Beyond Perfect Models: Predicting Impact Failure from Shrinkage Cavity Defects

This technical summary is based on the academic paper "Impact analysis of casting parts considering shrinkage cavity defect" by Si-Young Kwak, Jie Cheng, and Jeong-Kil Choi, published in CHINA FOUNDRY (2011). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Shrinkage Cavity Defects

- Secondary Keywords: Impact Analysis, Casting Simulation, Aluminum Alloy Wheel, Finite Element Method (FEM), Computational Analysis

Executive Summary

- The Challenge: Design engineers often use overly large safety factors because the quantitative impact of internal shrinkage cavity defects on casting performance is not well understood.

- The Method: The study used industrial CT scans to model real-world shrinkage cavities in an aluminum wheel and then performed a computational impact analysis using the Finite Element Method (FEM).

- The Key Breakthrough: The simulation revealed that a wheel predicted to pass an impact test would actually fail catastrophically when a shrinkage cavity defect in a high-strain area was included in the model.

- The Bottom Line: Ignoring shrinkage cavity defects in simulations can lead to a dangerous overestimation of a casting's durability; their location is as critical as their presence.

The Challenge: Why This Research Matters for HPDC Professionals

In modern industry, cast aluminum alloy wheels are critical components that must withstand harsh loads and environments. The traditional design-test-redesign cycle for ensuring their durability is both time-consuming and expensive. While computational analysis offers a faster alternative, most simulations have a critical flaw: they assume the casting is a perfect, defect-free part.

In reality, Shrinkage Cavity Defects are a common occurrence during the solidification process of molten metal. These internal voids can be detrimental to the mechanical performance of a casting. Due to an insufficient understanding of their quantitative effects, engineers often compensate by using overly large safety factors, which runs counter to the industry's demand for lighter-weight components. This research addresses this gap by creating a method to accurately predict the effects of internal shrinkage defects on a casting's performance under real-world impact loads.

The Approach: Unpacking the Methodology

To create a realistic simulation, the researchers developed a robust methodology that bridges the gap between a real-world defect and a computational model.

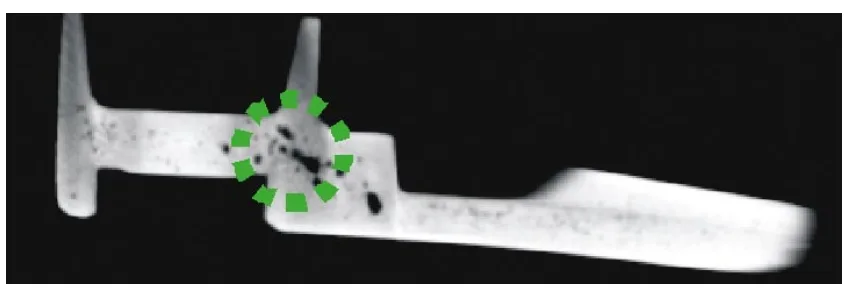

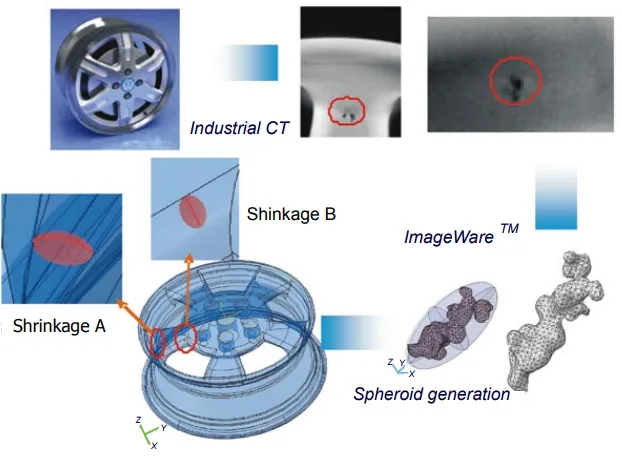

- Defect Identification: The process began by obtaining precise data on the size, shape, and location of actual shrinkage cavities within a cast aluminum wheel using industrial Computerized Tomography (CT).

- Defect Modeling: The complex defect geometry from the CT scan (in STL format) is difficult to mesh directly for simulation. The researchers employed a Shape Simplification Method (SSM), which reconstructs the shrinkage cavities as simplified hollow spheroid primitives. This approach accurately reflects the stress concentration effect of the defect while requiring significantly fewer finite elements than direct meshing, saving computational time and reducing numerical errors.

- Impact Simulation: Using the commercial FEM package ABAQUS™, the team simulated a standard wheel impact test (SAE J175). Two models were created:

- A "sound-assumed" wheel with no defects.

- A wheel with two distinct shrinkage cavities modeled using SSM, based on the CT scan data.

- Failure Criteria: The failure criterion was based on the material properties of the AC4C aluminum alloy. Fracture was predicted to occur if the simulated equivalent plastic strain (PEEQ) exceeded the material's critical true plastic strain of 0.059.

The Breakthrough: Key Findings & Data

The results of the comparative simulation revealed a stark difference in performance, highlighting the critical role of defects. The analysis focused on the moment of maximum strain, which occurred 0.00087 seconds after the striker contacted the wheel.

Finding 1: The "Perfect" Casting Passes the Test

In the simulation of the sound-assumed wheel with no defects, the maximum equivalent plastic strain was 0.048. As shown in Figure 8 of the paper, this value is below the material's fracture threshold of 0.059. Based on this "perfect" model, the wheel would be expected to pass the impact test without failure.

Finding 2: Internal Defects Trigger Catastrophic Failure

The simulation that included the CT-scanned defects told a very different story. The outcome depended entirely on the defect's location:

- Shrinkage Cavity A (near spoke-rim junction): This defect was located in a low-strain area. The simulation showed that the maximum principal elastic strain was less than 0.001, with no plastic strain occurring. This defect was determined to be harmless.

- Shrinkage Cavity B (near spoke-hub junction): This defect was in a high-strain area. The simulation showed the maximum equivalent plastic strain on the cavity surface reached 0.077, as seen in Figure 9(b) of the paper. This value is significantly over the 0.059 failure limit, indicating that the wheel would be expected to fracture, initiating from this internal defect.

Practical Implications for R&D and Operations

This study provides actionable insights for engineering and quality teams working with high-performance castings.

- For Process Engineers: This study suggests that adjusting casting process parameters to prevent porosity in known high-stress regions (like the spoke-hub junction in this wheel) is far more critical than eliminating all porosity everywhere.

- For Quality Control Teams: The data in Figure 9 illustrates that the location of a defect can be more important than its size. This supports the use of non-destructive testing like CT scanning to inform new quality inspection criteria that prioritize defect location in relation to high-stress zones.

- For Design Engineers: The findings indicate that part geometry directly influences defect formation and stress concentration. Designs that create isolated hot spots in high-stress areas should be reconsidered in the early design phase to mitigate the risk of performance-limiting Shrinkage Cavity Defects.

Paper Details

Impact analysis of casting parts considering shrinkage cavity defect

1. Overview:

- Title: Impact analysis of casting parts considering shrinkage cavity defect

- Author: Si-Young Kwak, Jie Cheng and Jeong-Kil Choi

- Year of publication: 2011

- Journal/academic society of publication: CHINA FOUNDRY

- Keywords: casting; shrinkage cavity defect; impact; computational analysis; Al alloy wheel

2. Abstract:

Shrinkage cavity may be detrimental to mechanical performances of casting parts. As a consequence, design engineers often use overly large safety factors in many designs due to insufficient understanding of quantitative effects of shrinkage cavity defects. In this paper, process of Al alloy wheel impact test was computationally analyzed for both the wheel models with and without shrinkage cavity defects. Based on shrinkage cavity data obtained from industrial CT (Computerized Tomography), the shrinkage cavity defects were modeled with SSM (Shape Simplification Method), which reconstructs shrinkage cavity defects to hollow spheroid primitives. After the impact simulation was conducted, the results show that under impact test condition, the wheel considering shrinkage cavity defects may fracture while the sound-assumed wheel may not.

3. Introduction:

Cast aluminum alloy wheels are widely used in the automotive industry and must be durable enough to withstand rough loads. The traditional design-test-redesign process is long and costly, making computational analysis an attractive solution. However, previous computational studies on wheel impact tests have not considered the effects of casting defects like shrinkage cavities. These defects occur during solidification, are present in most castings, and can be detrimental to mechanical performance. Because their quantitative effects are not fully understood, engineers either ignore them or use overly large safety factors, neither of which meets the modern demand for lighter-weight castings. This study aims to investigate the effects of shrinkage cavity defects under impact load.

4. Summary of the study:

Background of the research topic:

The research addresses the need for more accurate computational analysis of cast parts by incorporating the effects of common manufacturing defects, specifically shrinkage cavities.

Status of previous research:

A number of studies have been conducted on the computational analysis of aluminum wheel impact tests, but none have considered the effects of internal casting defects like shrinkage cavities.

Purpose of the study:

To develop and apply a method for modeling the effects of shrinkage cavity defects on the mechanical performance of casting parts under impact load, using an Al alloy wheel as a case study.

Core study:

The study compares the results of a simulated Al alloy wheel impact test for two models: one assuming a perfect, defect-free casting, and another incorporating real-world shrinkage cavity defects identified by an industrial CT scan and modeled using the Shape Simplification Method (SSM).

5. Research Methodology

Research Design:

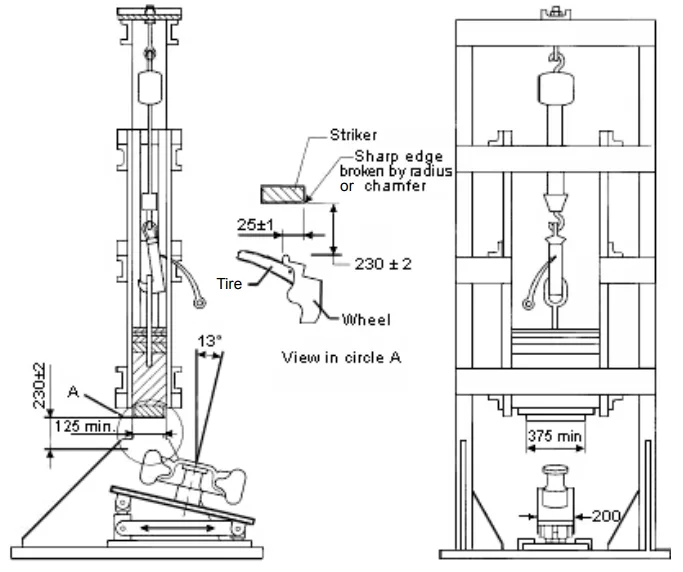

A comparative computational analysis was performed. Two finite element models of an Al alloy wheel were created: one without defects and one with defects. Both were subjected to a simulated impact test according to the SAE J175 standard.

Data Collection and Analysis Methods:

Shrinkage cavity data was acquired from an industrial CT scan of a real wheel. This data was processed using ImageWare™ software to simplify the defects into spheroid shapes (SSM). The impact simulation was conducted using the FEM package ABAQUS™. A benchmark study was first performed on a simple bar to determine the optimal element type and size for accuracy.

Research Topics and Scope:

The study focuses on modeling shrinkage cavities for structural impact analysis. It investigates the effects of these defects on the results of a simulated Al alloy wheel impact test. The failure criterion is based on the equivalent plastic strain of the AC4C material exceeding its known fracture strain.

6. Key Results:

Key Results:

- The simulation of the wheel without defects predicted a maximum equivalent plastic strain of 0.048, which is below the failure threshold of 0.059. This wheel is expected to pass the test.

- The simulation of the wheel with defects showed that the defect in a low-strain area (Shrinkage Cavity A) had a negligible effect.

- The defect in a high-strain area (Shrinkage Cavity B) caused a localized equivalent plastic strain of 0.077, which is above the failure threshold. This wheel is expected to fracture.

- The study concludes that considering shrinkage cavity defects, particularly their location, is critical for accurate prediction of impact performance.

Figure Name List:

- Fig. 1: Shrinkage cavity defects in castings

- Fig. 2: Stress concentration factor

- Fig. 3: Simple bar model for simulation

- Fig. 4: True strains depend on element size

- Fig. 5: Impact loading test machine (SAE J175)

- Fig. 6: Models and setting for simulation

- Fig. 7: Procedures of obtaining and modeling shrinkage data using CT

- Fig. 8: Contour of equivalent plastic strains (no shrinkage defects)

- Fig. 9: Contour of equivalent plastic strains (with shrinkage defects)

7. Conclusion:

This study presents an effective approach for analyzing the impact of shrinkage cavities on the performance of casting parts. By using industrial CT data and modeling defects as spheroid primitives with SSM, the simulation can reflect strain concentration effects with reasonable computational cost. For the Al wheel impact test, the results show that a shrinkage cavity located in a high-strained area can be far more detrimental than one in a low-strained area. This approach improves the accuracy of impact simulations, allowing for more reliable engineering decisions.

8. References:

- [1] SAE J328. Wheels-passenger car and light truck performance requirements and test procedures. Warrendale, (PA): Society of Automotive Engineering, Inc., 2001.

- [2] SAE J175. Wheels-impact test procedures-road vehicles. Warrendale, (PA): Society of Automotive Engineering, Inc., 2001.

- [3] Li P, Maijer D M, et al. A through process model of the impact of in-service loading, residual stress, and microstructure on the final fatigue life of an A356 automotive wheel. Material Science and Engineering A, 2007, 460-461: 20–30.

- [4] Zhu Maotao and Han Bing. Analysis of impact test of aluminum disc wheels based on FEM. SAE International, DOI: 10.4271/2007-01-3648.

- [5] Chang Weichan. Modeling for impact test of aluminum wheels. Master Thesis of Taiwan National Central University, July 2008.

- [6] Chia-Lung Chang and Shao-Huei Yang. Simulation of wheel impact test using finite element method. Engineering Failure Analysis, 2009, 16: 1711–1719.

- [7] Sigl K M, Hardin R A, Stephens R I, and Beckermann C. Fatigue of 8630 cast steel in the presence of porosity. Int'l J. of Cast Metals Research, 2004, 17(3): 130–146.

- [8] Kwak S Y, Cheng J, Kim J T and Choi J K. Structural analysis considering shrinkage defect of casting part. Int'l J. of Cast Metal Research, 2008, 21 (1-3): 419–423.

- [9] Dewey J M. The elastic constants of materials loaded with non-rigid fillers. Journal of Applied Physics, 1947, 18: 578–581.

- [10] Weaver D R. Dynamic strain concentration factor for a notch. Strorming Media, Report 0271076 (Report Date: Apr. 1968).

- [11] Pilkey W D. Peterson's Stress Concentration Factors. Second Edition, New York: John Wiley & Sons, Inc., 1997.

Expert Q&A: Your Top Questions Answered

Q1: Why was the Shape Simplification Method (SSM) chosen over directly meshing the CT scan data, which seems more direct?

A1: The paper explains that directly meshing the original shapes of shrinkage cavities from a CT scan (Direct Shape Method, DSM) requires an enormous number of elements. This can lead to elements with very poor aspect ratios, resulting in high computational costs and potential numerical errors. SSM provides a practical balance by capturing the critical stress concentration effect of the defect with a simplified spheroid shape, which requires far fewer elements and is more stable for analysis.

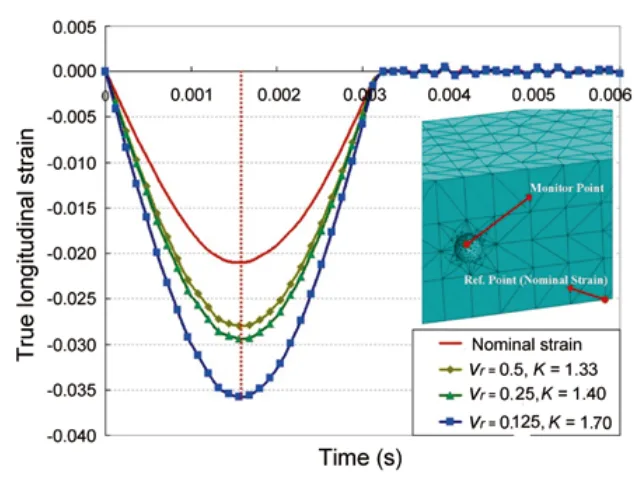

Q2: The paper recommends a specific element size of 0.125 relative to the cavity radius. How was this determined and why is it important?

A2: This recommendation came from a benchmark analysis performed on a simple bar with a spherical cavity, with results shown in Figure 4. The researchers tested different mesh densities and found that as the mesh on the cavity surface became finer, the simulated dynamic strain concentration factor converged more closely to the known analytical solution (2.05). An element size of 0.125 provided a good balance of accuracy and computational cost, making it a practical recommendation for engineers modeling these features.

Q3: The simulation showed one defect (Cavity A) was harmless while another (Cavity B) was critical. What does this imply about quality control standards?

A3: This is a key takeaway. It implies that a "go/no-go" quality standard based only on the size of a defect is insufficient. The location of the defect is paramount. As the results show, a defect in a high-strain area (the spoke-hub junction) is far more dangerous than one in a low-strain area. This suggests that advanced quality control protocols should incorporate stress analysis to identify critical zones and then use non-destructive testing to ensure those specific zones are free from significant defects.

Q4: What was the specific failure criterion used in this study, and how was it established?

A4: The failure criterion was based on material fracture strain. The study predicted failure if the equivalent plastic strain (PEEQ or ɛp) in the simulation was equal to or larger than the fracture strain of the material (ɛf). For the AC4C aluminum alloy used in the wheel, this critical value was determined to be 0.059 based on physical tensile test data for the material.

Q5: Can this simulation method replace physical impact testing entirely?

A5: The paper does not claim this method can replace physical testing entirely. However, it argues that by considering real-world Shrinkage Cavity Defects, the simulation's predictive power becomes "more reliable, focus and realistic." This approach allows engineers to make much more informed decisions before committing to expensive tooling and physical prototypes, potentially reducing the number of test-redesign cycles and catching critical flaws early in the design phase.

Conclusion: Paving the Way for Higher Quality and Productivity

This research powerfully demonstrates that assuming a "perfect part" in engineering simulations is a risky oversimplification. The presence and, more importantly, the location of internal Shrinkage Cavity Defects can be the deciding factor between a component passing an impact test or failing catastrophically. By integrating real-world defect data from CT scans into advanced FEM analysis, engineers can gain a far more accurate prediction of a casting's true performance. This allows for the optimization of both part design and casting processes, leading to safer, lighter, and more reliable components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Impact analysis of casting parts considering shrinkage cavity defect" by "Si-Young Kwak, Jie Cheng and Jeong-Kil Choi".

- Source: Article ID 1672-6421(2011)01-112-05, China Foundry Vol.8 No.1.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.