Can Centrifugal Casting Solve the Thin-Wall Challenge for Metal Matrix Composites?

This technical summary is based on the academic paper "THE STRUCTURE OF CENTRIFUGALLY CAST COMPOSITE CASTING" by Jacek Jackowski and Paweł Szymański, published in COMPOSITES THEORY AND PRACTICE (2012).

Keywords

- Primary Keyword: Centrifugal Composite Casting

- Secondary Keywords: metal matrix composites, thin-walled castings, gradient structure, silicon carbide particles, aluminum alloy matrix, dispersion composites

Executive Summary

- The Challenge: Conventional gravitational casting methods struggle to produce complex, thin-walled metal matrix composite parts without defects, limiting their application.

- The Method: Researchers used centrifugal casting to manufacture a complex, thin-walled turbine (1 mm blades) from an aluminum alloy reinforced with silicon carbide (SiC) particles.

- The Key Breakthrough: The process successfully produced castings free of shape flaws, proving its viability for creating intricate, thin-walled composite components.

- The Bottom Line: While Centrifugal Composite Casting enables the production of complex geometries, it also causes significant migration of the reinforcing particles, creating a gradient structure that must be understood and controlled for industrial applications.

The Challenge: Why This Research Matters for HPDC Professionals

For engineers working with metal matrix composites (MMCs), producing sound castings is a constant challenge. The diphase (liquid metal + solid particles) nature of the composite suspension behaves differently from standard alloys. Gravitational casting often limits the minimum achievable wall thickness and can lead to particle settling in thick sections. While pressure die casting can produce thin walls, the abrasive nature of reinforcing particles like SiC causes accelerated wear on expensive tooling, such as cylinders, pistons, and moulds.

This creates a critical industry gap: a reliable method for manufacturing complex, thin-walled composite components without excessive tool wear or casting defects. This research explores centrifugal casting as a potential solution to fill that gap, investigating its ability to produce sound castings and its effect on the final material structure.

The Approach: Unpacking the Methodology

The study was designed to test the feasibility of centrifugally casting a complex, thin-walled component and to analyze the resulting microstructure.

Method 1: Material and Component Selection

- Composite Material: The researchers used a standard DURALCAN composite, A359/20SiCp, which consists of a sub-eutectic aluminum-silicon alloy (silumin) matrix reinforced with 21.6% silicon carbide (SiC) particles.

- Test Component: A small turbine with a 70.9 mm diameter and complex, curved blades approximately 1 mm thick. The master model for the turbine was created using 3D printing (PMMA).

Method 2: Mould Preparation and Casting Process

- Mould: Disposable moulds were made from KERR casting gypsum using the 3D-printed turbine model. This precision ceramic mould is ideal for capturing fine details.

- Casting Equipment: A GIACETTI casting machine, which combines an induction furnace with a mechanism for rotating the mould around a vertical axis.

- Process Parameters: The mould was preheated to 300°C. The composite suspension was stabilized at 720°C before being poured. The mould was then rotated at a constant speed of 270 rpm until the casting fully solidified.

The Breakthrough: Key Findings & Data

The analysis of the resulting castings revealed two critical, interconnected outcomes: the method's success in forming the part and its profound impact on the material's internal structure.

Finding 1: Successful Production of Thin-Walled Castings

The primary goal of testing the method's viability was achieved. The paper states, "It was found that the casting conditions allow one to obtain thin-walled castings." Macroscopic examination confirmed this, with the authors noting, "All the castings were free of shape flaws, e.g. in the form of misruns (Fig. 3a)." This demonstrates that the centrifugal force provided sufficient pressure to completely fill the intricate 1 mm thick blade cavities of the mould, overcoming the limitations of gravitational methods.

Finding 2: Significant Particle Migration and Gradient Structure Formation

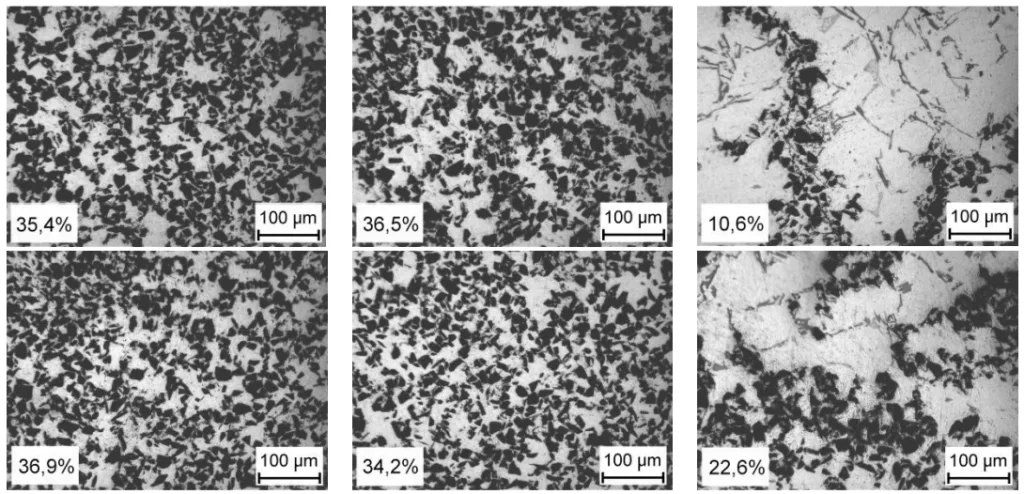

While the castings were geometrically sound, the centrifugal force caused a dramatic redistribution of the SiC reinforcing particles. The initial composite pig sow contained a baseline of 22.4% SiC particles (Figure 5). However, analysis of the final casting revealed significant variations:

- Gating System: As shown in Figure 6, the particle concentration within the gating system fluctuated wildly, from as low as 10.6% in some areas to as high as 36.9% in others.

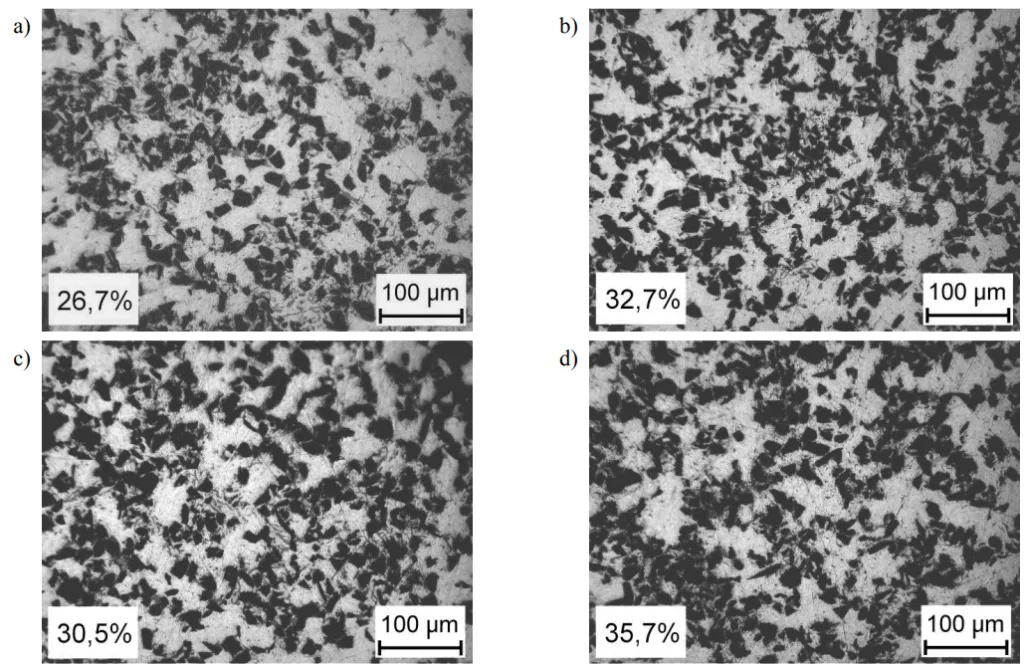

- Casting Blades: Within the turbine blades themselves, the SiC content ranged from 26.7% to 35.7% (Figure 7).

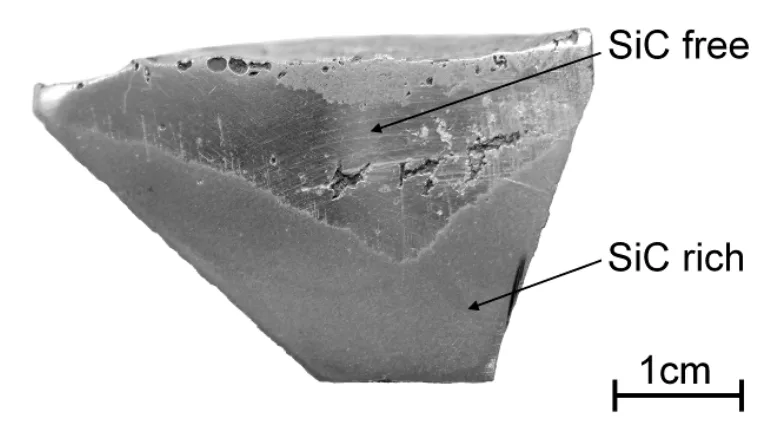

- Macro-Segregation: The cross-section of the pouring cup (Figure 9) showed a stark boundary between an "SiC rich" zone and an "SiC free" zone, providing clear visual evidence of particle sedimentation under centrifugal force. This confirms that the denser SiC particles migrated outward, away from the axis of rotation.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that rotational speed is a critical process parameter for controlling the final microstructure. Adjusting the rpm and the duration of rotation could be used to intentionally create or minimize a gradient structure, tailoring the material properties (e.g., wear resistance on the outer surfaces) to the application's needs.

- For Quality Control Teams: The data in Figure 6 and Figure 7 illustrates that the mechanical properties of a centrifugally cast composite part will not be uniform. Hardness, wear resistance, and strength will vary depending on the local concentration of SiC particles. This necessitates location-specific quality inspection criteria rather than assuming homogenous material properties.

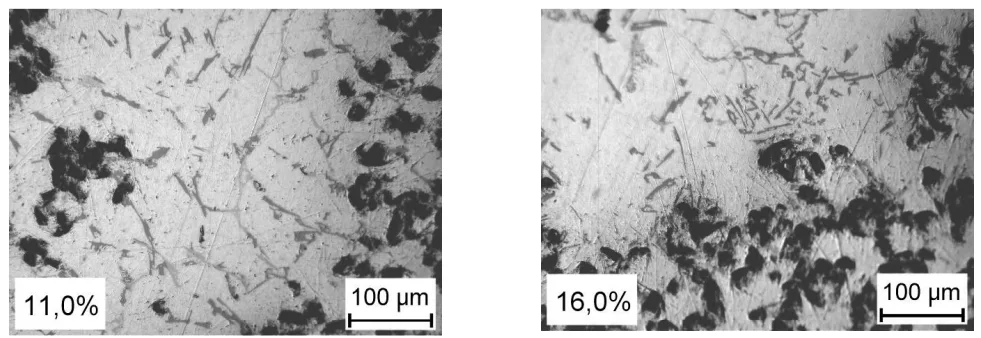

- For Design Engineers: The findings indicate that complex internal geometries, like the turbine blades, create complicated flow paths for the composite suspension. This resulted in "structure anomalies" with significantly lower particle content (as low as 11.0% in Figure 8). This suggests that component design must account for fluid dynamics under centrifugal force to avoid unintended particle-depleted zones.

Paper Details

THE STRUCTURE OF CENTRIFUGALLY CAST COMPOSITE CASTING

1. Overview:

- Title: THE STRUCTURE OF CENTRIFUGALLY CAST COMPOSITE CASTING

- Author: Jacek Jackowski, Paweł Szymański

- Year of publication: 2012

- Journal/academic society of publication: COMPOSITES THEORY AND PRACTICE, Polish Society of Composite Materials

- Keywords: dispersion composites, centrifugal casting, gradient structure

2. Abstract:

The most frequently used methods for manufacturing composite castings with an internal structure composed of a metal matrix and solid particles of the reinforcing phase are gravitational casting (into disposable or permanent moulds), pressure die casting, squeeze casting and centrifugal casting. The diphase character of the composite suspension designed for casting leads to the fact that its gravitational casting is delimited, among others, by a minimum thickness of the casting walls. The process of casting composite suspensions using the centrifugal method is unavoidably accompanied by migration of the reinforcing phase particles. It means that during the casting process, the particles move with respect to the liquid metal matrix. Therefore, experimental tests have been made with a view to manufacturing composite castings with the method of centrifugal casting. The tests were aimed at answering whether thin-walled castings may be manufactured using this method and checking the effect of the method on the behavior of the particles present in the cast suspension. The tests have been performed using a standard composite material with an aluminum alloy matrix including silicon carbide particles. The cast part was a small turbine with a blade thickness of about 1 mm. The casting moulds were made from a gypsum mass which was poured in a device composed of an induction furnace and a mechanism, referred to as a caster, that ensured rotation of the mould around a vertical rotation axis. The castings obtained in such way were evaluated with regard to matching the required shape and achieving a uniform distribution of the reinforcing phase in the composite material samples cut from various points of the casting and its gating system. It was found that the casting conditions allow one to obtain thin-walled castings, however, migration of the reinforcing phase particles in the cast suspension is significant. Hence, further research of the conditions of applying the method appeared necessary.

3. Introduction:

The advantageous properties of composite materials are leading to their growing application. For metal matrix composites, manufacturing is constrained by the material's properties and the shaping capabilities of foundry technology. A significant portion of these composites are manufactured from suspensions of technical alloys and solid reinforcing particles. The diphase nature of this suspension results in behavior different from conventional alloys during pouring and cooling. Common manufacturing methods include gravitational casting, pressurized casting, and centrifugal casting. Gravitational casting is limited by a minimum wall thickness and potential for non-uniform particle distribution in thick-walled parts. Pressurized casting, while effective for thin-walled parts, leads to accelerated wear of machinery and moulds. The potential to create gradient structures through particle migration during centrifugal casting has generated interest in this method, as proper control could tailor the internal structure of the casting to specific requirements.

4. Summary of the study:

Background of the research topic:

The manufacturing of metal matrix composite castings presents challenges due to the diphase (liquid metal and solid particles) nature of the material. Conventional methods like gravitational and pressure casting have distinct limitations, particularly concerning minimum wall thickness, particle distribution uniformity, and equipment wear.

Status of previous research:

The paper acknowledges that gravitational casting into permanent moulds has constraints on minimum wall thickness and that particle distribution can be worsened by gravitational forces [3, 4]. It also notes that pressurized casting suffers from faster wear of machine components. Prior research has shown interest in centrifugal casting for its potential to create composite castings with a gradient structure [5-7], where the distribution of reinforcing particles is intentionally non-uniform to achieve specific properties.

Purpose of the study:

The study aimed to achieve two primary objectives:

1. To determine if the centrifugal casting method could be used to successfully manufacture thin-walled composite castings.

2. To investigate the effect of the centrifugal casting process on the behavior and distribution of the reinforcing particles within the cast suspension.

Core study:

The core of the study involved the experimental centrifugal casting of a small, thin-walled (approx. 1 mm blade thickness) turbine using a standard aluminum-silicon carbide (A359/20SiCp) composite material. The resulting castings and their gating systems were sectioned and subjected to macroscopic and metallographic analysis to evaluate the casting's shape fidelity and the distribution of the SiC reinforcing phase.

5. Research Methodology

Research Design:

The study employed an experimental research design. A specific, complex-shaped part (turbine) was manufactured using a defined centrifugal casting process. The resulting product was then systematically analyzed through metallography to assess its internal structure. A sample from the initial raw material (composite pig sow) was used as a baseline for comparison.

Data Collection and Analysis Methods:

Data was collected through visual inspection of the castings for shape flaws and through microscopic examination of polished cross-sections. A metallographic microscope (Neophot 2) equipped with a camera was used for observations. The quantitative analysis of the reinforcing phase's share in the microstructure was performed using the IMAGE J software program.

Research Topics and Scope:

The research was focused on a single composite material (A359/20SiCp) and a single, complex casting geometry (turbine). The casting process was conducted under a fixed set of parameters: a mould temperature of 300°C, a pouring temperature of 720°C, and a constant rotational speed of 270 rpm. The analysis was limited to the final structure of the solidified casting and its gating system.

6. Key Results:

Key Results:

- The centrifugal casting method successfully produced thin-walled castings (1 mm blade thickness) that were free of shape flaws such as misruns.

- The process induced significant migration of the SiC reinforcing particles within the liquid matrix.

- The volume fraction of SiC particles in the final casting and gating system was highly non-uniform, varying from a low of 10.6% to a high of 36.9%, compared to the 22.4% measured in the initial material.

- Clear evidence of macro-segregation was observed in the pouring cup, with a distinct boundary between an SiC-rich region and an SiC-free region.

- The complex geometry of the turbine mould cavity resulted in complicated flow of the suspension, leading to anomalous areas within the casting that had a significantly lower concentration of reinforcing particles (e.g., 11.0%).

Figure Name List:

- Fig. 1. Image of turbine (Ø 70.9 mm)

- Fig. 2. Disposable turbine models

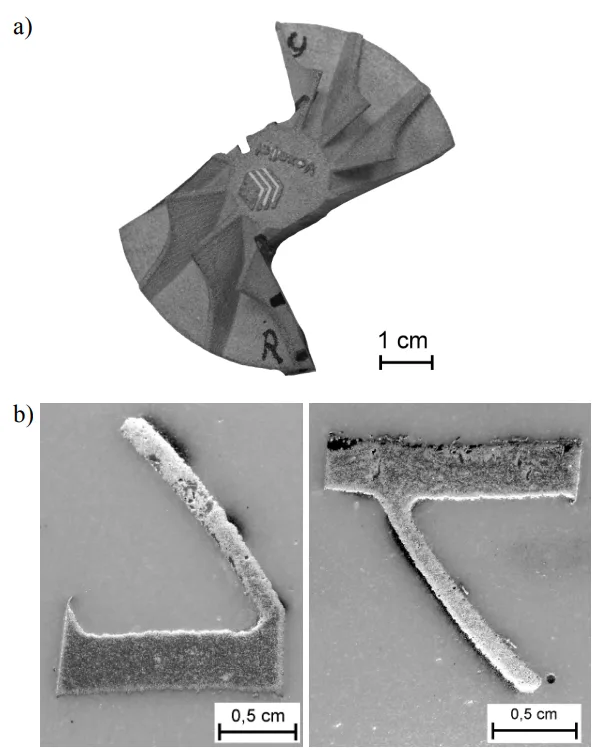

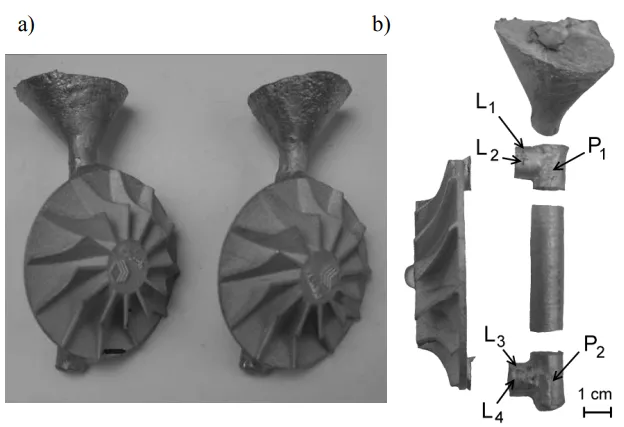

- Fig. 3. Raw composite castings: a) view; b) after initial cutting

- Fig. 4. Cut-up composite casting (a) and parts of occluded blades (b)

- Fig. 5. Structure of composite pig sow used for tests

- Fig. 6. Composite material structures in different areas of the casting gating system

- Fig. 7. Structure of composite casting in various locations

- Fig. 8. Structure anomalies found in parts of composite casting

- Fig. 9. Macrostructure of cross-section of pouring cup casting

7. Conclusion:

The experiments demonstrated that centrifugal pressure assisting the mould filling process allows for the production of thin-walled composite castings. However, this process is simultaneously conducive to evident migration of the reinforcing particles. The number of particles in most sections of the final casting was considerably higher than in the initial material, a result of centrifugal sedimentation. This effect was particularly pronounced in the larger cross-sections of the gating system, where the longer solidification time allowed for intensive particle motion. The reasons for areas with lowered particle content within the turbine structure have not been fully explained but are likely a result of the complex motion of the suspension stream within the mould. The authors conclude that further research is necessary, using moulds with simpler geometries, to better understand and control the conditions of particle migration during cooling and solidification.

8. References:

- [1] Dyzia M., Dolata-Grosz A., Śleziona J., Wieczorek J., Starczewski M., Kompozytowe tłoki do sprężarek wytwarzane metodą odlewania kokilowego, Kompozyty (Composites) 2007, 2, 83-86.

- [2] Sobczak J., Wojciechowski S., Współczesne tendencje praktycznego zastosowania kompozytów metalowych, Kompozyty (Composites) 2002, 3, 24-37.

- [3] Szweycer M., Jackowski J., Warunki topienia i odlewania kompozytów zawiesinowych o osnowie aluminiowej, Mat. VII Konferencji Metale nieżelazne w przemyśle okrętowym, Szczecin 1996, 185-192.

- [4] Jackowski J., Nagolska D., Szweycer M., Zjawiska sedymentacji w technologii kompozytów zawiesinowych, Krzepnięcie Metali i Stopów 2000, 43, 281-290.

- [5] Liu Q., Ciao Y., Yang Y., Hu Z., Theoretical analysis of the particle gradient distribution in centrifugal field during solidification, Metallurgical and Materials Transactions B, 1996, 27, 1025-1029.

- [6] Braszczyński J., Zyska A., Tomczyński S., Rozkład cząstek ceramicznych w obszarach powierzchniowych kompozytu odlewanego odśrodkowo o osi pionowej, Mat. IV Konf. Zjawiska powierzchniowe w procesach odlewniczych, Poznań-Kołobrzeg 1998, 35-42.

- [7] Dolata-Grosz A., Śleziona J., Wpływ odlewania odśrodkowego na jakość kompozytów umacnianych cząstkami ceramicznymi i fazami międzymetalicznymi: aspekt porowatości, Archiwum Odlewnictwa 2004, 4, 114-121.

- [8] Zyska A., Braszczyński J., Wpływ wielkości cząstek i szybkości chłodzenia na strukturę kompozytów AlSi7Mg2-SiC., Mat. Seminarium, Kompozyty - 98, Teoria i praktyka, Częstochowa 1998, 139-144.

- [9] Śleziona J., Grosz A., Wieczorek J., Wytwarzanie odlewów zbrojonych warstwowo cząstkami Al2O3, Mat. Konf. Zjawiska powierzchniowe w procesach odlewniczych, Poznań - Kołobrzeg 1998, 255-261.

- [10] Heynick M., Slotz I., 3D CAD, CAM and Rapid Prototyping, LAPA Digital Technology Seminar, Lozanna 6-9.04.2006.

Expert Q&A: Your Top Questions Answered

Q1: Why was a disposable gypsum mould used for this experiment instead of a more durable permanent mould?

A1: The paper specifies the use of a gypsum mass and disposable models made from PMMA via 3D printing. This approach, similar to investment casting, was likely chosen for its ability to create a precise, highly complex geometry (the turbine blades) for this pilot study without the significant cost and lead time associated with machining a permanent steel mould. It allowed the researchers to focus purely on the effects of the centrifugal process on the composite material.

Q2: The paper mentions a constant rotational speed of 270 rpm. What was the rationale for selecting this specific speed?

A2: The paper states that the rotational speed was constant at 270 rpm but does not provide the rationale for this specific value. For this initial investigation, the goal was likely to apply a significant and consistent centrifugal force to test the feasibility of filling a thin-walled mould and to observe the fundamental effects on particle migration. The study serves as a proof of concept, with the optimization of process parameters like rotational speed identified as a necessary area for future research.

Q3: What is the primary cause of the particle migration observed in the castings?

A3: The migration is caused by the difference in density between the silicon carbide (SiC) reinforcing particles and the liquid aluminum alloy matrix. SiC is denser than aluminum. During rotation, the centrifugal force acts more strongly on the denser SiC particles, pushing them outward, away from the axis of rotation, while the less dense liquid aluminum is displaced inward. This leads to the observed particle concentration in the outer regions of the casting and gating system.

Q4: The results show areas with particle concentrations (e.g., 36.9%) much higher than the initial material (22.4%). What are the practical implications of this?

A4: This localized concentration creates a "gradient structure." The areas with higher SiC content will exhibit significantly increased hardness and wear resistance but may also have lower ductility and fracture toughness compared to areas with fewer particles. While potentially detrimental if uncontrolled, this phenomenon could be harnessed to create components with enhanced wear properties on specific surfaces while maintaining toughness in the core of the part.

Q5: The paper concludes that further research on simpler geometries is needed. Why is this important?

A5: The complex geometry of the turbine created intricate flow patterns for the composite suspension, making it difficult to isolate the effects of the centrifugal force from the effects of the mould's geometry. As seen in Figure 8, this led to unexplained "anomalies" with low particle counts. By using simpler shapes (like cylinders or flat plates) in future studies, researchers can more easily model and predict the particle migration based on fundamental parameters like rotational speed and cooling rate, leading to a more robust and controllable manufacturing process.

Conclusion: Paving the Way for Higher Quality and Productivity

This research successfully demonstrates that Centrifugal Composite Casting is a viable method for producing complex, thin-walled components that are challenging for conventional techniques. The key breakthrough is the ability to create geometrically sound castings without flaws like misruns. However, the study also illuminates the critical challenge of the process: managing the significant migration of reinforcing particles that creates a gradient structure. For R&D and operations teams, this means that while the method opens doors to new component designs, it requires a deep understanding of process parameters to control the final microstructure and ensure consistent part quality.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "THE STRUCTURE OF CENTRIFUGALLY CAST COMPOSITE CASTING" by "Jacek Jackowski, Paweł Szymański".

Source: The paper was published in COMPOSITES THEORY AND PRACTICE, 12: 1 (2012) 66-71.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.