This introduction paper is based on the paper "Novel Method of Improving Squirrel Cage Induction Motor Performance by using Mixed Conductivity Fabricated Rotors (MCFR)" published by "North West University".

1. Overview:

- Title: Novel Method of Improving Squirrel Cage Induction Motor Performance by using Mixed Conductivity Fabricated Rotors (MCFR)

- Author: Constantin Danut PITIS

- Year of publication: 2006

- Journal/academic society of publication: North West University (Faculty of Engineering)

- Keywords: Induction motors, squirrel cage rotors, application engineering, mining industry

2. Abstract:

The ideal squirrel cage motor should have a varying rotor resistance; large at standstill, and decreasing as the speed rises. Overseas-designed high impedance rotors try to fulfil these conditions – mostly used are double cage rotors and die cast aluminium rotors. However, in the South African coal-mining industry these rotors recorded high rate failures with heavy financial losses. As a result, the need for an alternative rotor type that was able to comply with basic conditions ignored before appeared on the market:

- Higher reliability with extended life expectancy

- Lower total ownership costs

- Easy re-manufacturing with components available on the market

- Specific performance stability at competitive price

Over the years, only two principles were tacitly accepted in designing squirrel cage rotors:

- For a single cage rotor, in a circumferential direction around the rotor the squirrel cage bars are placed in the same cylindrical shell, with the same shape and same conductivity.

- For a double cage rotor, the same rule as above applies; however, in the radial direction, the bars have different shapes and typically different conductivities.

The invention is based on a new principle, i.e. “in a circumferential direction around the squirrel cage rotor, squirrel cage bars may have different conductivities and same shapes, or different conductivities and different shapes”.

Mixed Conductivity Fabricated Rotors (MCFR) are designed and manufactured based on this new principle, and are able to withstand the harsh South African mining conditions.

Since patented, the invention has been materialised in a set of special rotors powering continuous miners of a reputable coal-mining house, which was spending about R5 million annually on replacing specific imported die cast aluminium rotors only.

Fully complying with the above-mentioned basic conditions, the patent offers a large variety of technical and economical advantages, increasing mining processes efficiency beyond expectations.

The thesis describes the MCFR’s design adaptability by altering the rotor design to meet the demands of a specific engineering application as a base line of drives design.

The patent is part of the new South African trend of increasing processes efficiency. It offers large possibilities of designing dedicated motors with a positive impact on the South African economy. Some socio-economical advantages are worthy of considerable study:

- Being locally manufactured, the MCFR may reduce the country’s economical dependence.

- Requiring no special expertise, the MCFR can be produced in any quantity and size without excessive investment.

- The MCFR offers an alternative option (product interchangeability) on the market as well as sound competition (with export potential).

- The patent ensures business sustainability conditions which diffuse financial constraints on motor manufacturers and end-users during the re-capitalisation process (very loaded in South African economic and industrial environment).

3. Introduction:

This millennium emphasizes EFFICIENCY, a concept driven by energy and materials crises and new monetary policies, significantly impacting industries like South Africa's [Ref. [1], Ref. [2]]. The South African mining industry, in particular, faced challenges with the performance and reliability of overseas-designed electric motors used in harsh conditions [Ref. [3]]. This led to a need for "dedicated motors" tailored to specific applications, focusing on higher reliability, extended life, lower total ownership costs (TOC) (illustrated in Figure 1.1), and stable performance, especially as increased process speeds often led to higher operational costs if not managed efficiently (Figure 1.2) [Ref. [4], Ref. [5], Ref. [6]]. A significant issue was the high failure rate of existing rotor types, such as die cast aluminium rotors, especially in demanding applications like continuous miners, leading to substantial financial losses [Ref. [7]]. This research introduces the Mixed Conductivity Fabricated Rotor (MCFR) as a novel solution to these challenges, offering an alternative for both new dedicated motors and for repairing/upgrading old motors [Ref. [8], Ref. [9]]. The MCFR aims to improve technical and economic performance in mining by addressing limitations of conventional rotor designs.

4. Summary of the study:

Background of the research topic:

The ideal squirrel cage motor requires varying rotor resistance – high at standstill and decreasing with speed. Conventional high impedance rotors (double cage, die-cast aluminium) used in demanding industries like South African coal mining often fail, incurring significant financial losses (Abstract, Chapter 1). This highlighted a need for alternative rotor designs with improved reliability, longevity, and cost-effectiveness, capable of withstanding harsh operational conditions (Abstract, Chapter 1.6).

Status of previous research:

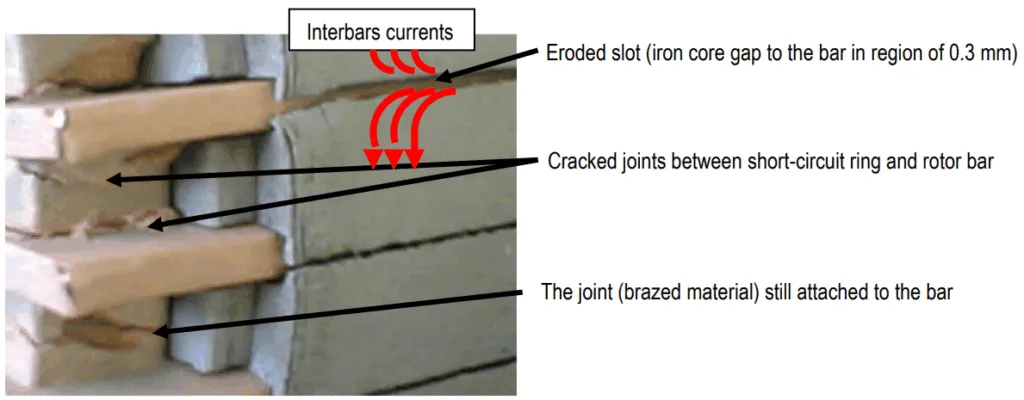

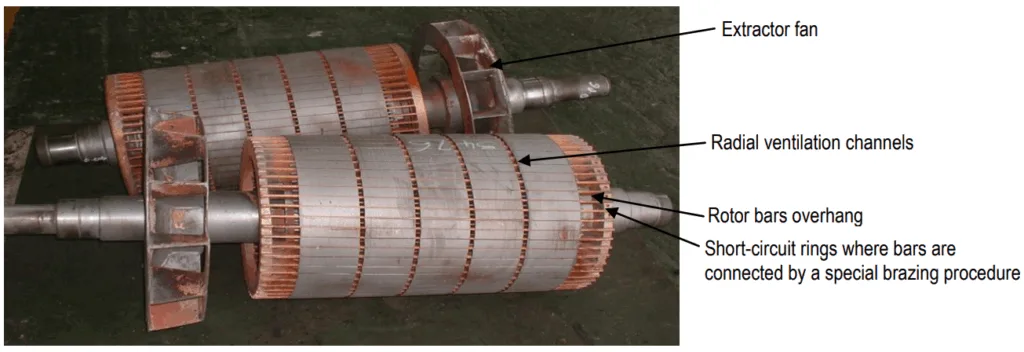

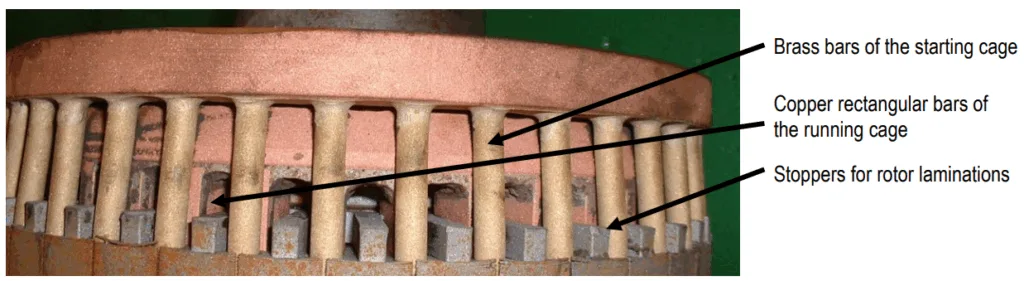

Traditional squirrel cage rotor design followed two main principles: 1) Single cage rotors have bars of the same shape and conductivity in a circumferential direction (Figure 5.2). 2) Double cage rotors also follow this circumferential rule but have bars of different shapes and conductivities in the radial direction (Figure 5.3) (Abstract, Chapter 5.3). Attempts to improve rotor performance involved various materials and designs, including die-cast aluminium and fabricated copper or brass rotors, but these had limitations in specific applications, particularly regarding thermal stress (Photo 4.9), mechanical failures (Photo 3.1), and manufacturing costs for specialized designs (Chapter 3, Chapter 4, Chapter 5.1). For instance, Loher, Damel, and Luck & King had supplied rotors for Voest Alpine Mining and Tunnelling (VAMT) machinery, each with specific trade-offs and failure modes under South African conditions (Chapter 5.1, Photo 5.1).

Purpose of the study:

The study aimed to develop a novel rotor, the Mixed Conductivity Fabricated Rotor (MCFR), to improve the performance, reliability, and cost-effectiveness of squirrel cage induction motors, particularly for harsh applications like those in the South African mining industry (Abstract, Chapter 1.8). The MCFR was designed to overcome the shortcomings of existing high impedance rotors by offering adjustable performance characteristics (Figure 2.1), extended life, and reduced total ownership costs (Chapter 1.6, Chapter 1.8). It also aimed to provide a local manufacturing option, reducing dependence on imported rotors and offering a solution for repairing obsolete motors (Abstract, Chapter 1.8).

Core study:

The core of the study is the invention, design, manufacturing, and validation of the Mixed Conductivity Fabricated Rotor (MCFR). The fundamental principle of the MCFR is that "in a circumferential direction around the squirrel cage rotor, squirrel cage bars may have different conductivities and same shapes, or different conductivities and different shapes" (Abstract, Chapter 5.4). This contrasts with traditional designs where circumferential bars in a single cage layer are uniform. The study details two main MCFR types: MCFR1 (same bar profile, different conductivities, Figure 5.4) and MCFR2 (different profiles and conductivities) (Chapter 5.5). The design leverages the "deep bar effect" (Figure 5.5) and mathematical models for flux and current density (Chapter 5.6, Figure 5.6). A specific MCFR1 was designed for a 36 kW spinner motor (Figure 6.2, Figure 6.3), replacing problematic die-cast aluminium rotors (Figure 6.1). The study includes theoretical analysis, manufacturing processes (Figure 6.4, Figure 6.5, Photo 6.4, Photo 6.5, Photo 6.6, Photo 6.7), experimental validation through SABS testing (Figure 7.1, Figure 7.2), and long-term operational performance assessment (Chapter 6, Chapter 7).

5. Research Methodology

Research Design:

The research involved a multi-stage approach:

- Identifying shortcomings of existing high-impedance rotors (double cage and die-cast aluminium) through literature review, analysis of failures in the South African mining industry, and economic impact assessment (Chapter 4).

- Developing a novel rotor concept, the Mixed Conductivity Fabricated Rotor (MCFR), based on a new design principle of circumferential variation in bar conductivity and/or profile (Chapter 5.4).

- Theoretical modeling of the MCFR, including mathematical expressions for flux density, current density in deep bars (Figure 5.5), and overall rotor performance characteristics (slip, torque, current) (Chapter 5.6, 5.8, Figure 5.7).

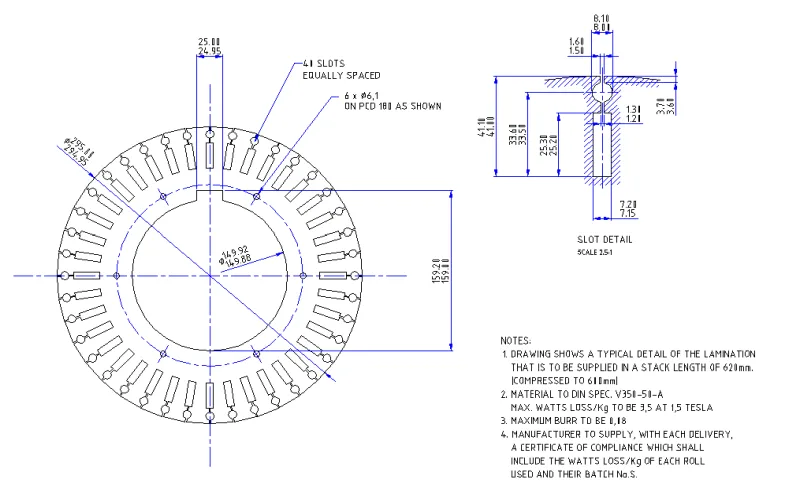

- Designing and manufacturing prototype MCFR1 rotors, specifically for a 36 kW spinner motor application (Chapter 6). This included material selection, lamination design (Figure 6.2, Figure 6.3), and assembly techniques (Figure 6.4, Figure 6.5).

- Experimental validation of the MCFR1 prototypes through comprehensive testing according to SABS and other relevant standards, including no-load, locked rotor (Figure 3.3), temperature rise, stall tests, and special transient tests (Chapter 7.1, 7.2).

- Long-term field testing and on-site validation of an MCFR1 rotor in a continuous miner application for 1.8 years (Chapter 6.6, Photo 6.8, Photo 6.9, Photo 6.10, Photo 6.11, Chapter 7.6.5).

- Comparative analysis of MCFR performance against existing rotor types (Loher, Damel, etc.) based on experimental data and estimated life span (Chapter 7.4, Table 7.1, Chapter 7.6.6, Table 7.5).

- Technical and economic assessment of the MCFR, including TOC and projected savings (Chapter 7.7, Table 7.6, Table 7.7, Table 7.8, Chapter 8.1).

Data Collection and Analysis Methods:

Data was collected through:

- Analysis of existing motor failure reports and financial loss data from mining houses (Chapter 4).

- Theoretical calculations and simulations using motor design programs (e.g., for electromagnetic design, as mentioned in Chapter 6, [Ref. [10]]).

- Laboratory testing of MCFR prototypes using a calibrated Schenk dynamometer and computerised data acquisition system (Chapter 7.1, Figure 7.1). Tests included measurements of voltage, current, power, speed, torque, temperature, and vibrations (Chapter 7.2).

- Oscillograms for DOL starting current analysis (Figure 7.3).

- Physical inspection and analysis of MCFR rotors after prolonged field operation (Chapter 6.6, Photo 7.1).

Data analysis involved: - Comparison of experimental results with theoretical predictions and design specifications.

- Statistical analysis of failure rates and economic data.

- Performance comparisons between MCFR and conventional rotors (Table 7.1, Table 7.2, Table 7.3, Table 7.4, Table 7.5, Table 7.6, Table 7.7, Table 7.8).

- Calculation of motor parameters like efficiency, power factor, slip, starting torque, breakdown torque, and temperature rise (Chapter 7.2).

Research Topics and Scope:

The research focuses on improving squirrel cage induction motor performance and reliability in demanding industrial applications, particularly within the South African mining sector.

Key research topics include:

- Failure mechanisms and economic impact of conventional high impedance rotors (double cage, die-cast aluminium) (Chapter 4).

- A novel design principle for fabricated squirrel cage rotors based on mixed conductivity bars in the circumferential direction (MCFR) (Chapter 5).

- Theoretical analysis of deep bar effects and their application in MCFR design (Chapter 5.6).

- Design, manufacturing processes, and optimization of MCFRs (Chapter 6).

- Experimental validation of MCFR performance, including starting characteristics, thermal behavior, and operational reliability (Chapter 7).

- Comparative assessment of MCFR against existing rotor technologies in terms of technical performance, life span, and economic benefits (Chapter 7, Chapter 8).

The scope is primarily focused on low-voltage motors (e.g., 36 kW spinner motors for continuous miners, Figure 7.2) but the principles could have broader applications. The study covers the entire lifecycle from concept development to long-term validation.

6. Key Results:

Key Results:

The research successfully developed and validated the Mixed Conductivity Fabricated Rotor (MCFR), demonstrating significant improvements over conventional high-impedance rotors, especially die-cast aluminium rotors used in harsh mining conditions.

- New Design Principle Validated: The core principle of using circumferentially arranged bars of different conductivities (and/or profiles) was proven effective in tailoring motor performance (Chapter 5, Chapter 7). The MCFR1 (same profile, different conductivities) for a 36 kW spinner motor showed performance comparable to or better than original die-cast aluminium rotors (Figure 5.1), particularly in starting torque stability under hot conditions (Chapter 5.7, Chapter 7.4, Table 7.1).

- Improved Reliability and Life Span: The MCFR exhibited higher reliability indicators. The estimated life span of an MCFR was significantly longer (e.g., 20 years MTBF for rotor, 10 years for motor) compared to die-cast aluminium rotors (1.6-2 years for rotor, 3-4 years for motor) in the same application (Table 7.5, Chapter 8.1). Investigations after 1.8 years of continuous underground operation showed the MCFR in excellent condition with no signs of overloading, hot spots, or harmonic-related issues (Chapter 6.6, Photo 6.9, Photo 7.1).

- Enhanced Thermal Performance: The MCFR demonstrated a lower thermal heat level. Rotor temperature rise on load and per DOL start was lower (150-160°C for MCFR vs 210-220°C for Damel aluminium) (Table 7.4). This allows for more DOL starts from hot conditions (8 for MCFR vs 2-3 for Damel) (Table 7.4). The MCFR did not radiate excessive heat towards the stator winding or transfer significant heat to bearings (Table 7.2, Table 7.3).

- Stable Starting Performance: The MCFR maintained a very constant starting torque even after reaching thermal stability ("HOT" condition), a key advantage over existing rotors (Chapter 5.7, Chapter 7.2.6, Chapter 7.2.7). It offered reliable torque with no major parasitic torques during start-up (Chapter 7.5.6, Figure 7.4).

- Economic Advantages: The MCFR offers substantial economic benefits through reduced Total Ownership Costs (TOC). For a 36 kW spinner motor, annual savings per rotor were estimated at R150,000, with total projected savings over 15 years being R2,258,000 for using MCFR only (Table 7.8, Table 8.1). This is due to longer life, reduced downtime, and lower repair costs as MCFRs are repairable (Chapter 6.7, Chapter 8.1).

- Local Manufacturing Feasibility: The MCFR can be manufactured locally using standard tooling and materials, reducing dependence on expensive imported rotors and offering a competitive alternative (Abstract, Chapter 6.7).

Figure Name List:

- Figure 1.1 TOC structure of an induction motor driving a particular mining process

- Figure 1.2 Evolution of specific costs indicators function of the process speed “v”

- Figure 2.1 Typical example of a speed-torque curve (STC) of an induction motor

- Figure 3.3 Typical short-circuit test characteristic graph (Ik = f(Uk) in p.u.) lot tips

- Figure 5.1 Speed-Torque curves of 36 kW, fitted with an aluminium and a copper rotor

- Figure 5.2 Illustration to classic principle no. 1 of the rotor construction

- Figure 5.3 Illustration to classic principle no. 2 of the rotor construction

- Figure 5.4 Schematic diagram of one of the simplest versions of the MCFR1

- Figure 5.5 Cross-section of a deep bar linked by a leakage flux

- Figure 5.6 Phasor diagram of the mutual flux and induced voltage

- Figure 5.7 MCFR1 reactance and resistance ratio evolution during motor starting

- Figure 6.1 Initial cast aluminium and fabricated bar rotor slot profiles

- Figure 6.2 Stator lamination design for 36 kW spinner motor

- Figure 6.3 Design of the rotor lamination for a 36 kW spinner motor fitted with the MCFR1

- Figure 6.4 Manufacturing instructions for the electric circuit of the MCFR1

- Figure 6.5 Assembly drawing of the MCFR1

- Figure 7.1 Functional block diagram of the testing bay

- Figure 7.2 3D picture of a spinner motor used for confirmation of MCFR1 performances

- Figure 7.3 Oscillogram of DOL starting current for a 36 kW fitted with MCFR

- Figure 7.4 Speed-torque curve of the 36 kW prototype

- Photo 3.1 Rotor bars separation from the short-circuit ring

- Photo 4.9 “Hot spots” with temperatures reaching melting point of the brass bars

- Photo 5.1 Brass rotor specially manufactured for the VAMT 36 kW spinner motor

- Photo 6.4 Rotor iron core pack build-up on the shaft for the MCFR1, 36 kW spinner motor

- Photo 6.5 Sequence of different bar conductivities fitted in an MCFR1

- Photo 6.6 The MCFR1 fitted with a unique short-circuit ring

- Photo 6.7 MCFR1 manufactured with two pairs of short-circuit rings

- Photo 6.8 A spinner motor fitted with an MCFR returned after 1,8 years running underground

- Photo 6.9 The MCFR1 after 1.8 years of running underground

- Photo 6.10 Water ingress into the motor during storage

- Photo 6.11 The stator was rusted due to water in the motor enclosure

- Photo 7.1 The MCFR iron core in excellent condition after running on load for 1.8 years

7. Conclusion:

The research concludes that conventional high-impedance double cage and die-cast aluminium rotors exhibit high failure rates and significant financial losses in the demanding South African coal-mining industry, primarily because their original designs do not meet the stringent local application engineering essentials. The Mixed Conductivity Fabricated Rotor (MCFR), developed based on a novel principle of circumferentially varying bar conductivities and/or profiles, successfully addresses these shortcomings. The MCFR offers superior reliability, extended operational life, and stable performance, particularly in maintaining starting torque under hot conditions, compared to existing die-cast aluminium rotors. Experimental validation and long-term field tests (1.8 years) confirmed the MCFR's design soundness and its ability to withstand harsh mining conditions. Economically, the MCFR leads to substantial reductions in total ownership costs by decreasing repair expenses, minimizing downtime, and offering a repairable, locally manufacturable alternative to expensive imported rotors. The MCFR patent represents a significant advancement, providing technical and economic advantages that enhance mining process efficiency (Chapter 8.1, Table 7.8, Table 8.1).

8. References:

- [1] IPCC (Intergovernmental Panel on Climate Change); “Revised 1996 guidelines for national greenhouse gas inventories”, Organization for Economic Co-operation and Development, Paris, 1996.

- [2] Department of Energy Federal Register; “Federal Energy Management Plan – FEMP”, USA, New York, March 2004.

- [3] Creamer, M.; “Golden Sunset in South Africa”, Mining Weekly, Feb. 17–23, 2006, pp10–11.

- [4] Anglo Gold Ashanti; “Medium and High Voltage (3300, 6600 &11000 Volts) Squirrel Cage and Wound Rotors Induction Motors”, 438/11 Specification, Johannesburg, 1998.

- [5] Pitis, C.D.; “Power Efficiency becoming Important in Electric Motors”, Materials Handling & Logistics TODAY, Johannesburg, Sept. 2003, pp 35–36.

- [6] Pitis, C.D., Livingstone, A.; “Energy efficient fans in underground auxiliary ventilation systems”, Proceedings, 1st ICUE International Conference of Industrial & Commercial Use of Energy, Cape Town, May 2004, pp 103–106.

- [7] Pitis, C.D.; “Electric Motors Life Extension by Renewal of Squirrel Cage Rotors”, Proceedings, 2nd ICUE International Conference of Industrial & Commercial Use of Energy, Cape Town, May 2005, pp 87–93.

- [8] Pitis C.D.; Provisional patent registered as “Mixed Conductivity Fabricated Rotors – MCFR” patent registration no. 6886, Spoor and Fisher, Johannesburg, August 2004.

- [9] Pitis, C.D.; “Mixed Conductivity Fabricated Rotor”, South African Patent No. 2005/07280, Johannesburg, September 2005.

- [10] Landy, C.F., Meyer, A.; “Squirrel cage motors design program – SCDES2”, Witwatersrand University, Johannesburg, 1998.

- [11] Say, M.G.; “Performance and design of alternating current machines”, 3rd Edition, Isaac Pitman & Sons, London, 1983, pp 300–320.

- [12] Gheorghiu, I.S.; “Electric Machinery – Problems and industrial uses”, 2nd Edition, Volume I and II, Technical Publishers, Romania, 1966.

- [13] Richter, R.; “Electric Machinery”, Vol. IV – “Asynchronous machinery”, Technical Publishers, Translation from German Version, Bucharest, 1960.

- [14] Say, M.G.; “Alternating Current Machines”, Chapter 8, 5th Edition, Longman Scientific & Technical Singapore Publishers Ltd, 1995.

- [15] Davies, H.G., Hicks, G.A.; “Mathematics for Scientific and Technical Students”, 4th Edition, Chapter 10 to 12, Longman Group Ltd., London, 1978.

- [16] Melaia, R., Grayer, I.; “Direct-On-Line Starting Current of Cage Induction Motors”, ABB, Elektron, June 1996, pp 25–27.

- [17] Norman, H.; “Induction motor locked saturation curves”, Transactions AIEE, 53, 1934, pp 536–541.

- [18] Ostovik, V.; “Computer-aided Analysis of Electric Machines”, Prentice-Hall, 1994, pp 307–318.

- [19] Agarwal, P.D., Alger, P.L.; “Saturation Factors for Leakage Reactance of Induction Motors”, AIEE, Paper 60 – 119, Chicago, Feb. 1961.

9. Copyright:

- This material is a paper by "Constantin Danut PITIS". Based on "Novel Method of Improving Squirrel Cage Induction Motor Performance by using Mixed Conductivity Fabricated Rotors (MCFR)".

- Source of the paper: https://www.researchgate.net/publication/26989276

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.

Key Questions & Answers for Researchers

Q1. What is the fundamental innovation of the MCFR design compared to traditional squirrel cage rotors?

A1. The MCFR design introduces the principle of circumferentially varying conductivities and/or profiles for rotor bars within the same cylindrical shell, unlike traditional rotors where bars in a circumferential layer are uniform in shape and conductivity. This allows for tailored motor performance characteristics.

Q2. What were the primary drivers for developing the MCFR, particularly in the context of the South African mining industry?

A2. The primary drivers were the high failure rates and significant financial losses associated with conventional high-impedance rotors (double cage and die-cast aluminium) in harsh mining conditions, necessitating a more reliable, durable, and cost-effective rotor solution.

Q3. How does the MCFR achieve improved thermal performance and starting characteristics compared to, for example, die-cast aluminium rotors?

A3. The MCFR's mixed conductivity design allows for better current distribution and heat management. It results in lower overall rotor temperature rise (e.g., 150-160°C for MCFR vs. 210-220°C for a comparable die-cast aluminium rotor) and enables more DOL starts from hot conditions (8 for MCFR vs. 2-3). The starting torque remains very constant even after the motor reaches thermal stability.

Q4. What are the main economic benefits of adopting MCFR technology?

A4. The MCFR offers significant economic benefits through a longer operational life (estimated 10-year motor life, 20-year rotor MTBF compared to 1.5-4 years for conventional rotors in similar applications), reduced downtime, lower repair costs (as it's repairable), and the potential for local manufacturing, leading to a lower Total Ownership Cost (TOC). Annual savings per 36kW spinner motor were estimated at R150,000.

Q5. The paper mentions MCFR1 and MCFR2. What is the main distinction, and which type was primarily developed and tested in this research?

A5. MCFR1 features rotor bars with the same profile but different conductivities arranged circumferentially. MCFR2 involves rotor bars with different profiles and different conductivities. The research primarily developed, designed, and extensively tested the MCFR1 type, specifically for a 36 kW spinner motor used in continuous miners.