Unlocking Superior Performance in Nickel Alloys: The Power of Titanium Carbide Modification

This technical summary is based on the academic paper "CHANGES IN THE PROPERTIES OF A NICKEL ALLOY DURING ITS MODIFICATION WITH TITANIUM CARBIDE" by Hlushkova D. B. and Kalinina N. E., published in INNOVATIONS AND PROSPECTS IN MODERN SCIENCE (2023).

Keywords

- Primary Keyword: Nickel Alloy Modification

- Secondary Keywords: Titanium Carbide, TiC, Grain Refinement, Heat-Resisting Alloys, Nickel Alloy Properties, GS3 Alloy, Microstructure Modification, Superalloy Casting

Executive Summary

- The Challenge: Conventional heat treatment is inefficient for strengthening modern heat-resisting nickel alloys, where the initial cast structure dictates final performance.

- The Method: The study investigates the volumetric modification of a molten GS3 nickel alloy using disperse, nano-sized titanium carbide (TiC) particles.

- The Key Breakthrough: Modifying the alloy with TiC resulted in a uniform, highly refined grain structure, reducing the average grain size by up to eight times.

- The Bottom Line: Volumetric modification with TiC is a highly effective strategy to refine the microstructure of nickel superalloys during casting, leading to significantly improved structural integrity.

The Challenge: Why This Research Matters for HPDC Professionals

In modern aviation gas turbine engines (GTE), heat-resisting nickel alloys are critical components, especially for turbine blades. For alloys containing around 50% strengthening phases, the final properties are determined not by post-cast heat treatment, but by the primary structure formed during crystallization.

However, controlling this primary structure, particularly the growth of dendritic crystals, is notoriously difficult due to high crystallization speeds in casting processes. This limitation presents a significant challenge for engineers seeking to produce components with a uniform, fine-grained structure, which is essential for superior mechanical performance and reliability. The industry needs an effective method to influence the alloy's structure directly in its liquid state, before solidification begins.

The Approach: Unpacking the Methodology

To address this challenge, the researchers employed a method of volumetric modification on multicomponent nickel alloys, focusing on the GS3 alloy. This approach introduces a modifying agent directly into the molten metal to influence the crystallization process.

Method 1: Modifier Selection and Synthesis

- Material: Disperse titanium carbide (TiC) with a particle size of 50 to 100 nm was selected as the modifier. TiC was chosen based on P. D. Dankov’s principle of structural correspondence; its face-centered cubic (FCC) lattice is a close match to the FCC lattice of nickel, making it an efficient crystallization nucleus.

- Synthesis: The TiC modifier was produced via plasma chemical synthesis, a method capable of creating sub-microcrystalline powders.

Method 2: Volumetric Modification Process

- Preparation: The powdered GS3 nickel alloy and TiC powders were mixed and formed into brickets.

- Introduction: The modifier was introduced into the already molten GS3 alloy at a temperature of 1,580°C.

- Process Control: The mixture was held for 90-120 seconds with mechanical mixing to ensure uniform distribution of the TiC particles throughout the liquid alloy.

The Breakthrough: Key Findings & Data

The introduction of the TiC modifier had a profound and measurable impact on the microstructure of the GS3 nickel alloy.

Finding 1: Dramatic Grain Refinement and Structural Uniformity

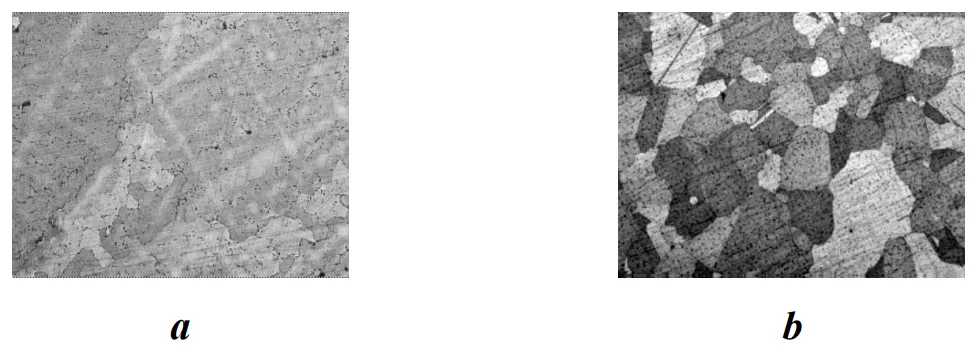

The most significant outcome was the refinement of the alloy's grain structure. Before modification, the GS3 alloy exhibited a non-uniform, coarse-grained structure with grain sizes ranging from 5 to 8 mm. After modification, the samples displayed a uniform, fine-grained structure.

As shown in Figure 1, the grain size was reduced up to eight times, achieving a grain dispersion degree of up to 1 mm. This demonstrates that TiC particles act as highly effective nuclei, promoting the formation of a much finer and more homogenous cast structure.

Finding 2: Confirmed Absorption and Elemental Distribution

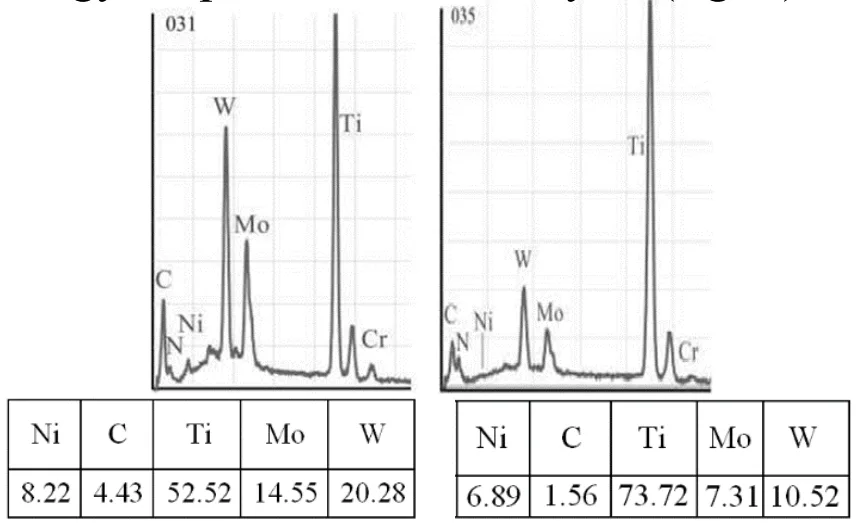

Electronic microprobe analysis confirmed the successful absorption of the modifier and its influence on the alloy's composition at a micro-level. The analysis demonstrated a rapid increase in the intensity of Titanium (Ti) and Carbon (C) elements in the modified sample.

As shown in Table 2, the elemental composition of the GS3 alloy before modification showed Ti content between 34.02% and 37.16% in the studied zones. The analysis of the modified alloy in Figure 3 reveals a significant increase in Ti content to 73.72% in the fixed points containing the modifier, confirming the successful integration and modifying influence of the titanium carbide.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that the volumetric modification of nickel alloys with TiC nanoparticles is a viable and highly effective method for achieving grain refinement directly in the melt, offering an alternative to relying solely on post-cast heat treatments.

- For Quality Control Teams: The data in Figure 1 and Figure 3 of the paper illustrates the clear microstructural and compositional differences between modified and unmodified alloys. These images and elemental maps can serve as a benchmark for verifying the success of the modification process in production.

- For Design Engineers: The findings indicate that a significantly refined and more uniform grain structure can be achieved through this process. This implies improved mechanical properties, which could allow for the design of more durable and complex components for high-stress applications like turbine blades.

Paper Details

CHANGES IN THE PROPERTIES OF A NICKEL ALLOY DURING ITS MODIFICATION WITH TITANIUM CARBIDE

1. Overview:

- Title: CHANGES IN THE PROPERTIES OF A NICKEL ALLOY DURING ITS MODIFICATION WITH TITANIUM CARBIDE

- Author: Hlushkova D. B., Kalinina N. E.

- Year of publication: 2023

- Journal/academic society of publication: INNOVATIONS AND PROSPECTS IN MODERN SCIENCE, Proceedings of XI International Scientific and Practical Conference

- Keywords: Nickel Alloy, Titanium Carbide, Modification, Microstructure, Grain Refinement

2. Abstract:

This study investigates the influence of volumetric modification with disperse titanium carbide (TiC) on the structure and properties of heat-resisting nickel alloys. Given the inefficiency of heat treatment for alloys with high concentrations of strengthening phases, controlling the primary cast structure is paramount. The research focused on the GS3 nickel alloy, modified with TiC nanoparticles (50-100 nm) via introduction into the molten metal. The methodology involved plasma chemical synthesis of the modifier and subsequent microstructural analysis using macrostructure imaging and electronic microprobe analysis. The results demonstrate that TiC modification leads to a uniform, highly refined alloy structure, with a grain size reduction of up to eight times. The absorption and modifying influence of TiC were confirmed by a significant increase in titanium and carbon content in the modified zones. The study concludes that TiC is an effective modifier for refining the grain structure of nickel alloys during casting.

3. Introduction:

In modern aviation gas turbine engines (GTE), cast heat-resisting nickel alloys are critical, with their performance characteristics largely determined by the operating characteristics of turbine blades. For alloys containing around 50% strengthening phases, the primary structure formed during crystallization is the principal determinant of the material's properties, as subsequent heat treatment has limited influence. Controlling the growth of dendritic crystals during casting is difficult due to high crystallization speeds. Therefore, the development of technological processes that ensure the formation of additional crystallization nuclei in the liquid alloy is required. Modification of the liquid alloy with disperse particles is an efficient method for influencing the structure and properties of cast materials. This study focuses on the volumetric modification of nickel alloys with disperse titanium-based compositions to refine the cast structure and improve material properties.

4. Summary of the study:

Background of the research topic:

The performance of modern GTEs is increasingly demanding, requiring functional materials with novel structures and properties. The primary structure of multicomponent nickel alloys, formed during crystallization, is the key determinant of their final properties, especially for alloys with a high percentage of strengthening phases where heat treatment is inefficient.

Status of previous research:

While classic works on the modification of nickel alloys exist, they often lack generalized criteria for modifier selection and technology applicable to various alloys. Modification with high-melting point metals can refine the cast structure but also risks the accumulation of non-metallic impurities, leading to flaws. The use of sized disperse particles is an efficient way to influence liquid alloys, but the specific application and effects of nano-sized TiC require further investigation.

Purpose of the study:

The aim of the study is to investigate the changes in the properties and structure of a heat-resisting nickel alloy resulting from its volumetric modification with disperse titanium carbide (TiC).

Core study:

The core of the study involved the modification of a multicomponent GS3 nickel alloy with disperse TiC particles ranging in size from 50 to 100 nm. The study analyzed the macrostructure, microstructure, and elemental composition of the alloy before and after modification to determine the efficacy of the TiC as a grain-refining agent. The mechanism of action involves the TiC particles serving as crystallization nuclei for the primary austenitic γ-phase, thereby dispersing the dendrites and refining the overall grain structure.

5. Research Methodology

Research Design:

The study was designed as an experimental investigation. It involved comparing the microstructural properties of a GS3 nickel alloy in its initial state and after undergoing a volumetric modification process with a TiC modifier.

Data Collection and Analysis Methods:

- Material Characterization: The chemical composition of the studied nickel alloys (GS6U-V1, GS6K, GS3) was documented.

- Modifier Synthesis: Disperse TiC powder was obtained via plasma chemical synthesis.

- Modification Process: A controlled process of mixing, bricketing, and introducing the TiC modifier into the molten GS3 alloy at 1,580°C was performed.

- Structural Analysis: The macrostructure of the alloy samples was analyzed and imaged (x100).

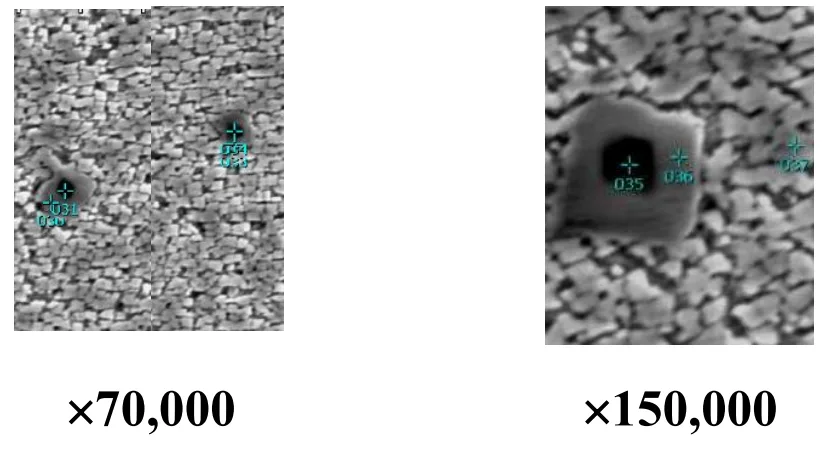

- Microprobe Analysis: An electronic microprobe analysis was conducted using a JSM-6360LA scanning microscope equipped with a JED2200 rentgenospectral energy-dispersive microanalysis system to determine the distribution of doping and modifying elements.

Research Topics and Scope:

The research scope was limited to the study of three multicomponent nickel alloys, with a primary focus on the GS3 alloy. The investigation covered the effects of TiC modification on grain size, structural uniformity, and the distribution of Ti and C elements within the alloy matrix.

6. Key Results:

Key Results:

- The modification process resulted in a uniform and highly refined alloy structure.

- The grain size refinement increased from five up to eight times, with the grain size reducing from 5-8 mm to up to 1 mm.

- The absorption of the titanium carbide modifier by the nickel liquid alloy was confirmed through electronic microprobe analysis, which showed a rapid increase in the intensity of Ti and C elements.

- The TiC modifier particles were observed to disperse the dendrites of the primary austenite in the GS3 alloy.

Figure Name List:

- Fig. 1. Macrostructure of the GS3 nickel alloy, х100 а: before the modification; b: after the modification

- Fig. 2. Structure of the modified GS3 alloy

- Fig. 3. Content of doping elements in the studied fixed points of the modified GS3 alloy

7. Conclusion:

- Titanium carbide, selected as a modifier for the GS3 high-melting point nickel alloy, was successfully acquired using the method of plasma-chemical synthesis. The modifier particle size was from 50 to 20 nm, and their specific surface varied from 2.5 to 12.5 m²/g.

- Technological operations for the GS3 alloy, including mixing, bricketing, and mechanical mixing, were developed. The suboptimal amount of the modifier introduced to the liquid alloy was from 0.01 to 0.1%.

- A uniform and highly refined alloy structure was acquired as a result of modification. The grain size refinement increased from five up to eight times.

- The absorption of the modifier by the nickel liquid alloy was approved with electronic microprobe analysis.

8. References:

- S. V. Hayduk, O. V. Hnatenko, O. H. Andreyenko, V. V. Smart Research on structural transformations of heat-resistant nickel alloys under creep conditions // New materials and technologies in metallurgy and mechanical engineering. 2012. p. 37-40. (in Ukrainian).

- E. I. Tsyvirko, A. A. Pedash Grinding the structure of internal surfaces of cooling parts, VMD // Visnyk dvizhnoboduvaniya. 2010, N 1, p. 99-103. (in Ukrainian).

- P. D. Zhemanyuk, A. A. Pedash, E. I. Tsyvirko, O. F. Pedash Combined modification when obtaining VMD turbine parts // Visnyk dvizhnoboduvaniya. 2010, N 1, p. 75-78. (in Ukrainian).

- V. A. Kostin, H. M. Grigorenko, V. V. Zhukiv Modification of the structure of welds of high-strength, low-alloy steels with nanoparticles of refractory metals // Collection of scientific works "Construction, materials science, mechanical engineering". 2016, N 89, p. 93-98. (in Ukrainian).

- N. E. Kalinina, D. B. Glushkova, A. I. Voronkov, V. T. Kalinin. Influence of nanomodification on structure formation of multicomponent nickel alloys// Functional Materials. 2019, N 3(26), p. 514-518.

- B. M. Baloyan, A. G. Kolmakov, M. I. Alimov, A. M. Moles. Nanomaterials. M.: Ugryna, 2007, 386 p. (in Russian).

- D. B. Hlushkova, V. A. Bagrov, S. V. Demchenko, V. M. Volchuk, O. V. Kalinin, N. E. Kalinina. Structure and properties of powder gas-plasma coatings based on nickel // Problems of Atomic Science and Technology. 2022, N 4(140), p. 125-130.

- V. S. Vahrusheva, D. B. Hlushkova, V. M. Volchuk, T. V. Nosova, S. I.Mamhur, N. I. Tsokur, V. A. Bagrov, S. V. Demchenko, Yu. V. Ryzhkov, V. O. Scrypnikov. Increasing the corrosion resistance of heat-resistant alloys for parts of power equipment // Problems of Atomic Science and Technology. 2022, N 4(140), p. 137-140.

- H. H. Nersisyan, J. H. Lee, C. W. Wok. Self-propagating high – temperature synthesis of nano – sized titanium carbide powder // J. Mater. Res. 2002, N 11(17), p. 2859-2864.

- V. T. Kalinin, V. A. Fedotov. Synthesis and application of nanodisperse powders - modifiers // System technologies. 2002, N 1, p. 67-71. (in Ukrainian).

Expert Q&A: Your Top Questions Answered

Q1: Why was Titanium Carbide (TiC) specifically chosen as the modifier over other potential compounds?

A1: The selection of TiC was based on P. D. Dankov’s principle of size and structural correspondence. As stated in the paper, TiC has a face-centered cubic (FCC) lattice with parameters close to the FCC lattice of nickel. This structural similarity makes TiC particles highly effective crystallization nuclei, which is essential for initiating grain refinement in the molten alloy.

Q2: What was the specific process for introducing the TiC modifier into the molten alloy?

A2: The paper outlines a three-step technological operation. First, the powdered nickel alloy and TiC powders were mixed. Second, this mixture was formed into brickets for controlled addition. Third, the modifier was introduced into the molten alloy at 1,580°C and mechanically mixed for 90-120 seconds to ensure a uniform distribution.

Q3: How significant was the grain refinement achieved through this Nickel Alloy Modification process?

A3: The grain refinement was substantial. The study found that before modification, the GS3 alloy had a coarse, non-uniform grain size of 5 to 8 mm. After modification, the structure became uniform and fine-grained, with a grain size reduced to as small as 1 mm. This represents a reduction of up to eight times, as shown in Figure 1.

Q4: How did the researchers verify that the TiC modifier was successfully absorbed and integrated into the alloy?

A4: The absorption was confirmed using electronic microprobe analysis. This technique, as detailed in the paper's conclusion and supported by Figure 3, demonstrated a rapid increase in the intensity of the Titanium (Ti) and Carbon (C) elements within the modified alloy structure. This provides direct evidence that the TiC particles were successfully incorporated into the liquid metal.

Q5: What is the primary mechanism by which the TiC modifier refines the grain structure?

A5: The mechanism of action is that the TiC particles act as surfaces for nucleation. As described in the paper, primary particles of the austenitic γ-phase appear on the surface of the TiC particles. This disperses the dendrites of the primary austenite throughout the GS3 alloy, preventing the formation of large, coarse dendrites and promoting a finer, more uniform grain structure.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of controlling the primary cast structure in high-performance nickel alloys is a critical barrier to improving component reliability. This research demonstrates that Nickel Alloy Modification using nano-sized titanium carbide particles is a powerful solution. By achieving up to an eight-fold reduction in grain size, this method creates a highly refined and uniform microstructure directly from the melt, overcoming the limitations of traditional heat treatment. For R&D and operations teams, this breakthrough offers a practical pathway to enhancing the mechanical properties and structural integrity of critical cast components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "CHANGES IN THE PROPERTIES OF A NICKEL ALLOY DURING ITS MODIFICATION WITH TITANIUM CARBIDE" by "Hlushkova D. B. and Kalinina N. E.".

Source: INNOVATIONS AND PROSPECTS IN MODERN SCIENCE, Proceedings of XI International Scientific and Practical Conference, October 23-25, 2023, STOCKHOLM 2023.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.