (waste) that lean manufacturing aims to eliminate.

Status of previous research:

The paper acknowledges the foundational work of Taiichi Ohno at Toyota, who identified the seven types of waste, and Henry Ford, who revolutionized manufacturing operations. The study applies these established lean concepts to a modern die casting environment.

Purpose of the study:

The main objectives of the project are:

- To improve productivity on the production floor using the time study method.

- To identify and prioritize issues for improvement based on customer complaints, using the House of Quality.

- To implement 5S principles in the company's production floor to improve organization and reduce waste.

Core study:

The core of the study involves a detailed analysis of a single assembly line at company ABC. It uses quantitative methods like time studies and Takt time calculations to measure and benchmark productivity. It also employs the qualitative and structured House of Quality tool to link customer needs to technical specifications. Finally, it assesses the current state of workplace organization and prescribes a detailed 5S implementation plan to address inefficiencies and quality issues.

5. Research Methodology

Research Design:

The study is designed as a case study of a single assembly line in the ABC company. The line includes grinding, milling, turning, and EDM stations. The research combines quantitative analysis (time studies) with structured qualitative methods (House of Quality) and process improvement frameworks (5S).

Data Collection and Analysis Methods:

Data was collected through time studies of each workstation to determine cycle times. Production forecasts and working schedules were used to calculate effective hours and Takt time. Customer requirements and competitive analysis were gathered to populate the House of Quality matrix. Direct observation and photographs of the workplace were used to assess the need for 5S housekeeping.

Research Topics and Scope:

The scope is focused on one assembly line within the ABC die casting company. The research topics cover the application of specific lean tools:

- Productivity analysis via time study and Takt time.

- Quality improvement via the House of Quality.

- Waste reduction via 5S housekeeping.

6. Key Results:

Key Results:

- The effective working time was calculated to be 430 minutes per day, with 235 working days per year (Tables 1 & 2).

- The daily production requirement for the assembly line is 11 units across four product categories (Table 3).

- The initial Takt time was calculated at 39.09 minutes, which was then adjusted to a more realistic target of 33.23 minutes using an 85% efficiency factor.

- A time study of the assembly line (Figure 1) showed that the EDM station had the longest cycle time (29.44 minutes) but was still within the Takt time, while other stations had significant idle time.

- The House of Quality (Figures 2-6) successfully translated customer priorities like "High Precision" and "Production of 100,000" into targeted technical specifications for the mould design, such as wall thickness and gate type.

- The study identified a clear lack of workplace organization (Figure 7) and proposed a structured 5S implementation, including visual guides for tool placement (Figure 8) and a formal tracking sheet (Table 8) to ensure standardization and sustainability.

Figure Name List:

- FIGURE 1. The Work Load in Assembly Line 1.

- FIGURE 2. Competitive Assessment of Customer Requirements.

- FIGURE 3. Converting Customer's Requirement to Design Characteristic.

- FIGURE 4. The Trade-off Matrix.

- FIGURE 5. Targeted Changes in Design.

- FIGURE 6. The House of Quality in Full Scale.

- FIGURE 7. The Overall Look of the Workplace.

- FIGURE 8. Setting the Tools and Machine.

- FIGURE 9. Scissors on the Ram EDM Workspace during Operation.

7. Conclusion:

The study concluded that while a low Takt time was an inherent characteristic of the process, significant improvements could be made. The implementation of 5S Housekeeping, supported by a standard tracking sheet, is recommended to enhance organization and reduce defects. Furthermore, the paper suggests developing a Cross-Training Matrix to allow operators to handle multiple EDM machines, thereby reducing idle time and increasing flexibility. The authors recommend that future analysis should focus on workplace plant layout and worker skill enhancement programs.

8. References:

- B. A. Henderson and J. L. Larco, Lean Transformation: How to Change Your Business into a Lean Enterprise, Virginia: Oaklea Press, 2002.

- C. A. Ortiz, Kaizen Assembly: Designing, Constructing, and Managing a Lean Assembly Line, New York: CRC Press, 2006.

- J. Pettersen, The TQM Journal 21 (2), 127-142 (2009).

- J. P. Womack and D. T. Jones, Lean Thinking: Banish Waste and Create Wealth in Your Corporation, London: Simon & Schuster UK Ltd., 2003.

- J. Worley and T. Doolen, Management Decision 44 (2), 228-245 (2006).

- L. E. Swayne, W. J. Duncan and P. M. Ginter, Strategic Management of Health Care Organizations, New Jersey: John Wiley & Sons, 2012.

- R. Shah and P. T. Ward, Journal of Operations Management 21 (2), 129-149 (2003).

- T. Melton, Chemical Engineering Research and Design 83(6), 662-673 (2005).

- W. M. Feld, Lean Manufacturing: Tools, Techniques, and How to Use Them, New York: CRC Press, 2000.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing productivity and quality in die casting operations. The findings offer a clear, data-driven path toward improving workplace organization, reducing defects, and optimizing production flow to better meet customer demand.

CASTMAN is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: What were the primary operational problems identified at the die casting company in the study?

- A1: The study identified four main problems: 1) Long idle time for operators, especially at the EDM station; 2) A large number of defective products; 3) Significant time wasted by operators searching for tools; and 4) Unexpected machine breakdowns that disrupted production. This is detailed in the "BACKGROUND OF CASE STUDY" section of the paper, "Case study of lean manufacturing application in a die casting manufacturing company."

- Q2: What is Takt Time and how did the study use it to improve the process?

- A2: Takt Time is the rate at which a company must produce a product to meet customer demand. It's calculated by dividing the available production time by the customer demand. In this study, the Takt Time was found to be 39.09 minutes (and adjusted to 33.23 minutes). This figure served as a benchmark to evaluate the performance of each workstation, revealing that while the EDM station was the bottleneck, all stations were operating within the required pace, highlighting opportunities to rebalance work. The calculations are shown in the "RESULTS AND DISCUSSIONS" section.

- Q3: How does the House of Quality (HoQ) help in designing better die cast moulds?

- A3: The House of Quality (HoQ) is a planning matrix that translates customer requirements into specific, measurable technical characteristics. As shown in Figure 3, the study used HoQ to link customer needs like "High Precision" and "Heat Quickly" to engineering specifications like "Wall thickness" and "Time require to reach 40°C." This ensures that the design team focuses its efforts and resources on features that directly create value for the customer.

- Q4: According to the paper, how can implementing 5S Housekeeping lead to fewer defects?

- A4: The paper argues that a disorganized workplace contributes directly to quality issues. By implementing 5S (Sort, Set, Shine, Standardize, Sustain), a company creates a clean and orderly environment. This allows operators to more easily spot machine wear and tear before it causes a problem, reduces the chance of using the wrong tool, and eliminates clutter that can hide or cause defects. The paper cites a source stating 25-30% of quality defects are related to this issue and provides a 5S tracking sheet (Table 8) to standardize the process.

- Q5: What was the key recommendation for addressing the long operator idle time at the EDM station?

- A5: The paper's conclusion suggests developing a "Cross-Training Matrix" for the EDM operators. The goal is to train a single operator to handle two to three different EDM machine models simultaneously. This would allow the company to utilize the operator's idle time effectively, increasing overall productivity without affecting product quality.

Copyright

- This material is an analysis of the paper "Case study of lean manufacturing application in a die casting manufacturing company" by Ng Tan Ching et al.

- Source of the paper: https://www.researchgate.net/publication/300889362 (DOI: 10.1063/1.4915851)

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 CASTMAN. All rights reserved.