This article introduces the paper "Thermal study on novel spokes fin for high power LED" presented at the Engineering Research Express

1. Overview:

- Title: Thermal study on novel spokes fin for high power LED

- Author: Tanmay Nandanwar, Jash Jani, and A Rammohan

- Publication Year: 2023

- Publishing Journal/Academic Society: Engineering Research Express

- Keywords: LED lights, junction temperature, radiation, spokes fin, heatsink

2. Research Background:

- Social/Academic Context of the Research Topic:

High Power LED (HPLED) lights are increasingly prevalent in industrial, residential, and consumer sectors due to their superior efficiency, reliability, and longevity. Efficient thermal management is critical for maintaining the performance and lifespan of LED lamps. Natural convection using heatsinks with fins is a widely adopted passive cooling technique due to its simplicity, lightweight nature, and lack of maintenance requirements. - Limitations of Existing Research:

Prior research has explored various heat sink designs, including rectangular and circular fins, and investigated parameters like fin spacing, height, and material. However, there is a need to explore novel fin geometries to further enhance heat dissipation performance in HPLED applications. Existing studies have also not fully explored the comparative thermal performance of different fin designs under varying HPLED configurations and operating conditions. - Necessity of the Research:

To address the limitations of existing research and to optimize thermal management in HPLED systems, this research introduces a novel "spokes fin" design. The study aims to evaluate and compare the thermal performance of this novel design against conventional rectangular and circular fin configurations under natural cooling conditions. This research is necessary to identify superior heat sink designs for HPLEDs, contributing to improved LED performance, reliability, and longevity in diverse applications.

3. Research Purpose and Research Questions:

- Research Purpose:

The primary objective of this study is to investigate and compare the thermal performance of novel spokes fins with circular and rectangular fins for cooling High Power LEDs (HPLEDs) under natural convection. The research aims to identify an optimal heat sink design that effectively dissipates heat from HPLEDs, thereby maintaining lower junction temperatures and enhancing operational efficiency. - Key Research Questions:

- How does the thermal performance of the novel spokes fin compare to that of circular and rectangular fins when attached to a heatsink base and HPLED?

- What is the impact of varying HPLED junction temperatures and fin lengths on the thermal performance of different fin designs?

- How does the inclusion of radiation effects influence the thermal performance of heatsinks and fins at high junction temperatures?

- How does the Nusselt number vary with changes in fin length and junction temperature for different fin designs?

- What is the optimal heatsink design, considering fin geometry and dimensions, for specific HPLED applications?

- Research Hypotheses:

The paper does not explicitly state research hypotheses but implicitly tests the hypothesis that the novel spokes fin design will exhibit superior thermal performance compared to conventional circular and rectangular fin designs for HPLED cooling applications. It is also hypothesized that fin length and junction temperature will significantly influence the thermal performance of all fin designs, and that radiation effects will become more prominent at higher junction temperatures.

4. Research Methodology

- Research Design:

This study employs a numerical simulation-based research design using Finite Element Analysis (FEM) to evaluate the thermal performance of different fin geometries. The research is comparative, assessing the performance of circular, rectangular, and novel spokes fins under various conditions. - Data Collection Method:

Data is collected through computational simulations using ANSYS 19.2, a commercial FEA software. The simulations model heat transfer under natural convection for different fin designs, HPLED configurations (single and six LED arrays), fin lengths (60 mm, 70 mm, 80 mm), and junction temperatures (130 °C, 110 °C, 90 °C, 70 °C, 50 °C). Mesh independence tests are conducted to ensure the accuracy and reliability of the simulation results. - Analysis Method:

The Finite Element Method (FEM) is utilized to solve the governing equations of heat transfer, specifically steady-state thermal conduction and convection. The Newton-Raphson method is employed for iterative solution processes. The Nusselt number, Rayleigh number, and Grashof number are calculated to characterize the heat transfer performance. Temperature distributions across the fins and heatsink are analyzed to compare the effectiveness of different fin designs. - Research Subjects and Scope:

The research focuses on the thermal management of HPLEDs using aluminum heatsinks with three different fin geometries: circular, rectangular, and novel spokes fins. The scope includes:- Simulation of single and six HPLED array configurations.

- Variation of fin lengths (60 mm, 70 mm, 80 mm).

- Analysis across a range of HPLED junction temperatures (50 °C to 130 °C).

- Consideration of natural convection and radiation heat transfer mechanisms.

- Evaluation of thermal performance based on temperature distribution and Nusselt number.

5. Main Research Results:

- Key Research Results:

- The novel spokes fin design demonstrated superior heat dissipation compared to rectangular and circular fins, achieving approximately 4.72% (6 °C) lower temperature on the upper fin and 5.87% (13 °C) lower temperature on the lower fin compared to rectangular fins.

- Rectangular fins exhibited better heat dissipation than circular fins for single HPLED configurations, with about 2.85% and 3.66% lower temperatures on the upper and lower fins, respectively. However, for six HPLED array configurations, rectangular and circular fins showed comparable dissipation effects.

- Increasing fin length generally reduced the fin base temperature for all fin types and LED junction temperatures.

- Radiation effects were considered in the simulations, and mesh independence tests confirmed the reliability of the numerical results.

- For higher LED junction temperatures, spokes fins are optimum, while rectangular fins are more suitable for lower LED temperatures due to economic and manufacturing considerations.

- Statistical/Qualitative Analysis Results:

The paper primarily presents numerical results and graphical comparisons rather than statistical analysis. Qualitative analysis is based on the interpretation of temperature distribution plots and performance curves for different fin designs and operating conditions. The graphical representations (Figures 7-16) visually demonstrate the temperature variations and Nusselt number changes across different fin types, lengths, and LED configurations. - Data Interpretation:

Data interpretation focuses on comparing the temperature profiles and heat dissipation capabilities of the three fin designs. The lower temperatures observed with spokes fins, particularly at higher HPLED junction temperatures, indicate their enhanced thermal performance. The analysis of Nusselt number variations provides insights into the convective heat transfer efficiency of each fin design under different conditions. The temperature difference (ΔT) between upper and lower fins is also analyzed to understand the heat dissipation along the fin length. - Figure Name List:

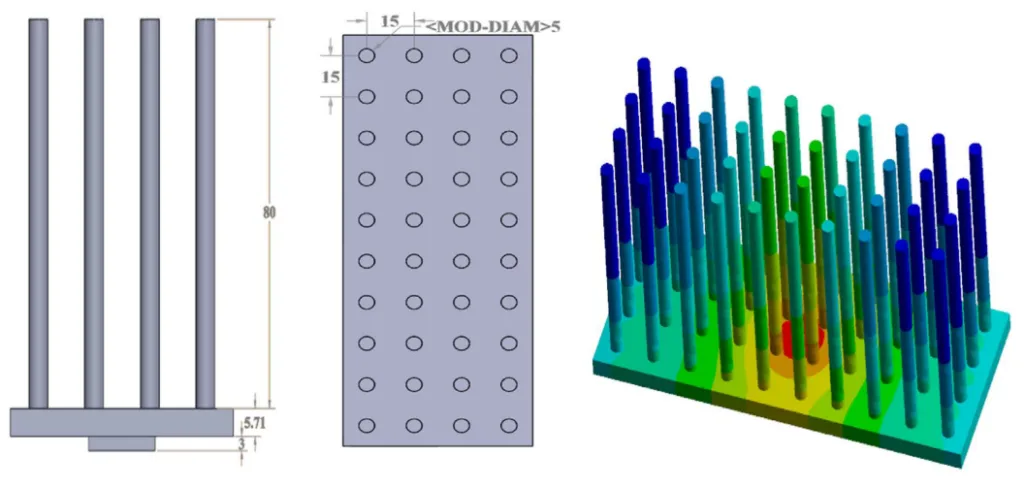

- Figure 1. Circular fins dimensions and structure.

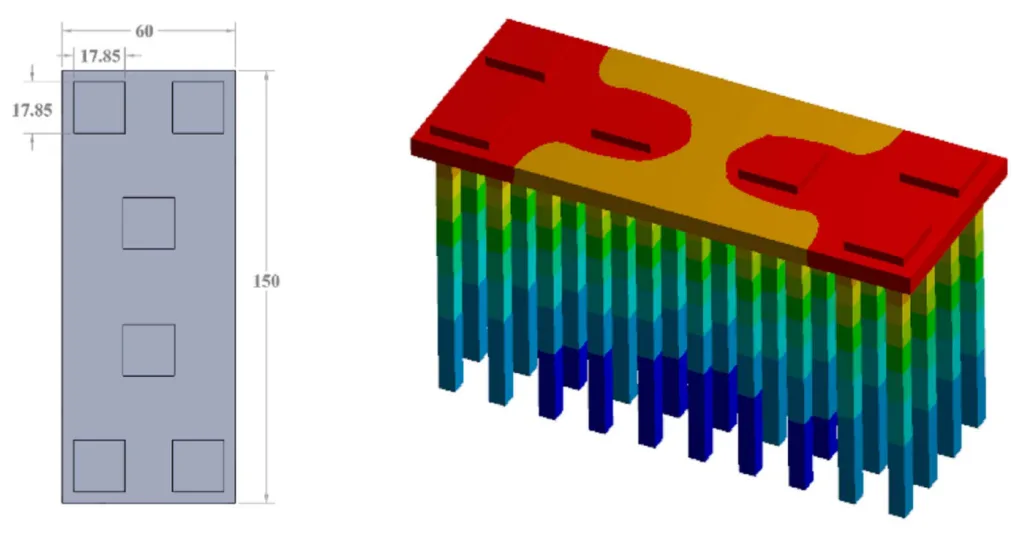

- Figure 2. Rectangular fins dimension and structure.

- Figure 3. Novel Spokes fins dimension and structure.

- Figure 4. Single LED placement and heat profile.

- Figure 5. Six LED Array configuration and temperature profile.

- Figure 6. Graphical representation of mesh independence test.

- Figure 7. Temperature for single LED Circular and rectangular fins.

- Figure 8. Temperature for six LED circular and rectangular.

- Figure 9. Temp. for upper fin 6 LED circular and rectangular.

- Figure 10. Temperature for the single LED spokes fin and rectangular fin.

- Figure 11. Temperature for six LED spokes fin and rectangular.

- Figure 12. Temperature difference for circular, rectangular and novel spokes fin.

- Figure 13. Temperature at the upper fins with and without radiation.

- Figure 14. Nusselt number for upper fins single LED.

- Figure 15. (a) Nu for lower fins - 1 LED 15(b) Nu for lower fins-six LEDs.

- Figure 16. Nu for upper fins for six LED.

- Figure 17. HPLED array thermal resistance model on a common heatsink.

6. Conclusion and Discussion:

- Summary of Main Results:

The study concludes that the novel spokes fin design exhibits superior thermal performance for HPLED cooling compared to circular and rectangular fins, especially at higher junction temperatures. Rectangular fins are more effective than circular fins for single HPLEDs, while both perform similarly for six HPLED arrays. Spokes fins offer the best heat dissipation, with a significant advantage in weight compared to rectangular fins of comparable performance. - Academic Significance of the Research:

This research contributes to the field of thermal management in LED lighting by introducing and validating a novel spokes fin design. The comparative analysis provides valuable insights into the performance characteristics of different fin geometries under varying HPLED operating conditions. The findings enhance the understanding of heat transfer mechanisms in finned heatsinks for LED cooling applications. - Practical Implications:

The practical implication of this study is the identification of spokes fins as an effective heat sink solution for HPLED applications, particularly where high heat dissipation and lightweight design are crucial. The research suggests that spokes fins can lead to more efficient and reliable HPLED lighting systems. For lower temperature applications or cost-sensitive designs, rectangular fins may offer a viable alternative. - Limitations of the Research:

The study is based on numerical simulations under idealized conditions. Experimental validation of the simulation results is recommended to confirm the real-world performance of the spokes fin design. The study focuses on natural convection; further research could explore the performance under forced convection conditions. The analysis is limited to aluminum heatsinks; investigating other materials could be beneficial.

7. Future Follow-up Research:

- Directions for Follow-up Research:

Future research directions include:- Experimental validation of the numerical simulation results to verify the thermal performance of spokes fins.

- Investigation of spokes fin performance under forced convection conditions to assess their effectiveness in different cooling scenarios.

- Exploration of other materials for spokes fin heatsinks to optimize thermal performance and cost-effectiveness.

- Application of machine learning algorithms to further analyze and optimize the available data for enhanced heat sink design.

- Detailed investigation into the manufacturing process and cost-effectiveness of producing spokes fin heatsinks for mass production.

- Areas Requiring Further Exploration:

Further exploration is needed in:- Optimizing the geometry of spokes fins for specific HPLED applications and environmental conditions.

- Investigating the long-term reliability and performance of HPLED systems cooled with spokes fin heatsinks.

- Analyzing the impact of different LED package designs on the overall thermal management system performance with spokes fins.

8. References:

- [1] De Santi C, Dal Lago M, Buffolo M, Monti D, Meneghini M, Meneghesso G and Zanoni E 2015 Failure causes and mechanisms of retrofit LED lamps Microelectron. Reliab. 55 1765-9

- [2] Yazdan Mehr M, van Driel W D, Koh S and Zhang GQ 2014 Reliability and optical properties of LED lens plates under high temperature stress Microelectron. Reliab. 54 2440-7

- [3] Zhao X-J, Cai Y-X, Wang J, Li X-H and Zhang C 2015 Thermal model design and analysis of the high-power LED automotive headlight cooling device Appl. Therm. Eng. 75 248-58

- [4] Adhikari R C, Wood D H and Pahlevani M 2020 Optimizing rectangular fins for natural convection cooling using CFD Thermal Science and Engineering Progress 17 100484

- [5] Mogaji T and Owoseni F 2017 Numerical Analysis of Radiation Effect on Heat Flow through Fin of Rectangular Profile American Journal of Engineering Research (AJER) 6 36-46

- [6] AlFalah G, Maatallah T S, Alzahrani M and Al-Amri F G 2020 Optimization and feasibility analysis of a microscale pin-fins heat sink of an ultrahigh concentrating photovoltaic, system Int. J. Energy Res. 44 11852-71

- [7] Mishra M, Chandramohan V P and Balasubramanian K 2019 Comparative study of cooling of automobile LED headlights without and with fins and finding comfortable operating conditions Archive of Mechanical Engineering. 66 295-314

- [8] Effendi N S and Kim K J 2017 Orientation effects on natural convective performance of hybrid fin heat sinks Appl. Therm. Eng. 123 527-36

- [9] Sun L, Zhu J and Wong H 2016 Simulation and evaluation of the peak temperature in LED light bulb heatsink Microelectron. Reliab. 61 140-4

- [10] Fu H-K, Wang C-P, Chiang H-C, Chen T-T, Chen C-L and Chou P-T 2013 Evaluation of temperature distribution of LED module Microelectron. Reliab. 53 554-9

- [11] Yung K C, Liem H and Choy H S 2014 Heat transfer analysis of a high-brightness LED array on PCB under different placement configurations Int. Commun. Heat Mass Transfer 53 79-86

- [12] Moon S-H, Park Y-W and Yang H-M 2017 A single unit cooling fins aluminum flat heat pipe for 100 W socket type COB LED lamp Appl. Therm. Eng. 126 1164-9

- [13] Mueller A, Buennagel C, Monir S, Sharp A, Vagapov Y and Anuchin A 2020 Numerical design and optimisation of a novel heatsink using ANSYS steady- state thermal analysis. 2020 27th international workshop on electric drives MPEI Department of Electric Drives 90th Anniversary (IWED).

- [14] Subahan K, Reddy E S and Reddy R 2019 CFD analysis of pin-fin heat sink used in electronic devices Int. J. Scientific & Technology Research 8 562-9

- [15] Wengang H, Lulu W, Zongmin Z, Yanhua L and Mingxin L 2017 Research on simulation and experimental of thermal performance of LED array heat sink Procedia Engineering 205 2084-91

- [16] Jeon D and Byon C 2017 Thermal performance of plate fin heat sinks with dual- height fins subject to natural convection Int. J. Heat Mass Transfer 113 1086-92

- [17] Manna S, Ghosh S K and Haldar S C 2019 Optimum fin parameters of radial heat sinks subjected to natural convection J. Thermal Science and Engineering Applications 11 051006

- [18] Huang G-J, Wong S-C and Lin C-P 2014 Enhancement of natural convection heat transfer from horizontal rectangular fin arrays with perforations in fin base Int. J. Therm. Sci. 84 164-74

- [19] Wu S-J, Hsu H-C, Fu S-L and Yeh J-N 2014 Numerical simulation of high power LED heat-dissipating system Electron. Mater. Lett. 10 497-502

- [20] Rammohan A and Rameshkumar C 2016 A review on effect of thermal factors on performance of high power light emitting diode (HPLED) J. Eng. Sci. Technol. Review 9 165-76

- [21] Rammohan A, Ramesh Kumar C and Chandramohan V P 2021 Experimental analysis on estimating junction temperature and service life of high power LED array Microelectron. Reliab. 120 114121

- [22] Subramanian R S Continuity equation Department of Chemical and Biomolecular Engineering Clarkson University (Potsdam, New York: Researchgate publications) 33457618913699

- [23] Kothandaraman C P and Subramanyan S 2018 Heat and Mass Transfer Data book (New Delhi: New Age International Publishers) 9th edn

- [24] Incropera F P, Dewitt D P, Bergman T L and Lavine A S 2006 Fundamentals of Heat and Mass Transfer 6th edn (Hoboken, NJ, USA: John Wiley and Sons)

- [25] Bahram R, Hamid Reza S, Yuwen Z and Khanna S 2016 Flow and heat transfer in micro spokes fin heat sinks with nano-encapsulated phase change materials J. Heat Transfer 138 062401

9. Copyright:

- This material is "Tanmay Nandanwar et al"'s paper: Based on "Thermal study on novel spokes fin for high power LED".

- Paper Source: https://doi.org/10.1088/2631-8695/acbd11

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.